Blog by Kenneth Lieblich

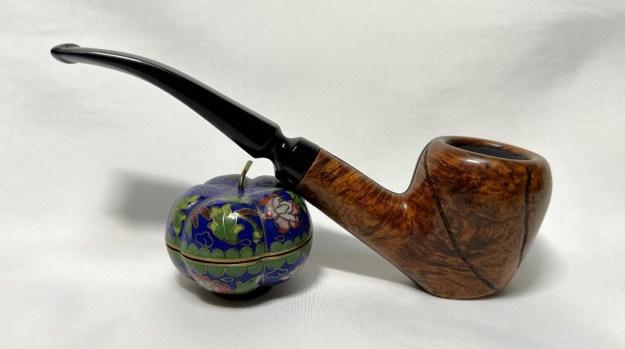

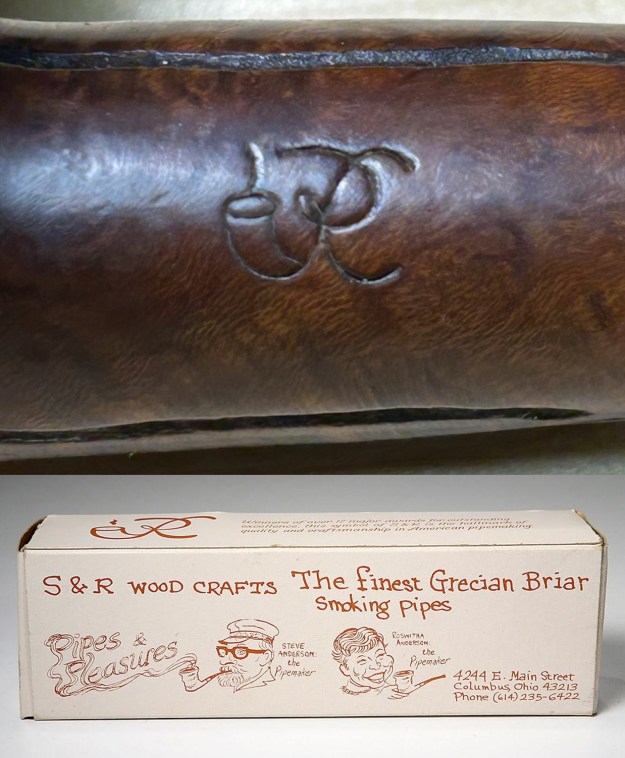

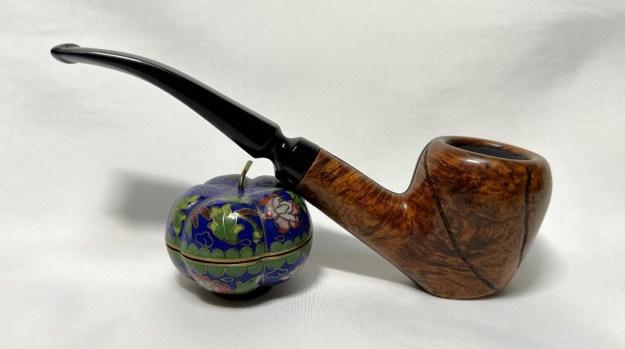

I’ve mentioned before that there are some pipes that are so challenging that they are an entire pipe-restoration course in and of themselves. This is one may not be as bad as some I’ve tackled in the past, but it certainly needs some major help! This is a S&R Woodcrafters Pipe and it belongs to my cousin in Montréal. He asked me if I could bring it back to life and I said I’d give it the old college try. This pipe reminded me that sometimes the wear-and-tear of the years needs to remain on a pipe as part of its story. This pipe has been abused over the years. I managed to bring great beauty back to this pipe, but it would always retain signs of its past.

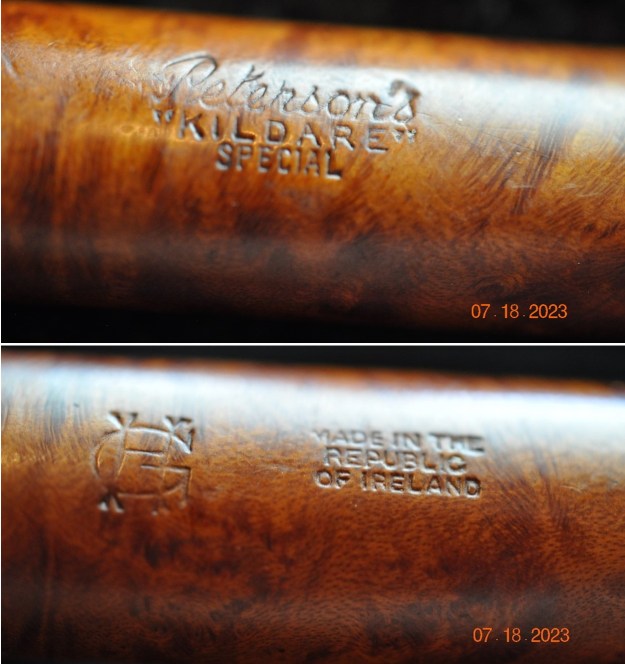

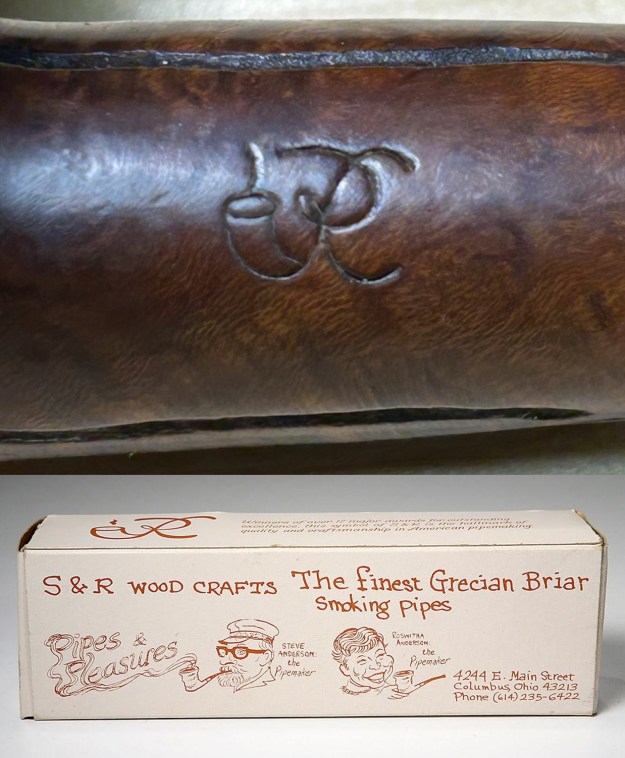

The pipe in question was made by Stephen and Roswitha Anderson (hence, S&R Woodcrafters) of Columbus, Ohio. They make unique, handcrafted pipes and are fascinating pieces. I read a blog Steve wrote on an S&R pipe earlier this year to learn more about the pipe’s background. I was directed to the Pipedia page on S&R and it has a lot of good information:

The pipe in question was made by Stephen and Roswitha Anderson (hence, S&R Woodcrafters) of Columbus, Ohio. They make unique, handcrafted pipes and are fascinating pieces. I read a blog Steve wrote on an S&R pipe earlier this year to learn more about the pipe’s background. I was directed to the Pipedia page on S&R and it has a lot of good information:

Stephen and Roswitha Anderson of S&R Pipes, also known as S&R Woodcrafters, have become pipe makers renowned throughout the world as talented carvers of high-grade briar pipes. They have been featured in several trade publications and magazines such as Pipes and Tobaccos and PipeSmoker, and have several pieces on display in museums in Europe and the United States.

They are the first American pipe carvers honored with induction into the Conferee of Pipe Makers of Saint-Claude, France; the very place where the carving of briar pipes became a world-wide industry. Sadly, Steve passed away in March of 2009. Roswitha is still carving S&R pipes and carrying on with the shop with help from her “guys” David, Marty, and Tony.

Steve and Roswitha began carving pipes in the 1960’s. They travelled to pipe shows and arts and crafts shows throughout the country and Europe selling their pipes and built up quite an extensive loyal customer base. Eventually, it became time to offer their pipes to the retail fraternity of pipe smokers.

Pipes & Pleasures had its grand opening in a distinct red brick house on Main Street in Columbus, Ohio in 1977. The front section of the house was converted into a traditional tobacco shop selling pipe tobacco, cigars, and pipes manufactured by well known companies such as Dunhill, Charatan, and Savinelli as well as the high-grade S&R pipes that Steve and Roswitha carved. A workshop was set up in the back section of the house.

When the cigar boom hit in the ’90’s, the shop was expanded by building a large computer controlled walk-in humidor. It’s no secret throughout the country that Pipes & Pleasures has the best maintained cigars in the Columbus area as well as the best selection of premium cigars available in the area including the much sought-after Davidoff line.

Soon after the boom began, Steve and Roswitha moved their pipe making workshop to their farm and converted that space into a large smoking lounge for their many customers. The lounge features comfortable easy chairs, a television set, a stereo, a library of books and magazines about every aspect of tobacciana, a chess table, and a couple of card tables. The lounge is populated daily with long-time loyal customers and newcomers to the enjoyment and relaxation of cigar and pipe smoking. It’s also the room where several cigar tastings and samplings are held every year by representatives from cigar companies such as Davidoff and La Flor Dominicana.

In fact, their shop, Pipes & Pleasures, is still running. You can visit their website here. This is a charming pipe, but it had a number of significant issues, aside from the usual. Let’s take a closer look.

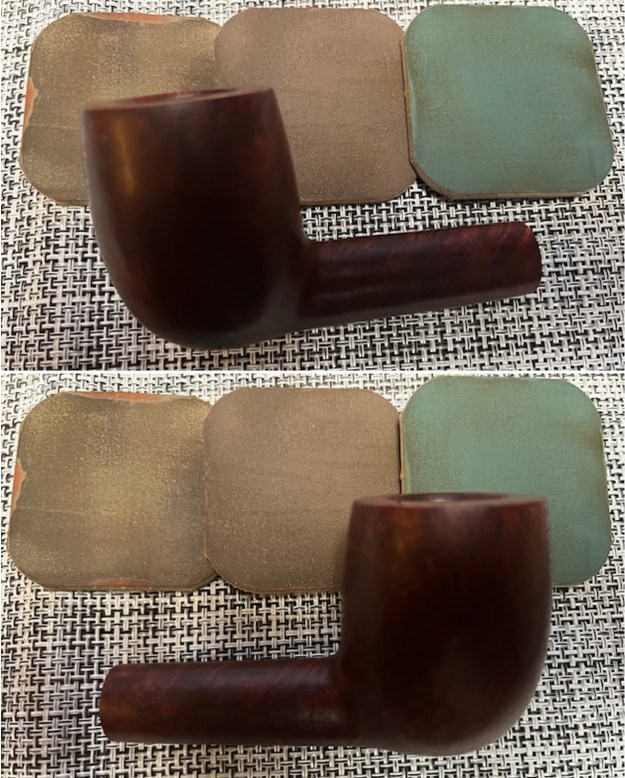

This is a charming pipe, but it had a number of significant issues, aside from the usual. Let’s take a closer look.

- The rim is heavily shredded and notably burned.

- The opening of the bowl is badly out of round.

- There’s a big gouge on the side of the bowl.

- There are several fissures inside the bowl (one of which might connect to the gouge).

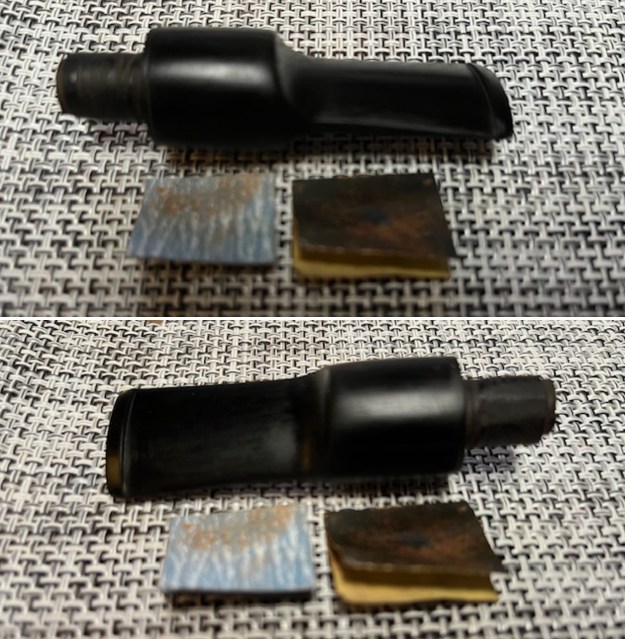

- There’s a crack on the top of the button.

- There’s a piece missing on the underside of the button.

- The mortise and tenon are not seated properly, but this might be corrected by a thorough cleaning.

I began by cleaning the outside of the stem with some Murphy’s Oil Soap on cotton rounds. This removed some of the surface staining. Then, I started cleaning the insides with isopropyl alcohol, cotton swabs, and pipe cleaners. The inside was dirty and it took a bit of cotton.

I began by cleaning the outside of the stem with some Murphy’s Oil Soap on cotton rounds. This removed some of the surface staining. Then, I started cleaning the insides with isopropyl alcohol, cotton swabs, and pipe cleaners. The inside was dirty and it took a bit of cotton. There was some oxidation and calcification on the stem, so I wiped it down with SoftScrub cleaner. Once this process was done, the stem went for an overnight soak in the Pipe Stem Oxidation Remover. This allows me to clean the oxidation off in a couple of ways: by applying a mild cleaner to the surface and sanding the stem. The next day, I used SoftScrub again with some cotton rounds.

There was some oxidation and calcification on the stem, so I wiped it down with SoftScrub cleaner. Once this process was done, the stem went for an overnight soak in the Pipe Stem Oxidation Remover. This allows me to clean the oxidation off in a couple of ways: by applying a mild cleaner to the surface and sanding the stem. The next day, I used SoftScrub again with some cotton rounds.

As the photos show, the bit of the stem was badly damaged. The top side was significantly cracked and ruptured, while the underside was missing a chunk of vulcanite. I brought out my black cyanoacrylate adhesive and I applied it to the topside damage. I used some accelerant to get the glue going, and then moved on to the underside.

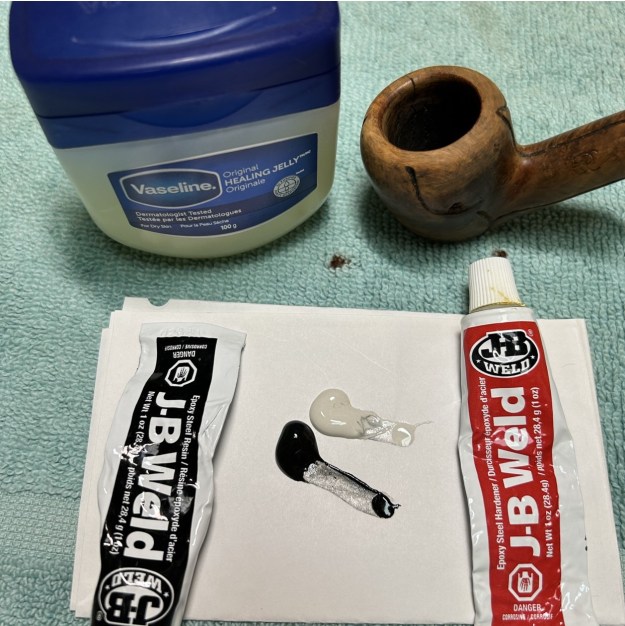

As the photos show, the bit of the stem was badly damaged. The top side was significantly cracked and ruptured, while the underside was missing a chunk of vulcanite. I brought out my black cyanoacrylate adhesive and I applied it to the topside damage. I used some accelerant to get the glue going, and then moved on to the underside. The major gouge would need far more work. I made a patch out of black cyanoacrylate adhesive and a little activated charcoal in). I first plugged up the stem’s draught hole with a shaped piece of cardstock, coated in petroleum jelly. This ensured that any of the CA glue would not accidentally plug up the air passage in the stem.

The major gouge would need far more work. I made a patch out of black cyanoacrylate adhesive and a little activated charcoal in). I first plugged up the stem’s draught hole with a shaped piece of cardstock, coated in petroleum jelly. This ensured that any of the CA glue would not accidentally plug up the air passage in the stem. This was a tricky business and it took some real patience and effort to make it work. As the photos show, after I applied the cyanoacrylate, it looked pretty darn ugly, but I was expecting that. After the curing, I ended up sanding down the end of the stem to reduce some of the excess material. To carry this process on, I used some miniature files to further shape the button and make it suitable for sanding. I used another file on the inside to ensure there were no rough edges in the bore.

This was a tricky business and it took some real patience and effort to make it work. As the photos show, after I applied the cyanoacrylate, it looked pretty darn ugly, but I was expecting that. After the curing, I ended up sanding down the end of the stem to reduce some of the excess material. To carry this process on, I used some miniature files to further shape the button and make it suitable for sanding. I used another file on the inside to ensure there were no rough edges in the bore. I then sanded the stem down with 220- and 400-grit sandpapers to meld seamlessly into the stem. This ensures that it keeps its shape and looks like it should. I then used all nine Micromesh pads (1,500 through 12,000 grit) to bring out the lovely black lustre on the stem. I also used Obsidian Pipe Stem Oil in between each pad scrubbing. It is worth noting that a repair this big on a stem will never be completely invisible, but I was pleased with the results.

I then sanded the stem down with 220- and 400-grit sandpapers to meld seamlessly into the stem. This ensures that it keeps its shape and looks like it should. I then used all nine Micromesh pads (1,500 through 12,000 grit) to bring out the lovely black lustre on the stem. I also used Obsidian Pipe Stem Oil in between each pad scrubbing. It is worth noting that a repair this big on a stem will never be completely invisible, but I was pleased with the results.

On to the stummel – and there was plenty of work here too. As the photos show, there was a notable crater on the outside of the bowl and I could see a couple of fissures. This concerned me greatly, as I wondered if the two wounds were connected (literally and figuratively). The insides (both bowl and shank) had plenty of cake and tar. The bowl really needed to be reamed, so I used the KleenReem tool to scrape off as much built-up cake.

On to the stummel – and there was plenty of work here too. As the photos show, there was a notable crater on the outside of the bowl and I could see a couple of fissures. This concerned me greatly, as I wondered if the two wounds were connected (literally and figuratively). The insides (both bowl and shank) had plenty of cake and tar. The bowl really needed to be reamed, so I used the KleenReem tool to scrape off as much built-up cake.  Generally, I prefer to sand the chamber down to bare briar. When restoring, it is important to ensure that there is no damage to the briar under the cake. There are a few situations when I might leave some cake in the bowl, but not today. Sadly, there were definitely some hidden flaws to the briar on this pipe. I’ll come back to that later.

Generally, I prefer to sand the chamber down to bare briar. When restoring, it is important to ensure that there is no damage to the briar under the cake. There are a few situations when I might leave some cake in the bowl, but not today. Sadly, there were definitely some hidden flaws to the briar on this pipe. I’ll come back to that later.

I wiped down the wood with some Murphy’s and pulled off lots of grime. Then I started cleaning the insides with isopropyl alcohol, cotton swabs, and pipe cleaners. The inside was pretty dirty and required some cotton to clean it up.

I wiped down the wood with some Murphy’s and pulled off lots of grime. Then I started cleaning the insides with isopropyl alcohol, cotton swabs, and pipe cleaners. The inside was pretty dirty and required some cotton to clean it up. I decided to de-ghost the pipe in order to remove any lingering smells and dirt of the past. I thrust cotton balls into the bowl and the shank and saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused oils, tars and smells to leach out into the cotton. I finished this part off by cleaning the shank with Castile soap and tube brushes. The bowl was nice and clean after this.

I decided to de-ghost the pipe in order to remove any lingering smells and dirt of the past. I thrust cotton balls into the bowl and the shank and saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused oils, tars and smells to leach out into the cotton. I finished this part off by cleaning the shank with Castile soap and tube brushes. The bowl was nice and clean after this.

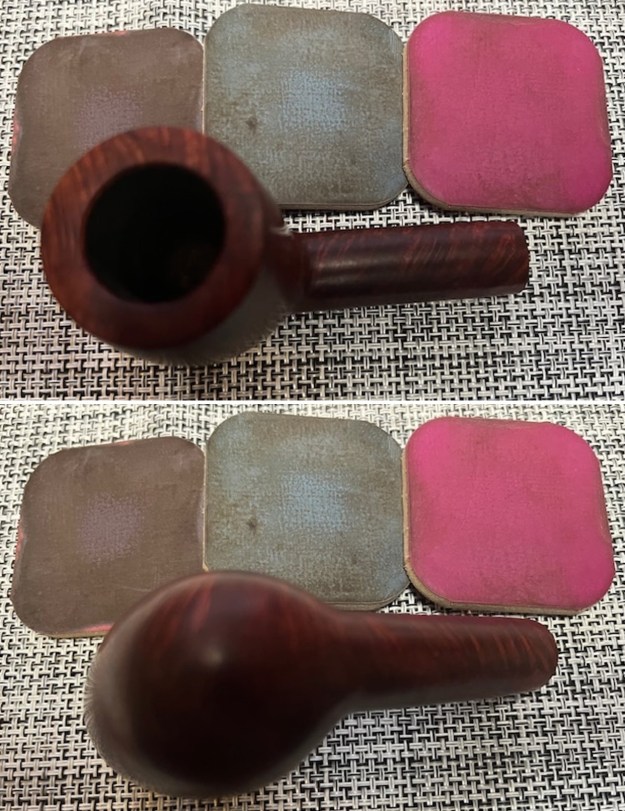

I went back for another go with the Murphy’s and a toothbrush, to ensure the grooves were done too. Now that the pipe was clean, I wanted to have a closer look at the state of the briar. One piece of good (and remarkable) news was that the crater on the outside of the bowl and the fissures on the inside did NOT meet up. This was a great relief. Nonetheless, both areas needed to be repaired.

I went back for another go with the Murphy’s and a toothbrush, to ensure the grooves were done too. Now that the pipe was clean, I wanted to have a closer look at the state of the briar. One piece of good (and remarkable) news was that the crater on the outside of the bowl and the fissures on the inside did NOT meet up. This was a great relief. Nonetheless, both areas needed to be repaired.

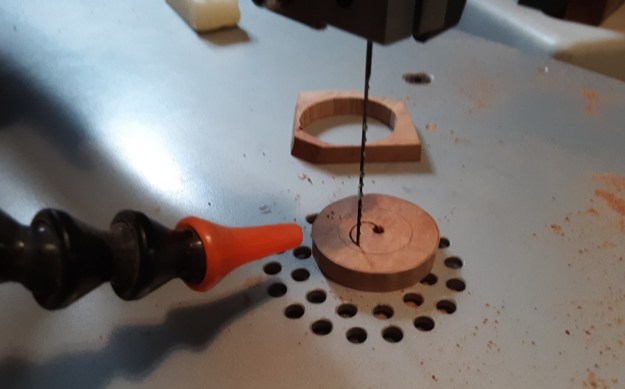

But before that, I wanted to correct the appalling roughness (and burns) on the rim of the pipe. It was bad – really bad – and it would be a challenge to make the pipe look normal. At the same time, it was necessary to address the bowl being so badly out of round. I put a sanding drum (and a couple of other bits) on my Dremel and carefully began removing the burns and shredded wood, and correcting the out-of-round- bowl. This is NOT an option that I use regularly. The risk of oversanding is high and that can be an even bigger problem. However, I worked slowly and cautiously. I only used the Dremel briefly before moving on to sandpaper. I also used a solid wooden sphere on the inner edge of the rim. In addition to this, I also sanded down the outside of the bowl, near the rim, so as to minimize the visual effect of the bashed edge. I sanded all the way around to ensure that the pipe retains its look. It was a laborious process to sort out these issues, but I was delighted in the end.

But before that, I wanted to correct the appalling roughness (and burns) on the rim of the pipe. It was bad – really bad – and it would be a challenge to make the pipe look normal. At the same time, it was necessary to address the bowl being so badly out of round. I put a sanding drum (and a couple of other bits) on my Dremel and carefully began removing the burns and shredded wood, and correcting the out-of-round- bowl. This is NOT an option that I use regularly. The risk of oversanding is high and that can be an even bigger problem. However, I worked slowly and cautiously. I only used the Dremel briefly before moving on to sandpaper. I also used a solid wooden sphere on the inner edge of the rim. In addition to this, I also sanded down the outside of the bowl, near the rim, so as to minimize the visual effect of the bashed edge. I sanded all the way around to ensure that the pipe retains its look. It was a laborious process to sort out these issues, but I was delighted in the end.

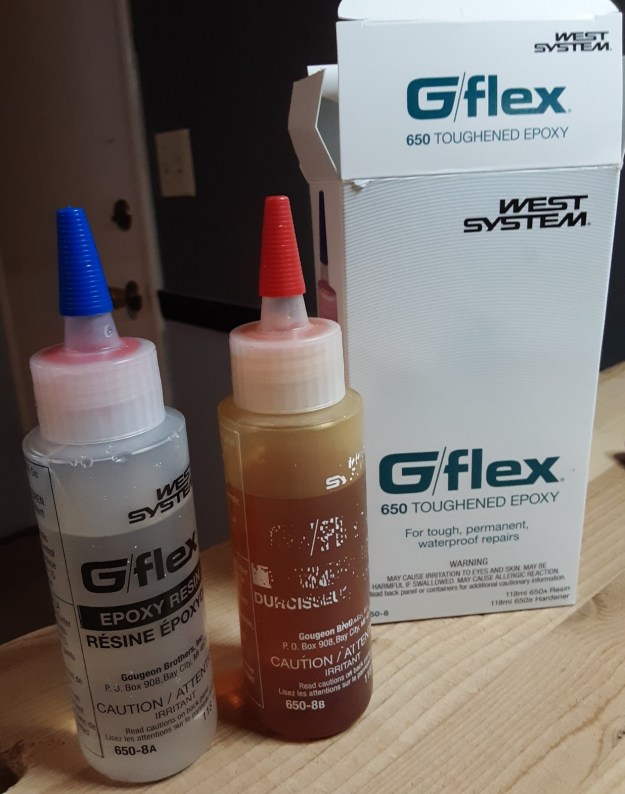

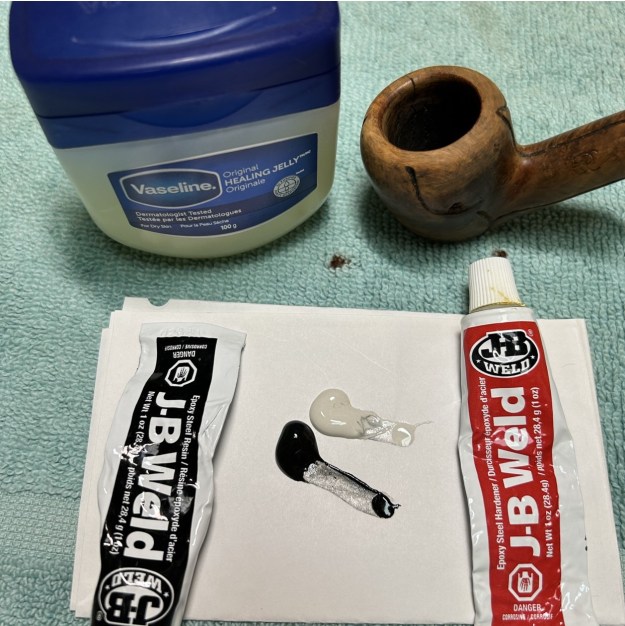

Moving back to the fissures – the solution to this problem is always a tricky one: epoxy. I prepared some J.B. Weld epoxy and filled the cracks and gouges, ensuring that the epoxy was evenly spread throughout the bowl. Of course, I did plug the draught hole with a folded pipe cleaner (coated in Vaseline) to make sure none of the epoxy made its way up there. Once done, a good 24 hours was needed to ensure that the epoxy was properly cured. Once done, I gently sanded the inside of the bowl to provide a rough surface for what was to come next. I coated the entire inside of the bowl with a mixture of activated charcoal and my wife’s homemade yogourt. Once hardened, this provided a good, slightly rough surface for a new cake to build.

Moving back to the fissures – the solution to this problem is always a tricky one: epoxy. I prepared some J.B. Weld epoxy and filled the cracks and gouges, ensuring that the epoxy was evenly spread throughout the bowl. Of course, I did plug the draught hole with a folded pipe cleaner (coated in Vaseline) to make sure none of the epoxy made its way up there. Once done, a good 24 hours was needed to ensure that the epoxy was properly cured. Once done, I gently sanded the inside of the bowl to provide a rough surface for what was to come next. I coated the entire inside of the bowl with a mixture of activated charcoal and my wife’s homemade yogourt. Once hardened, this provided a good, slightly rough surface for a new cake to build. As mentioned earlier, there was a crater on the bowl. It was large enough that I would not be able to make it disappear entirely, but I wanted to make it solid and smooth, and meld into the rest of the wood. I fixed it up with a mixture of cyanoacrylate adhesive and briar dust. This, too, was tricky, as the wound occurred immediately adjacent to one of the stylized grooves in the pipe.

As mentioned earlier, there was a crater on the bowl. It was large enough that I would not be able to make it disappear entirely, but I wanted to make it solid and smooth, and meld into the rest of the wood. I fixed it up with a mixture of cyanoacrylate adhesive and briar dust. This, too, was tricky, as the wound occurred immediately adjacent to one of the stylized grooves in the pipe.

Next, I used all nine Micromesh pads (1,500 through 12,000 grit) all over the stummel to make it lovely and smooth. Then, applying some Before & After Restoration Balm added that je ne sais quoi which brings out the wood’s beauty.

Next, I used all nine Micromesh pads (1,500 through 12,000 grit) all over the stummel to make it lovely and smooth. Then, applying some Before & After Restoration Balm added that je ne sais quoi which brings out the wood’s beauty.

At long last, I was off to my bench buffer to put the final touches on this pipe. I first gave it a thorough going-over with White Diamond compound. Following that, several coats of carnauba wax created a beautiful, glossy seal on the pipe and some closure to this long and involved repair.

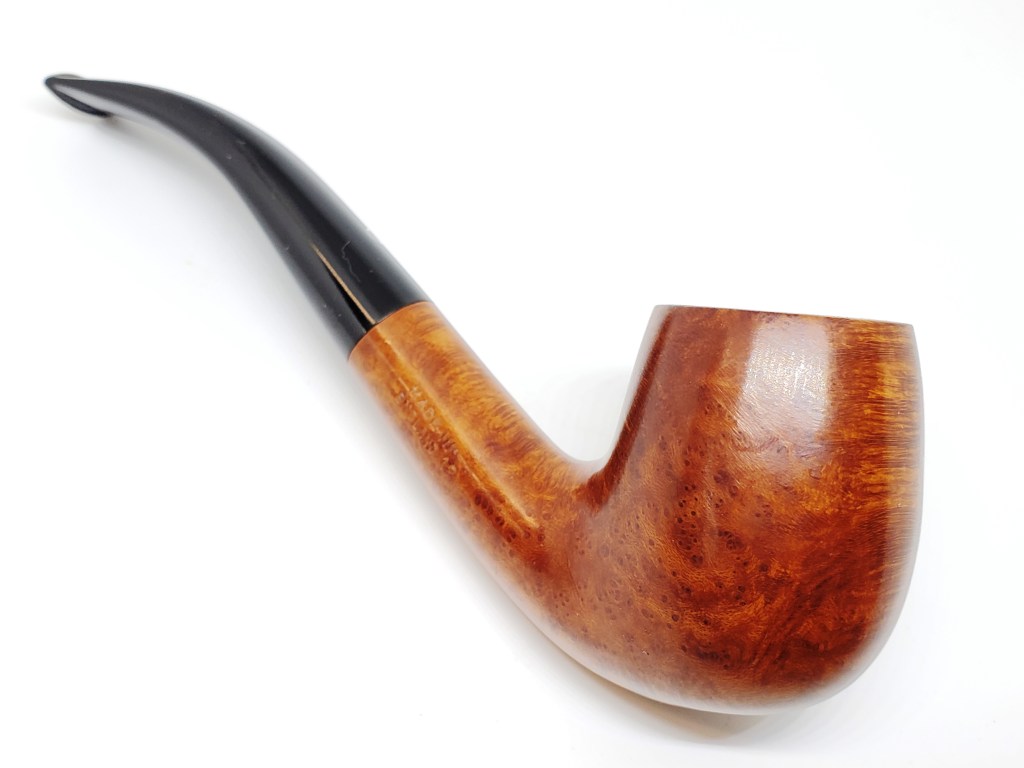

At long last, I was off to my bench buffer to put the final touches on this pipe. I first gave it a thorough going-over with White Diamond compound. Following that, several coats of carnauba wax created a beautiful, glossy seal on the pipe and some closure to this long and involved repair. The lovely shine made the wood look beautiful! Once again, I’m sure my cousin will love this pipe! I hope you enjoyed reading the story of this pipe as much I as I did restoring it. The approximate dimensions of the pipe are as follows: length 5¾ in. (146 mm); height 3½ in. (90 mm); bowl diameter 1½ in. (39 mm); chamber diameter ¾ in. (20 mm). The weight of the pipe is 1½ oz. (46 g). If you are interested in more of my work, please follow me here on Steve’s website or email me directly at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.

The lovely shine made the wood look beautiful! Once again, I’m sure my cousin will love this pipe! I hope you enjoyed reading the story of this pipe as much I as I did restoring it. The approximate dimensions of the pipe are as follows: length 5¾ in. (146 mm); height 3½ in. (90 mm); bowl diameter 1½ in. (39 mm); chamber diameter ¾ in. (20 mm). The weight of the pipe is 1½ oz. (46 g). If you are interested in more of my work, please follow me here on Steve’s website or email me directly at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.