Blog by Steve Laug

We probably paid too much for this beautiful meerschaum pipe but the shape and the carving are so unique that we had to buy it. It is made by CAO and is a shape I would call a Grecian urn. It has lattice carving around the bowl side and the rim is smooth. The shank has a pattern that looks a lot like scales and swirls. There was some very nice colouring happening on the shank and lightly on the bowl sides and rim. There was a cake in the bowl and some lava overflow on the rim top. There were some missing separators between two of the lattice windows but otherwise the bowl was undamaged. The stem was Lucite and had a round brass CAO logo on the top left side of the saddle. The stem had metallic gold flecks mixed in with the Lucite so that it had a natural sparkle to the reddish amberlike stem. There were not any tooth marks or dents on the stem surface but there were small scratches in the Lucite. There was also some wear and tear to the sharp edge of the button that would need to be cleaned up. Jeff took some photos of the pipe before he started the cleanup.

The next series of close up photos show the condition of the bowl and rim and the overall condition of the bowl sides. You can see the bowl and cake with the overflow of lava on the rim top. There is also some fuzz that has attached to the cake. It was a dirty bowl. The sides of the bowl look very good other than the damage to the separators between three of the tear drops in the lattice work on the front of the bowl. The second, third and fourth photos below show the damaged portion circled in red.

The next series of close up photos show the condition of the bowl and rim and the overall condition of the bowl sides. You can see the bowl and cake with the overflow of lava on the rim top. There is also some fuzz that has attached to the cake. It was a dirty bowl. The sides of the bowl look very good other than the damage to the separators between three of the tear drops in the lattice work on the front of the bowl. The second, third and fourth photos below show the damaged portion circled in red.

Other than that damage to the front of the bowl the rest of the carving is in excellent condition. The pipe, though imperfect will nonetheless be a beautiful addition to someone’s collection. They will just have to overlook the damaged area and enjoy the pipe.

Other than that damage to the front of the bowl the rest of the carving is in excellent condition. The pipe, though imperfect will nonetheless be a beautiful addition to someone’s collection. They will just have to overlook the damaged area and enjoy the pipe. The connector between the shank and stem is a push tenon. There is a Delrin insert in the shank of the pipe and a Delrin tenon threaded into the end of the stem. It is dirty and stained but is undamaged.

The connector between the shank and stem is a push tenon. There is a Delrin insert in the shank of the pipe and a Delrin tenon threaded into the end of the stem. It is dirty and stained but is undamaged. The round brass logo is dirty but it is undamaged. It is inset into the left topside of the saddle stem. The surrounding stem is quite dirty but there is no damage.

The round brass logo is dirty but it is undamaged. It is inset into the left topside of the saddle stem. The surrounding stem is quite dirty but there is no damage. The next two photos show the condition of the top and underside of the stem. You can see the metallic sparkles in the saddle portion and the scratches in the Lucite.

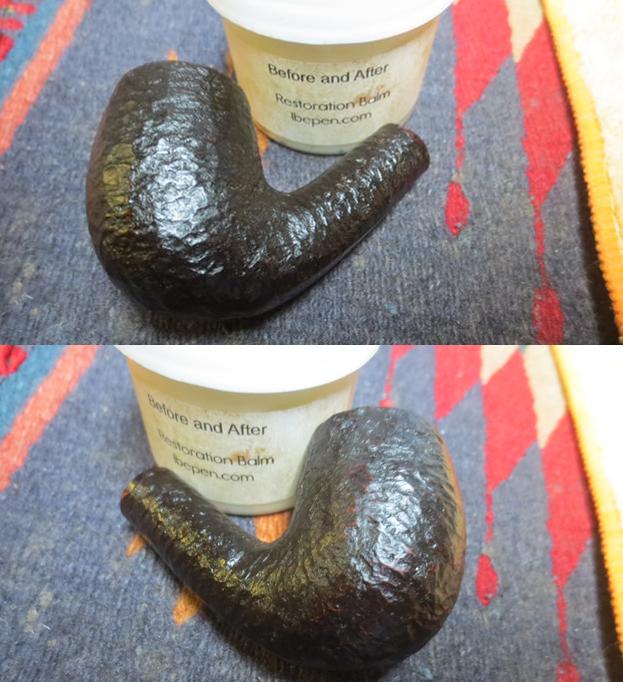

The next two photos show the condition of the top and underside of the stem. You can see the metallic sparkles in the saddle portion and the scratches in the Lucite. Jeff carefully reamed out the bowl with a Savinelli Fitsall Pipe Knife and took it back to the bare meerschaum walls. He scrubbed the rim top and scraped off the lava on the surface with a knife. He carefully cleaned the exterior of the bowl with a damp cloth to avoid further damage to the front of the bowl. He cleaned out the shank and airway in the bowl and stem with alcohol and pipe cleaners. He cleaned out the recessed area around the inset tenon in the stem with alcohol and cotton swabs. He washed the exterior of the stem with clean water. I took photos of the pipe when I brought it to my work table to show the condition of the pipe after Jeff’s work and before I polished it.

Jeff carefully reamed out the bowl with a Savinelli Fitsall Pipe Knife and took it back to the bare meerschaum walls. He scrubbed the rim top and scraped off the lava on the surface with a knife. He carefully cleaned the exterior of the bowl with a damp cloth to avoid further damage to the front of the bowl. He cleaned out the shank and airway in the bowl and stem with alcohol and pipe cleaners. He cleaned out the recessed area around the inset tenon in the stem with alcohol and cotton swabs. He washed the exterior of the stem with clean water. I took photos of the pipe when I brought it to my work table to show the condition of the pipe after Jeff’s work and before I polished it.

I took a photo of the rim top to show how well it cleaned up. Jeff did a great job getting rid of the lava overflow. I also took a photo of the cleaned up damaged area of the bowl.

I took a photo of the rim top to show how well it cleaned up. Jeff did a great job getting rid of the lava overflow. I also took a photo of the cleaned up damaged area of the bowl. The stem cleaned up really nicely. The gold flecks in the Lucite really stand out now and the gold/brass logo inset looks really good now. The stem should polish up nicely.

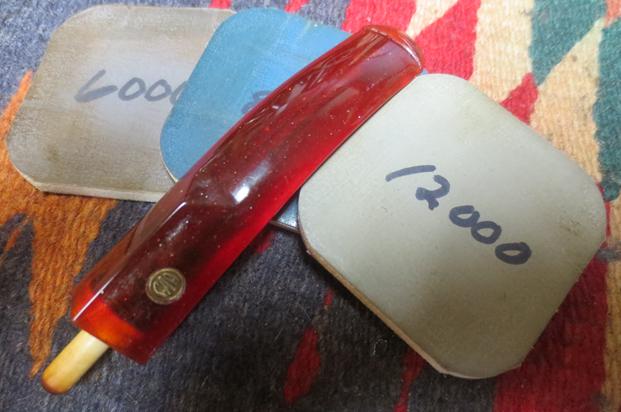

The stem cleaned up really nicely. The gold flecks in the Lucite really stand out now and the gold/brass logo inset looks really good now. The stem should polish up nicely. The mortise insert in the shank had a ragged edge to it. I used a sharp knife and a pen knife to clean up the ragged end. I wanted a smooth fit in the shank. Once I had finished that part of the shank and sanded it down I worked on polishing the rim and ring on the top of the bowl. I polished it with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the rim down after each pad with a damp cotton pad.

The mortise insert in the shank had a ragged edge to it. I used a sharp knife and a pen knife to clean up the ragged end. I wanted a smooth fit in the shank. Once I had finished that part of the shank and sanded it down I worked on polishing the rim and ring on the top of the bowl. I polished it with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the rim down after each pad with a damp cotton pad.

I polished out the scratches and marks in the metallic Lucite stem with micromesh sanding pads – wet sanding it with 1500-2400 grit pads and dry sanding it with 3200-12000 grit pads. I wiped the stem down with a damp cotton pad after each sanding pad. I lightly buffed the stem with Blue Diamond on the buffing wheel. After the final pad I wiped it down with a damp pad and rubbed it down with a final coat of oil and set it aside to dry.

I polished out the scratches and marks in the metallic Lucite stem with micromesh sanding pads – wet sanding it with 1500-2400 grit pads and dry sanding it with 3200-12000 grit pads. I wiped the stem down with a damp cotton pad after each sanding pad. I lightly buffed the stem with Blue Diamond on the buffing wheel. After the final pad I wiped it down with a damp pad and rubbed it down with a final coat of oil and set it aside to dry.

I put the stem back on the bowl and carefully worked the pipe on the buffing wheel with a clean pad. I used a gentle touch on both the meerschaum and the Lucite stem so as not to damage either of them. I gave the meerschaum bowl multiple coats of Conservator’s Wax and hand buffed it with a shoe brush and a microfiber cloth to deepen the shine. The finished pipe is shown in the photos below. Even with the damaged area on the front of the bowl it still looks better than it did in the beginning. The unique shape and lattice work carving work together to make this a beautiful pipe. The dimensions of the pipe are: Length: 6 inches, Height: 2 ½ inches, Diameter of the bowl: 1 1/8 inch, Diameter of the chamber: 3/4 inches. I will be adding this one to the rebornpipes store shortly if you are interested in adding it to your collection. It will make a fine addition to the rack. If you are interested email me at slaug@uniserve.com or send me a message on Facebook. Thanks for looking.

I put the stem back on the bowl and carefully worked the pipe on the buffing wheel with a clean pad. I used a gentle touch on both the meerschaum and the Lucite stem so as not to damage either of them. I gave the meerschaum bowl multiple coats of Conservator’s Wax and hand buffed it with a shoe brush and a microfiber cloth to deepen the shine. The finished pipe is shown in the photos below. Even with the damaged area on the front of the bowl it still looks better than it did in the beginning. The unique shape and lattice work carving work together to make this a beautiful pipe. The dimensions of the pipe are: Length: 6 inches, Height: 2 ½ inches, Diameter of the bowl: 1 1/8 inch, Diameter of the chamber: 3/4 inches. I will be adding this one to the rebornpipes store shortly if you are interested in adding it to your collection. It will make a fine addition to the rack. If you are interested email me at slaug@uniserve.com or send me a message on Facebook. Thanks for looking.