Blog by Steve Laug

I have been doing quite a few repairs lately and really needed a break to work on some of my own. I decided to work on one that my brother sent recently. It is a horn stemmed briar that is stamped Officier with a CCC triangle logo next to that. There is a copper coloured band on the shank for decoration since the shank is not cracked or damaged. The bowl also has embossed filigree on the front side. It reads Souvenir De France Campagne 1914-18. The band had several dents in the surface and there was a stamp on the band as well – a diamond with something stamped on the inside that is unreadable. The band is more of a ferrule than a band with the shank end cover by the edge of the ferrule. The pipe was incredibly dirty with grime and grit all over the outside of the bowl. There was also some dark stain on the front and right side of the bowl. The rim also has some dark spots. Removing that damage would also damage the gold lettering on the front of the bowl. There was a light cake in the bowl and some darkening on the top of the rim. The inner and outer edge of the bowl was also in great condition. There were some small nicks around the outer edge. The horn stem had a slight twist to the right side. There were some worm holes on the right side near the union of the stem and band. There was also some worm damage on the underside of the stem next to the button on the left side. There were some rough spots on the top of the stem between the shank and the button – almost some delaminated spots. Jeff took the following photos before he cleaned the pipe.

Jeff took close up photos of the rim top, the bottom of the bowl to show their general condition the grain is quite beautiful under the grime.

Jeff took close up photos of the rim top, the bottom of the bowl to show their general condition the grain is quite beautiful under the grime.

He took a great photo of the front of the bowl to show the gold stamping. It is very readable and in good condition. You can also see the dark stain on the briar underneath the stamping. I have seen this kind of stain on pipes in the past that has been caused by water or some kind of moisture that the pipe was laid in for a long period of time. In this case you can use your imagination and consider that possibly this damage occurred while in the hands of an officer in the French Campaign in WWI in between the years of 1914-18 or possibly after the closing date of the stamping.

He took a great photo of the front of the bowl to show the gold stamping. It is very readable and in good condition. You can also see the dark stain on the briar underneath the stamping. I have seen this kind of stain on pipes in the past that has been caused by water or some kind of moisture that the pipe was laid in for a long period of time. In this case you can use your imagination and consider that possibly this damage occurred while in the hands of an officer in the French Campaign in WWI in between the years of 1914-18 or possibly after the closing date of the stamping. He took several photos of the stamping on the shank and band. The shank bears a script text with the French spelling Officier and next to that is the rounded edge triangle with three C’s stamped inside. The band has a diamond stamp with something inside of it but it is not discernible.

He took several photos of the stamping on the shank and band. The shank bears a script text with the French spelling Officier and next to that is the rounded edge triangle with three C’s stamped inside. The band has a diamond stamp with something inside of it but it is not discernible.

The band/ferrule on the shank was loose on the shank. When the stem was removed the ferrule came off in hand. The tenon on the horn stem was an older nipple style tenon. It appears to be either horn or bone. It was intact but dirty.

The band/ferrule on the shank was loose on the shank. When the stem was removed the ferrule came off in hand. The tenon on the horn stem was an older nipple style tenon. It appears to be either horn or bone. It was intact but dirty.

The next photos show the worm damage to the right side of the stem near the band union and on the underside of stem at the button. Fortunately none of them went all the way through the horn.

The next photos show the worm damage to the right side of the stem near the band union and on the underside of stem at the button. Fortunately none of them went all the way through the horn.

I was unfamiliar with the triangle CCC brand so I did a bit of research. I looked on PipePhil’s site and did not find any information on the site. I also looked on Pipedia and found a possible link to a CC Paris in a triangle stamp. I followed the link on the French Pipes and Makers page to the CC Paris page. There I found the following information and interestingly photos of an Officier pipe. The only difference in the triangle logo was the stamping of Paris under the CC stamp instead of the CCC stamping. I am fairly confident that the CCC and CC Paris brands are linked together. I quote in full:

I was unfamiliar with the triangle CCC brand so I did a bit of research. I looked on PipePhil’s site and did not find any information on the site. I also looked on Pipedia and found a possible link to a CC Paris in a triangle stamp. I followed the link on the French Pipes and Makers page to the CC Paris page. There I found the following information and interestingly photos of an Officier pipe. The only difference in the triangle logo was the stamping of Paris under the CC stamp instead of the CCC stamping. I am fairly confident that the CCC and CC Paris brands are linked together. I quote in full:

Every collector of antique pipes knows that pipe factory and retail store catalogs from the 1800s – early 1900s are as rare as hen’s teeth to find…and an even rarer occasion, when found complete and in good to better condition. This fragile catalog from this little-known French manufactory, merchandised its pipes with the logo of a triangle bearing the letters “C C Paris” embossed in fitted cases. Cases with this logo are known, but the Wolf and Mathiss name, until now, was not known as the factory behind the retail establishment. Wolf & Mathiss was originally known as Cawley & Henry, a pipe manufacturer founded in 1867. The product line was fairly robust, catering to not only pipe and cigar smokers, but also to cigarette consumers, because the catalog includes cigarette rolling papers that, according to company information, had received silver medals at two expositions, Anvers (1885) and Paris (1889). https://pipedia.org/wiki/CC_Paris

I have included two photos from that website. The first is a photo of the cover of a catalogue of the CC Paris brand. The second is of the left side of the shank revealing the stamping – the Officier with a triangle CC Paris to the right of that. The photos are courtesy of Doug Valitchka. There was also a link to the Tobacco Pipe Artistory blog. That site has a full catalogue of the pipe brand and some interesting information. I have included the link for easy access to the info.

There was also a link to the Tobacco Pipe Artistory blog. That site has a full catalogue of the pipe brand and some interesting information. I have included the link for easy access to the info.

http://tobaccopipeartistory.blogspot.ca/2015/11/wolf-and-mathiss-catalog-paris-1890-1900.html

Jeff once again did his usual great job on cleaning this pipe, leaving it pristine and without damage to the finish. He was very careful to not damage the historic stamping on the front of the bowl. He reamed the bowl with a PipNet pipe reamer and cleaned up the remnants with the Savinelli Fitsall Pipe Knife. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He carefully cleaned the exterior of the bowl, rim and shank with a tooth brush and Murphy’s Oil Soap to remove the grime of the smooth finish on the bowl and shank. He was able to remove the tars and oil on the rim but the dark stain on the front, the right side and the rim top remained. He wiped off the soap with a damp cloth. He dried it off with a soft cloth. Once the dust and debris were removed the finish looked very good. He cleaned the inside of the stem with alcohol, pipe cleaners and cotton swabs to remove the tars and oils. He washed the exterior of the stem to remove debris from the worm damaged areas. I took photos of the pipe to show its condition before I started my work on it.

I took photos of the rim top and stem to show the condition of the pipe and stem when it came to Vancouver from Idaho.

I took photos of the rim top and stem to show the condition of the pipe and stem when it came to Vancouver from Idaho. I took the pipe apart and took a photo of the parts from the left side and from the front of the bowl. The ferrule was loose as was the fit of the stem in the shank.

I took the pipe apart and took a photo of the parts from the left side and from the front of the bowl. The ferrule was loose as was the fit of the stem in the shank. I used a multi-purpose white glue to reglue the ferrule to the shank. I pressed the ferrule into place and aligned the stamping on the ferrule with the shank stamping. I wiped off the excess glue that squeezed out and let the glue set.

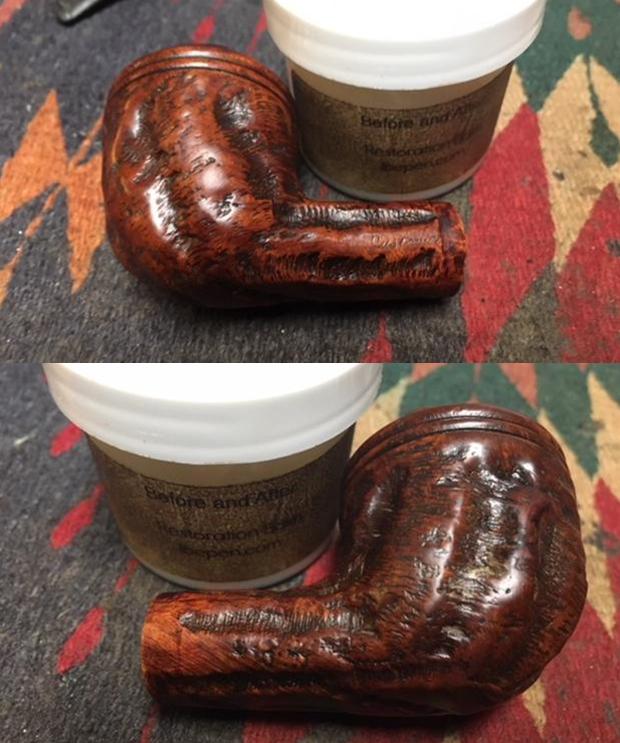

I used a multi-purpose white glue to reglue the ferrule to the shank. I pressed the ferrule into place and aligned the stamping on the ferrule with the shank stamping. I wiped off the excess glue that squeezed out and let the glue set. I worked Before & After Restoration Balm deep into the briar on the smooth finish to clean, enliven and protect it. I wiped it off with a soft cloth. I worked it into the rim and also on the stamping on the front of the bowl. I set it aside for a few minutes to let the balm work. I buffed it off carefully with a cotton cloth to polish it. The briar really began to have a deep shine. The dark spot though still present does not look bad and really is a part of the pipe’s story. I took some photos of the bowl at this point to mark the progress in the restoration. The grain on the bowl is really beginning to stand out and will only do so more as the pipe is waxed.

I worked Before & After Restoration Balm deep into the briar on the smooth finish to clean, enliven and protect it. I wiped it off with a soft cloth. I worked it into the rim and also on the stamping on the front of the bowl. I set it aside for a few minutes to let the balm work. I buffed it off carefully with a cotton cloth to polish it. The briar really began to have a deep shine. The dark spot though still present does not look bad and really is a part of the pipe’s story. I took some photos of the bowl at this point to mark the progress in the restoration. The grain on the bowl is really beginning to stand out and will only do so more as the pipe is waxed.

I cleaned out the worm damage with a qtip and alcohol. I filled in the damaged areas on the right side of the stem near the shank end and on the underside of the stem at the button with clear super glue. I set the stem aside to let the glue cure.

I cleaned out the worm damage with a qtip and alcohol. I filled in the damaged areas on the right side of the stem near the shank end and on the underside of the stem at the button with clear super glue. I set the stem aside to let the glue cure.

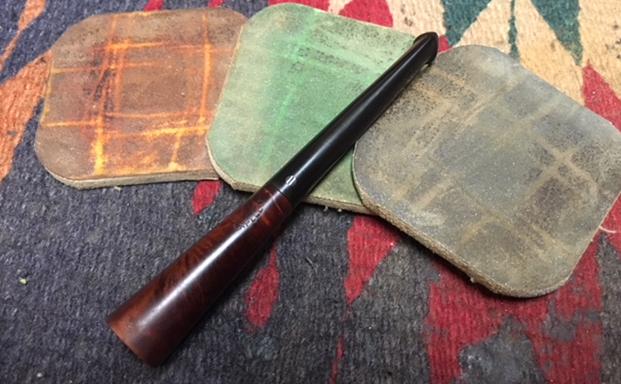

Once the glue had cured I sanded the repaired areas with 220 grit sandpaper to blend in the repairs with the surface of the horn. I also sanded out the areas of the stem that were beginning to delaminate. I used a small file to sharpen the edge of the button.

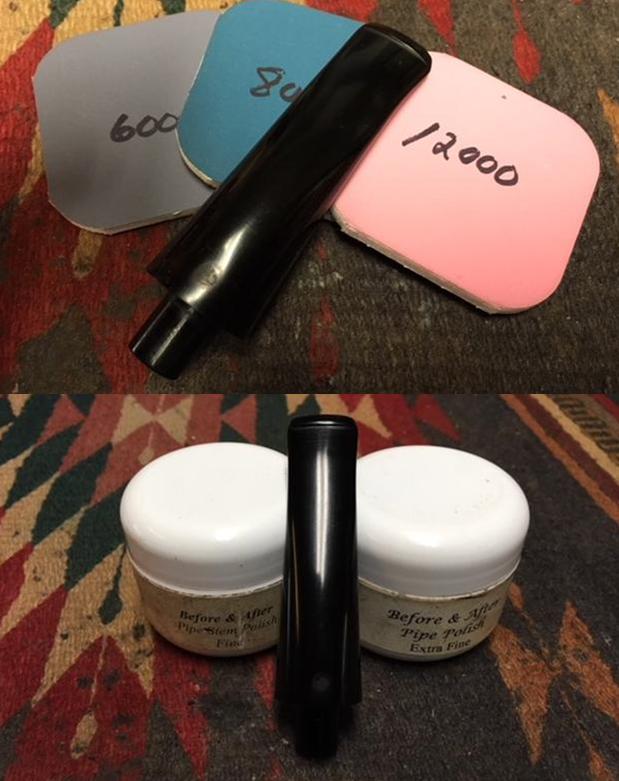

Once the glue had cured I sanded the repaired areas with 220 grit sandpaper to blend in the repairs with the surface of the horn. I also sanded out the areas of the stem that were beginning to delaminate. I used a small file to sharpen the edge of the button.  I polished stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the stem down with Obsidian Oil after each pad. I polished it with Before & After Pipe Stem Polish, both Fine and Extra Fine. I gave it a final coat of Obsidian Oil and set it aside to dry.

I polished stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the stem down with Obsidian Oil after each pad. I polished it with Before & After Pipe Stem Polish, both Fine and Extra Fine. I gave it a final coat of Obsidian Oil and set it aside to dry.

I used a dark brown stain pen to touch up the repairs on the horn stem. Somehow they had dried with a white spot in the center of each. The stain blended them into the surface of the horn and though they still showed were much better concealed. The loose tenon was an easy repair. I coated the tenon with several layers of clear fingernail polish to build up the diameter of the tenon.

I used a dark brown stain pen to touch up the repairs on the horn stem. Somehow they had dried with a white spot in the center of each. The stain blended them into the surface of the horn and though they still showed were much better concealed. The loose tenon was an easy repair. I coated the tenon with several layers of clear fingernail polish to build up the diameter of the tenon. Stem fit snugly in the shank and the pipe was beginning to look really good.

Stem fit snugly in the shank and the pipe was beginning to look really good. I took a photo of the stamping on the front of the bowl. I wanted to try to get more information on the history of the time. I did some research on the Campagne de France between the years 1914-1918 to see if I get a feel for that period – the time of World War I. My initial thinking was that the pipe was a souvenir of the war time intrusion of the Germans through the Alsace into the capital of France itself – Paris.

I took a photo of the stamping on the front of the bowl. I wanted to try to get more information on the history of the time. I did some research on the Campagne de France between the years 1914-1918 to see if I get a feel for that period – the time of World War I. My initial thinking was that the pipe was a souvenir of the war time intrusion of the Germans through the Alsace into the capital of France itself – Paris. I am quoting in part from two of the articles I found online about that time period. The first is part of a history that was written by Major Hubert Midy looking at the war from the perspective of the French Foreign Legion. It is entitled: HISTORY: The Foreign Legion, French Campaign 1914/1918. I have included a screen capture of the painting that was at the head of the article.

I am quoting in part from two of the articles I found online about that time period. The first is part of a history that was written by Major Hubert Midy looking at the war from the perspective of the French Foreign Legion. It is entitled: HISTORY: The Foreign Legion, French Campaign 1914/1918. I have included a screen capture of the painting that was at the head of the article. …This first world war is a baptism to the horror that will follow and will remain the most deadly century in the history of humanity.

…This first world war is a baptism to the horror that will follow and will remain the most deadly century in the history of humanity.

The centenary should be able to refresh our memory; thousands of books are dedicated to this war which still remains enigmatic in comparison with this second war whose motives for triggering are perfectly expressed.

And yet, everything was perfectly orchestrated, the French pointed out the German culprits, the latter accused the Russians, all suffered the latent aggressiveness of Austria and his hostility to his neighbor Serbia; the attack in Sarajevo giving him the opportunity to end once and for all.

As a result of this hostile Austrian act, the Russians take the responsibility to mobilize for Serbia, which immediately leads Germany to come to the aid of Austria.

Kaiser William II certainly did not imagine giving Vienna a “carte blanche” that a European war could take place.

Yet he could not ignore that there was a system of “bloc of alliance” which entailed a solidarity of several countries among them grouped against any external threat.

But in the end, despite this simplistic explanation of the outbreak of conflict, the objective factors are insufficient to understand how Europe threw itself into the furnace. Admittedly, there was indeed a suffocating climate of fear and suspicion, Germany scared and terrorized the French with its 25 million more than it, but nothing justified the entry into the war.

The war, deep down, no one knew what it was after forty years of armed peace. No one imagined the violence of a conflict in the industrial age, all thought that if it took place, it must be necessarily short, rough and brutal and specialists unanimously said that a war would mean total ruin belligerents.

Contrary to expectations, this war was long and marked with the red-hot iron of the blood of the fighters morally and physically destroyed by the destructive power of the heavy artillery which was able to neutralize an army of kilometers before the battlefield.

https://translate.google.ca/translate?hl=en&sl=fr&u=http://legionetrangere.fr/index.php/79-infos-fsale/299-histoire-la-legion-etrangere-campagne-de-france-1914-1918&prev=search

I searched further and found a second article that is a great summary of the war tracing the history from its beginnings in 1914 to its closure in 1918. I have included it for the information it gives.

The international context in which hostilities broke out in 1914 resulted from the profound changes that have affected Europe since the mid-nineteenth century.

The fragility of the Balkans crossed by strong nationalist pushes, the regrouping of the Austro-Hungarian monarchy (1867), the realization of the Italian unity (1870) and that of Germany (1871) destabilize the European equilibrium resulting from the treaty Vienna (1815).

Tensions between France, eager to find Alsace and Lorraine annexed in 1871, and Germany on the one hand, between Austria-Hungary and Russia on the other, not to mention the role of England, always anxious to maintain its global influence, fuel the risk of crises. The Ottoman Empire itself was forced at the Berlin Congress (1878) to recognize the independence of several countries that were integrated into its administration (Serbia, Romania, Bulgaria, Montenegro in particular).

Through the combination of these new divisions and competition between major states (repeated crises between 1904 and 1914), the confrontation could not be avoided.

The war broke out following the assassination on June 28, 1914 in Sarajevo of Franz Ferdinand, nephew and heir to the Emperor of Austria, by a Bosnian student linked to Serbian nationalist circles. Austria, after securing the support of Germany, presents an ultimatum to Serbia: this ultimatum requires that the investigation into the circumstances of the assassination be conducted on the Serbian territory by Austrian officials. Serbia accepts the conditions with the exception of the presence of Austrian agents which would constitute an attack on its sovereignty. Austria-Hungary declares war on July 28, 1914.

The cog of the alliances begins immediately: between the general mobilizations and the reciprocal ultimatums, Germany declares war on Russia on August 1st and on France on August 3rd, causing the reply of England declaring war in turn to Germany on August 4th. Patriotism, long nourished by various public opinions, allows the populations and the political classes of the different belligerents to accept this situation perceived as legitimate by each of the camps.

The German armies, regardless of the neutrality of Belgium, attack France first. This operation will be called the “Battle of the Borders” (7-24 August 1914): the French are moving forward to Mulhouse, Strasbourg and Lorraine. But in Mons and Charleroi the English and French are forced to retreat after fierce battles where they have difficulty coping with the dynamism of the attackers despite the effectiveness of the French artillery (exceptional light gun of 75).

Arrived at the gates of Paris on September 2, the Germans, instead of attempting to seize the capital, try to take the whole of the French battle body by a maneuver encirclement. Then commits the “Battle of the Marne” where Joffre, Chief of Staff, and General Gallieni, commanding the Place de Paris, launch a general counter-offensive marked by great feats of arms: General Foch heroically resisted in the swamps of Saint-Gond, and the army of General Maunoury was transported by Paris taxis to the north of the Marne: noting the failure of their action, the Germans retreated on September 10 to the Aisne; their commander-in-chief, von Moltke, is replaced by von Falkenhayn. Paris is saved.

Then begins the “race to the sea” between October and November 1914. The German army tries to outflank the allies on the left up to the north to reach the ports allowing British troops to disembark. The English and the French face tough and deadly engagements especially in Flanders (1-27 October). The first trenches appear, the soldiers digging them to protect themselves from both the enemy and winter. Finally the front stabilizes between the North Sea and Switzerland for nearly 700 km; 10 French departments are partially or totally occupied. The eastern front at the same time enabled the Germans to secure a victory over the Russians who had taken the offensive (Battle of Tannenberg, August 26-30, 1914); but the necessity of taking troops from the French battlefield weakened German power in the battle of the Marne.

The war of movement, initially planned to quickly defeat France, thus ends at the end of the year 1914 with two unexpected consequences: on the one hand a reciprocal neutralization of the armies in the presence, on the other hand a worldwide extension of the conflict Japan joined the Entente (Great Britain, Russia and France) and the Ottoman Empire and Bulgaria joined Germany and Austria-Hungary (October 1914).

The characteristics of this new conflict appear on both sides: the States must organize a real economy of war mobilizing all the means which they have to avoid the defeat (organization of the resources, supply, production of armaments, massive use of the railways, financing of the war effort).

In July 1918, Foch launched a counter-offensive which gave the signal for a progressive decline of the Germans, whose retreat continued to increase (the German front was sunk in Montdidier in August, the general offensive of Verdun to the Yser is triggered on October 31). The Italians erase on their side the disaster of Caporetto (October 1917) beating the Austrians to Vittorio-Veneto (October 1918). In the Balkans, under the influence of Allied pressure (Franchet d’Esperey, victorious at Uskub), the central empires are taken in reverse; Bulgaria and Turkey are increasingly isolated and demand an armistice (30 October); Austria does the same on November 3rd. Faced with the reversal of the military situation, political agitation spread to Germany: the German fleet revolts in Kiel, the revolution breaks out in Berlin, William II abdicates and the republic is proclaimed on November 9, the armistice is signed in Rethondes the 11th of November.

https://translate.google.ca/translate?hl=en&sl=fr&u=http://www.cheminsdememoire.gouv.fr/fr/la-premiere-guerre-mondiale-1914-1918&prev=search

Given that information I thought it would be helpful to look up the meaning of the French word Souvenir. I expected it to mean the same as the English word and it indeed did have. Here is the definition of the word:

Noun: a thing that is kept as a reminder of a person, place, or event. Synonyms: memento, keepsake, reminder, remembrance, token, memorial; bomboniere; trophy, relic. Use: “keep the key ring as a souvenir”

Verb: souvenir; 3rd person present: souvenirs; past tense: souvenired; past participle: souvenired; gerund or present participle: souveniring. Use: take as a memento -“many parts of the aircraft have been souvenired”

So now I knew that the pipe was a memento, memorial token, or remembrance of a horrible time in the history of the French. It was a time when Paris itself came under siege of the German army and the world as it was then known came to screeching end. The war forever changed the way people in those days viewed their time in history.

This small CCC Officier bent billiard with a horn stem is a real beauty with a mix of grains around the bowl and shank. The grain really is quite stunning. The rim top and the right side of the bowl have some dark stains that could not be removed without damaging the stamping on the front of the bowl. The horn stem is repaired and polished and has a shine that looks very good with the brass ferrule on the shank end. I buffed the bowl and the stem with Blue Diamond polish being careful to avoid the stamping on the front side of the bowl. The briar and the horn took on a deep and rich looking shine. I gave the bowl and stem multiple coats of Conservator’s Wax and buffed by hand with a microfiber cloth to raise the shine. The finished pipe is shown in the photos below. The rich brown stain allows the grain to really stand out on this little pipe and it works well with the polished richness of the stem. The dimensions of the pipe are: Length: 5 inches, Height: 1 5/8 inches, Outside Diameter: 1 inches, Diameter of the chamber: 5/8 inches. This little commemorative pipe has quite a history. I only wish that it could tell the story of its journey from France, to the US and up to Canada. I am sure that it would be a fascinating tale that would I am sure capture out imaginations. Thanks for walking through the restoration with me.

I took close up photos of the bowl, rim top and both sides of the stem to show the condition prior to cleaning. The buildup on the rim top is a combination of thick lava and damage to the surface of the briar. There appears to be some rustication on it but at this point I am not certain it is actually rusticated or just damaged.

I took close up photos of the bowl, rim top and both sides of the stem to show the condition prior to cleaning. The buildup on the rim top is a combination of thick lava and damage to the surface of the briar. There appears to be some rustication on it but at this point I am not certain it is actually rusticated or just damaged. On the top side of the stem was a round spot that I think had originally held a Kaywoodie logo. It was missing and there was a slight divot in the stem. I filled it in with a clear super glue and set it aside to cure.

On the top side of the stem was a round spot that I think had originally held a Kaywoodie logo. It was missing and there was a slight divot in the stem. I filled it in with a clear super glue and set it aside to cure. I cleaned up the rim top with a Savinelli Fitsall Knife blade. I scraped the surface of the rim and also the inner edge of the bowl to smooth things out. Once the rim was cleaned off the damage to the surface of the rim was visible. It was rough to touch. I reamed the bowl with a PipNet pipe reamer starting with the second cutting head and finishing with the third head which was the close to the same size as the bowl itself. I reamed the cake back to smooth briar.

I cleaned up the rim top with a Savinelli Fitsall Knife blade. I scraped the surface of the rim and also the inner edge of the bowl to smooth things out. Once the rim was cleaned off the damage to the surface of the rim was visible. It was rough to touch. I reamed the bowl with a PipNet pipe reamer starting with the second cutting head and finishing with the third head which was the close to the same size as the bowl itself. I reamed the cake back to smooth briar.

I worked over the beveled rim top with a folded piece of 220 grit sandpaper to smooth out the rough surface and remove as much of the damage as possible.

I worked over the beveled rim top with a folded piece of 220 grit sandpaper to smooth out the rough surface and remove as much of the damage as possible. I worked Before & After Restoration Balm deep into the rusticated patterns of the briar to clean, enliven and protect it. I worked it into the rustications with my fingertips and with cotton swabs. I worked it into the rim and shank end. I set it aside for a few minutes to let the balm work. I wiped it off with a soft cloth and buffed it with a horsehair shoe brush to polish it. The briar really began to have a deep shine. I took some photos of the bowl at this point to mark the progress in the restoration. The grain on the bowl is really beginning to stand out and will only do so more as the pipe is waxed.

I worked Before & After Restoration Balm deep into the rusticated patterns of the briar to clean, enliven and protect it. I worked it into the rustications with my fingertips and with cotton swabs. I worked it into the rim and shank end. I set it aside for a few minutes to let the balm work. I wiped it off with a soft cloth and buffed it with a horsehair shoe brush to polish it. The briar really began to have a deep shine. I took some photos of the bowl at this point to mark the progress in the restoration. The grain on the bowl is really beginning to stand out and will only do so more as the pipe is waxed.

I wiped down the rim top and polished it with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the rim top down with a damp cloth after each sanding pad. I restained the rim top to match the contrasting stains on the rest of the bowl.

I wiped down the rim top and polished it with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the rim top down with a damp cloth after each sanding pad. I restained the rim top to match the contrasting stains on the rest of the bowl.

I used a black Sharpie pen to colour in the grooves on the top of the rim to match the grooves around the bowl. When I had finished I like the final look of the pipe.

I used a black Sharpie pen to colour in the grooves on the top of the rim to match the grooves around the bowl. When I had finished I like the final look of the pipe. I used a dental spatula to clean out the hard tars and oils on the walls of the mortise. It did not take too much work to remove the hard build up. I scrubbed out the shank after that using cotton swabs, pipe cleaners and isopropyl alcohol. I cleaned out the airway in the stem with pipe cleaners, cotton swabs and alcohol. The airway in the end of the tenon was slightly out of round because somewhere along the way the stinger had been removed and the airway damaged. I used a knife to bevel the edge of the airway in the tenon and then sanded it with a folded piece of sandpaper to smooth it out.

I used a dental spatula to clean out the hard tars and oils on the walls of the mortise. It did not take too much work to remove the hard build up. I scrubbed out the shank after that using cotton swabs, pipe cleaners and isopropyl alcohol. I cleaned out the airway in the stem with pipe cleaners, cotton swabs and alcohol. The airway in the end of the tenon was slightly out of round because somewhere along the way the stinger had been removed and the airway damaged. I used a knife to bevel the edge of the airway in the tenon and then sanded it with a folded piece of sandpaper to smooth it out.

I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit sanding pads and dry sanding with 3200-12000 grit pads. I wiped the stem down with Obsidian Oil after each sanding pad. I finished polishing the stem with Before & After Pipe Stem Polish both Fine and Extra Fine to remove the last of the scratches. I gave it a final coat of Obsidian Oil and set it aside to dry.

I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit sanding pads and dry sanding with 3200-12000 grit pads. I wiped the stem down with Obsidian Oil after each sanding pad. I finished polishing the stem with Before & After Pipe Stem Polish both Fine and Extra Fine to remove the last of the scratches. I gave it a final coat of Obsidian Oil and set it aside to dry.

With the stem polished I put it back on the pipe and lightly buffed the bowl with Blue Diamond. I buffed the stem with a more aggressive buff of Blue Diamond. I gave the bowl multiple coats of Conservator’s Wax and the stem several coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The finished pipe is shown in the photos below. I will be posting it on the rebornpipes store very soon. It should make a nice addition to your pipe rack if you have been looking for a reasonably priced older Kaywoodie Hand Made Rhodesian carved in an almost classic Custombilt style. It should be a great smoking pipe with a good hand feel. The dimensions are Length: 5 3/4 inches, Height: 1 1/2 inches, Outside diameter of the bowl: 1 3/4 inches, Chamber diameter: 7/8 inches. Thanks for walking through the restoration with me as I worked this pipe over.

With the stem polished I put it back on the pipe and lightly buffed the bowl with Blue Diamond. I buffed the stem with a more aggressive buff of Blue Diamond. I gave the bowl multiple coats of Conservator’s Wax and the stem several coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The finished pipe is shown in the photos below. I will be posting it on the rebornpipes store very soon. It should make a nice addition to your pipe rack if you have been looking for a reasonably priced older Kaywoodie Hand Made Rhodesian carved in an almost classic Custombilt style. It should be a great smoking pipe with a good hand feel. The dimensions are Length: 5 3/4 inches, Height: 1 1/2 inches, Outside diameter of the bowl: 1 3/4 inches, Chamber diameter: 7/8 inches. Thanks for walking through the restoration with me as I worked this pipe over.