by Kenneth Lieblich

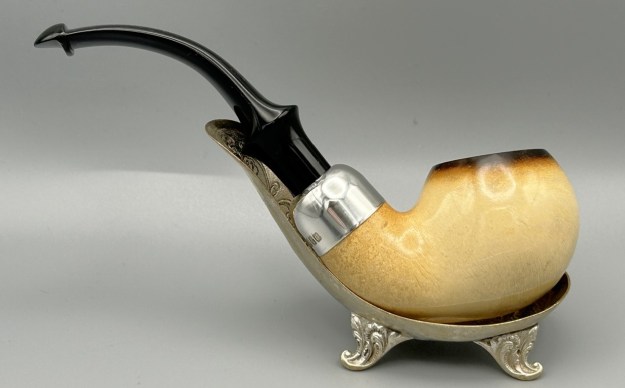

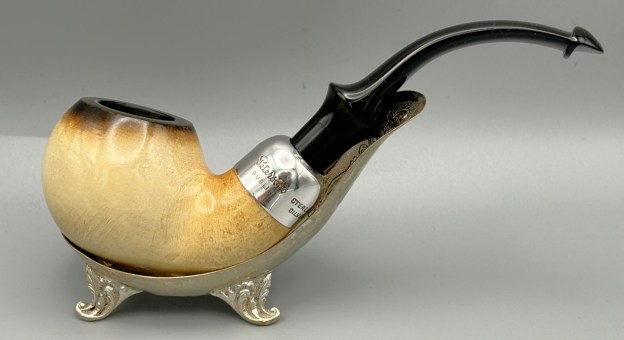

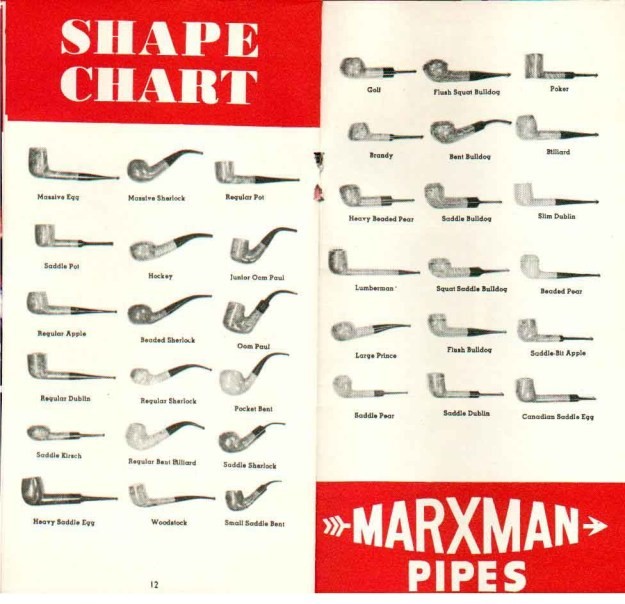

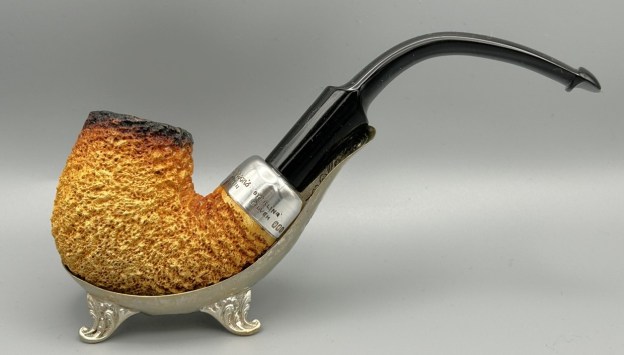

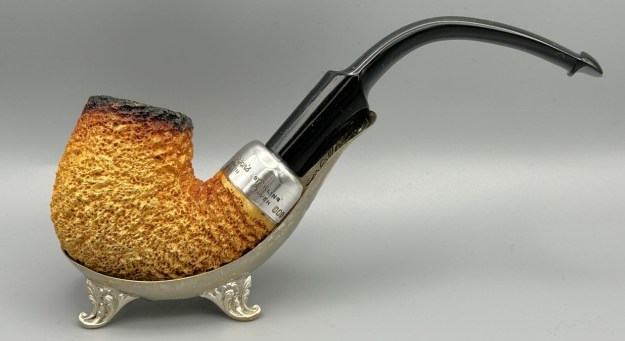

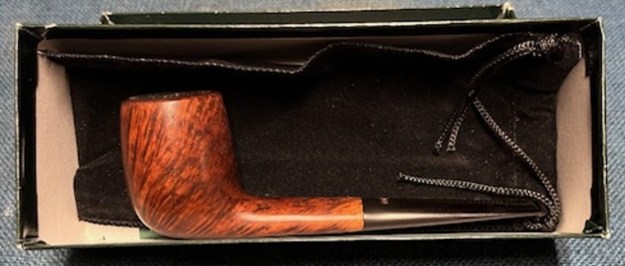

Following on from the rusticated Peterson meer the other day, I have now completed a really good-looking, smooth block meerschaum pipe from Peterson. It is a shape 303, medium bent apple. It doesn’t have the number marked on it, but it’s obviously a 303. Like the other Pete, this one was acquired by auction. It was a pleasure to work on it and I hope you will enjoy reading about it. There are many similarities in the two pipes. The band or cap around the shank is made in sterling silver, and that certainly adds a touch of class. The stem, as expected, has the traditional P-lip of the Peterson brand. The pipe was very well cared for by its previous owner, and it even comes with its own Peterson-branded pipe sock.

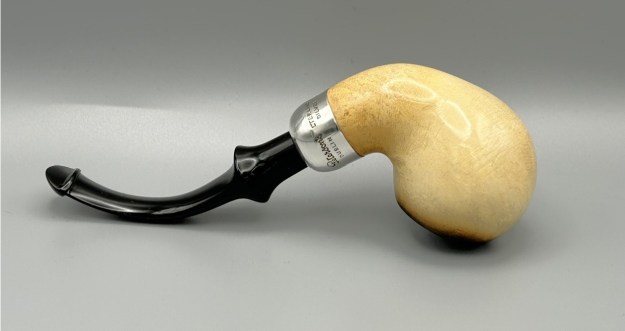

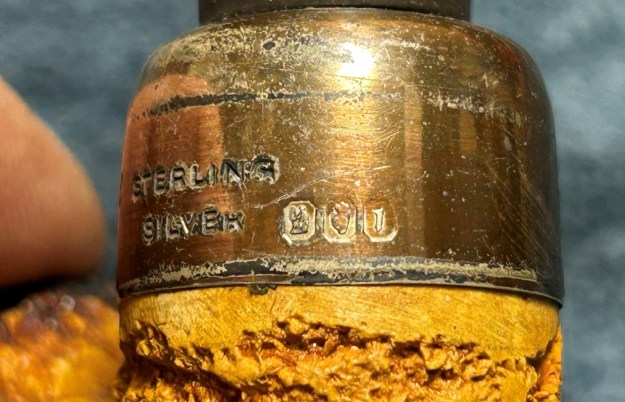

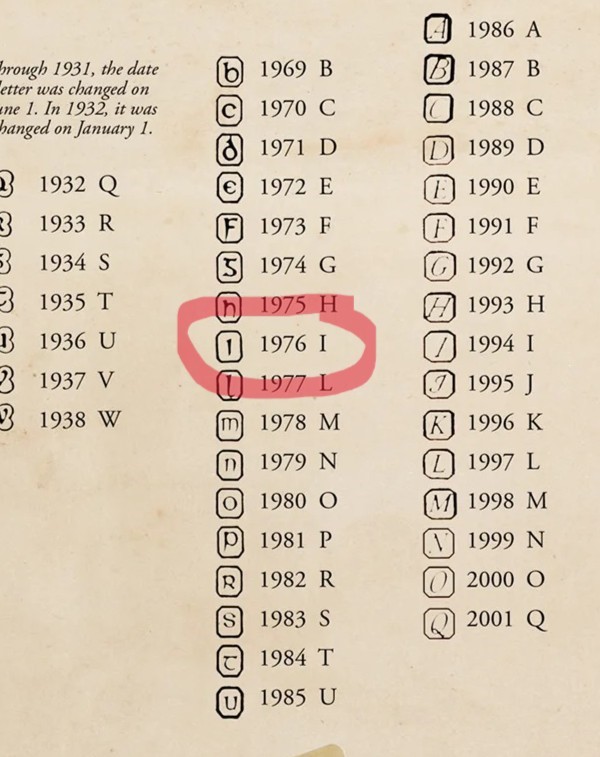

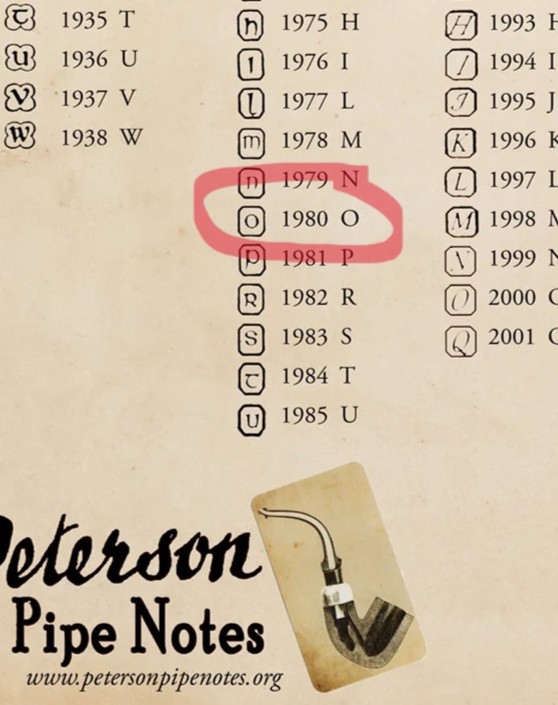

The meerschaum itself doesn’t hold any markings – nor does the stem. All the markings are on the sterling silver band. To start, the band says Peterson’s [over] Dublin. To the right of that, it reads Sterling [over] Silver. To the right of that, it has a set of proper silver hallmarks: Hibernia, which indicates that it was made in Dublin. Next is the Harp Crowned, which indicates sterling silver. Third is the date letter. In this case, it’s a stylized letter O. Checking the Irish hallmarks chart tells me that this pipe dates from 1980.

The meerschaum itself doesn’t hold any markings – nor does the stem. All the markings are on the sterling silver band. To start, the band says Peterson’s [over] Dublin. To the right of that, it reads Sterling [over] Silver. To the right of that, it has a set of proper silver hallmarks: Hibernia, which indicates that it was made in Dublin. Next is the Harp Crowned, which indicates sterling silver. Third is the date letter. In this case, it’s a stylized letter O. Checking the Irish hallmarks chart tells me that this pipe dates from 1980.

Moving on. The stummel was in nice shape. The outside had only seen some minor wear-and-tear, but there were no major issues. It was a bit dirty inside, but nothing more than what would be expected. Meanwhile, the stem was also in good condition. It was oxidized and calcified, but the tooth marks were very minor. The sterling silver band was fine – just heavily tarnished.

Moving on. The stummel was in nice shape. The outside had only seen some minor wear-and-tear, but there were no major issues. It was a bit dirty inside, but nothing more than what would be expected. Meanwhile, the stem was also in good condition. It was oxidized and calcified, but the tooth marks were very minor. The sterling silver band was fine – just heavily tarnished.

The stem’s calcification was notable. I used an old butter knife and gently scraped some of the thicker accretion off. Doing this now helps later in removing the oxidation.

The stem’s calcification was notable. I used an old butter knife and gently scraped some of the thicker accretion off. Doing this now helps later in removing the oxidation. I used isopropyl alcohol on a few cotton rounds and wiped down the stem to provide an initial cleaning of filth before moving on to the next steps. The primary cleaning came next. I disinfected the inside of the stem with both pipe cleaners and cotton swabs dipped in lemon-infused 99% isopropyl alcohol. I scrubbed thoroughly to make sure the interior was very clean.

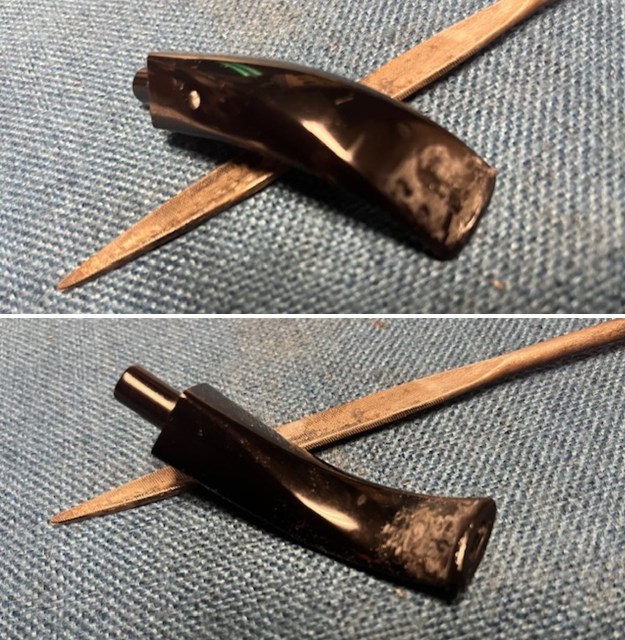

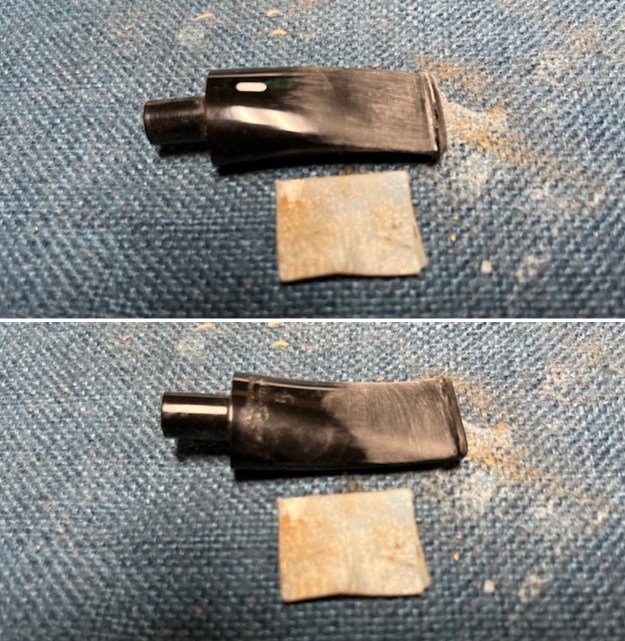

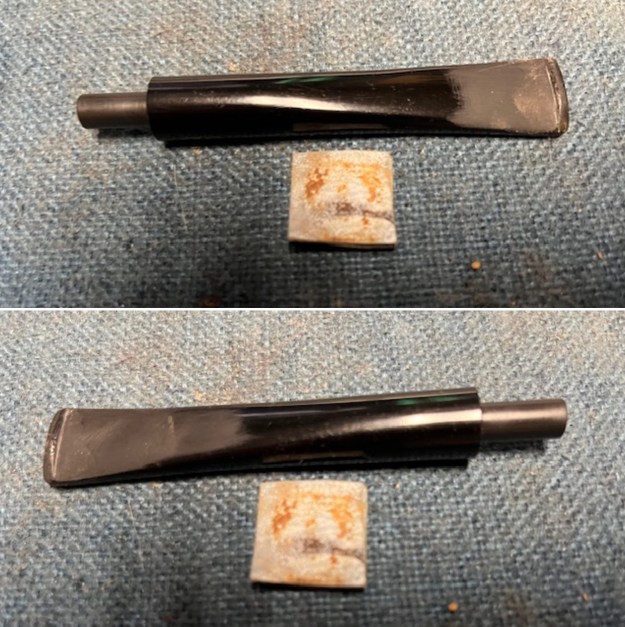

I used isopropyl alcohol on a few cotton rounds and wiped down the stem to provide an initial cleaning of filth before moving on to the next steps. The primary cleaning came next. I disinfected the inside of the stem with both pipe cleaners and cotton swabs dipped in lemon-infused 99% isopropyl alcohol. I scrubbed thoroughly to make sure the interior was very clean. The goal of the next step is the removal (or minimization) of oxidation. Going to my sink, I used cream cleanser, cotton rounds, and a toothbrush, and scoured the stem to remove as much surface oxidation as possible. As the photos show, the result was a hideous, ochre-coloured mess – but better off the stem than on it.

The goal of the next step is the removal (or minimization) of oxidation. Going to my sink, I used cream cleanser, cotton rounds, and a toothbrush, and scoured the stem to remove as much surface oxidation as possible. As the photos show, the result was a hideous, ochre-coloured mess – but better off the stem than on it. Once the stem was reasonably clean, I soaked it overnight in some Briarville Stem Oxidation Remover. This solution works to draw oxidation in the stem to the surface of the vulcanite. This is a major aid and an important step in ensuring a clean stem. The following day, I drew out the stem from its bath and scrubbed the lingering fluid with a toothbrush.

Once the stem was reasonably clean, I soaked it overnight in some Briarville Stem Oxidation Remover. This solution works to draw oxidation in the stem to the surface of the vulcanite. This is a major aid and an important step in ensuring a clean stem. The following day, I drew out the stem from its bath and scrubbed the lingering fluid with a toothbrush. As the stem was now clean and dry, I set about fixing the marks and dents in the vulcanite. This was done by filling those divots with black cyanoacrylate adhesive, impregnated with carbon and rubber. I left this to cure and moved on.

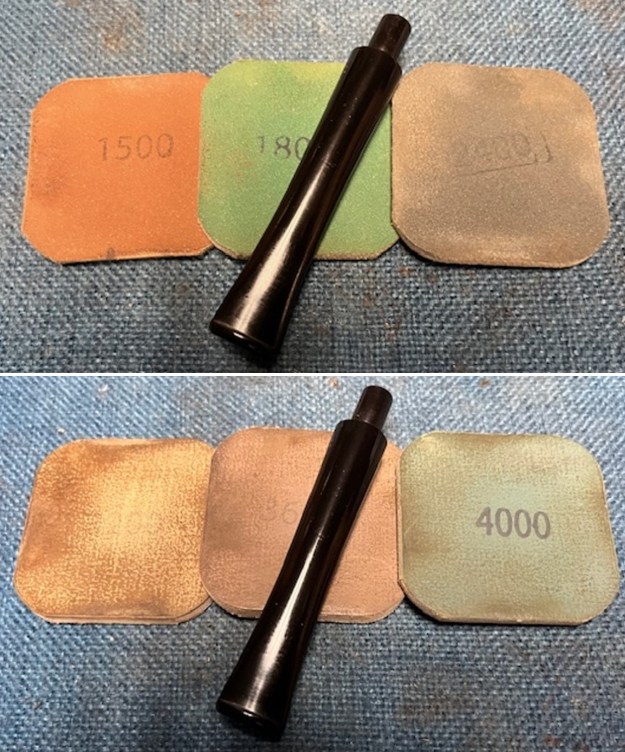

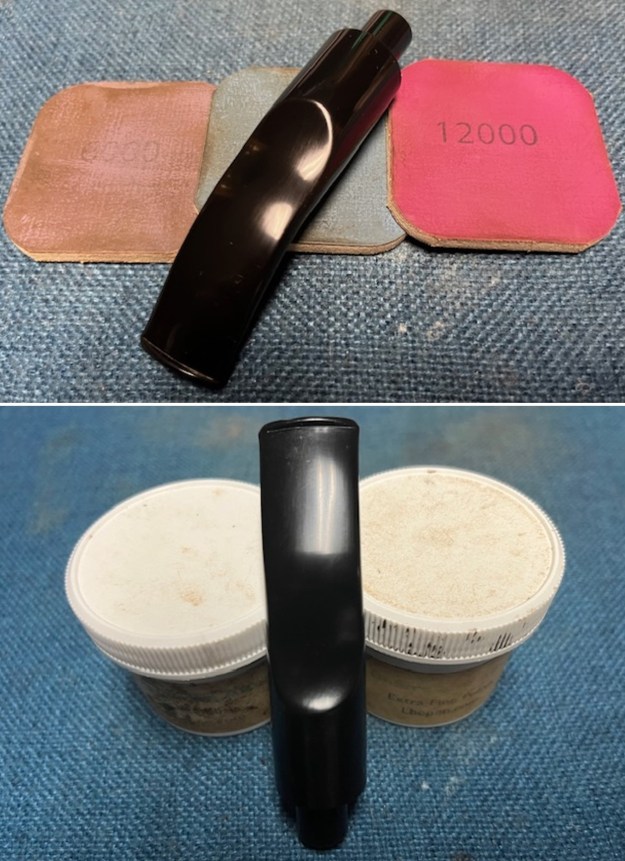

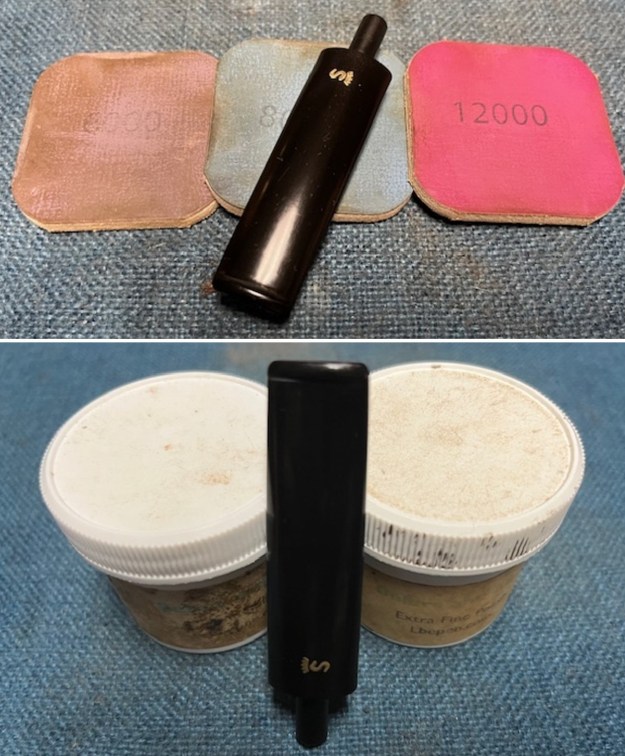

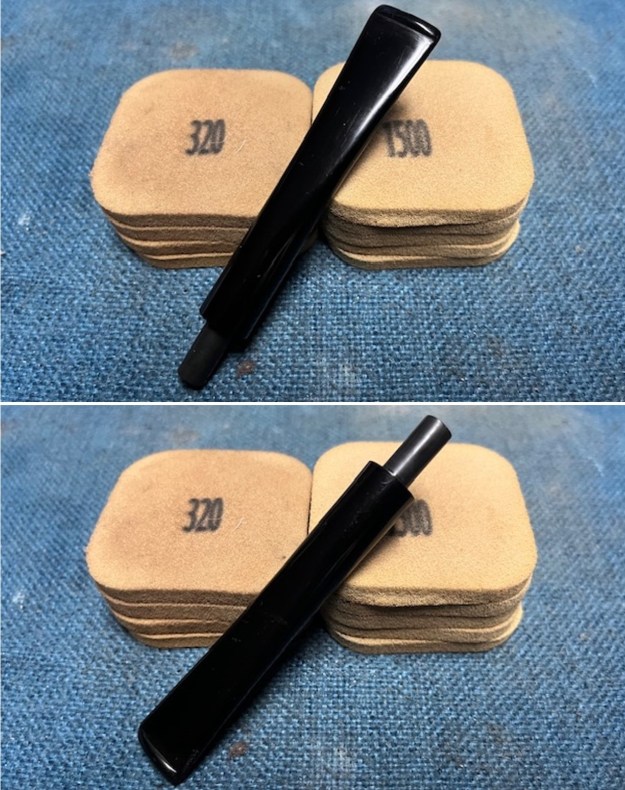

As the stem was now clean and dry, I set about fixing the marks and dents in the vulcanite. This was done by filling those divots with black cyanoacrylate adhesive, impregnated with carbon and rubber. I left this to cure and moved on. The penultimate step for the stem is sanding. First, with my set of needle files, I reduced the bulk of the cyanoacrylate repairs. I removed the excess adhesive as near to the surface as possible, without cutting into the vulcanite. Following that, I used all nine of the micromesh sanding pads (1,500 through 12,000 grit) to sand out flaws, even out the vulcanite, and provide gentle polishing of the finished surface. I also applied pipe-stem oil while using the last five micromesh pads. There was a wonderful, deep black shine to the stem when I was done.

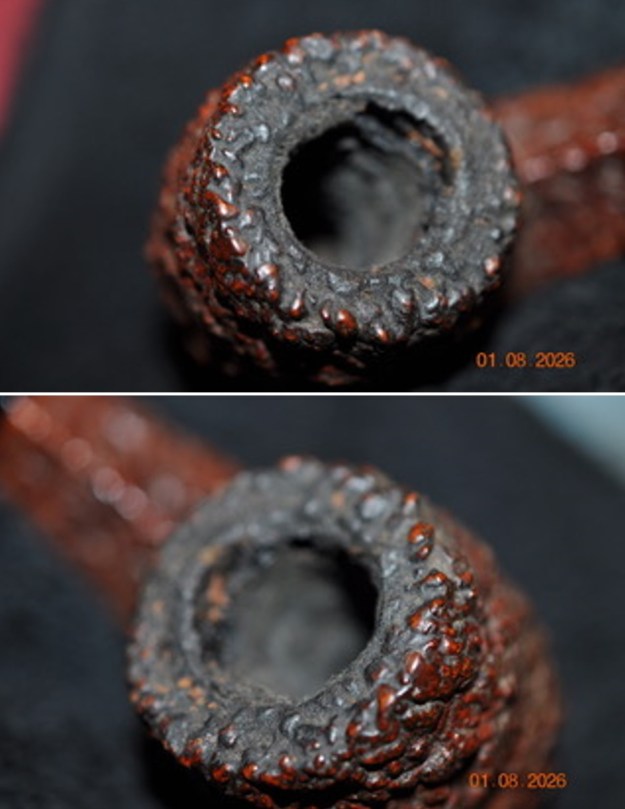

The penultimate step for the stem is sanding. First, with my set of needle files, I reduced the bulk of the cyanoacrylate repairs. I removed the excess adhesive as near to the surface as possible, without cutting into the vulcanite. Following that, I used all nine of the micromesh sanding pads (1,500 through 12,000 grit) to sand out flaws, even out the vulcanite, and provide gentle polishing of the finished surface. I also applied pipe-stem oil while using the last five micromesh pads. There was a wonderful, deep black shine to the stem when I was done. As the stem was (nearly) complete, I moved on to the stummel. The first step was to ream out the bowl – that is to say, remove all the cake inside the bowl. This accomplished a couple of things. First (and most obviously), it cleaned the bowl and provided a refurbished chamber for future smoking. Second, when the old cake was removed, I could inspect the interior walls of the bowl and determine if there was damage or not. Normally, at this point, I would use a reamer to remove the built-up cake inside the bowl, but meerschaum has the potential to crack in those circumstances. Instead, I used a pipe knife, and a piece of sandpaper taped to a wooden dowel. Collectively, these ensured that all the debris was removed.

As the stem was (nearly) complete, I moved on to the stummel. The first step was to ream out the bowl – that is to say, remove all the cake inside the bowl. This accomplished a couple of things. First (and most obviously), it cleaned the bowl and provided a refurbished chamber for future smoking. Second, when the old cake was removed, I could inspect the interior walls of the bowl and determine if there was damage or not. Normally, at this point, I would use a reamer to remove the built-up cake inside the bowl, but meerschaum has the potential to crack in those circumstances. Instead, I used a pipe knife, and a piece of sandpaper taped to a wooden dowel. Collectively, these ensured that all the debris was removed. Similar to the stem, I then cleaned the stummel with both pipe cleaners and cotton swabs dipped in lemon-infused 99% isopropyl alcohol. I did it carefully because too much soaking can cause meerschaum to soften. In this case, I moved quickly, nothing softened, and everything turned out well.

Similar to the stem, I then cleaned the stummel with both pipe cleaners and cotton swabs dipped in lemon-infused 99% isopropyl alcohol. I did it carefully because too much soaking can cause meerschaum to soften. In this case, I moved quickly, nothing softened, and everything turned out well. To tidy up the bowl, I wiped down the outside, using a solution of a pH-neutral detergent and some distilled water, with cotton rounds. I used my micromesh pads to sand the outside of the stummel and finish it off. This sanding minimizes flaws in the meerschaum and provides a beautiful smoothness to the surface.

To tidy up the bowl, I wiped down the outside, using a solution of a pH-neutral detergent and some distilled water, with cotton rounds. I used my micromesh pads to sand the outside of the stummel and finish it off. This sanding minimizes flaws in the meerschaum and provides a beautiful smoothness to the surface.

I then applied some Clapham’s Beeswax Finish to the meerschaum and let it sit for about 30 minutes. As meerschaum pipes don’t do well on a bench-polisher, I then buffed it with a microfibre cloth. I repeated this process and left it – it sure was pretty! I also polished the silver with my jeweller’s cloth and made it shine.

I then applied some Clapham’s Beeswax Finish to the meerschaum and let it sit for about 30 minutes. As meerschaum pipes don’t do well on a bench-polisher, I then buffed it with a microfibre cloth. I repeated this process and left it – it sure was pretty! I also polished the silver with my jeweller’s cloth and made it shine.

For the final step, I took the stem to my bench polisher and carefully buffed it with a blue diamond compound.

For the final step, I took the stem to my bench polisher and carefully buffed it with a blue diamond compound.

All done! This Peterson 303 Sterling Silver Meerschaum bent apple looks fantastic again and is ready to be enjoyed by its next owner. I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the ‘Irish’ section of the store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the pipe are as follows: length 5 in. (127 mm); height 3⅜ in. (87 mm); bowl diameter 1⅔ in. (42 mm); chamber diameter ¾ in. (18 mm). The weight of the pipe is 1⅝ oz. (49 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I enjoyed restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.