Blog by Steve Laug

My brother Jeff picked up four pipes in classic shapes at an auction in Nampa, Idaho. All four pipes are stamped JR Handmade. Beside the Bulldog there were two Canadians and an Apple. All were stamped the same on the shank JR over Handmade and the opposite side Algerian Briar. I have been researching the brand on the web. I came across a potential pipemaker with the JR initials on Pipedia named J. Rinaldi but from what I can see he did not make classic shaped pipes. He pipes are very well made and have more of a freehand/freeform shape with shank adornments so it makes me wonder if these are his. I enlarged each photo on the Pipedia article but I was unable to see the stamping on his pipes for comparison sake. This leaves me with a lot of questions about the brand. The foursome came from the Boise, Idaho area like the House of Robertson pipes that I worked on last year. Those came from a pipe shop in Boise, Idaho and I wonder if it is not possible that the JR Handmade brand was also a pipe shop brand from a small shop in that area or even somehow connected with the House of Robertson brand. Perhaps I will never know… if any of you readers have any idea about the brand your help would be greatly appreciated. The above photo shows the foursome after Jeff had cleaned them. But before he cleaned each of them he took photos of the pipes as they came to him. I already wrote about the restoration of the Bulldog (https://rebornpipes.com/2019/01/28/the-first-of-a-foursome-a-jr-handmade-bulldog/) and the first Canadian (https://rebornpipes.com/2019/01/30/the-second-of-a-foursome-a-jr-handmade-canadian/). The next pipe is the second pipe down on the left side of the above photo – a classic Canadian with a flat rim top. It is longer than the previous Canadian and also has a longer stem. I have included the photos of the Canadian before cleanup. The pipe is very well made and follows the classic shape of an oval shank Canadian perfectly. The bowl was stained with a slightly different looking finish to the other pipes in the lot. It was more of a medium brown with no black undercoat. Because of that the grain showed up differently on this one. It is a well-shaped pipe that captures the mixture of flame and cross and birdseye grain around the bowl sides and shank. The top of the bowl had some damage on the top and inner edge. The inner edge had some knife marks on the right side at the top that left damage. The bowl had a very thick cake in the bowl. There was a light overflow of lava onto the rim top. The stamping on the top side of the oval shank read JR over HAND MADE. The stamping on the underside read Algerian Briar. The black vulcanite stem had light tooth dents and chatter on the top and the underside of the stem. Otherwise it was in very good condition. It was the most oxidized of the foursome and also had some calcification.

The above photo shows the foursome after Jeff had cleaned them. But before he cleaned each of them he took photos of the pipes as they came to him. I already wrote about the restoration of the Bulldog (https://rebornpipes.com/2019/01/28/the-first-of-a-foursome-a-jr-handmade-bulldog/) and the first Canadian (https://rebornpipes.com/2019/01/30/the-second-of-a-foursome-a-jr-handmade-canadian/). The next pipe is the second pipe down on the left side of the above photo – a classic Canadian with a flat rim top. It is longer than the previous Canadian and also has a longer stem. I have included the photos of the Canadian before cleanup. The pipe is very well made and follows the classic shape of an oval shank Canadian perfectly. The bowl was stained with a slightly different looking finish to the other pipes in the lot. It was more of a medium brown with no black undercoat. Because of that the grain showed up differently on this one. It is a well-shaped pipe that captures the mixture of flame and cross and birdseye grain around the bowl sides and shank. The top of the bowl had some damage on the top and inner edge. The inner edge had some knife marks on the right side at the top that left damage. The bowl had a very thick cake in the bowl. There was a light overflow of lava onto the rim top. The stamping on the top side of the oval shank read JR over HAND MADE. The stamping on the underside read Algerian Briar. The black vulcanite stem had light tooth dents and chatter on the top and the underside of the stem. Otherwise it was in very good condition. It was the most oxidized of the foursome and also had some calcification.

Jeff took a close-up photo of the bowl and rim to capture the condition of the pipe pre-cleanup work. The rim top had some lava overflow and a lot of damage to the inner and outer edges of the bowl. The pipe is dirty with thick cake and damage around the rim.

Jeff took a close-up photo of the bowl and rim to capture the condition of the pipe pre-cleanup work. The rim top had some lava overflow and a lot of damage to the inner and outer edges of the bowl. The pipe is dirty with thick cake and damage around the rim. He also took a photo of the bottom of the bowl and shank to show the various grains on the pipe. Even though the photo is a bit blurry it show the finish of the bowl and that it is lighter in colour than the other pipes in the foursome. The finish is very dirty but this is another beautiful pipe.

He also took a photo of the bottom of the bowl and shank to show the various grains on the pipe. Even though the photo is a bit blurry it show the finish of the bowl and that it is lighter in colour than the other pipes in the foursome. The finish is very dirty but this is another beautiful pipe.

The bowl also has a few fills on the back side of bow and lower right side. Jeff took a photo to capture the stamping on the topside of the oval shank. The photo shows stamping JR over HAND MADE. On the underside it reads Algerian Briar.

Jeff took a photo to capture the stamping on the topside of the oval shank. The photo shows stamping JR over HAND MADE. On the underside it reads Algerian Briar.  The next two photos show the stem surface. There are tooth marks and chatter on both sides near the button. There is also some wear on the sharp edge of the button. There is a thick oxidation and accost of calcification.

The next two photos show the stem surface. There are tooth marks and chatter on both sides near the button. There is also some wear on the sharp edge of the button. There is a thick oxidation and accost of calcification. As mentioned before, Jeff and I have developed a pattern of working on the pipes that has become habit to both Jeff and me. I include it here so you have a sense of that pattern. Jeff reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and Murphy’s Oil Soap to remove the oils and tars on the rim and the grime on the finish of the bowl. He rinsed it under running water. He dried it off with a soft cloth. He was able to remove the lava build up on the rim top and the rim top damage and the damage around the edges – both inner and outer is quite extensive. I took photos of the pipe to show its condition before I started my work on it.

As mentioned before, Jeff and I have developed a pattern of working on the pipes that has become habit to both Jeff and me. I include it here so you have a sense of that pattern. Jeff reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and Murphy’s Oil Soap to remove the oils and tars on the rim and the grime on the finish of the bowl. He rinsed it under running water. He dried it off with a soft cloth. He was able to remove the lava build up on the rim top and the rim top damage and the damage around the edges – both inner and outer is quite extensive. I took photos of the pipe to show its condition before I started my work on it.

I took close up photos of the bowl and rim top as well as the stem. You can see the condition of the rim top and bowl in the first photo. Jeff was able to remove all of the tar and oils but you can now see the burn damage to the back inner edge of the bowl. The vulcanite stem had light tooth chatter and some tooth marks on the top and underside of the stem near and on the button surface.

I took close up photos of the bowl and rim top as well as the stem. You can see the condition of the rim top and bowl in the first photo. Jeff was able to remove all of the tar and oils but you can now see the burn damage to the back inner edge of the bowl. The vulcanite stem had light tooth chatter and some tooth marks on the top and underside of the stem near and on the button surface. I took photos of the stamping on both sides of the oval shank. You can see that the stamping on both sides was light toward the front of the pipe. It was still readable but faint nonetheless.

I took photos of the stamping on both sides of the oval shank. You can see that the stamping on both sides was light toward the front of the pipe. It was still readable but faint nonetheless. I decided to address the rim top damage first. I topped the bowl with 220 grit sandpaper on a topping board to remove the damage to the top and the outer edges of the rim top. I was also able to reduce the damage to the back inner edge of the rim.

I decided to address the rim top damage first. I topped the bowl with 220 grit sandpaper on a topping board to remove the damage to the top and the outer edges of the rim top. I was also able to reduce the damage to the back inner edge of the rim. I also needed to take care of the inner edge so I used a folded piece of 220 grit sandpaper to smooth out the burn marks and darkening around the edge. I gave the edge a very slight bevel to minimize the damage.

I also needed to take care of the inner edge so I used a folded piece of 220 grit sandpaper to smooth out the burn marks and darkening around the edge. I gave the edge a very slight bevel to minimize the damage.  The pink putty fills bugged me! I used a dental pick to remove them as much as possible and wiped the briar down with alcohol on a cotton pad to remove the dust and debris. I filled in the holes with clear super glue and briar dust to repair the fills.

The pink putty fills bugged me! I used a dental pick to remove them as much as possible and wiped the briar down with alcohol on a cotton pad to remove the dust and debris. I filled in the holes with clear super glue and briar dust to repair the fills. When the repairs had cured I sanded them smooth with 220 grit sandpaper to blend the into the surface of the briar.

When the repairs had cured I sanded them smooth with 220 grit sandpaper to blend the into the surface of the briar. I sanded the repairs smooth and blended them into the rest of the bowl. It took a bit of work but soon they were blended in. I would need to stain the bowl repairs but first I want to polish the sanding marks out. I polished the rim top, the edge and exterior of the bowl and shank with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the rim off after each sanding pad to remove the dust. The damage on the rim edges and top looked really good after polishing.

I sanded the repairs smooth and blended them into the rest of the bowl. It took a bit of work but soon they were blended in. I would need to stain the bowl repairs but first I want to polish the sanding marks out. I polished the rim top, the edge and exterior of the bowl and shank with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the rim off after each sanding pad to remove the dust. The damage on the rim edges and top looked really good after polishing.

I decided to stain the entire pipe with a tan stain. I heated the briar, applied the stain and flamed it to set it in the grain. I repeated the process until I was satisfied with the coverage of the stain.

I decided to stain the entire pipe with a tan stain. I heated the briar, applied the stain and flamed it to set it in the grain. I repeated the process until I was satisfied with the coverage of the stain. I set the bowl aside overnight to let the stain cure and set in the briar.

I set the bowl aside overnight to let the stain cure and set in the briar. I buffed the bowl the next evening after work with red Tripoli and Blue Diamond to remove the crust coat of the stain and bring the briar to life. I wiped the bowl down with alcohol on a cotton pad to make it more transparent. Once I finished the cleanup of the stain I worked some Before & After Restoration Balm into the smooth surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little wall and then buffed with a cotton cloth to raise the shine. The following photos show the bowl at this point in the restoration process. The reworked rim top looks really good and matches the colour of the rest of the pipe.

I buffed the bowl the next evening after work with red Tripoli and Blue Diamond to remove the crust coat of the stain and bring the briar to life. I wiped the bowl down with alcohol on a cotton pad to make it more transparent. Once I finished the cleanup of the stain I worked some Before & After Restoration Balm into the smooth surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little wall and then buffed with a cotton cloth to raise the shine. The following photos show the bowl at this point in the restoration process. The reworked rim top looks really good and matches the colour of the rest of the pipe.

I set the bowl aside and worked on the stem. There were some tooth marks on the top and underside at the button that needed to be addressed. I also needed to do some work on the surface of the button on both sides. I also sanded away some of the surface oxidation.

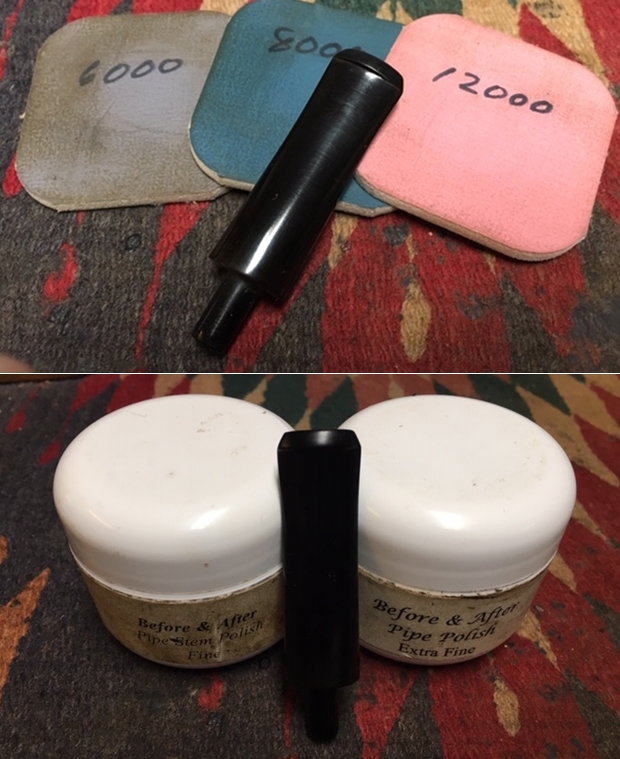

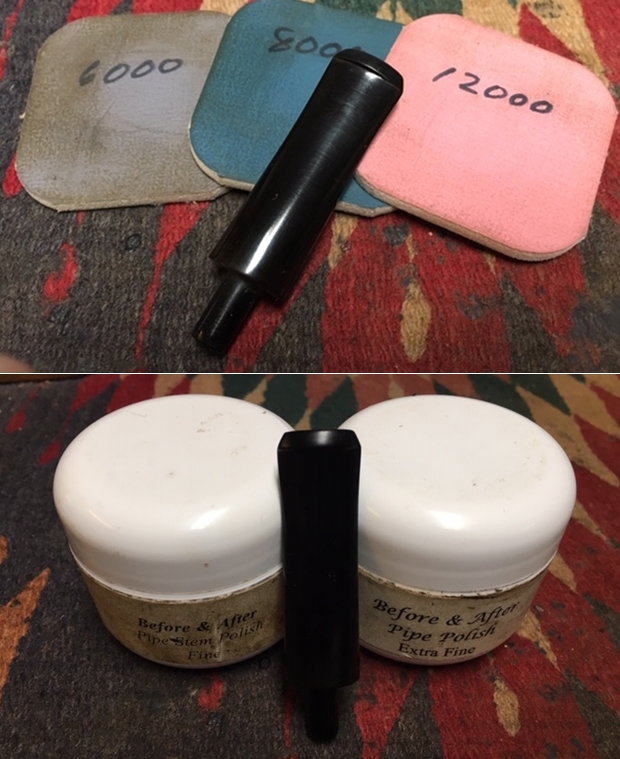

I set the bowl aside and worked on the stem. There were some tooth marks on the top and underside at the button that needed to be addressed. I also needed to do some work on the surface of the button on both sides. I also sanded away some of the surface oxidation. I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit sanding pads and dry sanding it with 3200-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish and wiped it down with a last coat of Obsidian Oil.

I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit sanding pads and dry sanding it with 3200-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish and wiped it down with a last coat of Obsidian Oil.

With this third JR Hand Made pipes from the Nampa, Idaho auction I am even more certain that there is some connection to the House of Robertson Pipe Shop in Boise, Idaho. I wonder if it is a seconds line for House of Robertson. Even with the fills and the repairs to the pipe this is another nice pipe. The three of the four JR Hand Made pipes that I have to restore are really well made and shaped. The stain job was done to highlight the mix of grain on the bowl. I polished stem and the bowl with Blue Diamond polish on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The contrasting grain really began to stand out; it seemed to take on life with the buffing. The rich contrasting brown colour works well with the polished black vulcanite stem. This finished pipe has a rich look just like the Bulldog and the other Canadian and it is also quite catching. Have a look at it in the photos below. It is a longer and slimmer looking pipe. The shape, finish and flow of the pipe and stem are very well done. The dimensions are Length: 6 1/2 inches, Height: 2 inches, Outside diameter of the bowl: 1 1/4 inches, Chamber diameter: 3/4 of an inch. I will be putting this newly finished JR Hand Made Canadian on the rebornpipes store shortly if you are interested in adding it to your collection. Thanks for walking through the restoration with me as I worked over the third of the foursome from JR Hand Made pipes.

With this third JR Hand Made pipes from the Nampa, Idaho auction I am even more certain that there is some connection to the House of Robertson Pipe Shop in Boise, Idaho. I wonder if it is a seconds line for House of Robertson. Even with the fills and the repairs to the pipe this is another nice pipe. The three of the four JR Hand Made pipes that I have to restore are really well made and shaped. The stain job was done to highlight the mix of grain on the bowl. I polished stem and the bowl with Blue Diamond polish on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The contrasting grain really began to stand out; it seemed to take on life with the buffing. The rich contrasting brown colour works well with the polished black vulcanite stem. This finished pipe has a rich look just like the Bulldog and the other Canadian and it is also quite catching. Have a look at it in the photos below. It is a longer and slimmer looking pipe. The shape, finish and flow of the pipe and stem are very well done. The dimensions are Length: 6 1/2 inches, Height: 2 inches, Outside diameter of the bowl: 1 1/4 inches, Chamber diameter: 3/4 of an inch. I will be putting this newly finished JR Hand Made Canadian on the rebornpipes store shortly if you are interested in adding it to your collection. Thanks for walking through the restoration with me as I worked over the third of the foursome from JR Hand Made pipes.