Blog by Steve Laug

On Friday a fellow from my local pipe shop called and said that he was bringing a pipe by for repair. He had a pipe that he had bitten through on the top side of the stem. He said he would leave it for me to work on. I have been having the shop drop their repairs off in my mail box. When my daughter picked this one up she was blown away by the heavy vanilla aromatic smell that filled the mail box and wafted from the pipe wherever it was. She brought it to my basement work table for me to see. This is what I saw.

It was obviously a well smoked pipe that the pipeman must have really loved. It had a thick cake in the bowl and heavy overflow of lava on the rim top that was also very thick. The inner edge of the bowl was also thickly caked. The photos I took of the stem are also very clear. There were tooth marks and chatter on both sides of the acrylic stem and a small bit through on the topside of the stem. Fortunately it was not too big a bit through so it was repairable.

It was obviously a well smoked pipe that the pipeman must have really loved. It had a thick cake in the bowl and heavy overflow of lava on the rim top that was also very thick. The inner edge of the bowl was also thickly caked. The photos I took of the stem are also very clear. There were tooth marks and chatter on both sides of the acrylic stem and a small bit through on the topside of the stem. Fortunately it was not too big a bit through so it was repairable. I took a photo of the stamping on the shank and it read Stanwell [over] Made in Denmark [over] Calabash in script. The brass decorative band was dull and oxidized.

I took a photo of the stamping on the shank and it read Stanwell [over] Made in Denmark [over] Calabash in script. The brass decorative band was dull and oxidized. I took the stem off the shank and took photos of the pipe. The first photo below shows the pipe in profile and shows the bite through very clearly. The second photo shows the end of the tenon and how clogged it was with the tars and oils. My first thoughts were that it had an adapter in the tenon to fill it and convert it to a non-filter pipe. Once I cleaned it up it was clear that it was a regular tenon with a slight inset.

I took the stem off the shank and took photos of the pipe. The first photo below shows the pipe in profile and shows the bite through very clearly. The second photo shows the end of the tenon and how clogged it was with the tars and oils. My first thoughts were that it had an adapter in the tenon to fill it and convert it to a non-filter pipe. Once I cleaned it up it was clear that it was a regular tenon with a slight inset. I like working on clean pipes so I reamed the bowl with three of the four cutting heads on the PipNet Pipe Reaming set. The bowl is conical so it took all three heads to remove the cake from the bowl. I cleaned up the remnants of cake with a Savinelli Fitsall Pipe Knife. I also scraped the calabash rim top with the knife to remove the lava.

I like working on clean pipes so I reamed the bowl with three of the four cutting heads on the PipNet Pipe Reaming set. The bowl is conical so it took all three heads to remove the cake from the bowl. I cleaned up the remnants of cake with a Savinelli Fitsall Pipe Knife. I also scraped the calabash rim top with the knife to remove the lava.

I cleaned out the internals of the shank and stem with pipe cleaners, cotton swabs and alcohol. I worked them over until the inside of the pipe was clean.

I cleaned out the internals of the shank and stem with pipe cleaners, cotton swabs and alcohol. I worked them over until the inside of the pipe was clean. I scrubbed the exterior of the bowl and rim with a tooth brush and Murphy’s Oil Soap. I scrubbed the buildup on the rim top with the soap and tooth brush and was able to remove it all from the calabash top. I rinsed it off with running water and dried the pipe with a cotton cloth.

I scrubbed the exterior of the bowl and rim with a tooth brush and Murphy’s Oil Soap. I scrubbed the buildup on the rim top with the soap and tooth brush and was able to remove it all from the calabash top. I rinsed it off with running water and dried the pipe with a cotton cloth.

I polished the smooth calabash rim top with micromesh sanding pads – 1500-12000 grit pads. I wiped the rim top down with a damp cloth after each sanding pad. The rim top began to look very good as it took on its shine.

I polished the smooth calabash rim top with micromesh sanding pads – 1500-12000 grit pads. I wiped the rim top down with a damp cloth after each sanding pad. The rim top began to look very good as it took on its shine.

I rubbed the bowl and rim top down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips and a horse hair shoe brush to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth and shoe brush to raise the shine. The Balm does a great job in bringing life to aged briar that has been cleaned.

I rubbed the bowl and rim top down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips and a horse hair shoe brush to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth and shoe brush to raise the shine. The Balm does a great job in bringing life to aged briar that has been cleaned.

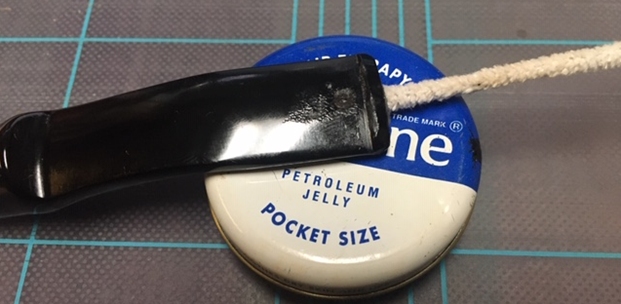

I set the bowl aside and went to work on the stem. I cleaned off the surface of the stem with alcohol to remove greases and oils from the acrylic. I wanted it clean and dry so I could do the repair. Once it was clean I greased a pipe cleaner with Vaseline and inserted it into the airway of the stem. The greased pipe cleaner keeps the glue from filling in the airway.

I set the bowl aside and went to work on the stem. I cleaned off the surface of the stem with alcohol to remove greases and oils from the acrylic. I wanted it clean and dry so I could do the repair. Once it was clean I greased a pipe cleaner with Vaseline and inserted it into the airway of the stem. The greased pipe cleaner keeps the glue from filling in the airway. Since the hole in the top of the stem was quite small I decided to use just black super glue to fill in the damaged spot. I also used it to fill in the tooth marks and the dents in the surface. I set the stem aside to let the repairs cure.

Since the hole in the top of the stem was quite small I decided to use just black super glue to fill in the damaged spot. I also used it to fill in the tooth marks and the dents in the surface. I set the stem aside to let the repairs cure. Once the repair cured I used a needle file to smooth out the repaired areas. I also cut the edges of the button on both sides and smooth it out. I would need to do a lot of sanding to blend it in but it would certainly look better. I sanded it with a folded piece of 220 grit sandpaper to smooth it out. I started the polishing with a folded piece of 400 grit wet dry sandpaper.

Once the repair cured I used a needle file to smooth out the repaired areas. I also cut the edges of the button on both sides and smooth it out. I would need to do a lot of sanding to blend it in but it would certainly look better. I sanded it with a folded piece of 220 grit sandpaper to smooth it out. I started the polishing with a folded piece of 400 grit wet dry sandpaper.

I polished the acrylic stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the acrylic stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

The repairs and restoration of the Stanwell Calabash turned out really well. The mix of brown stains highlights the sandblasted grain around the bowl sides as well as the smooth calabash rim top. The finish on the pipe is in excellent condition and the contrasting stains work well with the polished acrylic saddle stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Stanwell Calabash fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ¾ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. I am looking forward to hearing what the pipeman who dropped it off thinks of it when he picks it up. It should continue to serve him well. Thanks for reading this blog and my reflections on the pipe while I worked on it. This is an interesting pipe to bring back to life.

The repairs and restoration of the Stanwell Calabash turned out really well. The mix of brown stains highlights the sandblasted grain around the bowl sides as well as the smooth calabash rim top. The finish on the pipe is in excellent condition and the contrasting stains work well with the polished acrylic saddle stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Stanwell Calabash fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ¾ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. I am looking forward to hearing what the pipeman who dropped it off thinks of it when he picks it up. It should continue to serve him well. Thanks for reading this blog and my reflections on the pipe while I worked on it. This is an interesting pipe to bring back to life.