Blog by Steve Laug

This is another pipe that I have taken out of my personal collection as I just do not use it too much. I picked this pipe up along with another on one of my trips to Budapest, Hungary. It is a Hungarian made pipe that I picked up at the Pipatórium . It is another pipe that I smoked solely Virginia tobaccos in so it is very clean. The airway in the shank and the mortise were quite clean. The smooth rim top and edges were in excellent condition. The smooth finish was very clean and still had a shine. It is stamped on the underside of the shank near the stem/shank joint and reads Bruyere Szabo. There was a light cake in the bowl but the top and inner edge of the bowl was dark at the back. The acrylic saddle stem is in good condition with some light tooth chatter ahead of the button on both sides. I took photos of the pipe before I did my clean up work on it.

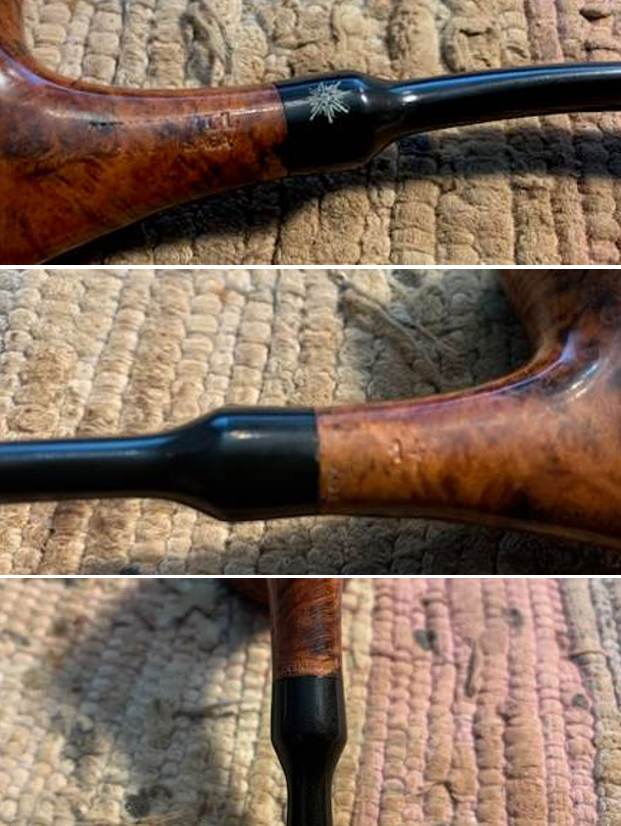

I took a photo of the bowl and rim top to verify the description above. I also took photos of the stem surface showing the light chatter on either side.

I took a photo of the bowl and rim top to verify the description above. I also took photos of the stem surface showing the light chatter on either side. I took a photo of the stamping on the underside of the shank. It was hard to capture with the camera as it is wrapped around the shank end. It is clear and readable as noted above.

I took a photo of the stamping on the underside of the shank. It was hard to capture with the camera as it is wrapped around the shank end. It is clear and readable as noted above.  I took the stem off the bowl and took a photo of the pipe to give a sense of proportion of the pipe. It is a beauty. There was also an adapter in the stem that was removable so that the pipe could be smoked with or without a filter.

I took the stem off the bowl and took a photo of the pipe to give a sense of proportion of the pipe. It is a beauty. There was also an adapter in the stem that was removable so that the pipe could be smoked with or without a filter.

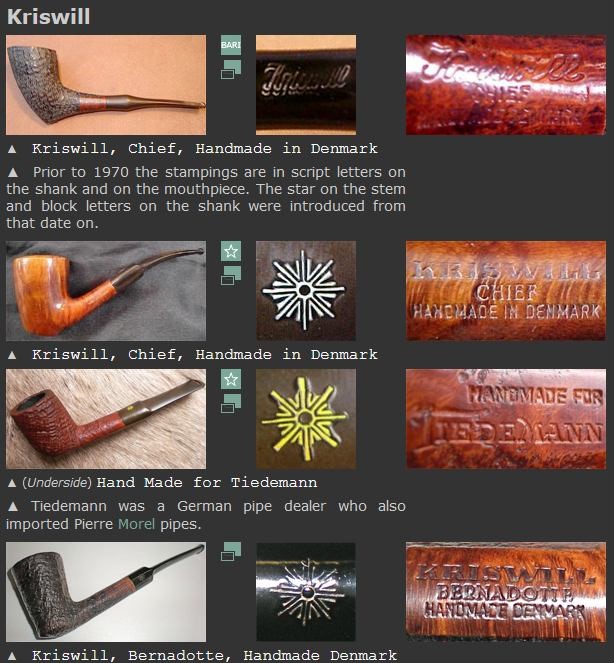

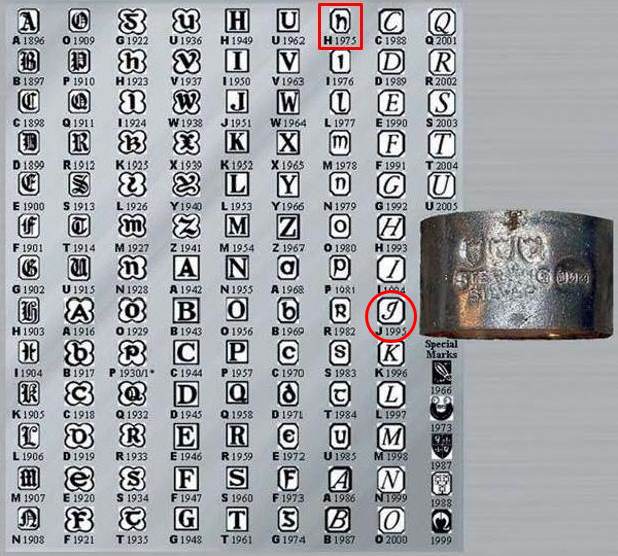

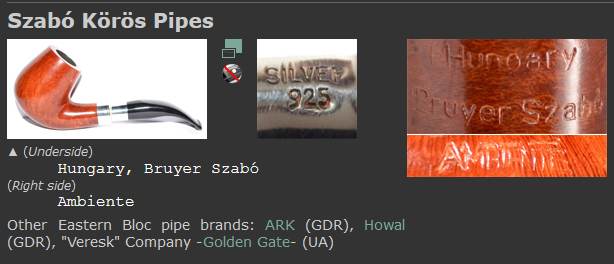

I turned to Pipephil’s site for a quick overview of the brand (http://pipephil.eu/logos/en/logo-s14.html). I have included a screen capture of the brand below. From that I knew that the pipe I was working on was post 1970 because of the stamping and the star on the stem.

I turned to Pipephil’s site for a quick overview of the brand (http://pipephil.eu/logos/en/logo-s14.html). I have included a screen capture of the brand below. From that I knew that the pipe I was working on was post 1970 because of the stamping and the star on the stem. There was also a side bar that gave further information on the brand. I quote below

There was also a side bar that gave further information on the brand. I quote below

After the politcal changes in the early 1990s, Balázs Szabó Jr. bought back the Nagykörösi Pipe Factory established about 1930. This grandson of one of the founders renamed the corporate and focused production on briar pipes.

Pipedia has a short history on the brand (https://pipedia.org/wiki/K%C3%B6r%C3%B6s_Pipes). I quote from the page below.

The brand origins from the central Hungarian city of Nagykörös, where the Nagykörösi Pipe Factory was founded in 1930. Balázs Szabó Jr., a grandson of one of the founders, was able to buy back the company in 1989 after the politcal changes in the former Warsaw Pact territory. Now named Szabó Körös Pipe Factory.

I googled and found the website of the pipe maker (https://www.pipagyar.hu/?lang=en). I quote from the front page below.

Our company specialises in traditional handmade smoking pipes with deigns unique to Nagykőrös in Hungary. While we respect traditions, we always follow the latest trends and customer needs besides the classical and unique designs. Together with other specialist smoking pipe manufacturers and colleagues we strive to pass on smoking pipe manufacturing and the culture of pipe smoking to the next generations. It is our company philosophy to support wholesalers as well as small businesses.

THE ONLY TRADITIONAL SMOKING PIPE MANUFACTURER WITH FAMILY PASSION IN HUNGARY SINCE 1930.

The Szabó Smoking Pipe Manufacturer Ltd. is the home of Hungarian smoking pipe manufacturing, based on the high street in the city centre of Nagykőrös. It is a historical fact that wooden smoking pipes and their accessories were made exclusively in Nagykőrös even after the nationalisation took place in Hungary. We have been continuously manufacturing the usual classical pipe shapes. We follow customer needs and the latest trends and sell our smoking pipes nationally as well as internationally.

Irony of fate, that after the Change in Hungary, the Pipe Manufacture become the private property of Szabó Balázs. The Szabó’s have guaranteed and do it also nowadays that the tradition and secret of handmade pipe-craftsmanship will be continued to live up to generations. Sen. Szabó Balázs founded he firm in 1930. His son Szabó Balázs followed his father’s footsteps and now Szabó Balázs, the third in the generation directs the firm.

We have been manufacturing the classical pipe types continuously. Following the latest trends, we produce our products to Hungary and import them to different countries. I clicked on the button at the bottom of the graphic above and found the photo below that is the exact pipe that I purchased (https://www.pipagyar.hu/portfolio-posts/sc056/?lang=en). I include the photo below of the Szabo Bruyere sc056 pipe.

I clicked on the button at the bottom of the graphic above and found the photo below that is the exact pipe that I purchased (https://www.pipagyar.hu/portfolio-posts/sc056/?lang=en). I include the photo below of the Szabo Bruyere sc056 pipe. Now it was time to work on the pipe. I cleaned up the light cake in the bowl with a Savinelli Fitsall Pipe Knife. I sanded the bowl walls with a piece of dowel wrapped in 220 grit sandpaper.

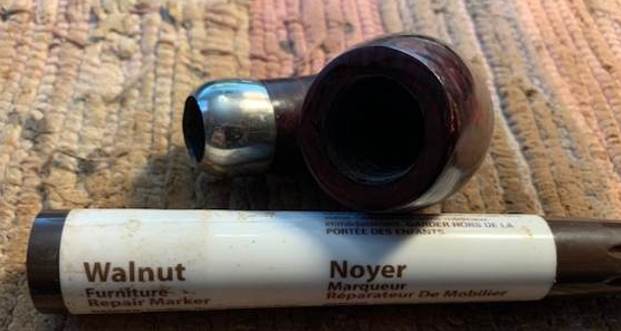

Now it was time to work on the pipe. I cleaned up the light cake in the bowl with a Savinelli Fitsall Pipe Knife. I sanded the bowl walls with a piece of dowel wrapped in 220 grit sandpaper. I cleaned the mortise and airways in the shank and stem with cotton swabs, pipe cleaners and isopropyl alcohol to remove the debris and tars from my smoking. You can see that it was not too bad as I tend to keep my pipes clean.

I cleaned the mortise and airways in the shank and stem with cotton swabs, pipe cleaners and isopropyl alcohol to remove the debris and tars from my smoking. You can see that it was not too bad as I tend to keep my pipes clean. The bowl was in such good condition that decided to give the bowl and shank a coating of Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

The bowl was in such good condition that decided to give the bowl and shank a coating of Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

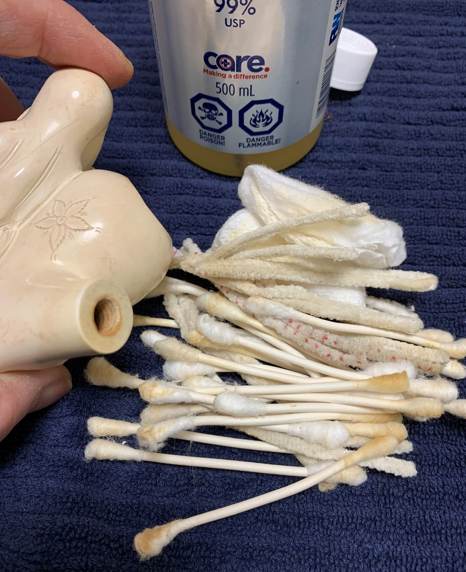

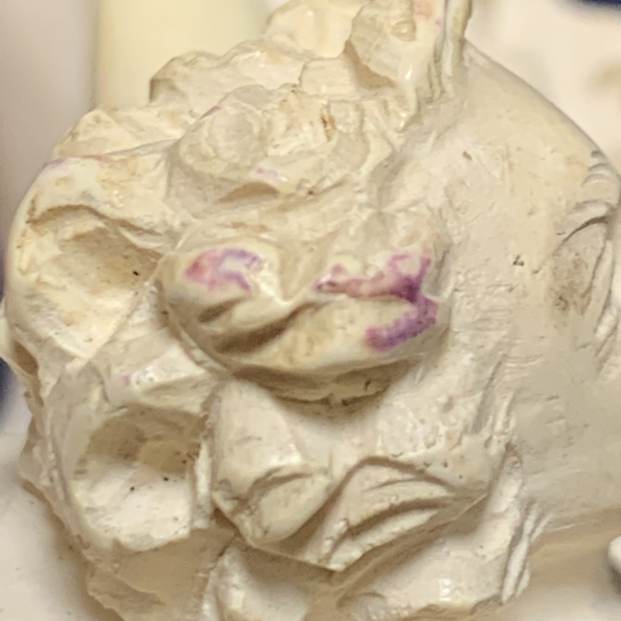

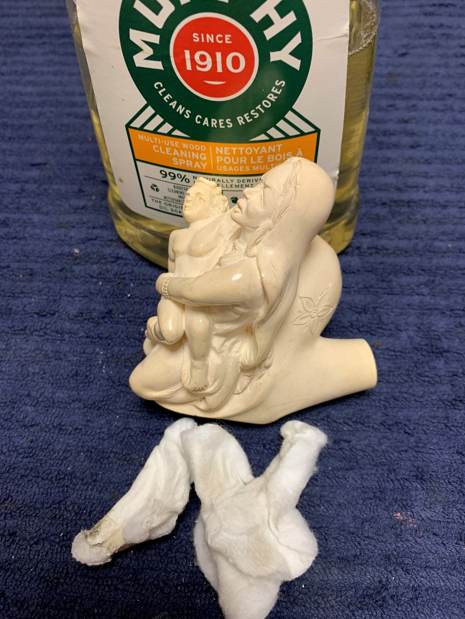

The tenon adapter used to reduce a filter tenon to a regular tenon was included with the pipe when I bought it. It is white and the end is threaded though the stem is not threaded inside to hold it. It was stained from smoking but I cleaned it up a bit with 220 grit sandpaper. I put the adapter back in the tenon.

The tenon adapter used to reduce a filter tenon to a regular tenon was included with the pipe when I bought it. It is white and the end is threaded though the stem is not threaded inside to hold it. It was stained from smoking but I cleaned it up a bit with 220 grit sandpaper. I put the adapter back in the tenon. Since the stem was in quite good condition other than tooth chatter I polished it with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I rubbed it down between pads with Obsidian Oil. I polished it with Before & After Fine and Extra Fine Pipe Stem Polish. I wiped it down with some Obsidian Oil and buffed it off. It is a beautiful stem.

Since the stem was in quite good condition other than tooth chatter I polished it with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I rubbed it down between pads with Obsidian Oil. I polished it with Before & After Fine and Extra Fine Pipe Stem Polish. I wiped it down with some Obsidian Oil and buffed it off. It is a beautiful stem.

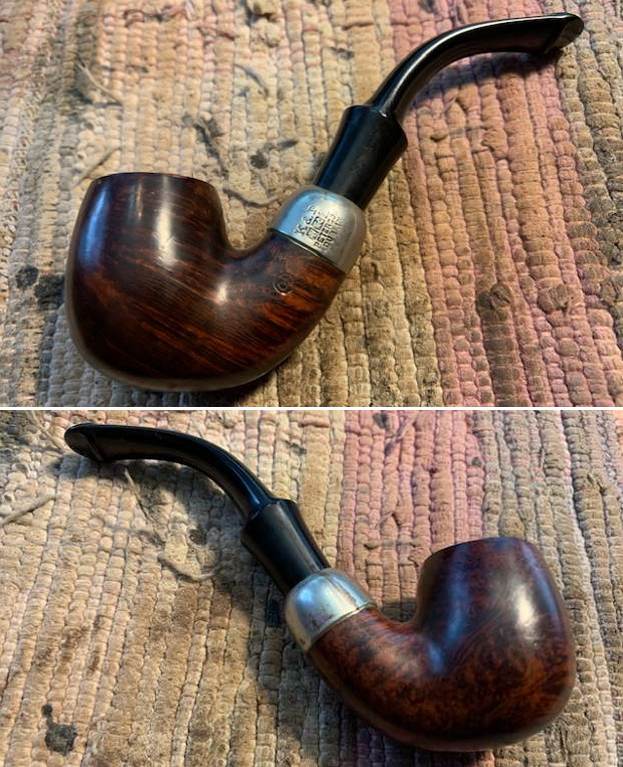

I am excited to put the final touches on this Hungarian Made Bruyere Szabo sc056. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with beautiful mixed grain all around it. Added to that the polished black acrylic stem combined with the bowl and make a stunning pipe. This smooth Hungarian Made Bruyere Szabo is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ¾ inches, Height: 2 inches, Outside diameter of the bowl: 2 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 58 grams/2.05 ounces. It is a beautiful pipe that I will soon be putting on the rebornpipes store in the Pipes From Various Makers Section. If you are interested in adding it to your collection send me an email or a message. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.

I am excited to put the final touches on this Hungarian Made Bruyere Szabo sc056. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with beautiful mixed grain all around it. Added to that the polished black acrylic stem combined with the bowl and make a stunning pipe. This smooth Hungarian Made Bruyere Szabo is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ¾ inches, Height: 2 inches, Outside diameter of the bowl: 2 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 58 grams/2.05 ounces. It is a beautiful pipe that I will soon be putting on the rebornpipes store in the Pipes From Various Makers Section. If you are interested in adding it to your collection send me an email or a message. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.