Blog by Steve Laug

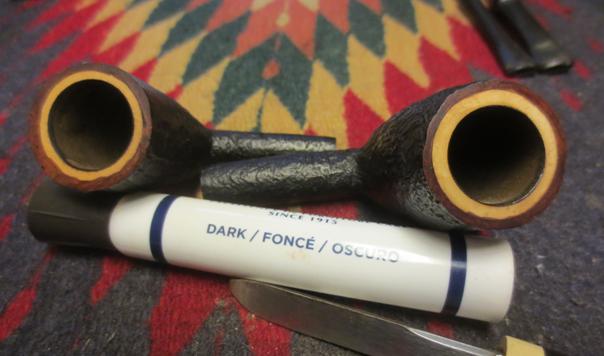

This was the third pipe I found on my recent trip to Sofia, Bulgaria in the open market near the Cathedral. The shape, the grain and the finish caught my eye when I saw it on the seller’s table and I knew that I wanted it. I paid the price and it was mine to bring home. It is simply stamped ALKO on the top right side of the oval shank and Old Briar on the top left side of the oval shank. There are no other stampings on the pipe or stem. The narrow stem and button shape hint to an older pipe but I could find no information on the brand in my searches on the internet. The finish of the bowl was dirty and had some scars and dings. Sadly they were not dents but rather cut marks. No amount of steaming would raise them. The finish was nice enough that I chose to clean them up rather than fill them in. The rim had an overflow of tars on it and had some damage to the inner edge. There was a thin cake in the bowl. The stem had a bit of tooth chatter on the top and the bottom sides near the button and was lightly oxidized. The vulcanite of the stem was high quality and hard. The light oxidation literally was on the surface.

I took a close-up photo of the rim to show the damage to the inner edge and the build up and the marks on the surface. It would clean up nicely but some of the damage would take some finesse to blend into the rim.

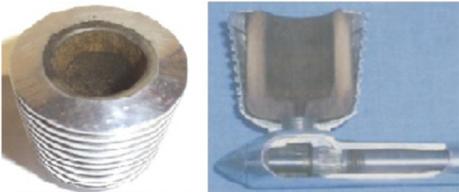

I took a close-up photo of the rim to show the damage to the inner edge and the build up and the marks on the surface. It would clean up nicely but some of the damage would take some finesse to blend into the rim. The stem was interesting in that it had a tube that ran from the button all the way into the bottom of the bowl. It was not removable so it had to be clean in place. It did function well and the shank was actually cleaner than I had anticipated.

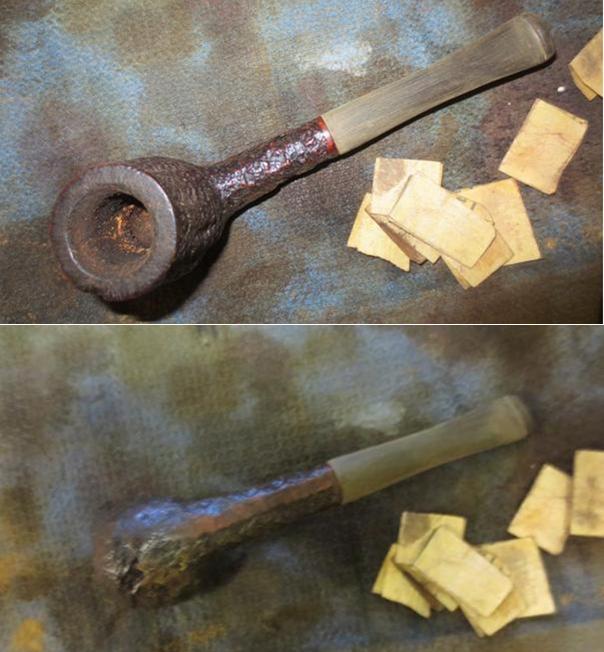

The stem was interesting in that it had a tube that ran from the button all the way into the bottom of the bowl. It was not removable so it had to be clean in place. It did function well and the shank was actually cleaner than I had anticipated. I reamed the bowl with the Savinelli Pipe Knife and took the cake back to bare briar. I also used the knife to clean up the inner edge of the rim. I sanded the bowl with a rolled piece of 220 grit sandpaper to smooth out the inner edge and the bowl interior.

I reamed the bowl with the Savinelli Pipe Knife and took the cake back to bare briar. I also used the knife to clean up the inner edge of the rim. I sanded the bowl with a rolled piece of 220 grit sandpaper to smooth out the inner edge and the bowl interior. I scraped the rim surface with a pen knife and then scrubbed it with saliva and cotton pads until I removed all of the tars and oil that had accumulated there.

I scraped the rim surface with a pen knife and then scrubbed it with saliva and cotton pads until I removed all of the tars and oil that had accumulated there. I scrubbed the inside of the mortise and airway with cotton swabs and alcohol and found that I removed more stain from the inside than tars. The inner tube had actually worked very well in keeping the bowl and shank clean.

I scrubbed the inside of the mortise and airway with cotton swabs and alcohol and found that I removed more stain from the inside than tars. The inner tube had actually worked very well in keeping the bowl and shank clean. The stem was another story. The tars had accumulated quite thickly inside the inner tube and collected at the end of the tube just before the slot in the button. It took many pipe cleaners and much alcohol to get rid of the accumulated debris in the tube and slot.

The stem was another story. The tars had accumulated quite thickly inside the inner tube and collected at the end of the tube just before the slot in the button. It took many pipe cleaners and much alcohol to get rid of the accumulated debris in the tube and slot. I sanded the tube with 0000 steel wool and then the stem with 220 grit sandpaper to remove the tooth chatter and the surface oxidation.

I sanded the tube with 0000 steel wool and then the stem with 220 grit sandpaper to remove the tooth chatter and the surface oxidation. I wet sanded the stem with 1500-2400 grit micromesh sanding pads and gave the stem a coat of Obsidian Oil. I dry sanded it with 320-4000 grit pads and gave it another coat of oil. I finished sanding it with 6000-12000 grit pads and gave it a final coat of Obsidian Oil and set it aside to dry.

I wet sanded the stem with 1500-2400 grit micromesh sanding pads and gave the stem a coat of Obsidian Oil. I dry sanded it with 320-4000 grit pads and gave it another coat of oil. I finished sanding it with 6000-12000 grit pads and gave it a final coat of Obsidian Oil and set it aside to dry.

I sanded the entire bowl with 6000-12000 grit micromesh sanding pads and then buffed the bowl and stem with Blue Diamond. I gave the bowl and stem multiple coats of carnauba wax and buffed it with a clean buffing pad. I finished the buffing by hand with a microfibre cloth. The finished pipe is shown in the photos below. Can anyone help me with the ALKO brand? I am wondering if it is not an Eastern European brand. Thanks for looking.

I sanded the entire bowl with 6000-12000 grit micromesh sanding pads and then buffed the bowl and stem with Blue Diamond. I gave the bowl and stem multiple coats of carnauba wax and buffed it with a clean buffing pad. I finished the buffing by hand with a microfibre cloth. The finished pipe is shown in the photos below. Can anyone help me with the ALKO brand? I am wondering if it is not an Eastern European brand. Thanks for looking.

![thumbnail_20160709_144214-1_resized[1]](https://rebornpipes.com/wp-content/uploads/2016/06/thumbnail_20160709_144214-1_resized1.jpg?w=625&h=313)

![thumbnail_20160709_144222-1_resized[1]](https://rebornpipes.com/wp-content/uploads/2016/06/thumbnail_20160709_144222-1_resized1.jpg?w=625&h=682)

![thumbnail_20160709_144234-1_resized[1]](https://rebornpipes.com/wp-content/uploads/2016/06/thumbnail_20160709_144234-1_resized1.jpg?w=625&h=651)

![thumbnail_20160709_144253-1_resized[1]](https://rebornpipes.com/wp-content/uploads/2016/06/thumbnail_20160709_144253-1_resized1.jpg?w=625&h=683)

![thumbnail_20160709_144305-1_resized[1]](https://rebornpipes.com/wp-content/uploads/2016/06/thumbnail_20160709_144305-1_resized1.jpg?w=625&h=568)