by Kenneth Lieblich

Next on the old chopping block is a wonderful Savinelli Dry System 3621 Bent Dublin. It’s a really good-looking pipe and I understand that this is a popular and well-loved series. I got it recently in a lot of pipes and it called out to me for some help. I suppose this pipe is meant to be reminiscent of the Peterson system pipes – it even has a sort of P-lip button! It’s a terrific-looking pipe, with a bit of a rough history.

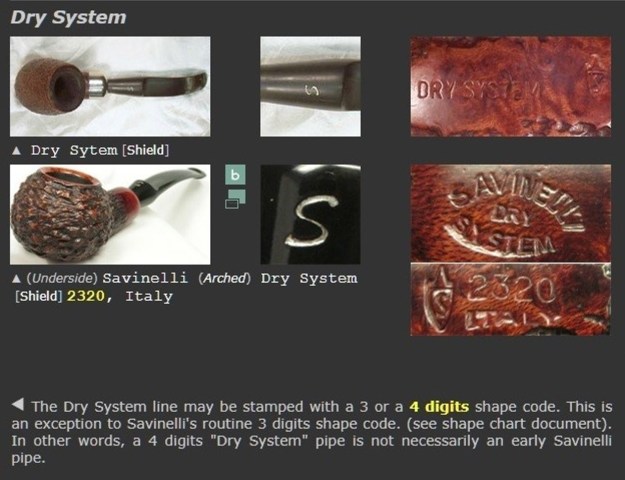

The main markings of the pipe are on the underside of the stummel. On the left it reads Savinelli [over] Dry [over] System. Next to that is the Savinelli crown and “S” logo. And next to that is 3621 [over] Italy. The shank has a nickel cap with Savinelli stamped on it. Finally, the stem has a worn, but still readable, stylized “S” on the top.

The main markings of the pipe are on the underside of the stummel. On the left it reads Savinelli [over] Dry [over] System. Next to that is the Savinelli crown and “S” logo. And next to that is 3621 [over] Italy. The shank has a nickel cap with Savinelli stamped on it. Finally, the stem has a worn, but still readable, stylized “S” on the top. Savinelli is one of the most recognized names in pipe smoking and they have a long and storied history. You can read about them from their own website or from Pipedia’s article about them. However, I was particularly interested in learning more about the Dry System. Sadly, Pipedia had nothing on this subject. I checked with Pipephil and they did have a bit of information which I provide here below:

Savinelli is one of the most recognized names in pipe smoking and they have a long and storied history. You can read about them from their own website or from Pipedia’s article about them. However, I was particularly interested in learning more about the Dry System. Sadly, Pipedia had nothing on this subject. I checked with Pipephil and they did have a bit of information which I provide here below:

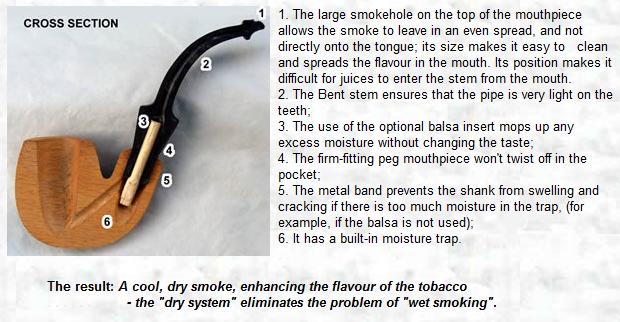

However, the definitive word on the Dry System comes from Savinelli’s own website. It provided some very useful information.

However, the definitive word on the Dry System comes from Savinelli’s own website. It provided some very useful information.

In 1981, after several years of research, Savinelli launched the “Dry System”, combining trap and filter. The name “Dry” comes from the introduction of the balsa “filter” into the traditional system pipe – the “System” being the presence of the built-in moisture trap in the shank. The balsa mops up the moisture in the smoke hence the term “Dry” system, and if the pipe is smoked without the balsa all that will happen is that this moisture will condense and collect in the trap. It can then either be mopped up with a folded pipe cleaner, or flicked out.

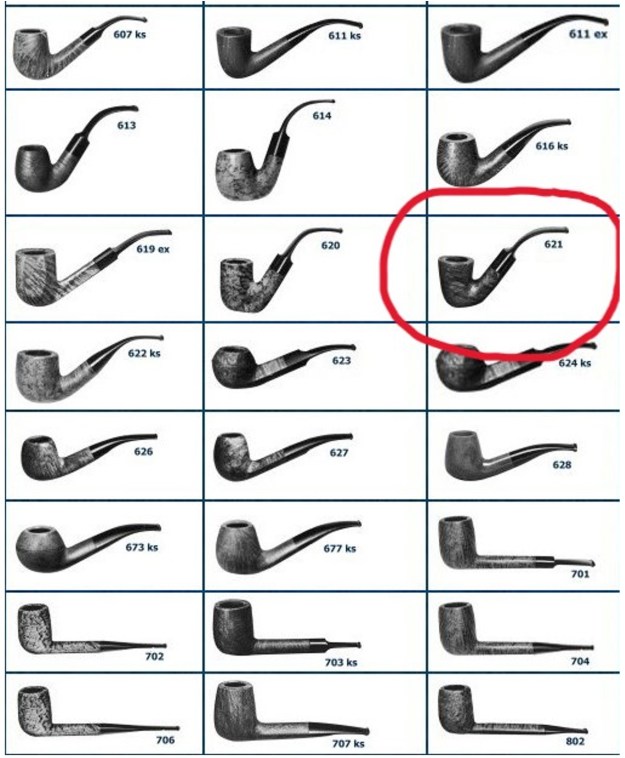

Finally, here’s an image of the pipe from an old Savinelli shape chart: This was obviously a terrific smoker, as the wear and tear on this pipe shows. The stummel was quite dirty – both inside and out – and even appeared to have some dust-bunnies inside the bowl (not to mention all the cake). The finish was well worn and would need to be addressed. The nickel cap had some mess on it too. The stem, however, was from another planet. Have you ever seen such oxidation on a pipe stem? In fact, my wife asked me if the stem was actually meant to be brown. “No” was my emphatic answer! Aside from that, the stem had some tooth marks and nicks. I could tell that this stem was going to be a bear to deal with.

This was obviously a terrific smoker, as the wear and tear on this pipe shows. The stummel was quite dirty – both inside and out – and even appeared to have some dust-bunnies inside the bowl (not to mention all the cake). The finish was well worn and would need to be addressed. The nickel cap had some mess on it too. The stem, however, was from another planet. Have you ever seen such oxidation on a pipe stem? In fact, my wife asked me if the stem was actually meant to be brown. “No” was my emphatic answer! Aside from that, the stem had some tooth marks and nicks. I could tell that this stem was going to be a bear to deal with.

This pipe is always going to retain some marks from its hard life, but it is my job to make sure this pipe looks as good as possible. It’s a wonderful pipe and it deserves to be part of someone’s collection again.

This pipe is always going to retain some marks from its hard life, but it is my job to make sure this pipe looks as good as possible. It’s a wonderful pipe and it deserves to be part of someone’s collection again.

The stem is going to take a lot of work, so let’s get started. I took up the stem and cleaned it off with Murphy’s Oil Soap. It was quite dirty and needed some scrubbing. I then cleaned out the insides of the stem with pipe cleaners and lemon-infused isopropyl alcohol, and, as you can see, if was pretty dirty inside. I also took a BIC lighter and ‘painted’ the stem with its flame in order to lift the tooth marks. This was only moderately successful in raising the dents. Now to tackle the epic oxidation. Next, I scrubbed (and scrubbed and scrubbed) the stem with some SoftScrub cleanser and then put the stem in my container of deoxidizing fluid overnight. This works to draw the oxidation to the surface of the stem, so that it can be cleaned off again with more SoftScrub. As you can see, this worked in the sense that it drew out the oxidation, but there remained a lot of labour ahead. In fact, I repeated the process of scrubbing and soaking overnight, because the situation was so dire. Eventually, I got to a point where the stem was something I could work with.

Now to tackle the epic oxidation. Next, I scrubbed (and scrubbed and scrubbed) the stem with some SoftScrub cleanser and then put the stem in my container of deoxidizing fluid overnight. This works to draw the oxidation to the surface of the stem, so that it can be cleaned off again with more SoftScrub. As you can see, this worked in the sense that it drew out the oxidation, but there remained a lot of labour ahead. In fact, I repeated the process of scrubbing and soaking overnight, because the situation was so dire. Eventually, I got to a point where the stem was something I could work with.

Before I moved on to sanding, I built up the tooth marks on the stem with black cyanoacrylate adhesive and let them fully cure. I then sanded them down with sandpapers to merge a bit better into the stem. I also added some nail polish to the ‘S’ on the stem.

Before I moved on to sanding, I built up the tooth marks on the stem with black cyanoacrylate adhesive and let them fully cure. I then sanded them down with sandpapers to merge a bit better into the stem. I also added some nail polish to the ‘S’ on the stem.

At this point, it was clear that more than the ‘usual’ sanding was going to be required here. I took two sanding sponges (220- and 320-grit) and worked the stem hard. I needed to sand out the remaining oxidation to get this stem the best chance of looking decent again. I then used all nine Micromesh pads (1,500 through 12,000 grit) to bring out the lovely black lustre. I also used Obsidian Pipe Stem Oil in between each pad scrubbing. As I mentioned before, there are still hints of its past life, but I’m pretty pleased with how the stem came out.

At this point, it was clear that more than the ‘usual’ sanding was going to be required here. I took two sanding sponges (220- and 320-grit) and worked the stem hard. I needed to sand out the remaining oxidation to get this stem the best chance of looking decent again. I then used all nine Micromesh pads (1,500 through 12,000 grit) to bring out the lovely black lustre. I also used Obsidian Pipe Stem Oil in between each pad scrubbing. As I mentioned before, there are still hints of its past life, but I’m pretty pleased with how the stem came out.

On to the stummel and the usual cleaning procedures were in order for this pipe. I used the KleenReem to remove the cake in the bowl and I followed up by sanding the walls down with some 220-grit sandpaper attached to a wooden dowel. I took it down to bare briar, as I wanted to see if there were any issues in the walls of the bowl. There was some charring and some slight fissures, but nothing serious. I then proceeded to clean out the insides of the shank with Q-tips, pipe cleaners, and isopropyl alcohol. There was some nastiness inside this stummel and it took a lot of cotton to get this thing clean.

On to the stummel and the usual cleaning procedures were in order for this pipe. I used the KleenReem to remove the cake in the bowl and I followed up by sanding the walls down with some 220-grit sandpaper attached to a wooden dowel. I took it down to bare briar, as I wanted to see if there were any issues in the walls of the bowl. There was some charring and some slight fissures, but nothing serious. I then proceeded to clean out the insides of the shank with Q-tips, pipe cleaners, and isopropyl alcohol. There was some nastiness inside this stummel and it took a lot of cotton to get this thing clean.

I decided to de-ghost the bowl to be on the safe side. I thrust some cotton balls into the bowl and the shank and saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused any remaining oils, tars and smells to leach out into the cotton.

I decided to de-ghost the bowl to be on the safe side. I thrust some cotton balls into the bowl and the shank and saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused any remaining oils, tars and smells to leach out into the cotton. I then moved on to cleaning the outside of the stummel with Murphy’s Oil Soap and a toothbrush. What a difference that made! I followed that up by cleaning the insides with some dish soap and tube brushes.

I then moved on to cleaning the outside of the stummel with Murphy’s Oil Soap and a toothbrush. What a difference that made! I followed that up by cleaning the insides with some dish soap and tube brushes.

As I mentioned earlier, there were some minor issues to fix inside the bowl. The solution to this problem is an excellent one: epoxy. I prepared some J.B. Weld epoxy and smeared the walls, ensuring that the epoxy was evenly spread. Once done, a good 24 hours was needed to ensure that the epoxy was properly cured. After that, I gently sanded the inside of the bowl to provide a rough surface for what was to come later. I coated the entire inside of the bowl with a mixture of activated charcoal and my wife’s homemade yogurt. Once hardened, this provides a good, slightly rough surface for a new cake to build.

As I mentioned earlier, there were some minor issues to fix inside the bowl. The solution to this problem is an excellent one: epoxy. I prepared some J.B. Weld epoxy and smeared the walls, ensuring that the epoxy was evenly spread. Once done, a good 24 hours was needed to ensure that the epoxy was properly cured. After that, I gently sanded the inside of the bowl to provide a rough surface for what was to come later. I coated the entire inside of the bowl with a mixture of activated charcoal and my wife’s homemade yogurt. Once hardened, this provides a good, slightly rough surface for a new cake to build.

Due to the pipe’s hard life, it was clear to me that the pipe needed to be stained. I applied some Fiebing’s Dark Brown Leather Dye. I flamed it with a BIC lighter and let it set. I then removed the excess with isopropyl alcohol on a cotton round. It looked so much better after this.

Due to the pipe’s hard life, it was clear to me that the pipe needed to be stained. I applied some Fiebing’s Dark Brown Leather Dye. I flamed it with a BIC lighter and let it set. I then removed the excess with isopropyl alcohol on a cotton round. It looked so much better after this.

I then rubbed some Before & After Restoration Balm into the wood. I gently brushed it into the rustication grooves and let the balm sit for fifteen minutes or so. The BARB works so well at bringing out the best in the wood. I brushed it with a horsehair brush and buffed it with a microfibre cloth. Beauty!

I then rubbed some Before & After Restoration Balm into the wood. I gently brushed it into the rustication grooves and let the balm sit for fifteen minutes or so. The BARB works so well at bringing out the best in the wood. I brushed it with a horsehair brush and buffed it with a microfibre cloth. Beauty!

I rubbed the nickel band with 0000 steel wool. This is the least abrasive grade of steel wool and I wouldn’t use anything harsher than that. I then used a few MicroMesh pads to make the metal shine.

I rubbed the nickel band with 0000 steel wool. This is the least abrasive grade of steel wool and I wouldn’t use anything harsher than that. I then used a few MicroMesh pads to make the metal shine.

Later, I went to the bench buffer and applied some White Diamond to the stummel and stem. Then the final polish! The rusticated surface meant that I didn’t use carnauba wax – it gets gummed up in the grooves. Instead, I used Lee Valley Conservator’s Wax which worked like a charm.

Later, I went to the bench buffer and applied some White Diamond to the stummel and stem. Then the final polish! The rusticated surface meant that I didn’t use carnauba wax – it gets gummed up in the grooves. Instead, I used Lee Valley Conservator’s Wax which worked like a charm. This was a nifty restoration and I had fun with it. I think the result is terrific and it’s a very handsome pipe once again. I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the “Italy” pipe section of the store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the Savinelli Dry System 3621 Bent Dublin are as follows: length 5 in. (126 mm); height 4 in. (101 mm); bowl diameter 1⅜ in. (36 mm); chamber diameter ¾ in. (19 mm). The weight of the pipe is 1⅛ oz. (35 g). I hope you enjoyed reading the story of this restoration as much as I enjoyed restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.

This was a nifty restoration and I had fun with it. I think the result is terrific and it’s a very handsome pipe once again. I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the “Italy” pipe section of the store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the Savinelli Dry System 3621 Bent Dublin are as follows: length 5 in. (126 mm); height 4 in. (101 mm); bowl diameter 1⅜ in. (36 mm); chamber diameter ¾ in. (19 mm). The weight of the pipe is 1⅛ oz. (35 g). I hope you enjoyed reading the story of this restoration as much as I enjoyed restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.