Blog by Steve Laug

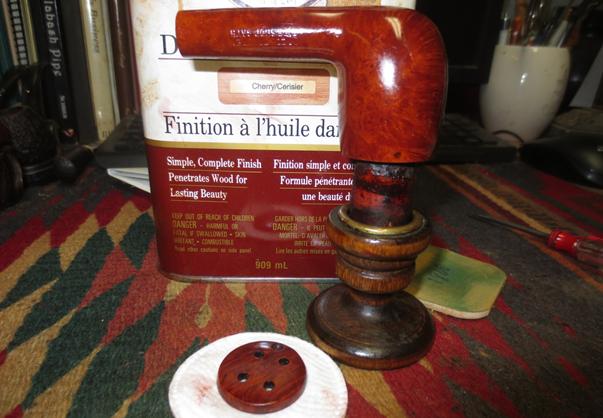

The next pipe on my work table is another one that I have no idea where or when we picked it up. I know that it has been here for a long time. I figure that it probably came in the same lot as the Captain Peterson N23 Apple. The pipe is stamped on the left side and read “Captain Peterson” (upper case letters in two lines). On the right side it was stamped A “Peterson’s Product” [over] Made in England. That is followed by the shape number N24 near the shank/bowl union. There is a C in a Circle logo on the left side of the taper stem. The pipe had been reamed and cleaned somewhere along its journey which told me that it had come to me from Jeff after he had done is work. He also has no idea of the provenance of the pipe. The finish on the bowl was dull but very clean. There were burn marks on the right and left side toward the cap and on the rim top and edges. It appeared that the pipe had been laid in an ashtray. The bowl was reamed and the rim top was also clean. The inner edge of the bowl looked quite good. The taper stem was also very clean. It had no oxidation on the finish but there were tooth marks and chatter on the surface of the stem. There was a bite through on the underside next to the button edge. This one lacked a stinger. I took photos of the pipe before I started my work on it.

I took a photo of the bowl and rim top to show how well it had cleaned up. There was no lava on top and no cake in the bowl. You can see the burn marks or darkening on the rim top and edges – both the inner and outer.

I took a photo of the bowl and rim top to show how well it had cleaned up. There was no lava on top and no cake in the bowl. You can see the burn marks or darkening on the rim top and edges – both the inner and outer. I took photos of the stamping on the sides of the shank. It is clear and readable as noted above. The stamped white logo on the side of the taper stem is also clear and readable.

I took photos of the stamping on the sides of the shank. It is clear and readable as noted above. The stamped white logo on the side of the taper stem is also clear and readable. I removed the stem from the shank to give a sense of proportion to the pipe and to also show the unique stinger apparatus in the tenon end of the other Captain Peterson was missing on this one.

I removed the stem from the shank to give a sense of proportion to the pipe and to also show the unique stinger apparatus in the tenon end of the other Captain Peterson was missing on this one. I have included the information from the previous Captain Peterson restoration. For me this is a part of the restoration. I turned first to Pipephil’s site where I found both Captain Pete and Captain Peterson (http://www.pipephil.eu/logos/en/logo-peterson-rep.html#captainpete). I have included a screen capture of the Captain Pete information and also one of the Captain Peterson information. I also included the sidebar information as well.

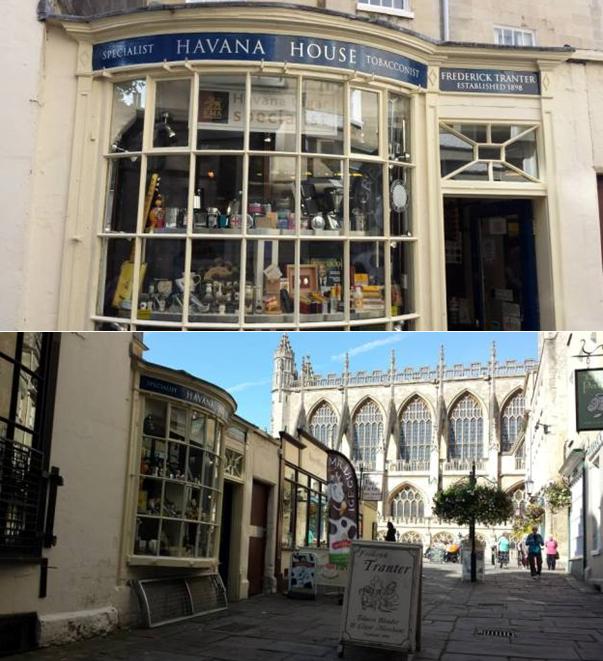

I have included the information from the previous Captain Peterson restoration. For me this is a part of the restoration. I turned first to Pipephil’s site where I found both Captain Pete and Captain Peterson (http://www.pipephil.eu/logos/en/logo-peterson-rep.html#captainpete). I have included a screen capture of the Captain Pete information and also one of the Captain Peterson information. I also included the sidebar information as well. Captain Pete was a brand of Peterson’s English branch (1899-1960). Dublin continued to produce Captain Petes a couple of years after 1960. At the end of the eighties just as the Sherlock Holmes range was being issued, Peterson reintroduced the modern Captain Pete series.

Captain Pete was a brand of Peterson’s English branch (1899-1960). Dublin continued to produce Captain Petes a couple of years after 1960. At the end of the eighties just as the Sherlock Holmes range was being issued, Peterson reintroduced the modern Captain Pete series. Captain Peterson was a brand of Peterson’s English branch. This English made pipe was crafted prior to 1960.

Captain Peterson was a brand of Peterson’s English branch. This English made pipe was crafted prior to 1960.

From there I turned to the “Peterson Pipe The Story of Kapp & Peterson” by Mark Irwin and Gary Malmberg, page 295 to see what information I could find there. I quote:

Captain Pete – This line’s name was derived from the nickname of Charles Peterson, known affectionately by friends and employees as “Captain Peterson.” The first issue. C. 1940-62, was in a smooth finish produced for Rogers Imports with a white stamped P inside C or a circled P on the mouthpiece. CAPTAIN over PETE on shank, and MADE IN IRELAND in a circle. English made versions show CAPTAIN over PETE on the shank or “CAPTAIN PETERSON” and a PETERSON’S PRODUCT over MADE IN ENGLAND or LONDON MADE over ENGLAND. The second issue (1998-), features an XL bowl with Sherlock Holmes shapes and compact stems, in rustic or combination of smooth and rustic finish, with a nickel band between two narrow brass bands.

I knew that I was working on a pipe made before 1960 in London, England. Thus, the pipe was a first issue C. 1940-62. It is a beautiful pipe that will need some work but overall was in very good condition for a pipe made before 1960. It was time to start my work on the pipe.

I began by cleaning up the inner edge of the bowl and gently topped the rim top with a folded piece of 220 grit sandpaper. I sanded the edge to give it very slight bevel and minimize the damage. I also sanded the burnt spots on the sides of the bowl to blend them into the surface.

I polished the briar with micromesh sanding pads – dry sanding the bowl and shank with 1500-12000 grit pads and wiping it down with a damp cloth between each sanding pad. The bowl took on more of a shine with the completion of each sanding pad.

I polished the briar with micromesh sanding pads – dry sanding the bowl and shank with 1500-12000 grit pads and wiping it down with a damp cloth between each sanding pad. The bowl took on more of a shine with the completion of each sanding pad.

I gave the bowl and shank a wash of Light Brown aniline stain and alcohol. I applied it with a wool dauber and flamed it to set it in the briar. Once it cured I buffed it with Blue Diamond on the buffing wheel.

I gave the bowl and shank a wash of Light Brown aniline stain and alcohol. I applied it with a wool dauber and flamed it to set it in the briar. Once it cured I buffed it with Blue Diamond on the buffing wheel.

After buffing I worked some Before & After Restoration Balm into the briar with my fingertips. I let it sit on the bowl for 15 minutes. I buffed it off with a soft cotton cloth to raise the shine. It was a beautiful piece of briar.

After buffing I worked some Before & After Restoration Balm into the briar with my fingertips. I let it sit on the bowl for 15 minutes. I buffed it off with a soft cotton cloth to raise the shine. It was a beautiful piece of briar.

With the bowl finished other than the final buffing I set it aside and turned my attention to the stem. I greased a pipe cleaner with Vaseline and inserted it in the button below the bite through. I filled in the bite through on the underside with black super glue and the tooth marks on the top side with you. I removed the pipe cleaner from the stem and then used a small file to flatten the repair. I sanded it with 220 grit sandpaper and then started polishing it with 600 grit wet dry sandpaper.

With the bowl finished other than the final buffing I set it aside and turned my attention to the stem. I greased a pipe cleaner with Vaseline and inserted it in the button below the bite through. I filled in the bite through on the underside with black super glue and the tooth marks on the top side with you. I removed the pipe cleaner from the stem and then used a small file to flatten the repair. I sanded it with 220 grit sandpaper and then started polishing it with 600 grit wet dry sandpaper.

I touched up the Circle C logo the left side of the stem with some white acrylic fingernail polish. Once it dried I sanded off the excess and the logo looked very good.

I touched up the Circle C logo the left side of the stem with some white acrylic fingernail polish. Once it dried I sanded off the excess and the logo looked very good. I polished it with micromesh sanding pads. I wiped the stem down between each pad with a cloth impregnated with Obsidian Oil. By the final pad the pipe stem looked very good.

I polished it with micromesh sanding pads. I wiped the stem down between each pad with a cloth impregnated with Obsidian Oil. By the final pad the pipe stem looked very good.

I finished polishing the stem with Before & After Pipe Stem polish (both Fine and Extra Fine) then wiped the stem down with another coat of Obsidian Oil.

I finished polishing the stem with Before & After Pipe Stem polish (both Fine and Extra Fine) then wiped the stem down with another coat of Obsidian Oil.  I am excited to finish the easy restoration of this “Captain Peterson” Made in England N24 Rhodesian. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine and hand buffed it with microfiber cloth to deepen the shine. It is fun to see what the polished bowl looks like with the polished black, taper vulcanite stem was beautiful. This “Captain Peterson” N24 Rhodesian turned out very well and feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 1 ¼ inches, Outside diameter of the bowl: 1 ¼ inch, Chamber diameter: ¾ of an inch. The weight of the pipe is .99 ounces/28 grams. It is a beautiful pipe and one that I will be putting on the rebornpipes store in the Irish Pipe Makers Section. If you are interested in carrying on the trust of this let me know through a message or an email to slaug@unserve.com . Thanks for walking through the cleanup with me as I worked over this pipe.

I am excited to finish the easy restoration of this “Captain Peterson” Made in England N24 Rhodesian. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine and hand buffed it with microfiber cloth to deepen the shine. It is fun to see what the polished bowl looks like with the polished black, taper vulcanite stem was beautiful. This “Captain Peterson” N24 Rhodesian turned out very well and feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 1 ¼ inches, Outside diameter of the bowl: 1 ¼ inch, Chamber diameter: ¾ of an inch. The weight of the pipe is .99 ounces/28 grams. It is a beautiful pipe and one that I will be putting on the rebornpipes store in the Irish Pipe Makers Section. If you are interested in carrying on the trust of this let me know through a message or an email to slaug@unserve.com . Thanks for walking through the cleanup with me as I worked over this pipe.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.