Blog by Ryan Thibodeau

I have been following Ryan’s work on FaceBook’s Tobacco Pipe Restorers Group and have been impressed with his work. When he posted the work on this old Canadian stummel with a lot of issues I wrote and asked if he would be willing to post it on rebornpipes. He said sure and sent me the following write up. I am happy to welcome Ryan to the pages of the blog. It is a pleasure to have you here. Without further ado I will let Ryan introduce himself to you all. — Steve

My name is Ryan Thibodeau, I live in the Hamilton Ontario region I stumbled upon this hobby by accident. When my Father learned of my new hobby, he gave me his 1959 Dunhill shell briar pipes. They hadn’t been smoked in 38 years and needed some TLC. I had them restored and they were the first two pipes in my rack.

From there I joined various Facebook Groups and happened upon Steve’s blog “Reborn Pipes”, I was inspired immediately. Since that time I’ve been collecting tired worn out pipes and testing my ability to return them to a condition that I would be proud of. It is a wonderful hobby, that doesn’t require a lot of space to do.

Every pipe has a story! Usually the smoker who owned it, and their story, is more interesting than the pipe itself.

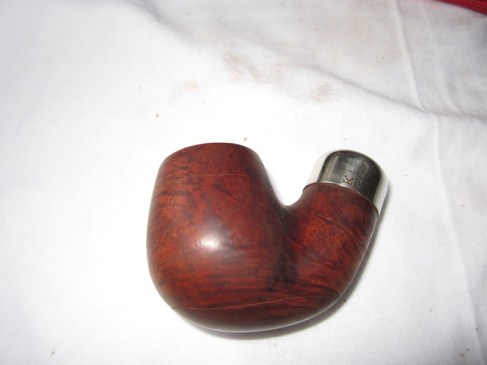

I purchased this pipe in a lot of 12. There were only one or two pipes in the lot that I really wanted and the price was right, so I wasn’t heartbroken if the rest came to rest in the bottom of my box of pipes. One of them came in a case that was meant for a meerschaum, and it looked decent when in the picture, but further investigation revealed a lot of issues that would need to be repaired.  I started by removing the silver band, which came off without any effort and used Heirloom Stripper to remove all the dirt, grime, old finish and lift some of the stain. This allowed me to get a real good look at the damage to this pipe.

I started by removing the silver band, which came off without any effort and used Heirloom Stripper to remove all the dirt, grime, old finish and lift some of the stain. This allowed me to get a real good look at the damage to this pipe.

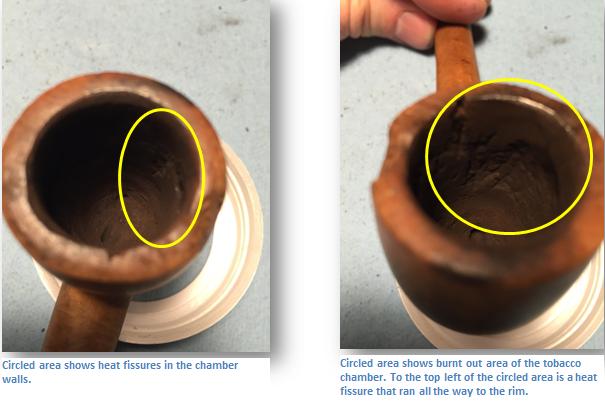

Next I used my Castleford reamer to remove all the cake out of the bowl. There was very little cake lining the bowl, however; once I removed the cake I found that walls of the tobacco chamber were severely charred. I suspect this pipe was smoked very hot and the briar was charred to charcoal. I wanted to see how much of the chamber was damaged ( I prefer to ream my bowls right back to fresh briar. This way I can see if there are any heat fissures or major issues that would make a restoration go sour after the first smoke)

Next I used my Castleford reamer to remove all the cake out of the bowl. There was very little cake lining the bowl, however; once I removed the cake I found that walls of the tobacco chamber were severely charred. I suspect this pipe was smoked very hot and the briar was charred to charcoal. I wanted to see how much of the chamber was damaged ( I prefer to ream my bowls right back to fresh briar. This way I can see if there are any heat fissures or major issues that would make a restoration go sour after the first smoke)

I removed the charred wood. The reamers will shave away the charred wood, once you feel the resistance of the blades rubbing the fresh briar you know you’ve removed the charring. I used a combination of Briar dust and CA Glue to create a patch for the gouge on the side of the bowl. Using a flat file, I filed the patch down to the profile of the pipe. Afterwards I topped the bowl to level out the rim and the patch. The bowl was also over reamed by its previous owner so I added a bevel to the inside of the bowl at the rim to blend everything in.

I used a combination of Briar dust and CA Glue to create a patch for the gouge on the side of the bowl. Using a flat file, I filed the patch down to the profile of the pipe. Afterwards I topped the bowl to level out the rim and the patch. The bowl was also over reamed by its previous owner so I added a bevel to the inside of the bowl at the rim to blend everything in.

There was a lot of filing and sanding through this process to get it just right. Unfortunately I get hyper focused during this process and forgot to take step-by-step pictures.

The grey patches you see inside the bowl is a product called JB Weld. I mixed up a batch and filled the problem areas in the chamber, afterwards I sanded it down to blend with the rest of the chamber. In my experience the product is completely inert once cured. It is handy for a reconstruction of this kind, but I’d recommend adding a bowl coating as an added barrier. This pipe came to me without a stem. Fortunately I had a stem that would be the perfect length, I just needed to shape the tenon to fit the pipe. For this I used the Pimo Tenon cutter from Vermont Freehand.

This pipe came to me without a stem. Fortunately I had a stem that would be the perfect length, I just needed to shape the tenon to fit the pipe. For this I used the Pimo Tenon cutter from Vermont Freehand.

I also used the opportunity while I was at this end of the pipe to drill a hole ahead of the crack in the shank and filled used briar dust and CA Glue. As sometimes happens with restorations, I thought I stopped the crack from spreading, well I was wrong and it continued from the patch further up the shank about ¼ of an inch. So I drilled another hole and patched it again. This time I seemed to have everything under control.

The stem was quite simple to shape to the profile of the pipe and was a welcome change from the frustrations of the other repairs that didn’t go according to plan.

Once I had all the parts and repairs completed. I sanded the entire pipe and stem with 320 grit sandpaper up to 8000 grit (1500-8000 with micro mesh pads)  Rustication

Rustication

At this point I had to consider how I was going to finish this pipe. Originally this was a smooth finish Canadian Billiard, but those days were long behind this tired old pipe. I originally thought of using a really dark stain to hide all the imperfections, polish it and call it a day, then I thought I’d take a risk and create something new, and breath new life into this pipe. For all the effort I put into this pipe up to this point I figured I’d let my creativity flow.

I decided that I would rusticate this pipe and leave a smooth patch somewhere, where I hadn’t determined yet. Using a Dremel and a 107 Carving bit I started to rusticate the shank and worked my way to the heel, then up the stummel. Halfway up the stummel the pipe revealed its final design-leave the top of the bowl smooth! I wasn’t sure at first because it would mean I had to blend in that CA patch, but I now avoided trying to rusticate it.

I was very pleased with the result.

Staining & Finishing

I used Fiebings Dark Brown alcohol based dye over the entire pipe as a base, then wiped on Fiebings Oxblood till I achieved the colour I wanted. To seal the stain in the pipe I applied a thin layer of shellac which gave it a glossy look I didn’t like. I left it, and just stayed the course with this experiment to see how it turned out.

In the morning the Shellac had cured. I began the polishing process at this point. I don’t have a buffing wheel yet, so I use cotton wheel buffing bits that fit to my dremel.

I started with Tripoli and thoroughly went over the entire pipe and stem. The tripoli did a good job of taking down the shellac, and making it less pronounced. I followed that up with white diamond and then finally carnauba wax. I used a fluffy felt bit to polish the whole pipe.

Bowl Coating

You will find a variety of recipes and opinions on bowl coatings. I use them when needed and I prefer the waterglass recipe that a pipe maker shared with me. It is a combination of Sodium Silicate, Activated Charcoal and White Pumice. Once cured it provides a refractory layer on the inside of the bowl, and it feels like 800 grit sandpaper which promotes new cake build up without putting a lot of heat stress on the worn out briar.

This pipe definitely tested the limits of my abilities and I learned some new techniques that I had only seen others use. Here’s the finished pipe!