Blog by Steve Laug

The next pipe in the queue is yet another interesting pipe from the Michigan lot – a well-made Freehand with plateau on the rim top and shank end. The entire pipe had some beautiful straight and flame grain around the bowl and shank with birdseye on the bottom of the bowl and shank. It is one of the unique freehand pipes that were in the collection. It is not a large pipe – but the bowl is large enough that I can put my entire thumb inside. The rim top is tapered and thin on the front half of the bowl and thicker at the backside. The entire rim is plateau. The shank end is flared and is also plateau briar. The pipe has a contrasting black stain on the plateau areas and medium brown stain coat on the rest of the bowl. The combination really accentuates the grain. There is no identifying brand or maker stamp on the shank sides or underside. The freehand style stem is vulcanite and has no marking or stamping on it. This is another nice looking piece much like the rest of those in this 21 pipe Michigan pipe lot. The Freehand I am working on is shown on the bottom shelf of the rack pictured below. It is the fourth pipe from the right and I put a red box around it to make it easy to identify. Jeff took some photos of the pipe when he received them to show the general condition of the pipe before he started his cleanup work. Like the rest of the pipes from the Michigan collection this pipe was very dirty and well used. There was a thick cake in the bowl and lava overflowing onto the plateau rim top. It was hard to know if the edges of the bowl were damaged or not because of the cake and lava. The exterior of the briar was dirty with grease and oils from being held. The vulcanite stem is lightly oxidized and has some calcification at the button. There are scratches in the surface of the vulcanite from what looked like an attempt to scrape off oxidation. There were deep tooth marks on both sides of the stem at the button edge and some wear on the button edge itself. The photos below tell the story and give a glimpse of the beautiful no name Freehand.

Jeff took some photos of the pipe when he received them to show the general condition of the pipe before he started his cleanup work. Like the rest of the pipes from the Michigan collection this pipe was very dirty and well used. There was a thick cake in the bowl and lava overflowing onto the plateau rim top. It was hard to know if the edges of the bowl were damaged or not because of the cake and lava. The exterior of the briar was dirty with grease and oils from being held. The vulcanite stem is lightly oxidized and has some calcification at the button. There are scratches in the surface of the vulcanite from what looked like an attempt to scrape off oxidation. There were deep tooth marks on both sides of the stem at the button edge and some wear on the button edge itself. The photos below tell the story and give a glimpse of the beautiful no name Freehand.

Jeff took two photos of the bowl and rim to capture the condition of the pipe before he started his cleanup work. The second photo is a close up of the lava on the rim and the cake in the bowl. It shows the mess this pipe was in when we received it. There was a thick hard cake in the bowl from lots of use. The rim top had some thick lava overflow and some darkening. The thick lava on the rim top made it hard to know what the inner and outer edges of the bowl looked like. There is also a general accumulation of dust in the finish on the rest of the bowl and shank.

Jeff took two photos of the bowl and rim to capture the condition of the pipe before he started his cleanup work. The second photo is a close up of the lava on the rim and the cake in the bowl. It shows the mess this pipe was in when we received it. There was a thick hard cake in the bowl from lots of use. The rim top had some thick lava overflow and some darkening. The thick lava on the rim top made it hard to know what the inner and outer edges of the bowl looked like. There is also a general accumulation of dust in the finish on the rest of the bowl and shank. He also took photos of the right and underside of the bowl and shank to show the interesting grain around the bowl and shank. The finish is very dirty but the grain is visible in each of the photos. This is another beautiful pipe.

He also took photos of the right and underside of the bowl and shank to show the interesting grain around the bowl and shank. The finish is very dirty but the grain is visible in each of the photos. This is another beautiful pipe.

The next two photos show the stem surface. They show the tooth marks and chatter on both sides near the button. There are also some marks on the sharp edge of the button. The stem is dirty, oxidized and is covered in scratches.

The next two photos show the stem surface. They show the tooth marks and chatter on both sides near the button. There are also some marks on the sharp edge of the button. The stem is dirty, oxidized and is covered in scratches.  Jeff reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and Murphy’s Oil Soap to remove the oils and tars on the rim and the grime on the finish of the bowl. He rinsed it under running water. He dried it off with a soft cloth. He was able to remove the lava build up on the rim top and you could see the great condition of the bowl top and edges of the rim. He soaked the stem in Before & After Deoxidizer to remove the oxidation. I took photos of the pipe to show its condition before I started my work on it.

Jeff reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and Murphy’s Oil Soap to remove the oils and tars on the rim and the grime on the finish of the bowl. He rinsed it under running water. He dried it off with a soft cloth. He was able to remove the lava build up on the rim top and you could see the great condition of the bowl top and edges of the rim. He soaked the stem in Before & After Deoxidizer to remove the oxidation. I took photos of the pipe to show its condition before I started my work on it.

I took a close up photo of the rim top to show the plateau on the surface of the rim. Jeff had done an amazing job cleaning off the lava buildup. The front part of the rim top is thinner and the bowl angles back toward the rear of the pipe. The outer edge of the rim looks really good. The plateau on the shank end is also visible in the photos of the stem. The stem photos show the tooth marks and the wear on the button surface on both sides.

I took a close up photo of the rim top to show the plateau on the surface of the rim. Jeff had done an amazing job cleaning off the lava buildup. The front part of the rim top is thinner and the bowl angles back toward the rear of the pipe. The outer edge of the rim looks really good. The plateau on the shank end is also visible in the photos of the stem. The stem photos show the tooth marks and the wear on the button surface on both sides.  The bowl and shank of the pipe were in great condition so I started by polishing it with micromesh sanding pads. I wet sanded with 1500-2400 grit pads and dry sanded with 3200-12000 grit pads. I wiped the bowl and rim down with a damp cloth after each pad.

The bowl and shank of the pipe were in great condition so I started by polishing it with micromesh sanding pads. I wet sanded with 1500-2400 grit pads and dry sanded with 3200-12000 grit pads. I wiped the bowl and rim down with a damp cloth after each pad.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect it. I used a horsehair shoe brush to work it into the nooks and crannies of the plateau rim top and shank end. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The following photos show the bowl at this point in the restoration process. The bowl and the rim top look really good. The finish looks very good with the rich finish on the bowl and rim. I am very happy with the results.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect it. I used a horsehair shoe brush to work it into the nooks and crannies of the plateau rim top and shank end. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The following photos show the bowl at this point in the restoration process. The bowl and the rim top look really good. The finish looks very good with the rich finish on the bowl and rim. I am very happy with the results.

With the bowl finished I set it aside and turned my attention to the stem. I cleaned out the tooth marks on both sides of the stem with a cotton swab and alcohol. I filled in the tooth marks with clear super glue. Once the repairs had cured I used a needle file to flatten out the repaired areas. I filed it until the patches were smooth with the surface of the stem.

With the bowl finished I set it aside and turned my attention to the stem. I cleaned out the tooth marks on both sides of the stem with a cotton swab and alcohol. I filled in the tooth marks with clear super glue. Once the repairs had cured I used a needle file to flatten out the repaired areas. I filed it until the patches were smooth with the surface of the stem.

I used a folded piece of 240 grit sandpaper to blend the repairs into the surface of the stem. Once the surface was smooth I sanded out the scratch marks and started the polishing of the stem with a folded piece of 400 grit sandpaper. I wiped the stem down with Obsidian Oil and took the following photos.

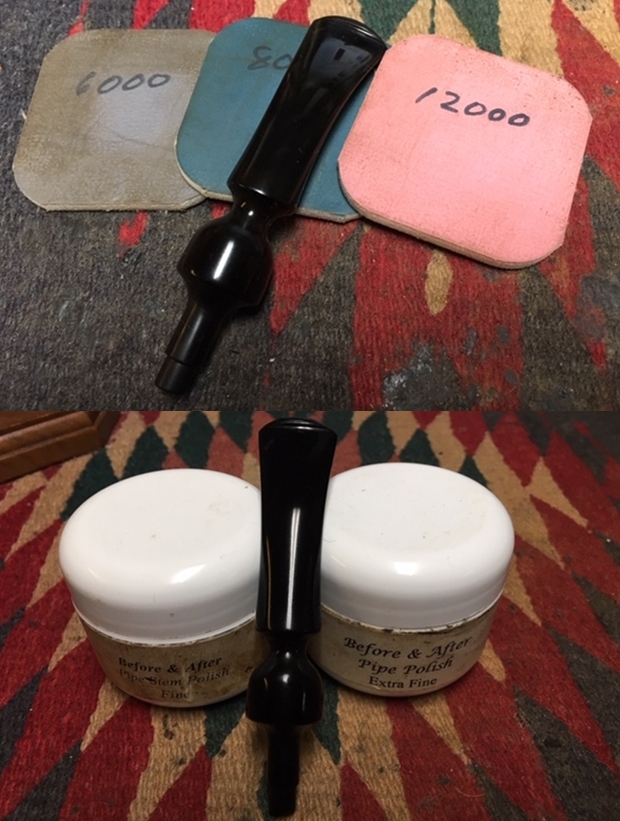

I used a folded piece of 240 grit sandpaper to blend the repairs into the surface of the stem. Once the surface was smooth I sanded out the scratch marks and started the polishing of the stem with a folded piece of 400 grit sandpaper. I wiped the stem down with Obsidian Oil and took the following photos. I polished the stem with micromesh sanding pads – wet sanding it with 1500-2400 grit pads and dry sanding it with 3200-12000 grit pads. I wiped the stem down with a damp cloth after each pad. I further polished it with Before & After Pipe Polish – both Fine and Extra Fine. I wiped it down with a coat of Obsidian Oil and set it aside to dry.

I polished the stem with micromesh sanding pads – wet sanding it with 1500-2400 grit pads and dry sanding it with 3200-12000 grit pads. I wiped the stem down with a damp cloth after each pad. I further polished it with Before & After Pipe Polish – both Fine and Extra Fine. I wiped it down with a coat of Obsidian Oil and set it aside to dry.

I put the stem back on the bowl and polished them both with Blue Diamond polish on the buffing wheel. I gave the bowl and stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The dark stained plateau on the rim top and shank end was a great contrast with the black and brown stain on the rest of the bowl and shank. Once again the pipe came alive with the buffing. I have no idea who carved the pipe but it is well laid out and proportioned and feels great in the hand. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. This beauty will soon be on the rebornpipes store. It would make a great Freehand addition to somebody’s pipe rack. Thanks for walking through the restoration of this interesting Freehand with me it was a pleasure to work on.

I put the stem back on the bowl and polished them both with Blue Diamond polish on the buffing wheel. I gave the bowl and stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The dark stained plateau on the rim top and shank end was a great contrast with the black and brown stain on the rest of the bowl and shank. Once again the pipe came alive with the buffing. I have no idea who carved the pipe but it is well laid out and proportioned and feels great in the hand. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. This beauty will soon be on the rebornpipes store. It would make a great Freehand addition to somebody’s pipe rack. Thanks for walking through the restoration of this interesting Freehand with me it was a pleasure to work on.