Blog by Steve Laug

In talking with a friend a few days ago via email she mentioned that she had come across an old Barling pipe on US Ebay. She described it as a small billiard with nice grain, a few scratches and some over reaming in the bowl. The stem had a faded “W” or a crown on it the top. The stamping is Barling’s arched over Make on the left side and possibly a faint EL and a 3 near the bowl on the right side. She sent me the following two photos for me to have a look at the pipe.

From the photos and her description I was pretty certain the pipe stem was not original. It just did not look right in the photos above – the fit was off on the shank and the length was too short. I was pretty sure she had a replacement stem on the pipe. She packed it up and sent it off to me. I received it yesterday and took it to the work table. My assessment is below.

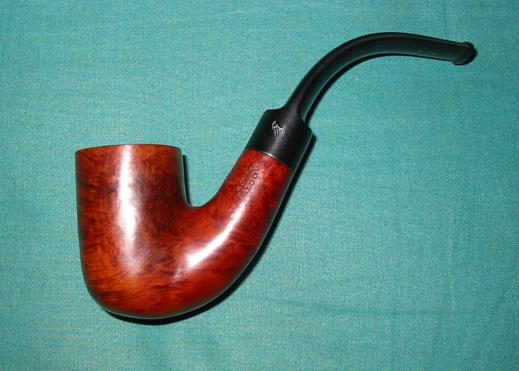

The pipe is old and very worn. The scratches that she mentioned were deeper than I expected from the photos. The finish was worn on the underside of the shank and in places on the sides of the bowl. There were some dark spots on the top and bottom of the shank that looked like stains from moisture or something sitting against the shank in a box. Several of the scratches had white markings in them. As she noted the bowl was over reamed but that too was worse than I expected. It had been reamed to the point that the walls were very thin all the way around and the inner edge of the bowl was out of round. In examining the tapered stem up close it indeed seems to be proportionally short in comparison to the length of the bowl and shank. The shoulders at the shank/stem union are rounded and the fit is not tight. The crown or “W” stamping she mentioned is very hard to see and I am not sure of the actual stamp. There were deep scratches on the vulcanite of the stem as well. In my opinion the pipe needed to be restemmed. The next three photos below show the pipe on my work table before I started fitting a new stem.

I had a slab cut stem blank in my box of stems that had a Barling like look to it. The tenon needed to be turned slightly and hand sanded to fit the shank well. The diameter of the stem at the joint of the shank and stem was larger and needed to be trimmed to fit well. The slab blank had casting seams along the edges, a tight slot and an unfinished look to the edges. I used a Dremel with a sanding drum to cut back the diameter of the stem at the shank. I also used it to sand away the casting marks and to smooth out the edges of the slab to give it a more finished looked. I took it back to the work table and sanded the saddle and slab with medium grit emery cloth to reduce the scratches left behind by the Dremel and to smooth out the fit to the shank. The next four photos show the state of the pipe after fitting the stem, using the Dremel and the emery cloth. The saddle still shows the marks of the sanding drum and needs more fine tuning to be a good tight fit but it is getting there. To me this stem looks more fitting to the old Barling’s Make billiard.

I sanded the stem with 220 grit sandpaper and a medium grit sanding sponge to fine tune the fit and to remove the scratches. I then sanded the stem with micromesh sanding pads. I wet sanded the stem with 1500-2400 grit pads and used needle files to open up the slot in the button. I used the round, oval and flattened files to open and shape the slot. I sanded it with a folded piece of 220 grit sandpaper to smooth out the newly shaped slot. I then dry sanded with the remaining grits of micromesh from 3200-12,000 grit. The photos below show the progress of the sanding.

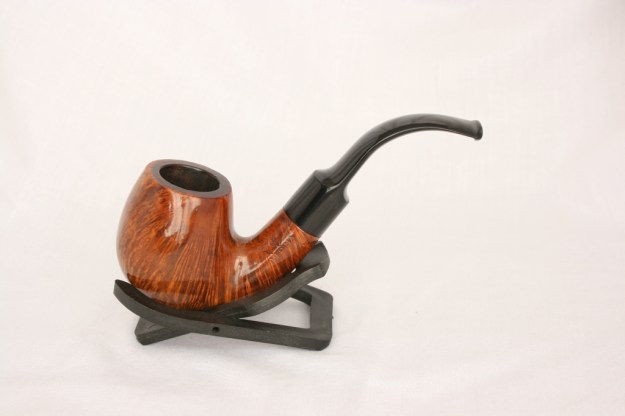

I rubbed the stem down with Obsidian Oil and set it aside to dry while I worked on giving the bowl a new coat of stain to bring it back to life. I gave it a coating of Medium Walnut aniline stain and flamed it. I took it to the buffer and gave it a light buff with White Diamond on the buffing pad. I was careful around the faint stampings on the shank and hand buffed the shank.

I reinserted the new stem and gave the stem a buff with White Diamond and then waxed the entire pipe with carnauba wax. I applied several coats of the wax and the buffed it with a clean flannel buff to bring up the shine. The finished pipe is pictured in the four photos below. The new stem gives the pipe a much more dignified new look. I can’t wait to get it back to the owner and see what she thinks of the “new” look her pipe now sports!