by Steve Laug

The next pipe on the work table is a classic Prince shaped pipe with a vulcanite taper stem. We picked the pipe up from a seller in Ogden, Utah, USA on 12/12/2024. It is stamped on the left side of the shank and reads Charatan’s Make [over] London, England [over] De Luxe. That stamping is followed by the shape number stamp, 502. The finish is smooth and has some great straight grain around the bowl sides and birdseye on the rim top and heel of the bowl. It was quite dirty but still had a charm about it. The bowl was caked and there was a light lava coat and spots on the top and the inner edge of the rim. The stem was vulcanite and was a tapered. There were light tooth marks and chatter on both sides of the stem. The was a Charatan CP interlocked logo on the left side of the stem. Jeff took some photos of the pipe to show the general condition of the pipe before he started his clean up. He took some photos of the rim top and bowl from various angles to give me a clear picture of the condition of the rim top and bowl. You can see the cake in the bowl and the darkening and lava coat on the rim top. It is hard to tell if there was any damage to the inner edge at this point. The next photos show the top and underside of the stem. It is dirty and has oxidation and calcification on both sides at the button. There is also some tooth chatter and light tooth marks.

He took some photos of the rim top and bowl from various angles to give me a clear picture of the condition of the rim top and bowl. You can see the cake in the bowl and the darkening and lava coat on the rim top. It is hard to tell if there was any damage to the inner edge at this point. The next photos show the top and underside of the stem. It is dirty and has oxidation and calcification on both sides at the button. There is also some tooth chatter and light tooth marks.

Jeff took some photos of the sides of the bowl to show the condition of the finish on the pipe. The photos showed beautiful grain around the bowl sides. Under the oils and grime, it is a nice looking bowl.

Jeff took some photos of the sides of the bowl to show the condition of the finish on the pipe. The photos showed beautiful grain around the bowl sides. Under the oils and grime, it is a nice looking bowl.

He took a photo of the stamping on the left side of the shank. The stamping was clear and readable. He also captured a photo of the Charatan logo on the left side of the stem.

He took a photo of the stamping on the left side of the shank. The stamping was clear and readable. He also captured a photo of the Charatan logo on the left side of the stem. I looked up an article on determining dates of manufacture of Charatan’s Make pipes (https://pipedia.org/wiki/Dating_of_Charatans). That article helped me date this pipe with some level of certainty to the Rueben Era Charatan made between the years 1910-1960. I quote from the portion of the article that gave the identifying characteristics of that era. I quote in full.

I looked up an article on determining dates of manufacture of Charatan’s Make pipes (https://pipedia.org/wiki/Dating_of_Charatans). That article helped me date this pipe with some level of certainty to the Rueben Era Charatan made between the years 1910-1960. I quote from the portion of the article that gave the identifying characteristics of that era. I quote in full.

Identification of a second era pipe (Rueben’s era, 1910-1960)

Pipes belonging to this period are rare, however is it possible to come across one. They can be distinguished from a pipe of the first era mainly because their larger size. Their characteristics are similar to the ones of the previous era.

1) Pipes can be larger, up to the dimension of a Dunhill group 5

2) The mouthpiece is tapered or saddle.

3) No double comfort

4) the CP logo is engraved so that the C enters the P

5) Absence of £ on the pipe shank (note that from 1955 all the pipe imported in the USA by Lane has it, however that stamping is not synonymous of the Lane era).

6) Absence of the letter X on the shape code engraved on the shank (for ex. 2502 and not 2502X)

7) Absence of letters DC after the shape number (for ex. 2502 and not 2505DC)

8) Absence of the engraving “MADE BY HAND” on the shank (introduced for the first time in 1958)

9) Presence of the writing “CHARATAN’S MAKE LONDON ENGLAND” on 2 lines

10) The CP logo is finer than in following eras

All ten of the items in the above list apply to the pipe in hand. From the stamping on the stem where the C enters the P to the missing L which places it as pre-1955 to the lack of a double comfort bit all help to place this pipe in this time period.

Armed with that information I turned to work on the pipe itself. Jeff had done a great job cleaning up the pipe as usual. He cleaned up the inside of the bowl with a Savinelli Fitsall Pipe Knife. The rim top and the inner edge of the bowl are in excellent condition. The bowl walls looked very good. He scrubbed the interior of the bowl and shank with shank brushes, pipe cleaners, cotton swabs and alcohol to remove the tars and oils. He scrubbed the exterior of the pipe with Murphy’s Oil Soap and a tooth brush to remove the grime from the finish. He scrubbed the inside of the stem with alcohol and pipe cleaners. He scrubbed the exterior with Soft Scrub and then soaked it in Briarville’s Pipe Stem Deoxidizer. He washed it off with warm water to remove the deoxidizer. The stem looked very good. I took photos of the pipe before I started working on it.

I took close up photos of the bowl, rim top and stem to show how clean the pipe was. The bowl was clean and the rim top and the inner edge look beautiful. The stem was clean and did not show either tooth marks or chatter.

I took close up photos of the bowl, rim top and stem to show how clean the pipe was. The bowl was clean and the rim top and the inner edge look beautiful. The stem was clean and did not show either tooth marks or chatter. I took a photo of the stamping on the side of the shank. It is very clear and readable and read as noted above. I also removed the stem from the shank and took photos of the pipe to show the look of the parts.

I took a photo of the stamping on the side of the shank. It is very clear and readable and read as noted above. I also removed the stem from the shank and took photos of the pipe to show the look of the parts.  I started my work on the pipe by addressing the damage on the inner edge of the rim. I used a folded piece of 220 grit sandpaper to clean up the darkening and the damage on the inner edge of the bowl.

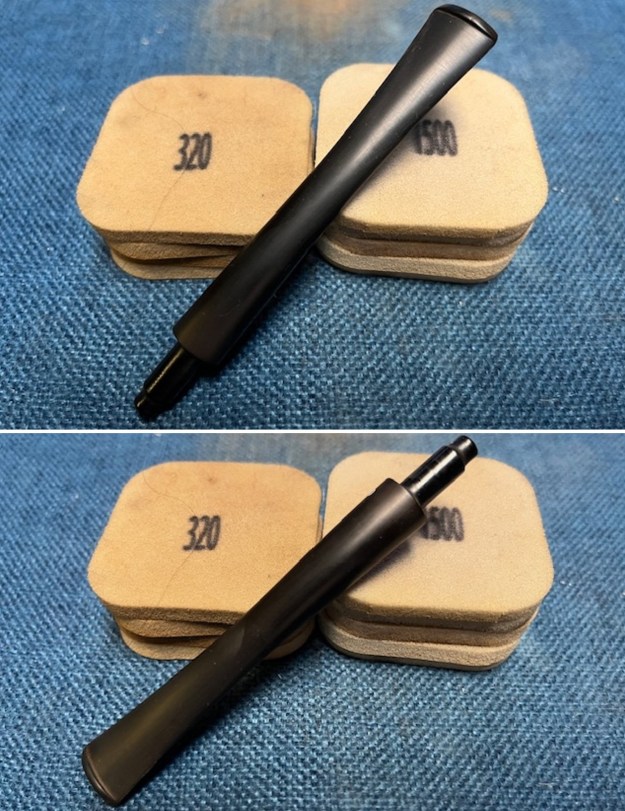

I started my work on the pipe by addressing the damage on the inner edge of the rim. I used a folded piece of 220 grit sandpaper to clean up the darkening and the damage on the inner edge of the bowl. I sanded the bowl with 320-3500 grit sanding pads to smooth out sanding on the rim top and also to blend in the scratches on the bowl sides and heel.

I sanded the bowl with 320-3500 grit sanding pads to smooth out sanding on the rim top and also to blend in the scratches on the bowl sides and heel.

I polished the bowl and shank with 1500-12000 grit micromesh sanding pad – dry sanding it with the pads. I wiped the bowl down with a damp cloth after each pad. It began to take on a deep shine.

I polished the bowl and shank with 1500-12000 grit micromesh sanding pad – dry sanding it with the pads. I wiped the bowl down with a damp cloth after each pad. It began to take on a deep shine.

The exterior of the bowl look better after sanding. I worked some Before & After Restoration Balm into the briar with my finger tips. I let it sit on the bowl for 10 minutes and then buffed it off with a paper towel and soft cloth. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. It is a product I use on every pipe I restore.

The exterior of the bowl look better after sanding. I worked some Before & After Restoration Balm into the briar with my finger tips. I let it sit on the bowl for 10 minutes and then buffed it off with a paper towel and soft cloth. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. It is a product I use on every pipe I restore.

I set the bowl aside and turned my attention to the stem. I sanded it with 320-3500 grit sanding pads to remove the light tooth marks and chatter. It did not take much for them to be gone. I wiped the stem down with Obsidian Oil after each sanding pad to remove the debris and dust of the sanding. By the last pad the stem looks very good.

I set the bowl aside and turned my attention to the stem. I sanded it with 320-3500 grit sanding pads to remove the light tooth marks and chatter. It did not take much for them to be gone. I wiped the stem down with Obsidian Oil after each sanding pad to remove the debris and dust of the sanding. By the last pad the stem looks very good. I touched up the Charatan logo stamp on the left side of the stem with white acrylic fingernail polish. I worked it into the stamping with a tooth pick. I scraped off the excess and used a worn 1500 grit micromesh sanding pad to finish removing the excess.

I touched up the Charatan logo stamp on the left side of the stem with white acrylic fingernail polish. I worked it into the stamping with a tooth pick. I scraped off the excess and used a worn 1500 grit micromesh sanding pad to finish removing the excess.  It was ready for the next step. I polished it with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping the surface down with Obsidian Oil after each sanding pad. It is really shining. I polished it further with Before & After Stem Polish – both Fine and Extra Fine. I gave it another coat of Obsidian Oil to finish this step.

It was ready for the next step. I polished it with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping the surface down with Obsidian Oil after each sanding pad. It is really shining. I polished it further with Before & After Stem Polish – both Fine and Extra Fine. I gave it another coat of Obsidian Oil to finish this step.

It was great to finish this Charatan’s Make London, England De Luxe 502 Prince. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. It is fun to see what the polished bowl looks like with deep sandblast all around it. Added to that the polished black, vulcanite, saddle stem was beautiful. This Charatan’s Make De Luxe Prince is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 ½ inches, Height: 1 ¼ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 35 grams/1.20 ounces. It is a beautiful pipe and one that will soon be on the rebornpipes store in the British Pipe Makers Section of the store. If you want to add it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe.

It was great to finish this Charatan’s Make London, England De Luxe 502 Prince. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. It is fun to see what the polished bowl looks like with deep sandblast all around it. Added to that the polished black, vulcanite, saddle stem was beautiful. This Charatan’s Make De Luxe Prince is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 ½ inches, Height: 1 ¼ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 35 grams/1.20 ounces. It is a beautiful pipe and one that will soon be on the rebornpipes store in the British Pipe Makers Section of the store. If you want to add it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.