Blog by Dal Stanton

When I first laid eyes on this unique ‘Feather’ or ‘Plume’ shaped pipe, I debated adding it to my own personal collection and not posting it in the For “Pipe Dreamers” Only! collection, making it available for pipe men and women to commission. Well, the Feather did find a place in the ‘Dreamers’ collection and Daniel eventually added the P. Viou Feather to his trove of commissioned pipes totaling 7(!) benefiting the Daughters of Bulgaria. I acquired the P. Viou Feather from the French eBay auction block in 2018. This ‘French Lot of 50’, which is what I have affectionately called it, has offered up several treasures – one restoration that became my first publication adding to Pipedia’s wealth of information (See: Discovering the History with the Reclamation of this Petite EPC Majestic Bent Horn Stem Billiard and for Pipedia contribution see: A. Pandevant & Roy Co.). The picture of the Lot provided by the Parisian seller only created the urge to know what was hidden within the tangle of stems and stummels. That I could see so many interesting shapes and horn stems supplied the impetus to acquire the Lot. The P. Viou Feather is mostly hidden in the picture (arrow below left) and it wasn’t until later after the package arrived in Sofia and I gleefully sorted and grouped the pipes that I came to realize the treasure trove of pipes in this Lot. The Feather grouping is pictured below. Looking more closely at the P. Viou Feather, I take some additional pictures.

Looking more closely at the P. Viou Feather, I take some additional pictures.

The nomenclature is worn and thin at points but generally recognizable. On the left flank is stamped in fancy cursive ‘P’ [underscored] followed by ‘Viou’ which is punctuated with a flared underline. The COM stamped on the right flank of the Feather stummel reads: St CLAUDE [over] FRANCE. St. Claude is the pipe center of France and the birthplace of the production of briar pipes. The horn stem is also stamped, P. VIOU. This stamp is also thin, but I’m hopeful to refresh it later.

The nomenclature is worn and thin at points but generally recognizable. On the left flank is stamped in fancy cursive ‘P’ [underscored] followed by ‘Viou’ which is punctuated with a flared underline. The COM stamped on the right flank of the Feather stummel reads: St CLAUDE [over] FRANCE. St. Claude is the pipe center of France and the birthplace of the production of briar pipes. The horn stem is also stamped, P. VIOU. This stamp is also thin, but I’m hopeful to refresh it later.  I had the opportunity of restoring another Paul Viou from the French Lot of 50 – a Churchwarden (See: Recommissioning a Vintage French Paul Viou Churchwarden of St. Claude). There is scant information about the Paul Viou name on the internet that I could find. Pipedia’s article of Paul Viou is brief:

I had the opportunity of restoring another Paul Viou from the French Lot of 50 – a Churchwarden (See: Recommissioning a Vintage French Paul Viou Churchwarden of St. Claude). There is scant information about the Paul Viou name on the internet that I could find. Pipedia’s article of Paul Viou is brief:

From Pipes, Artisans and Trademarks, by José Manuel Lopes’

Paul Viou was the brand and name of a French artisan who sold his pipes by correspondence and then he was a pipe supplier for military institutions. He also made sculpted pipes and sometime used horn stems.

The brand is currently sold by Jacques Craen and made by Genod in Saint-Claude, after having also belonged to Paul Guilland and Vuillard. They are stamped P. Viou and made primarily for export.

This information is confirmed by Pipephil.eu with the addition of the date of 2006 when the Paul Viou name transferred to Sebastien Beaud of Genod. As I broaden my online research, I discover that Sebastien Beaud is an interesting story. He currently is the owner of the Genod house of pipes in St. Claude and is a younger entrepreneur. In trying to find out further information about Paul Viou, Genod information is prevalent in the research. The Pipedia article dedicated to Genod of St. Claude is also interesting (See: Genod). The Genod story began in 1865 when Comoy founded pipe production in St. Claude. In 1923 the production is taken over by Georges Vincent and in 1939, son in law John Craen joined Vincent. John Craen’s son, Jacques, joined the business in 1959 and took over the business in 1977 where he expanded the Genod name and opened the shop in St. Claude to visitors to observe the pipe production.

As I broaden my online research, I discover that Sebastien Beaud is an interesting story. He currently is the owner of the Genod house of pipes in St. Claude and is a younger entrepreneur. In trying to find out further information about Paul Viou, Genod information is prevalent in the research. The Pipedia article dedicated to Genod of St. Claude is also interesting (See: Genod). The Genod story began in 1865 when Comoy founded pipe production in St. Claude. In 1923 the production is taken over by Georges Vincent and in 1939, son in law John Craen joined Vincent. John Craen’s son, Jacques, joined the business in 1959 and took over the business in 1977 where he expanded the Genod name and opened the shop in St. Claude to visitors to observe the pipe production.

From the same Pipedia article: In 2006 the young pipemaker Sebastien Beaud started his work in Jacky’s factory. As Craen himself he took over the brand Viou to start with. In future he will take over the business in its entire and continue this sympathetic workshop in its traditional way.

From the same Pipedia article: In 2006 the young pipemaker Sebastien Beaud started his work in Jacky’s factory. As Craen himself he took over the brand Viou to start with. In future he will take over the business in its entire and continue this sympathetic workshop in its traditional way.

In the excerpt above, the Paul Viou line is mentioned as continuing under Genod during the Craen period, then Sebastien Beaud took over the Viou line. Unfortunately, this article nor the article in Pipedia dedicated to Paul Viou, provide much in the way of specific dating of the Paul Viou branding.

I’ve searched several forums for answers to questions regarding when the historical Paul Viou began production using this name? The Paul Viou Feather, or Plume (French translation) appears to have some age. The horn stem would suggest a dating in the 1940s during the rubber shortages of WW2. Horn became a ‘go to’ material in place of rubber compound stems. Yet, a question arises regarding this older dating when I discovered in Genod’s current offerings of pipes on its website an almost identical ‘Plume’ yet, not with a horn stem but an ebonite or vulcanite stem (See: Link). Also missing is the P. Viou nomenclature. Furthermore, more than many pipe manufacturers today, Genod’s quality offerings include many horn stemmed options. I like this(!) but it brings into question the necessity of an older dating for the P. Viou on my worktable. With the foundational question being, when did the P. Viou name begin? Was it before or during the Craen era of Genod? Was the P. Viou stamp on this Feather an indicator of a pre-Genod production? My experience with tracking down and nailing down French pipe production details has never been easy but always interesting!

With the foundational question being, when did the P. Viou name begin? Was it before or during the Craen era of Genod? Was the P. Viou stamp on this Feather an indicator of a pre-Genod production? My experience with tracking down and nailing down French pipe production details has never been easy but always interesting!

Potentially to find answers about the dating of the Paul Viou name, I sent an email via the ‘Contact’ form provided on the Genod website. I have been surprised in the past to receive responses from ‘Hail Mary’ requests to pipe houses in Europe and America. We’ll see what happens.

Well, I am continually amazed at ‘names’ in the pipe world being accessible to folks like me! The next day I received a reply from Sebastien Beaud, currently at the helm of Genod. I include my original message with the replies that followed:

Well, I am continually amazed at ‘names’ in the pipe world being accessible to folks like me! The next day I received a reply from Sebastien Beaud, currently at the helm of Genod. I include my original message with the replies that followed:

DAL: Greetings, Thank you in advance for your time! I restore vintage pipes and publish the restoration process and research online at www.ThePipeSteward.com. I have restored some Paul Viou pipes and have researched a lot and enjoy the connection of Paul Viou and Genod. However, there is very little information that I can find on the internet regarding Paul Viou, historically. Can you please provide any information about Paul Viou’s origins, when he lived, when the P. Viou name started being placed on pipes? My current restoration is a P. Viou Plume with a horn stem. I see that you still produce these shapes on your website but with Ebionite stems. I’m trying to determine the potential dating of this pipe but cannot find much information about when Paul Viou came onto the pipe scene. Thanks so much for your help in advance if you are able!

———–

Dear Dal,

Congratulations for your work and your website! All I know about Paul Viou is that as a former officer in the French army, he used to advertise his pipes in the army magazines. So he used to sell a lot to the soldiers during the Algerian war, back in the 50’s / 60’s. He ran the business together with his wife Odette. Their workshop was located right next to ours, and when they got old, Jacques Craen, started making pipes for them. At the same time, Jacques Craen created the “Genod” brand to start selling directly to the smokers instead of selling to whole sellers. Genod is a tribute to his grandfather Georges Vincent-Genod (on his mother’s side) with whom he had learned and from whom he inherited the workshop. In the early 90’s, Jacques bought the Paul Viou brand and customers’ addresses file. I myself took over when Jacques retired, and kept Paul Viou’s name for a while, but it is the exact same product as a Genod pipe, so now I stamp all the pipes “Genod”. I hope this helps.

Best regards,

Sebastien BEAUD

www.maitrepipier.fr

SARL GENOD VIOU

13 Faubourg Marcel – BP 145

39205 SAINT CLAUDE Cedex FRANCE

Tél. (+33) (0)3 84 45 00 47

———

DAL: Sebastien, Thank you so much for responding to my inquiries! This information needs to be added to Pipedia. If I could ask one follow up question regarding the pipe on my worktable. The nomenclature is the cursive ‘P. Viou’ and COM: St. Claude, France. The horn stem is stamped, ‘P. Viou’. Can you venture a guess as to what period this ‘Plume’ was manufactured with this nomenclature and horn stem? Before the Jacques Craen period (50/60s?) or when Jacques Craen was making them for Paul Viou (60/70s) or during the Genod period starting in the 70s but still using the ‘P. Viou’ stamp? I hope you can understand this! I’m simply trying to place this pipe in a time period. I’ve attached a few pictures if this is a help. Again, much thanks.

———

I think this pipe has been made by Jacques Craen back in the 80’s (even though it could also be the 90’s or late 70’s).

Best regards,

Sebastien BEAUD

With deep appreciation to Sebastien Beaud for his time and for the information he supplied, I have a much better understanding of the Paul Viou name and a small piece of the man himself. Valuable information added was regarding Paul Viou, the man. He was formerly an officer in the French army – a military man but also a pipe man/entrepreneur. Apparently after his time with the military and residing in St. Claude, he was undoubtedly very much a part of the ‘pipe world’ milieu and at one point added his hand to the pipe making industry. With his connections in the military, he advertised his pipes in the military magazines of the time and in military institutions.

It is noteworthy that Sebastien pinpoints this activity during the Algerian War. A quick search on the internet renders a Wikipedia article describing the war that was from 1954 to 1962 that found France engaged in a ‘decolonization’ war with the Algerian National Liberation Front and facing turbulent times at home with a war that garnered international attention. The war gradually resulted in an independent Algeria – much resembling the turmoil of the Viet Nam conflict of the United States. Paul Viou had developed his business selling pipes and during this difficult time, with French servicemen abroad, Paul Viou, along with the support of his wife, Odette, provided pipes for the troops via army magazine adds. The personal relationship between Jacques Craen and Viou family is interesting – their shops were next door to each other and the aging of the senior Viou created a transition from Paul Viou’s actively working in the shop to his work being done by Jacques. During this transition period, undoubtedly steps were taken to sign over the Viou name to Craen and the Vincent-Genod legacy. Another transition alluded to by Sebastien’s words – the brand created by Jacques, “Genod”, was a tribute to his grandfather. The Viou brand joined the Genod brand and again, this legacy was passed on to Sebastien Beaud. The Viou name is no longer used to mark pipes, but the quality of the Viou pipe was brought under Genod craftsmanship.

One last question I brought to Sebastien was the dating of the P. Viou Feather on my worktable. His qualified answer is somehow in sync with French pipe dating in general! Most likely the P. Viou Feather is from the hands of Jacques in the 80s, but the late 70s or the 90s could be possibilities as well! Much thanks to Sebastien Beaud for his help in this project!

One very interesting piece of information related to horn stems I discovered on the Genod site written by Sebastien Beaud in March of 2020 regarding Genod’s current use of horn stems (See tab: All About Pipes). More than most pipe houses, Genod continues to fit their pipes with horn stems which I find interesting. His article was excellent and apropos since a horn stem from the Genod house is now on the worktable! I include his article which taught me a good bit!

March 16, 2020/ in All about the pipe / by Sébastien Beaud

Most of the pipes fitted to briar pipes are made of ebonite because this material combines flexibility and resistance to wear by the teeth. But other materials are interesting for the production of pipes. There is one that is dear to us, because it is comfortable, beautiful, and presents various shades of colors, it is the horn.

The horn is made of hairs bonded with keratin, the material from which our nails are made. This hair-armed keratin protects and strengthens the bone that grows on each side of the head of cattle. The horn we use to make the pipe stems is that of the zebu. It can reach 1 meter in length. As we have seen, a horn is hollow because it contains a bone. Therefore, only the end (the tip) is suitable for turning work. A cow’s horn is therefore not long enough to be used in turning.

Zebus also have a brown, white or marbled coat, their horn presents a magnificent variety of shades, ranging from sometimes very dark brown to blond, the association of the two colors being called “marbled”.

Filming on horn.

The zebu is bred for its meat in Brazil, Argentina and Madagascar. The horns, instead of being lost like the other inedible parts, are exported for use in the manufacture of combs, knife handles, beads, and of course, for turning pipe stems.

Once arrived in the workshops of the Jura, the horns are possibly softened by heating in a bath or steam, in order to straighten them by pressing. Then comes cutting, turning, shaping, then drilling. Now here is a straight pipe stem.

If necessary, it can be bent in a “form” press dipped in a hot oil bath, and there it is, ready to be adjusted to the heather.

How to maintain the horn?

An organic material, the horn offers a soft contact, and quickly takes the mark of the teeth. And what a pleasure to combine plants and animals in a beautiful object! The maintenance of horn pipes is very simple: just avoid exposure to heat sources, and if you want to prevent the shine of the pipe fading over time, you can rub it regularly with a simple cloth, as a polish. Choose now the pipe with horn stem that suits you, fill it with your favorite mixture, natural or aromatic, and… good tasting!

With a better understanding of the Paul Viou name and man who originally have his name to the pipes, I take a critical look at the Feather or Plume shape now on the worktable. The grain on the stocky Feather stummel is attractive. The briar block was cut allowing very intricate Bird’s Eye grain to emerge on both sides. Looking at the stummel straight on – at the nose of the ‘torpedo’, the cross grain is visible connecting the sides creating the cross grain perspective. The finish on the briar is dark and in need of cleaning. The surface shows dents and scrapes on the heel of the stummel as well as on the upper side. The diminutive size of the Feather allows it to be the perfect ‘pocket pipe’ but in the pocket are keys and change to compete with!

The finish on the briar is dark and in need of cleaning. The surface shows dents and scrapes on the heel of the stummel as well as on the upper side. The diminutive size of the Feather allows it to be the perfect ‘pocket pipe’ but in the pocket are keys and change to compete with!  The chamber has light cake buildup and will be removed to allow a fresh start for the briar. The rim also shows caking which needs removing so that the condition of the rim can be seen more clearly and to rediscover the rim’s grain. There are nicks and dents around the rise to the rim.

The chamber has light cake buildup and will be removed to allow a fresh start for the briar. The rim also shows caking which needs removing so that the condition of the rim can be seen more clearly and to rediscover the rim’s grain. There are nicks and dents around the rise to the rim.  The horn stem is predominantly a dark hue except for near the bit area where it lightens. The horn is rough but should clean up very nicely.

The horn stem is predominantly a dark hue except for near the bit area where it lightens. The horn is rough but should clean up very nicely. I start the restoration of the P. Viou Feather by addressing the cake in the chamber. Only the smallest blade head is accommodated by the 3/4-inch diameter chamber. The process of clearing the carbon cake transitions quickly to employing the Savinelli Fitsall Tool to scrape the chamber walls. The rim is carefully scraped as well with my Winchester pocketknife then the chamber is sanded with 240 grade sanding paper wrapped around a Sharpie Pen. The progress looks good.

I start the restoration of the P. Viou Feather by addressing the cake in the chamber. Only the smallest blade head is accommodated by the 3/4-inch diameter chamber. The process of clearing the carbon cake transitions quickly to employing the Savinelli Fitsall Tool to scrape the chamber walls. The rim is carefully scraped as well with my Winchester pocketknife then the chamber is sanded with 240 grade sanding paper wrapped around a Sharpie Pen. The progress looks good.

With the chamber cleared of the cake buildup, After taking a starting picture, I clean the external briar surface using undiluted Murphy’s Oil Soap. The stummel is scrubbed with a cotton pad as well as utilizing a brass bristled brush to work on the darkened rim. The brass brush will not negatively impact the briar as it scrubs the rim.

With the chamber cleared of the cake buildup, After taking a starting picture, I clean the external briar surface using undiluted Murphy’s Oil Soap. The stummel is scrubbed with a cotton pad as well as utilizing a brass bristled brush to work on the darkened rim. The brass brush will not negatively impact the briar as it scrubs the rim. To further the cleaning the stummel is transitioned to the sink. Using warm water, shank brushes are employed with anti-oil liquid dish washing soap to clean the internal mortise chamber. The brass bristled brush is used a bit more on the rim. Back at the worktable I take another picture to show the cleaning progress. The cleaning did a great job revealing very nice looking briar. The rim is much improved as well.

To further the cleaning the stummel is transitioned to the sink. Using warm water, shank brushes are employed with anti-oil liquid dish washing soap to clean the internal mortise chamber. The brass bristled brush is used a bit more on the rim. Back at the worktable I take another picture to show the cleaning progress. The cleaning did a great job revealing very nice looking briar. The rim is much improved as well.  With a clean stummel before me, I take a closer look at the dents and pits primarily on the underside of the stummel I observed earlier. The rough surface is from normal wear placing the Feather stummel down on the table or other harder surfaces. The pictures show the comparison of ‘before and after’ to see how much progress is made with the repair.

With a clean stummel before me, I take a closer look at the dents and pits primarily on the underside of the stummel I observed earlier. The rough surface is from normal wear placing the Feather stummel down on the table or other harder surfaces. The pictures show the comparison of ‘before and after’ to see how much progress is made with the repair. The approach I take capitalizes on the fact that wood is a very porous substance – spongelike in its composition. Using a hot iron (with my wife’s permission!), I place a wetted cloth between a hot iron and the dents and press. The heat generated by the iron heats the water in the cloth turning it into steam which permeates the briar surface with water. The hot steamed water is absorbed and softens the wood allowing it to regain all or some of its pre-damaged condition.

The approach I take capitalizes on the fact that wood is a very porous substance – spongelike in its composition. Using a hot iron (with my wife’s permission!), I place a wetted cloth between a hot iron and the dents and press. The heat generated by the iron heats the water in the cloth turning it into steam which permeates the briar surface with water. The hot steamed water is absorbed and softens the wood allowing it to regain all or some of its pre-damaged condition.  A comparison after several steaming sessions shows that the main heel damaged has lessened in its severity as the briar has expanded. The side dent is now almost invisible.

A comparison after several steaming sessions shows that the main heel damaged has lessened in its severity as the briar has expanded. The side dent is now almost invisible.  To repair the residual pitting, using a toothpick as a guide, clear CA glue is spot dropped to fill the pits. I put the stummel aside to allow the CA to cure.

To repair the residual pitting, using a toothpick as a guide, clear CA glue is spot dropped to fill the pits. I put the stummel aside to allow the CA to cure. Turning now to the horn stem, pipe cleaners wetted with isopropyl 99% are used to clean the airway. Along with smooth and bristled pipe cleaners wetted with isopropyl 99%, shank brushes are used to clean the airway. A dental probe is used to scrape inside the slot as well as inside the nickel tenon. Eventually, the pipe cleaners begin to emerge lighter and I move on.

Turning now to the horn stem, pipe cleaners wetted with isopropyl 99% are used to clean the airway. Along with smooth and bristled pipe cleaners wetted with isopropyl 99%, shank brushes are used to clean the airway. A dental probe is used to scrape inside the slot as well as inside the nickel tenon. Eventually, the pipe cleaners begin to emerge lighter and I move on. Before continuing working on restoring the horn stem surface, I place a piece of painter’s tape over the thin P. Viou stem stamping to protect it. In no way do I desire to contribute to its demise!

Before continuing working on restoring the horn stem surface, I place a piece of painter’s tape over the thin P. Viou stem stamping to protect it. In no way do I desire to contribute to its demise! I approach working on horn stem much like on vulcanite stems. I take a few more pictures looking at the current condition of the horn material – upper and lower. I like the solid blackish hue of the horn’s midsection contrasting with the gradual lightening of the bit.

I approach working on horn stem much like on vulcanite stems. I take a few more pictures looking at the current condition of the horn material – upper and lower. I like the solid blackish hue of the horn’s midsection contrasting with the gradual lightening of the bit. The condition of the stem is good except for one small tooth compression on the lower bit. I fill it with a drop of CA glue and allow it to cure before sanding.

The condition of the stem is good except for one small tooth compression on the lower bit. I fill it with a drop of CA glue and allow it to cure before sanding.  The CA patches on the stummel heel have cured. A flat needle file is used to file the glue mounds down to the briar surface.

The CA patches on the stummel heel have cured. A flat needle file is used to file the glue mounds down to the briar surface.

Transitioning to 240 grade paper, the patches are sanded further followed by 600 grade paper. I’m pleased with the results. There is almost no visible reminder remaining of the rough area. The repair blends nicely.

Transitioning to 240 grade paper, the patches are sanded further followed by 600 grade paper. I’m pleased with the results. There is almost no visible reminder remaining of the rough area. The repair blends nicely.

The rim continues with darkened, scorched areas. There are nicks as well on the right side of the rim (top of the picture below). Using a hard backing behind a piece of 240 sanding paper, the slightly canted bevel is sanded and refreshed. Following the 240 paper, the same is done with 600 grade paper. I’m pleased with the refreshed rim.

The rim continues with darkened, scorched areas. There are nicks as well on the right side of the rim (top of the picture below). Using a hard backing behind a piece of 240 sanding paper, the slightly canted bevel is sanded and refreshed. Following the 240 paper, the same is done with 600 grade paper. I’m pleased with the refreshed rim.

Next, utilizing the full regimen of micromesh pads, the stummel is sanded. Before sanding, painters’ tape is used to cover the P. Viou and COM on the sides of the stummel. Using pads 1500 to 2400 the stummel is wet sanded. Following this, the stummel is dry sanded with pads 3200 to 4000 and 6000 to 12000. The protective tape was removed for the last 3 pads to even out the briar tone. The beauty of the briar grain emerges through the micromesh process – I’m liking what I see!

Next, utilizing the full regimen of micromesh pads, the stummel is sanded. Before sanding, painters’ tape is used to cover the P. Viou and COM on the sides of the stummel. Using pads 1500 to 2400 the stummel is wet sanded. Following this, the stummel is dry sanded with pads 3200 to 4000 and 6000 to 12000. The protective tape was removed for the last 3 pads to even out the briar tone. The beauty of the briar grain emerges through the micromesh process – I’m liking what I see!

Before returning to the stem, I’m looking forward to applying Mark Hoover’s ‘Before and After Restoration Balm’ to the stummel. I apply some of the Balm to my fingers and rub it into the briar surface. At first it has a cream-like consistency but as it works into the briar it transforms into a waxy consistency. After applying the Balm, the stummel is set aside for 20 minutes or so for the Balm to enrich the briar.

Before returning to the stem, I’m looking forward to applying Mark Hoover’s ‘Before and After Restoration Balm’ to the stummel. I apply some of the Balm to my fingers and rub it into the briar surface. At first it has a cream-like consistency but as it works into the briar it transforms into a waxy consistency. After applying the Balm, the stummel is set aside for 20 minutes or so for the Balm to enrich the briar.  After 20 minutes I use a microfiber cloth to wipe off excess Balm and then hand buff the stummel to raise the shine. I like the way the Restoration Balm enhances the natural hues of the briar.

After 20 minutes I use a microfiber cloth to wipe off excess Balm and then hand buff the stummel to raise the shine. I like the way the Restoration Balm enhances the natural hues of the briar. Returning now to the horn stem, the sanding process is much like that of vulcanite stems. After the CA patch has cured filling a tooth compression, using the flat needle file, the lower bit patch is filed until level with the stem surface. The file also helps to refresh the lower button lip.

Returning now to the horn stem, the sanding process is much like that of vulcanite stems. After the CA patch has cured filling a tooth compression, using the flat needle file, the lower bit patch is filed until level with the stem surface. The file also helps to refresh the lower button lip.  Next, I transition to 240 sanding paper and smooth further the lower bit blending the patch more. Flipping the stem over, the upper bit is sanded to smooth and tighten the horn surface from normal wear.

Next, I transition to 240 sanding paper and smooth further the lower bit blending the patch more. Flipping the stem over, the upper bit is sanded to smooth and tighten the horn surface from normal wear.  Next, the entire stem is wet sanded using 600 grade paper.

Next, the entire stem is wet sanded using 600 grade paper. As with vulcanite stems, next I apply 0000 steel wool to the entire stem to smooth and shine further. While using steel wool, I also apply it to the nickel tenon which shines it up very nicely.

As with vulcanite stems, next I apply 0000 steel wool to the entire stem to smooth and shine further. While using steel wool, I also apply it to the nickel tenon which shines it up very nicely.  Next, with the P. Viou stem stamping still covered with painters’ tape, the stem is the recipient of the full regimen of micromesh pads. Starting with pads 1500 to 2400, the horn is wet sanded. Following the wet sanding, I dry sand with pads 3200 to 4000 and 6000 to 12000. I remove the tape for the last two pads to sand more closely to blend the area. Obsidian Oil is applied and worked into the horn between each set of 3 pads. The horn almost ‘drinks up’ the oil.

Next, with the P. Viou stem stamping still covered with painters’ tape, the stem is the recipient of the full regimen of micromesh pads. Starting with pads 1500 to 2400, the horn is wet sanded. Following the wet sanding, I dry sand with pads 3200 to 4000 and 6000 to 12000. I remove the tape for the last two pads to sand more closely to blend the area. Obsidian Oil is applied and worked into the horn between each set of 3 pads. The horn almost ‘drinks up’ the oil.

To get a look at the progress, the stummel and horn stem are reunited. Two issues surface after I do this. The seating of the stem into the mortise is off. The next picture shows this with a gap of sunlight on the upper side of the connection point. To remedy this, I fold a piece of 240 sanding paper and insert it between the lower halves of the stem and stummel and sand in a sawing motion. This hopefully will even out the high point to bring the two faces back together flush – or as close as possible.

To get a look at the progress, the stummel and horn stem are reunited. Two issues surface after I do this. The seating of the stem into the mortise is off. The next picture shows this with a gap of sunlight on the upper side of the connection point. To remedy this, I fold a piece of 240 sanding paper and insert it between the lower halves of the stem and stummel and sand in a sawing motion. This hopefully will even out the high point to bring the two faces back together flush – or as close as possible.  The result is good. There is still some daylight, but I’m satisfied at this point. Sanding to remedy an unseated stem can be a bit finicky and sometimes ‘less’ is ‘more’ – I don’t want to complicate things!

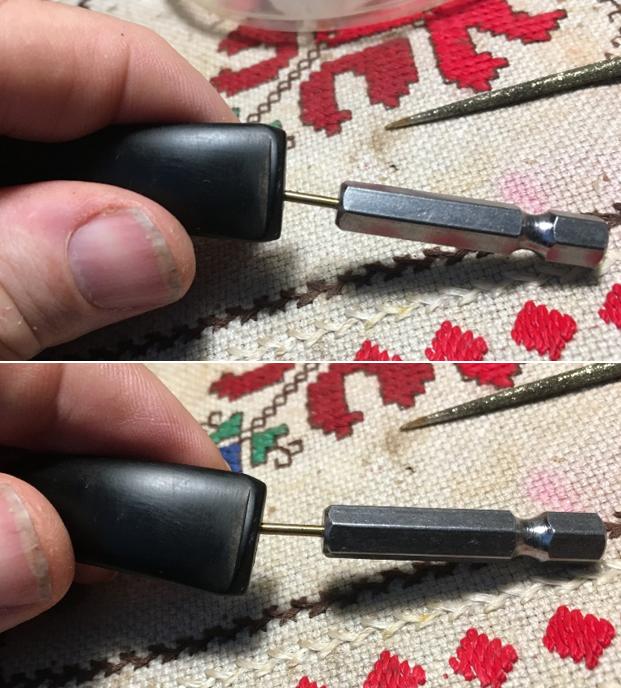

The result is good. There is still some daylight, but I’m satisfied at this point. Sanding to remedy an unseated stem can be a bit finicky and sometimes ‘less’ is ‘more’ – I don’t want to complicate things! The other issue that emerged was that through the cleaning process the internal mortise cavity expanded somewhat so that the nickel tenon is not as snug as it should be. The ways to fix this are limited. If this were a vulcanite stem and tenon, the approach would be to expand the width of the tenon by heating it and forcing expansion by wedging the end of a drill bit in the softened tenon airway. A nickel tenon, however, does not expand. The remedy is to paint the external surface of the metal tenon with an acrylic nail polish or with CA glue. The results are the same. The hardening of the acrylic creates a hardened layer around the metal tenon, thus expanding its diameter and creating a snugger fit seated into the mortise. I use a small bottle of acrylic nail polish and apply the acrylic polish with the small brush that comes along with the bottle.

The other issue that emerged was that through the cleaning process the internal mortise cavity expanded somewhat so that the nickel tenon is not as snug as it should be. The ways to fix this are limited. If this were a vulcanite stem and tenon, the approach would be to expand the width of the tenon by heating it and forcing expansion by wedging the end of a drill bit in the softened tenon airway. A nickel tenon, however, does not expand. The remedy is to paint the external surface of the metal tenon with an acrylic nail polish or with CA glue. The results are the same. The hardening of the acrylic creates a hardened layer around the metal tenon, thus expanding its diameter and creating a snugger fit seated into the mortise. I use a small bottle of acrylic nail polish and apply the acrylic polish with the small brush that comes along with the bottle.  After each coating, I wait until the acrylic is cured before applying another layer. After each cycle, the tenon is carefully fitted into the mortise to determine if another layer is needed. To help it to dry evenly after each application, I ‘post’ the stem vertically on the end of a chop stick. After several coats of clear acrylic nail polish, the fit of the stem was much snugger. Mission accomplished.

After each coating, I wait until the acrylic is cured before applying another layer. After each cycle, the tenon is carefully fitted into the mortise to determine if another layer is needed. To help it to dry evenly after each application, I ‘post’ the stem vertically on the end of a chop stick. After several coats of clear acrylic nail polish, the fit of the stem was much snugger. Mission accomplished.  Next, I attempt to refresh the P. Viou stem stamping, but am not successful. The vestiges of the stamping were not deep enough to allow the white acrylic paint to grab the stamp channels. After several attempts, I settle for what is.

Next, I attempt to refresh the P. Viou stem stamping, but am not successful. The vestiges of the stamping were not deep enough to allow the white acrylic paint to grab the stamp channels. After several attempts, I settle for what is.

Now on the homestretch. After mounting a cotton cloth buffing wheel to the Dremel, speed set at about 40% full power, I apply Blue Diamond compound to horn stem and stummel. After completing this, a felt cloth is used to buff the pipe to clear the compound dust before applying the wax.

Now on the homestretch. After mounting a cotton cloth buffing wheel to the Dremel, speed set at about 40% full power, I apply Blue Diamond compound to horn stem and stummel. After completing this, a felt cloth is used to buff the pipe to clear the compound dust before applying the wax. To apply carnauba wax, the cotton cloth wheel is changed to a wheel dedicated to carnauba. With the speed on the Dremel maintaining 40% power, wax is applied to the entire pipe. The first coat applies the wax thoroughly over the surfaces. Following this, the pipe is buffed up using the Dremel to make sure all the wax is dispersed and absorbed. Finally, the pipe is given a rigorous hand buffing with a microfiber cloth to raise the shine further.

To apply carnauba wax, the cotton cloth wheel is changed to a wheel dedicated to carnauba. With the speed on the Dremel maintaining 40% power, wax is applied to the entire pipe. The first coat applies the wax thoroughly over the surfaces. Following this, the pipe is buffed up using the Dremel to make sure all the wax is dispersed and absorbed. Finally, the pipe is given a rigorous hand buffing with a microfiber cloth to raise the shine further. I’m pleased with how this product of Jacques Craen in St. Claude has turned out. With Sebastien Beaud’s generous assistance, we can date this pipe after Jacques received the P. Viou name from the aging Paul Viou and his wife, Odette, who provided pipes to French military servicemen. This ‘Plume’ is a beautiful example of French pipe making with its subtle intricacies, flow, and lines. The grain, especially the exceptionally tight Bird’s Eye, is pleasing to behold! The horn stem with its gentle natural bend, has unique coloring. The glassy shine of finely polished horn is pleasing to the eye and its rustic character will make it a pleasure to enjoy tobacco fellowship. Last but not least, the unique Plume or Feather diminutive shape allows it to cradle very nicely in the palm. This is the second of Daniel’s commissioned pipes and he will have the first opportunity to claim the P. Viou Feather from The Pipe Steward Store benefiting the Daughters of Bulgaria – women and girls who have been trafficked and sexually exploited. Thanks for joining me!

I’m pleased with how this product of Jacques Craen in St. Claude has turned out. With Sebastien Beaud’s generous assistance, we can date this pipe after Jacques received the P. Viou name from the aging Paul Viou and his wife, Odette, who provided pipes to French military servicemen. This ‘Plume’ is a beautiful example of French pipe making with its subtle intricacies, flow, and lines. The grain, especially the exceptionally tight Bird’s Eye, is pleasing to behold! The horn stem with its gentle natural bend, has unique coloring. The glassy shine of finely polished horn is pleasing to the eye and its rustic character will make it a pleasure to enjoy tobacco fellowship. Last but not least, the unique Plume or Feather diminutive shape allows it to cradle very nicely in the palm. This is the second of Daniel’s commissioned pipes and he will have the first opportunity to claim the P. Viou Feather from The Pipe Steward Store benefiting the Daughters of Bulgaria – women and girls who have been trafficked and sexually exploited. Thanks for joining me!