Blog by Eric Boehm

This collated information was collected by Eric Boehm and Permission was granted to include it here on the blog. Many thanks to Eric for the information he has collected for us.

Briar & Leaf Followers,

For years, I have been interested in collecting and smoking Dunhill pipes. During this time, I have been an avid follower of the late John C. Loring, his collections, and his writings on the subject of Dunhill pipes. I have also tried to collect all of the published Dunhill catalogs. Despite the occasional listings of Dunhill pipe shapes in various catalogs, books and on the web, I had yet to come across a single complete list of published Dunhill pipe shapes. Thus, the impetus for the current listings.

The tables below follow a set pattern for each shape entry. First, the shape category is listed in bold, then, for each entry, I have provided the shape number, a short descriptor, group number estimate, size (inches), catalog presence, and the modern shape number equivalent.

Shape Descriptor Group Size Catalog(s) Modern #

Billiards

31 Billiard, tapered bit 1 4¾” 1928, 1950 3

32 Billiard, tapered bit 1 5″ 1928, 50, 60, 69 3

34 Billiard, tapered bit (Dental) 2 5½” 1928, 50, 60, 69 3

35 Billiard, tapered bit (Dental) 3 5½” 1928, 50, 60, 69 3

35 Airstream billiard, tapered 3 5″ 1950, 1969 3

39 Billiard, saddle bit 3 5½” 1950, 1969 3

41 Billiard, tapered bit 1928 3

44 Billiard, oval shank, tapered 3 5¾ 1928, 50, 60, 69 3

57 Army mount billiard 3 6½” 1928, 50, 69 3

59 Billiard, tapered bit 4 5¾” 1928, 50, 69 3

60 Billiard, tapered bit 4 5½” 1928, 50, 60, 69 3

59 Bamboo billiard 4 5¾” 1950, 1969 3

60 Bamboo billiard 4 5½” 1950, 1969 3

59 Airstream billiard, tapered bit 4 5¾” 1950, 1969 3

60 Airstream billiard (Dental) 4 5½” 1950 3

64 Billiard, tapered bit 1 5½” 1950, 1969 3

66 Billiard, tapered, stand-up 1928

70 Army mount billiard 2 1928, 50, 69 3

72 Billiard, canted, oval, tapered 1928

92 Army mount billiard 4 1950, 1969 3

94 Army mount billiard (Dublin?) 1928

104 Billiard, canted, oval, tapered 4 5½” 1928,1950, 1969 3

105 Billiard, tapered bit 1 5¼” 1950, 1969 3

111 Billiard, tapered bit 3 5¼” 1950, 1960, 1969 3

113 Billiard, long tapered bit 2 5½” 1928, 50, 60, 69 3

114 Billiard, extended tapered bit 1 5¼” 1928, 50, 69 3

116 Billiard, extended tapered bit 1928

126 Billiard, tapered bit 1928

131 Billiard, diamond shank, tapered 1928

164 Billiard, tapered, stand-up 1928

171 Billiard, tapered, stand-up 1928

196 Billiard, tapered bit 4 5½” 1928, 1950, 1969 3

197 Billiard, extended tapered bit 4 6½” 1950, 1969 3

248 Billiard, tapered bit 1 5¼” 1950, 1960, 1969 3

249 Billiard, tapered bit 1 5¾” 1950, 1969 3

250 Billiard, long tapered bit 2 5¾” 1960, 1969 3

250 The Windscreen Pipe 2 5¾” 1960 3

251 Billiard, tapered bit (Relief bit) 3 5¾” 1950 3

251 Airstream billiard, tapered bit 4 5¾” 1950 3

251 The Windscreen Pipe 5 5¾” 1950, 1969

252 Billiard, tapered bit 4 5¾” 1950, 1969 3

253 Billiard, tapered bit 4 57/8″ 1950, 1969 3

260 Billiard, tapered bit 2 5½” 1950, 1969 3

305 Riding or Sport 2 3¼ 1928, 1950, 1969 3

332 Billiard, canted, oval 1928

335 Billiard, canted, oval 1928

576 Billiard, saddle bit 1 5″ 1950, 1960, 1969 3

577 Billiard, saddle bit 2 4¾” 1950, 60 (5″), 69 3

632 Billiard, saddle bit 1 5¼” 1950, 1969 3

634 Billiard, saddle bit 2 5¼” 1950, 1969 3

635 Billiard, saddle bit 3 5¾” 1950, 1969 3

635 The Windscreen Pipe 3 1969 3

659 Billiard, saddle bit 4 5½” 1950, 1969 3

660 Billiard, saddle bit 4 5½” 1950, 1969 3

710 Billiard, tapered bit 4 5½” 1950, 1969 3

715 Scandinavian billiard 2 5″ 1950, 1969 3

LB Billiard, large, tapered bit 4 5¾” 1928, 1950, 1969 3

LBS Billiard, large, tapered bit 4 6½” 1950, 1969 3

Bent Billiards

50 Bent billiard army shank 1928 2

51 Bent billiard army shank 1928 2

52 Bent billiard, short cut bowl 1928 2

53 Bent billiard 3 5¼” 1928, 50, 60, 69 2

53 Bent Windscreen Pipe 3 1969

54 Bent billiard 2 4¾” 1928, 1950, 1969 2

56 Bent billiard 4 5½” 1928, 50, 60, 69 2

120 Bent billiard, large 4 6″ 1950, 1969 2

121 Bent billiard, oval shank 2

132 Bent billiard, straight sided bowl, 1928 2

306 Bent billiard, large round brandy 1928 2

321 Bent billiard, large flat bowl, 2

329 Bent billiard, large round apple bowl 1928 2

LC Bent billiard, very large, quaint shape 1928 2

Apples

67 Apple triangular shank stand-up, angled tapered bit 1928 1

85 Apple, round shank, reg. tapered bit 1928 1

97 Army mounts (silver) straight apple 1928 1

98 Army mounts (silver) straight apple 1928 1

107 Apple, tapered bit 3 5¼ 1928, 1950, 1969 1

110 Apple, long tapered bit 1 5½” 1928, 1950, 1960 1

112 Apple, tapered bit 2 5¾” 1928, 1950, 1960 1

115 Apple, canted, extended tapered 1928 1

191 Apple, beveled, short shank, extended tapered bit 1928 1

256 Apple, long saddle bit 2 5¼” 1950, 1960 1

308 Apple Army Mount (Silver) push bit 1928 1

309 Apple Army Mount (Silver) push bit 1928 1

310 Apple Army Mount (Silver) push bit 1928 1

311 Apple Army Mount (Silver) push bit 1928 1

376 Apple, bowl canted forward, extended tapered bit 1928 1

K Apple, tapered bit 4 5¼” 1950, 1960 1

Pots

463 Pot, long tapered bit 2 5¾” 1950, 1960, 1969 6

501 Pot, tapered bit 3 5¾” 1950, 1969 6

R Pot, tapered bit, “Quaint” 4 5¼” 1928, 50, 60, 69 6

Princes

258 Prince, apple-like, long straight

tapered bit 1 5¾” 1950, 1960, 1969 7

314 Prince, slightly bent tapered 2 6¼” 1950, 1969 7

315 Prince, straight tapered bit 2 6¼” 1950, 1969 7

FE Prince, large, squat apple-like bowl (Quaint in 1928) 4 6½” 1928, 1950, 1969 7

FET Prince (upright) large squat applelike bowl (Quaint in 1928) 4 6¼” 1928, 50, 60, 69 7

Canadians

335 Canadian, oval shank, short tapered bit 3 5¾” 1928, 1950, 1969 9

EC Canadian, oval shank, short tapered bit (Quaint in 1928) 4 5½” 1928, 1950, 1969 9

850 Canadian, over-sized OD850, Giant, short tapered bit 8¾ 1950, 1969 9

Liverpools

33 Liverpool, tapered 2 5¼” 1928, 50, 60, 69 10

36 Liverpool, large, tapered 4 5½” 1928, 50, 60, 69 10

331 Liverpool, long shank, tapered 3 6″ 1950, 1969 10

Lovats

37 Lovat, short, thick, saddle 1928 11

38 Lovat, long shank, saddle bit 3 4¾” 1928, 50, 60, 69 11

40 Lovat, long shank, saddle bit 4 5″ 1928, 1950, 1969 11

481 Lovat, long shank, saddle bit 1 5″ 1950, 1969 11

Dublins

42 Dublin, tapered bit 3 5½” 1928, 50, 60, 69 5

43 Dublin, tapered bit 2 4¾” 1928, 50, 69 5

65 Dublin, tapered bit 1928

73 Dublin, tapered bit 1928

77 Dublin, tapered bit 1928

130 Dublin, long tapered bit 1 6¼” 1928, 1950, 1969 5

137 Dublin, long tapered bit 4 6¼” 1950, 1969 5

140 Dublin, peg, round shank 1928

142 Dublin, tapered bit 4 5¾ 1928, 1950, 1969 5

143 Dublin, long tapered bit 1928

178 Dublin full bent 1928

Bulldogs & Rhodesians

45 Bulldog, ringed, diamond shank, straight saddle 1928 4

46 Bulldog, +/- ringed, diamond shank, straight tapered 2 5″ 1950, 1960, 1969 4

47 Bulldog, +/- ringed, diamond shank, straight tapered 3 5″ 1928, 1950, 1969 4

48 Bulldog, +/- ringed, diamond shank, straight saddle 4 5¼” 1928, 50, 60, 69 4

OX Bulldog, ringed, diamond shank, straight saddle 4 5¼” 1928, 50, 69 4

69 Bulldog, ringed, diamond shank, short saddle bit 1928 4

88 Bulldog, non-ringed, diamond shank, tapered bit 1928 4

146 Bulldog, ringed, diamond shank, slight bent tapered bit 1928 4

148 Bulldog, ringed, diamond shank, straight saddle 3 5¼” 1950, 1969 4

156 Bulldog, ringed, diamond shank, tapered bit 1928 4

189 Bulldog, non-ringed, large, tall bowl, diamond shank, tapered bit 1928 4

190 Bulldog, non-ringed, large, short bevelled bowl, diamond shank, tapered 1928 4

721 Scandinavian Bulldog, elevated bowl, 3-ringed, extended bent, saddle bit 5¼” 1950, 1969

?O Straight Rhodesian, ringed, diamond shank, tapered bit 4 5″ 1928, 50, 60, 69 17

P Bent Rhodesian, ringed, diamond shank, tapered bent bit 4 5¾” 1928, 50, 69 8

PO Rhodesian, slightly bent, tapered, non-ringed 3 51/2 ? ?

6P Bent Rhodesian, ringed, diamond shank, bent saddle bit 5½” 1960 8

145 Straight Rhodesian, ringed, short diamond shank, tapered bit 1928 17

334 Bent Rhodesian, ringed, diamond shank, bent saddle bit 1928 8

344 Rhodesian, ringed, squat bowl, diamond shank, extended bent tapered bit (Prince) 1928 7?

580 Straight Rhodesian, non-ringed, squat bowl, saddle bit 4 1969 17

Pokers

90 Poker “Stand-up” 2 4¾” 1928, 1950, 1969 22

95 Poker “Stand-up” Army bit 1928

475 Friendly 4 5½” 1960

6475 Friendly (=475?) 4 5½” 1950, 1969

483 Poker with cane stem 6½ 1960

Zulus

49 Zulu, straight round stem, tapered bit 1928 21

83 Zulu, oval shank, slightly bent tapered bit 3 5½” 1928, 1950, 1969 21

Miscellaneous

320 Evening Dress (Pot) 4 4½” 1950, 1960, 1969

misc. Dri-way billiard (screw bowl) 4 5¼” 1950, 1960

misc. Cavalier shape 4 6¼” 1950, 1960

misc. Calabash 7″ 1950

misc. Churchwarden 4 10¼” 1950, 1960

misc. “The Bamboo Bent”, bent saddle bit 7½” 1960

misc. “The Bijou”, small bowl, long tapered bit 5″ 1960

misc. Leather covered 4 1950, 1969

Letter Shapes

SS “Quaint Shape” Billiard hexagonal shank & tapered bit 1928

EC “Quaint Shape” Canadian, oval shank, short tapered bit 1928

FR “Quaint Shape” Octagonal panel billiard, round shank, extended tapered bit 1928

OE “Quaint Shape” Octagonal panel billiard, square shank, angled tapered bit 1928

EK “Quaint Shape” Hexagonal panel billiard, square shank, angled tapered bit “Stand-up” 1928

VT “Quaint Shape” tirangular panel billiard, tirangular shank and bit “Stand-up” 1928

SA “Quaint Shape” octogonal tall panel billiard, hexagonal shank, angled bit “Stand-up” 1928

GD “Quaint Shape” Circular tall billiard, ringed low at bowl base, round shank and bit 1928

PK “Quaint Shape” Four sided panel billiard, diamond shank and bit 1928

PL “Quaint Shape” Four sided panel billiard,triangular shank and bit 1928

EL “Quaint Shape” Four sided panel billiard, triangular shank and bit 1928

FJ “Quaint Shape” Cutty, canted round bowl, extended tapered bit 1928

KS “Quaint Shape” Apple, flattened bowl support peg “Stand-up” 1928

K “Quaint Shape” Round Apple, converging rim, round shank, tapered bit 1928

FE “Quaint Shape” Apple, large squat bowl, round shank, extended tapered bit 1928

FET “Quaint Shape” Apple, large squat bowl, round shank, extended tapered bit 1928

E “Quaint Shape” Army mount (silver) large squat bowl, round shank, extended tapered bit 1928

ET “Quaint Shape” Army mount (silver) large squat bowl, round shank, extended tapered bit 1928

EK Paneled billiard 1950, 1969

343 Inverted low-slung bowl, narrow rim, round shank and tapered bit 1928

ODA Shapes (From: John C. Loring, http://loringpage.com/pipearticles/ODchart.htm)

801 Belge, Cocked bowl (5) large for shape – early dating, rare

802 Bent Antique, spur (4) ‘70s/’80s with non ODA #s – early dating, rare

803 Odd Bent (4) – early dating, rare

804 Odd Bent (4) – early dating, rare

805 Skater (4) CH shape – early dating, rare

806 Apple, Tapered Bit

818 Oom Paul (5) – early dating, rare

821 Danish Bent (4) ‘70s/’80s with non ODA #s – early dating, rare

824 Brandy Glass – early dating, rare

827 Rhodesian, Small – early dating, rare

830 Liverpool – early dating extremely rare

831 Bent, Cocked bowl (4) ‘70s/’80s with non ODA #s – early dating, rare

832 Lovat – early dating quite rare

833 Danish Style Bent – early dating, rare

834 Prince – early dating quite rare

835 Billiard, Tapered Bit

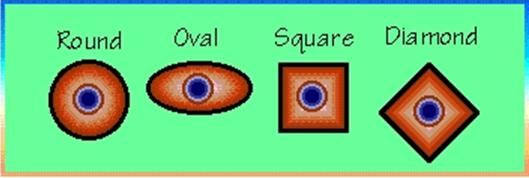

836 Square Panel

837 Bulldog

838 Straight Rhodesian – early dating, rare

839 Qtr Bent Rhodesian – early dating, rare

840 Bent Billiard – (= 846?) early dating, rare

841 Lovat – early dating, rare

842 Apple, Saddle Bit –early dating, rare- (later stamped 6806)

843 Billiard, Saddle Bit -early dating, rare – (later stamped 6835)

844 Poker – early dating , rare

845 Canadian, Large Bowl

846 Bent Apple, Saddle – (= 840?) early dating rare

847 Rhodesian, Quarter Bent, Round Shank – early dating, rare

848 Dublin

849 Stacked Billiard – less thin & shorter than 856 – early dating, rare

850 Canadian, Small Bowl

851 Canadian, Small Bowl, Extra Long – early dating, rare

853 Pot – early dating rare

854 Rhodesian, Full Bent – early dating, rare

855 Canadian, Large Bowl, Extra Long – early dating, rare

856 Stack Billiard – is thinner & taller then the 856 – early dating, rare

857 Bent Brandy – early dating quite rare

861 Angled Squat Panel Bowl, Tapered Square Shank – early dating, rare

862 Dublin Panel – early dating, rare

863 Squat Panel, Front Bottom Curve (4) – early dating extremely rare

865 Angled Convex Rectangular Panel (5) – ‘70s/’80s in Shell finish, rare

866 Square Bowl (4) – early dating, rare