Blog by Steve Laug

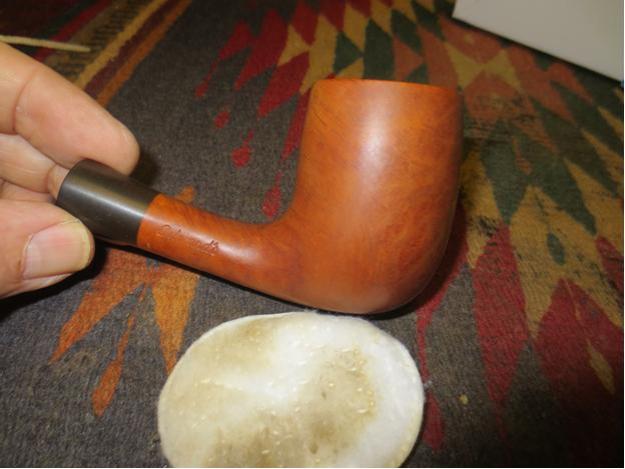

This Edwards Author 722 came to me in the gift box I received. The shape has always been one of my favourites. This one is stamped Edwards in script on the left side of the shank. On the right side it is stamped Algerian Briar over 722. I am guessing that the 722 is the shape number. I have looked but cannot find any information on the Edwards shapes. On the underside of the shank it is stamped with a large number 5. On the underside of the stem was stamped the word FRANCE.

From what I could find Edwards left all of their pipes with a natural finish, as was the case with this one. It was dirty and had darkened from smoking but it did not have a finish or stain on the briar. The bowl had been reamed and cleaned and the shank was clean. The briar had fills on the topside and the underside of the shank and on the left side of the bowl. They were white putty and some of them were shrunken and missing bits of the putty. The rim was dirty and slightly damaged.

From what I could find Edwards left all of their pipes with a natural finish, as was the case with this one. It was dirty and had darkened from smoking but it did not have a finish or stain on the briar. The bowl had been reamed and cleaned and the shank was clean. The briar had fills on the topside and the underside of the shank and on the left side of the bowl. They were white putty and some of them were shrunken and missing bits of the putty. The rim was dirty and slightly damaged.

The stem was very tight in the shank and I carefully twisted it slowly from the shank. There was a yellow waxy substance on the tenon like old and dried beeswax. The mortise area was clean briar and was unstained by tars or oils. The fit of the stem to the shank was perfect. It was a smooth transition with no ridges or gaps.

The stem was very tight in the shank and I carefully twisted it slowly from the shank. There was a yellow waxy substance on the tenon like old and dried beeswax. The mortise area was clean briar and was unstained by tars or oils. The fit of the stem to the shank was perfect. It was a smooth transition with no ridges or gaps.

I wanted to know more about the brand. I have had several Edwards pipes over the years and still have them. I checked out my two usual sources Pipedia and PipePhil’s site. Reading on Pipedia I found the following information that I quote. http://pipedia.org/wiki/Edward%27s

I wanted to know more about the brand. I have had several Edwards pipes over the years and still have them. I checked out my two usual sources Pipedia and PipePhil’s site. Reading on Pipedia I found the following information that I quote. http://pipedia.org/wiki/Edward%27s

“Edward’s pipes were originally produced in St. Claude, France when France actually was a world-class pipe maker with longstanding business & political connections to Colonial Algeria that allowed them to obtain the finest briar. During the tumultuous 1960’s, Edward’s created a business model to offer the finest briar available in both Classic and Freehand shapes – all at a fair price. They bought the company & equipment and cornered the market on the finest, choice Algerian Briar just before the supply vanished in political turmoil of Algeria’s independence. Edward’s packed up both machinery and briar-treasure to America, safely caching the essentials to create a new pipe-making dynasty. This was a coup, for the 70’s and 80’s were grim years for pipe smokers as quality briar all but disappeared.”

“Edward’s Design Philosophy is hard to pin down, think of their style as the “American Charatan” with unique & clever twists all their own. Today, they fashion pipes in several locations across the USA. All of Edward’s pipes are Algerian Briar – a fact very few pipe companies can claim, and all are oil-cured utilizing natural finishes – no strange concoctions are used to interfere in your tastebud’s dance with the briar. Algerian, Calabrian, Sardinian, Corsican – take your pick, but Algerian Briar is generally considered the finest smoking briar ever used. When combined with oil-curing, Algerian takes on a magical quality that even Alfred Dunhill recognized as far back as 1918 as the choice for both his Bruyere and Shell.”

There was also a non-working link to http://www.otcpipes.com that reference a collection of vintage Edward’s pipes and scans of Edward’s catalogs. I wish I could get that link to work. (If anyone has information on this please let me know as I would love to view this site and its information.)

I found a bit of additional information on the PipePhil site (http://www.pipephil.eu/logos/en/logo-e1.html). I quote it here as well.

“Edward’s Pipes, headquartered in Tampa, FL, got its start importing pipes from France and continued to do so from 1958 to 1963 when it started producing pipes in Florida from prime Algerian Briar, a practice they continue to this day (2010).”

I also found an interesting exchange on the Pipes Magazine site regarding Edwards that was posted three years ago. http://pipesmagazine.com/forums/topic/edwards-pipe I have copied one portion of that interchange by a poster named cypresspipe. He adds a personal dimension to the information having worked for Edwards in the 70’s. I quote him in full below.

“I worked at an Edward’s Pipe Shop in Jacksonville in the 70’s and I can provide more information about Edward’s pipes. Edward’s still exists with a few remaining shops around the country. Like the rest of the industry, they are primarily cigar stores and gift shops now. Edward’s pipes were and are their house brand and they were made in their factory in Tampa. I visited the Tampa store several years ago and they told me that Edward’s pipes are now made in Spain. They also told me that they were running out of Algerian Briar and, as a result, many of their pipes were no longer carrying that stamping.”

“If you are familiar with Randy Wiley pipes, he started out making pipes in the Edward’s factory in Tampa back in the 1970’s.”

“The models Skylark, Skipper, Royce, Benton, etc. are fairly recent name categories, probably starting in the 90’s. They didn’t use these names when I worked there, except the “Skipper” was a pipe with a particular style of etching on it. At the time they made some very nice high-grade freehands that sold in the $100-150 price range (several hundred dollars today).”

“While the individual Edward’s shops are franchisee-owned the parent company is FGT Enterprises of Tampa, Florida. The company makes pipes under the “Benton” brand for other shops around the country, and makes private label pipes for some shops as well. They are a leading wholesaler of smoking accessories. You can go to their website and download their catalog (www.fgtenterprises.com–you might want to check out the “About Us” page on the site. FGT at one time did not stress their connection to the Edward’s shops, as they wanted to downplay the fact that they were associated with stores that were competitors to some of their other customers.”

“I have about 20-30 Edward’s pipes from the time I worked there and they have always been good smokers. The only problem with them is that pipes in the 70’s tended to be smaller (about group 3) than they are today.”

“As far as I know, there are still Edward’s shops in Los Altos (CA), Englewood (CO), Tampa, Atlanta, Jacksonville, and Dallas. In case you are interested Edward’s was named after Edward Rowley, a Tampa TV personality of the 50’s and 60’s who founded the company in partnership with Frank Smith (“Smitty”). Rowley was essentially the “face” of the shops while Smitty was the tobacco and pipes guy. Smitty bought out Rowley’s interest in the company sometime in the late 70’s or early 80’s.”

Armed with that information I went to work cleaning up the pipe. I started by topping the bowl with 220 grit sandpaper on a topping board to smooth out the rim and even out the smooth surface. I followed that by sanding it with a medium and a fine grit sanding sponge.

I picked out the ugly pink/white fills with a dental pick. I scrubbed the bowl down with acetone on cotton pads to remove the grime and the dust from the fills. When the bowl was clean I refilled the sand pits with briar dust from the rim and clear super glue. I have learned that these turn almost black but that is far easier to work with than the pink/white putty.

I picked out the ugly pink/white fills with a dental pick. I scrubbed the bowl down with acetone on cotton pads to remove the grime and the dust from the fills. When the bowl was clean I refilled the sand pits with briar dust from the rim and clear super glue. I have learned that these turn almost black but that is far easier to work with than the pink/white putty.

I sanded the repairs with 220 grit sandpaper and then with a medium and fine grit sanding sponge. I followed that by sanding with 1500-2400 grit micromesh sanding pads.

I sanded the repairs with 220 grit sandpaper and then with a medium and fine grit sanding sponge. I followed that by sanding with 1500-2400 grit micromesh sanding pads.

I have a dark alcohol bath – I filter out the sludge monthly but leave the alcohol dark. I have found that a soak in it not only removes the finish but also gives a patina to the briar. It tends to make blending the repairs and the topped rim much easier.

I have a dark alcohol bath – I filter out the sludge monthly but leave the alcohol dark. I have found that a soak in it not only removes the finish but also gives a patina to the briar. It tends to make blending the repairs and the topped rim much easier. While the bowl soaked in the bath I turned to the stem. I sanded the tooth marks and tooth chatter on the stem with 220 grit sandpaper to remove it and smooth out the surface.

While the bowl soaked in the bath I turned to the stem. I sanded the tooth marks and tooth chatter on the stem with 220 grit sandpaper to remove it and smooth out the surface.

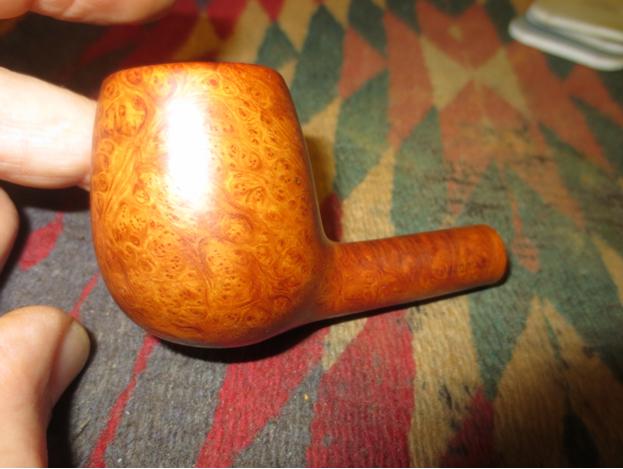

By the time I finished the initial sanding of the stem it was time to remove the bowl from the bath. I dried off the bowl and took the photos below to show the colour that the bath added to the briar.

By the time I finished the initial sanding of the stem it was time to remove the bowl from the bath. I dried off the bowl and took the photos below to show the colour that the bath added to the briar.

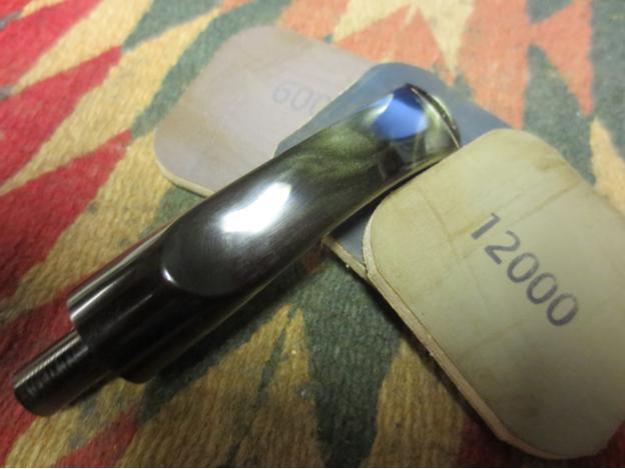

I set it aside and finished working on the stem. I sanded it with medium and fine grit sanding sponges and then with micromesh sanding pads. I wet sanded with 1500-2400 grit pads and dry sanded with 3200-12,000 grit pads.

I set it aside and finished working on the stem. I sanded it with medium and fine grit sanding sponges and then with micromesh sanding pads. I wet sanded with 1500-2400 grit pads and dry sanded with 3200-12,000 grit pads.

I buffed the stem with White Diamond and Blue Diamond on the buffing wheel. I gave it several coats of carnauba wax and lightly buffed it with a flannel buff. I am always careful when buffing the stem without the bowl (in fact I rarely do it) because it is very easy to round the shoulders on the stem making a tight fit against the shank impossible.

I buffed the stem with White Diamond and Blue Diamond on the buffing wheel. I gave it several coats of carnauba wax and lightly buffed it with a flannel buff. I am always careful when buffing the stem without the bowl (in fact I rarely do it) because it is very easy to round the shoulders on the stem making a tight fit against the shank impossible.

I buffed the bowl with red Tripoli and White Diamond to remove the surface scratches around the patches. I buffed the rim carefully with the same product. I took the next two close-up photos of the rim to show the repaired and polished rim.

I buffed the bowl with red Tripoli and White Diamond to remove the surface scratches around the patches. I buffed the rim carefully with the same product. I took the next two close-up photos of the rim to show the repaired and polished rim.

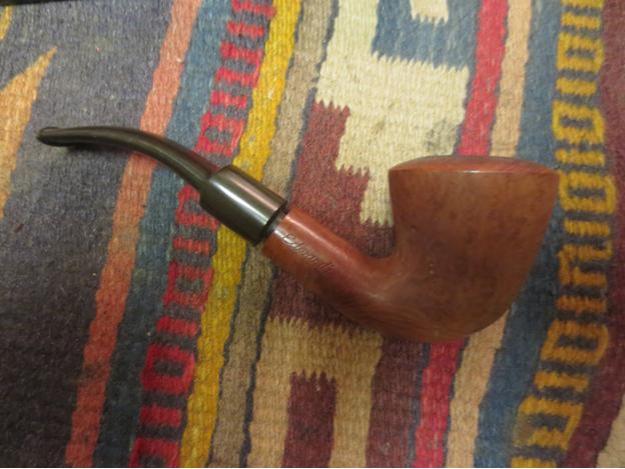

The finished pipe is shown in the photos below. The rich patina is only from the alcohol bath. I used a stain pen to touch up the light spots around the patches on the right side of the bowl and shank. I gave the pipe several coats of carnauba wax and buffed it with a soft flannel buff to raise a shine. All that is left to do is to load the bowl and fire it up. Something I hope to do before the end of the week.

The finished pipe is shown in the photos below. The rich patina is only from the alcohol bath. I used a stain pen to touch up the light spots around the patches on the right side of the bowl and shank. I gave the pipe several coats of carnauba wax and buffed it with a soft flannel buff to raise a shine. All that is left to do is to load the bowl and fire it up. Something I hope to do before the end of the week.

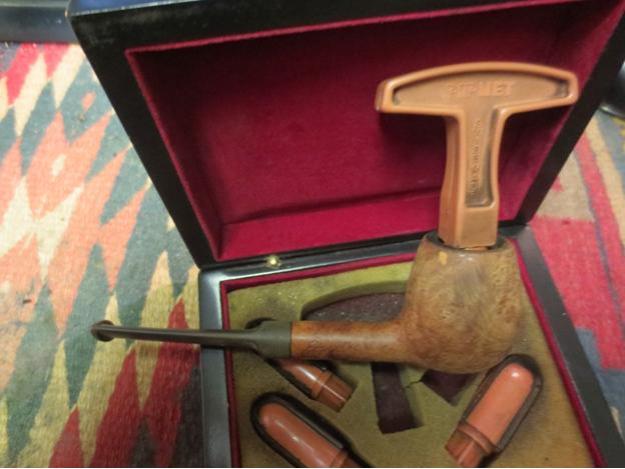

The last of the foursome of Edward’s pipes that I cleaned up for the fund raiser on Smoker’s Forums is a large Billiard with a vulcanite ferrule. It came to me without a stem so I would need to go through my stem can and see if I had any stem that would work with this bowl. The pipe is stamped Edward’s in script on the right side of the shank. On the left side it is stamped Algerian Briar in block letters. On the underside of the stem there is a large + sign and the shape number 42 near the ferrule. The bowl was in rough shape. The finish was dirty and there are some large and small fills along the shank from the bowl shank union to the ferrule. The ferrule was oxidized. The internals of the bowl and shank were dirty. The bowl was caked with the same heavy soft cake as the other Edward’s pipes. The tars had flowed over the beveled inner rim of the pipe and hardened into a dark hard cake. The briar itself was quite beautiful under the grime so a good cleaning would reveal some excellent grain as it had in the other three pipes.

The last of the foursome of Edward’s pipes that I cleaned up for the fund raiser on Smoker’s Forums is a large Billiard with a vulcanite ferrule. It came to me without a stem so I would need to go through my stem can and see if I had any stem that would work with this bowl. The pipe is stamped Edward’s in script on the right side of the shank. On the left side it is stamped Algerian Briar in block letters. On the underside of the stem there is a large + sign and the shape number 42 near the ferrule. The bowl was in rough shape. The finish was dirty and there are some large and small fills along the shank from the bowl shank union to the ferrule. The ferrule was oxidized. The internals of the bowl and shank were dirty. The bowl was caked with the same heavy soft cake as the other Edward’s pipes. The tars had flowed over the beveled inner rim of the pipe and hardened into a dark hard cake. The briar itself was quite beautiful under the grime so a good cleaning would reveal some excellent grain as it had in the other three pipes.

I took one close-up photo of the bowl to show the state of the rim and the cake in the bowl. It would take some work to clean off the lava and bring the finish back to pristine.

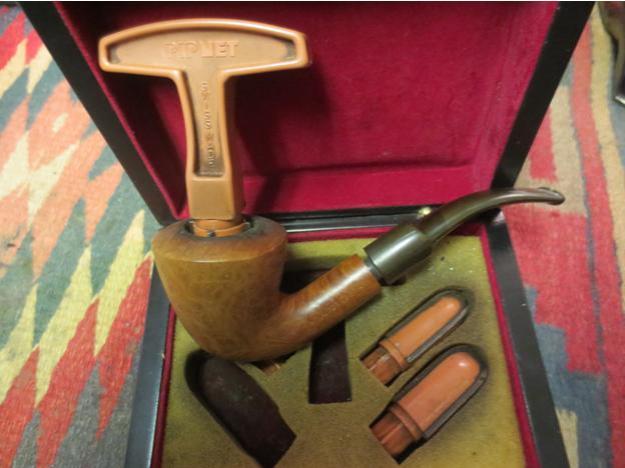

I took one close-up photo of the bowl to show the state of the rim and the cake in the bowl. It would take some work to clean off the lava and bring the finish back to pristine. I reamed the bowl with the PipNet reamer and took it back to bare wood to remove the crumbling, soft cake in the bowl.

I reamed the bowl with the PipNet reamer and took it back to bare wood to remove the crumbling, soft cake in the bowl.

Once I had the bowl reamed I took a photo of the stem and then took it to the heat gun to soften and rebend it to fit the bend of the pipe. There was a slight wave in the top of the stem that needed to be straightened as a part of the new bend.

Once I had the bowl reamed I took a photo of the stem and then took it to the heat gun to soften and rebend it to fit the bend of the pipe. There was a slight wave in the top of the stem that needed to be straightened as a part of the new bend.

I heated it until the vulcanite was pliable and then straightened it before rebending it to match the curve of the bowl and when held in the mouth was horizontal with the top of the bowl.

I heated it until the vulcanite was pliable and then straightened it before rebending it to match the curve of the bowl and when held in the mouth was horizontal with the top of the bowl.

I liked the look of the stem with the new bend so I set it aside and went to work on the bowl. I used 0000 steel wool on the rim to remove the lava overflow and repolish the rim. I am finding that this works really well as Troy shared in various blog posts he has done here and on his own site. There is always something new to learn and add to the refurbishing skill set.

I liked the look of the stem with the new bend so I set it aside and went to work on the bowl. I used 0000 steel wool on the rim to remove the lava overflow and repolish the rim. I am finding that this works really well as Troy shared in various blog posts he has done here and on his own site. There is always something new to learn and add to the refurbishing skill set. With the rim cleaned up I wiped down the bowl with acetone on a cotton pad to remove the grime in the finish and refresh the briar.

With the rim cleaned up I wiped down the bowl with acetone on a cotton pad to remove the grime in the finish and refresh the briar.

I cleaned out the bowl, shank and the airway in the stem with pipe cleaners, cotton swabs and alcohol. It was pretty clean which is amazing when you consider the condition of the rim and the cake.

I cleaned out the bowl, shank and the airway in the stem with pipe cleaners, cotton swabs and alcohol. It was pretty clean which is amazing when you consider the condition of the rim and the cake.

I sanded the stem with 220 grit sandpaper to clean up the shape and smooth out the angles and make the sides proportionally the same when the stem was in the mortise. I finished by sanding it with a medium and fine grit sanding sponge to smooth out the scratch marks left behind by the sandpaper.

I sanded the stem with 220 grit sandpaper to clean up the shape and smooth out the angles and make the sides proportionally the same when the stem was in the mortise. I finished by sanding it with a medium and fine grit sanding sponge to smooth out the scratch marks left behind by the sandpaper.

I lightly sanded the bowl and the rim with micromesh sanding pads – wet sanding with 1500-2400 and dry sanding with 3200-4000. I also sanded the vulcanite ferrule at the same time to remove the oxidation.

I lightly sanded the bowl and the rim with micromesh sanding pads – wet sanding with 1500-2400 and dry sanding with 3200-4000. I also sanded the vulcanite ferrule at the same time to remove the oxidation. I sanded the stem with the micromesh sanding pads as well – wet sanding with 1500-2400 grit pads and then rubbing it down with Obsidian Oil. I also used the oil on the ferrule. I dry sanded with 3200-4000 grit pads and rubbed it down again with the oil.

I sanded the stem with the micromesh sanding pads as well – wet sanding with 1500-2400 grit pads and then rubbing it down with Obsidian Oil. I also used the oil on the ferrule. I dry sanded with 3200-4000 grit pads and rubbed it down again with the oil.

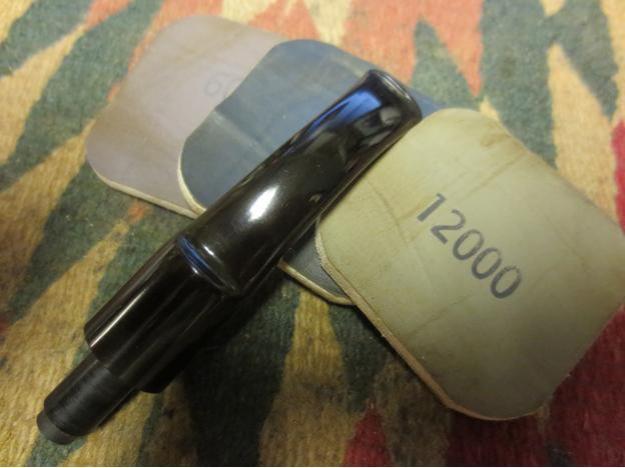

I buffed the stem with Tripoli and White Diamond before sanding it with the final grits of micromesh pads. I finished with 6000-12000 grit pads and then gave the stem and ferrule a final rub down with the Obsidian Oil. I let it soak in and dry before taking it to the buffer.

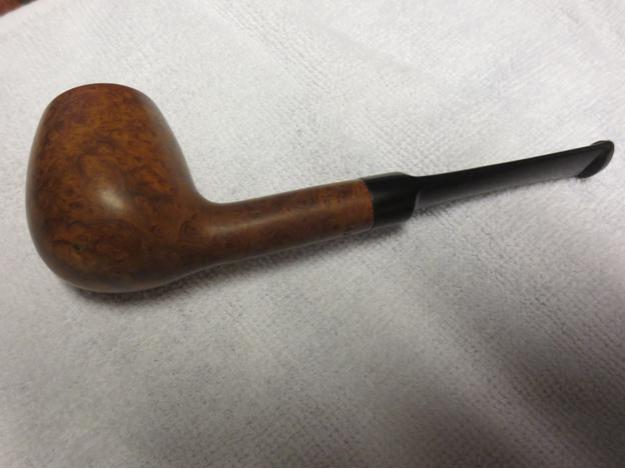

I buffed the stem with Tripoli and White Diamond before sanding it with the final grits of micromesh pads. I finished with 6000-12000 grit pads and then gave the stem and ferrule a final rub down with the Obsidian Oil. I let it soak in and dry before taking it to the buffer. I gave the bowl a light coat of olive oil to bring life back into the briar and then gave it a buff with Blue Diamond on the buffing wheel. I gave the bowl and stem multiple coats of carnauba wax and then buffed it with a clean flannel buff. I finished by hand buffing it with a microfibre cloth to bring depth to the shine. The finished pipe is shown below. The first photo is of the pipe with the Edward’s large apple to give a sense of the size of the pipe. It is a large piece of briar.

I gave the bowl a light coat of olive oil to bring life back into the briar and then gave it a buff with Blue Diamond on the buffing wheel. I gave the bowl and stem multiple coats of carnauba wax and then buffed it with a clean flannel buff. I finished by hand buffing it with a microfibre cloth to bring depth to the shine. The finished pipe is shown below. The first photo is of the pipe with the Edward’s large apple to give a sense of the size of the pipe. It is a large piece of briar.