Blog by Dal Stanton

This pipe was gifted to me in 1980 while a seminary student. I was Professor Freundt’s student assistant and I spent much time with him in his office which was a virtual jungle of books, papers and journals – heaped in piles here and there yet the professor knew where to find the most obscure minutia. Added to the smells of old books and leather covers were the tobacco and smoke that regularly provided an upper layer haze in his work space. The Professor introduced me to the art and enjoyment of smoking pipes – now some 36 years ago. I was young and eager, soaking in the ambiance of academia at a post-graduate level and pipes I discovered, were very comfortable partners in this environment. Professor Freundt gave me the Hesson Guard, showed me how to pack its first bowl in my hands, and I smoked it, adding my offerings to the perpetual haze. After these days, pipe smoking was put aside until last fall when Steve reintroduced me to it. At this point, 3 pipes made up my collection: a corncob I also bought during those seminary days to use while fishing and duck hunting, a Willard I received after my grandfather’s passing (a future restoration), and the WDC Milano Hesson Guard that I had tucked away in drawers over the past three and a half decades. Anxious to put a pipe back into service last fall, I grabbed the Hesson Guard, to clean it and do what I thought then were needed repairs…. I made a mess of the pipe – cracked the shank, reamed out the mortise so that the metal tenon was too loose – sloppy repair with super glue…. I’m anxious now to return to ‘The Professor’ (its given name) and try to make amends for the rough treatment he received last fall!

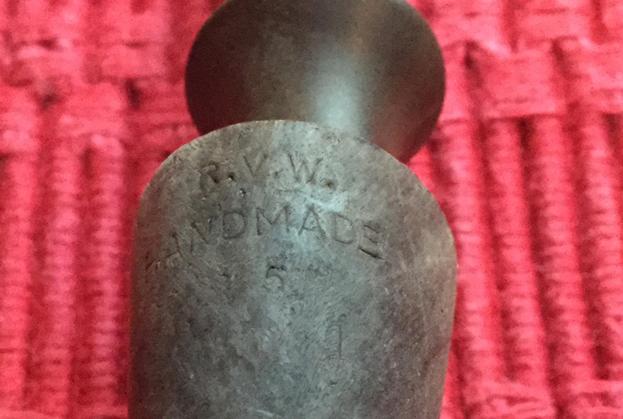

The right side of the shank is stamped with the well-known WDC inverted triangle next to Milano over Real Briar. The left side holds Hesson Guard. The bottom of shank had PAT. 1855800 which enabled me quickly zero in on the dating of the pipe. The patent application was submitted by the inventor of the special internals, William W. Hesson, in 1930 and granted two years later. An excerpt from the patent documentation describes the essence of the design:

The principal object of the invention is to provide a pipe which will eliminate contamination of the natural aroma of the tobacco through noxious secretions and which will remain sweet and clean. A further object is to devise a construction of pipe which will be simple and inexpensive to manufacture and which. will be devoid of pockets to harbor noxious elements. The principal feature of the invention consists in the novel arrangement of a tubular resilient member surrounding and embracing a metal stem which extends from the pipe bowl to the mouth piece and forming a seal to prevent the seepage of moisture around the metal stem.

(https://www.google.bg/patents/US1855800?dq=1855800&hl=en&sa=X&ved=0ahUKEwibqa2KsOjNAhUFVBQKHZ1DAvMQ6AEIGjAA)

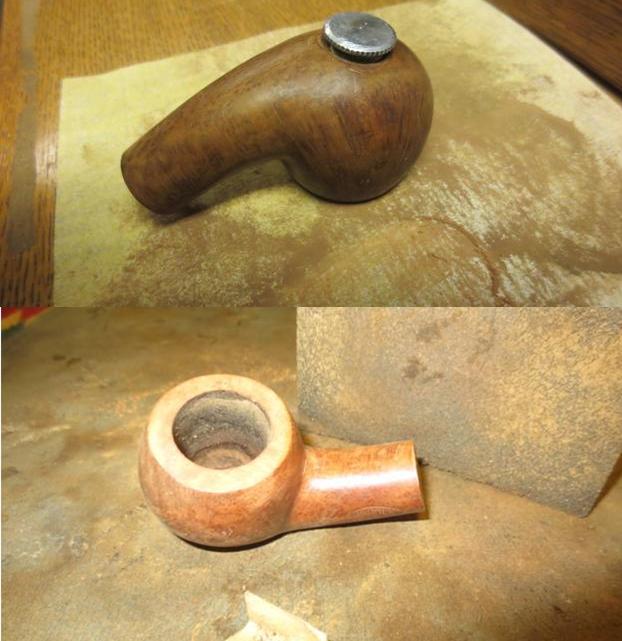

I was curious to compare my Hesson Guard with the patent diagram which essentially is a long metal tenon meeting up with a metal sleeve at the base of the bowl and shank junction. This design, along with many other designs, was to eliminate the moisture build up, gurgle and gunk. Figure 1 (below) is followed by my overlay comparison picture – the tube inserts quite a way according to the 1930 design. Following are pictures telling the current story of The Professor:

The pipe is attractive and has a good feel in my hand. The free-hand sculpting on the bowl gives the appearance of flames rising and is showcased in 3 paneled murals around the bowl. I notice that one of the panel dividers has been damaged at the top by cutting the briar. It looks like they were seeking to connect the panels – not sure. That will need to be filled in. The rim will also need some gentle repair to what appears to be nicks created by wear and tear. The cracked shank will need repair to keep it from growing and cleaning up the metal tenon and creating a good fit with the mortise might be a challenge. The bit has very mild tooth chatter. The last picture above captures not only the crack in the shank but the metal sleeve deep in the mortise that the chamfered tube/tenon docks with to create a dryer smoke – according to the patent information. Before any cosmetic restoration takes place I first must deal with the major issues of the shank crack repair and the tenon/mortise fit. I start the crack repair by drilling a small hole at the end of the crack to keep the crack from creeping up the shank. I use my Dremel tool and a 1.5mm drill bit to make the hole. I utilize a magnifying glass to trace the crack which had become a ‘hairline’. I’m careful not to drill too far and breach the mortise wall. Next time, I want to use a 1mm drill bit to leave less of a footprint. Next, after inserting the tenon into the mortise to expand the crack area for glue penetration, I create a mixture of briar dust and CA Instant Glue filling the hole and running a line of glue along the crack. I then sprinkle briar dust over the entire area and wait to dry. The timing worked out well as my wife just called me for lunch! After lunch, I work on cleaning up the tenon removing the old superglue with fingernails, Winchester knife, brass brush and 240 grit sanding paper – back in pristine shape.

The pipe is attractive and has a good feel in my hand. The free-hand sculpting on the bowl gives the appearance of flames rising and is showcased in 3 paneled murals around the bowl. I notice that one of the panel dividers has been damaged at the top by cutting the briar. It looks like they were seeking to connect the panels – not sure. That will need to be filled in. The rim will also need some gentle repair to what appears to be nicks created by wear and tear. The cracked shank will need repair to keep it from growing and cleaning up the metal tenon and creating a good fit with the mortise might be a challenge. The bit has very mild tooth chatter. The last picture above captures not only the crack in the shank but the metal sleeve deep in the mortise that the chamfered tube/tenon docks with to create a dryer smoke – according to the patent information. Before any cosmetic restoration takes place I first must deal with the major issues of the shank crack repair and the tenon/mortise fit. I start the crack repair by drilling a small hole at the end of the crack to keep the crack from creeping up the shank. I use my Dremel tool and a 1.5mm drill bit to make the hole. I utilize a magnifying glass to trace the crack which had become a ‘hairline’. I’m careful not to drill too far and breach the mortise wall. Next time, I want to use a 1mm drill bit to leave less of a footprint. Next, after inserting the tenon into the mortise to expand the crack area for glue penetration, I create a mixture of briar dust and CA Instant Glue filling the hole and running a line of glue along the crack. I then sprinkle briar dust over the entire area and wait to dry. The timing worked out well as my wife just called me for lunch! After lunch, I work on cleaning up the tenon removing the old superglue with fingernails, Winchester knife, brass brush and 240 grit sanding paper – back in pristine shape.

Well, after about a week, I return to the Milano Hesson Guard after my wife and I take advantage of the summer opportunities at the Black Sea coast. We enjoy some days at the beach near our favorite coastal fishing town, Sozopol. While at the beach, I thought about the Milano and how best to approach the overly loose tenon/mortise fit. Instead of applying clear nail polish around the metal tenon, which is what I did before, I attempt to rebuild the mortise wall by applying a very gentle coat of superglue on the inner wall of the mortise, rotating it as I applied superglue to achieve, what I hope, will be an even texture around the mortise wall. Amazingly, this seems to have worked! After drying, I gently reach into the mortise to remove some superglue ‘bumps’ with a needle file and I use a tightly rolled piece of 240 sanding paper carefully to smooth things down. I don’t want to inadvertently remove too much of the restored mortise wall! I also give the crack repair a light, strategic sanding with 240 grit paper, careful to guard the stampings. I refit the stem and to my relief, a snug fit was restored.

Well, after about a week, I return to the Milano Hesson Guard after my wife and I take advantage of the summer opportunities at the Black Sea coast. We enjoy some days at the beach near our favorite coastal fishing town, Sozopol. While at the beach, I thought about the Milano and how best to approach the overly loose tenon/mortise fit. Instead of applying clear nail polish around the metal tenon, which is what I did before, I attempt to rebuild the mortise wall by applying a very gentle coat of superglue on the inner wall of the mortise, rotating it as I applied superglue to achieve, what I hope, will be an even texture around the mortise wall. Amazingly, this seems to have worked! After drying, I gently reach into the mortise to remove some superglue ‘bumps’ with a needle file and I use a tightly rolled piece of 240 sanding paper carefully to smooth things down. I don’t want to inadvertently remove too much of the restored mortise wall! I also give the crack repair a light, strategic sanding with 240 grit paper, careful to guard the stampings. I refit the stem and to my relief, a snug fit was restored.

With the stem refitting correctly and inserted, I return to the shank crack to finish sanding it to remove the excess superglue – I do this with stem in so as to not create unevenness between the mortise and stem shoulder. Satisfied with the shank crack repair and rebuilding the mortise wall, I put the stem in an Oxyclean bath for a soak to soften up the moderate oxidation buildup. I move my attention to the bowl to ream the mild cake down to the briar and then move to rim repairs and then to the panel repair. I want to have all these completed before looking at the general stummel cleanup and refinishing. I move out to the 10th floor balcony adjoining my bedroom work station with Pipnet reaming kit to minimize the airborne cake soot – maximizing happy wife status! I started with the smallest reaming blade moving to use 3 of the 4 blades available to remove the moderate cake in the bowl. I finished the reaming by employing 120 grit paper on the chamber wall to remove remaining cake and smoothing the wall. I took a close up of the chamber and rim to show progress and to get a good idea of how to approach the rim repair. Inspecting the rim, I place a drop of superglue on one particular ‘dent’ that reached significantly down the external side of the bowl. I’m hoping that this small fill will enable me not needing to take as much off during the bowl topping to repair the rim.

With the stem refitting correctly and inserted, I return to the shank crack to finish sanding it to remove the excess superglue – I do this with stem in so as to not create unevenness between the mortise and stem shoulder. Satisfied with the shank crack repair and rebuilding the mortise wall, I put the stem in an Oxyclean bath for a soak to soften up the moderate oxidation buildup. I move my attention to the bowl to ream the mild cake down to the briar and then move to rim repairs and then to the panel repair. I want to have all these completed before looking at the general stummel cleanup and refinishing. I move out to the 10th floor balcony adjoining my bedroom work station with Pipnet reaming kit to minimize the airborne cake soot – maximizing happy wife status! I started with the smallest reaming blade moving to use 3 of the 4 blades available to remove the moderate cake in the bowl. I finished the reaming by employing 120 grit paper on the chamber wall to remove remaining cake and smoothing the wall. I took a close up of the chamber and rim to show progress and to get a good idea of how to approach the rim repair. Inspecting the rim, I place a drop of superglue on one particular ‘dent’ that reached significantly down the external side of the bowl. I’m hoping that this small fill will enable me not needing to take as much off during the bowl topping to repair the rim.

After the superglue sets up on the rim dent fill, I top the bowl using 240 grit sanding paper on top of a chopping block. Since the day is beautiful, I again move to the 10th floor balcony to do the work. With the rim having no burns, I expect the surface to plane off evenly without pulls toward softer burned areas of the rim. I rotate in a clockwise circular even motion and take off only as much as needed to remove the damaged area of the rim. As I like to do, I create a small bevel on the inner wall of the rim to give a more finished, classier look. I use 120 grit paper to form the initial bevel angle followed by 240. I also decide to give the outer rim edge a slight sanding to round off the lip which seems to be consistent with the original Milano design. Again, I make the initial cut on the lip with 120 grit paper and finish off with 240. I have grown to appreciate more the rim presentation in finished pipes. To me, the rim, it’s nuances, are the first thing the eye is drawn to when looking at a pipe – much like the first thing one sees when looking a person are the eyes, then one follows by taking in the general appearances. The following pictures show the Milano’s rim progress.

After the superglue sets up on the rim dent fill, I top the bowl using 240 grit sanding paper on top of a chopping block. Since the day is beautiful, I again move to the 10th floor balcony to do the work. With the rim having no burns, I expect the surface to plane off evenly without pulls toward softer burned areas of the rim. I rotate in a clockwise circular even motion and take off only as much as needed to remove the damaged area of the rim. As I like to do, I create a small bevel on the inner wall of the rim to give a more finished, classier look. I use 120 grit paper to form the initial bevel angle followed by 240. I also decide to give the outer rim edge a slight sanding to round off the lip which seems to be consistent with the original Milano design. Again, I make the initial cut on the lip with 120 grit paper and finish off with 240. I have grown to appreciate more the rim presentation in finished pipes. To me, the rim, it’s nuances, are the first thing the eye is drawn to when looking at a pipe – much like the first thing one sees when looking a person are the eyes, then one follows by taking in the general appearances. The following pictures show the Milano’s rim progress.

You can see in the immediate preceding picture the rim superglue fill spot at the 11 o’clock position of the rim and the ongoing panel repair just below it (to the left in the picture). Before moving to the stummel finishing, I now need to resolve the panel repair. I realize at this point with all the stummel repairs (cracked shank, topping and panel line), I will be removing the finish and refinishing the surface in order to achieve an even briar tone appearance. Now, continue to ‘heal’ the panel cut – earlier I applied superglue to it to build it up. I take a close up of the panel as it is now in order to know what I have. In order to blend more, I rough up the original superglue with a Dremel stone sander instrument. I apply on top of it a thick mixture of superglue and briar dust to form the restored surface that will join the side briar panel with the solid ring around the top of the bowl. I use toothpicks to mix, spread and tamp the mixture into place. I want this briar dust putty to setup well so I put the stummel aside for the time and turn to the stem which has been soaking in Oxyclean.

You can see in the immediate preceding picture the rim superglue fill spot at the 11 o’clock position of the rim and the ongoing panel repair just below it (to the left in the picture). Before moving to the stummel finishing, I now need to resolve the panel repair. I realize at this point with all the stummel repairs (cracked shank, topping and panel line), I will be removing the finish and refinishing the surface in order to achieve an even briar tone appearance. Now, continue to ‘heal’ the panel cut – earlier I applied superglue to it to build it up. I take a close up of the panel as it is now in order to know what I have. In order to blend more, I rough up the original superglue with a Dremel stone sander instrument. I apply on top of it a thick mixture of superglue and briar dust to form the restored surface that will join the side briar panel with the solid ring around the top of the bowl. I use toothpicks to mix, spread and tamp the mixture into place. I want this briar dust putty to setup well so I put the stummel aside for the time and turn to the stem which has been soaking in Oxyclean.

The Oxyclean bath did the job of bringing the oxidation to the stem surface. I attack this initial layer with 000 steel wool and then use 240 grit paper to address the minor tooth chatter – I take pictures of bit top and bottom before starting to show progress. In order to have a good match between the mortise and the stem, I want to eyeball what the fit looks like before I proceed further. As I suspected, with all the superglue applied to the mortise area, the fit between mortise end and stem was not flush. I took the stummel back to the topping board and gently rotated the shank end on the board to regain a flush docking between stummel and stem. After a few rotation cycles and testings to eyeball things, I am satisfied.

The Oxyclean bath did the job of bringing the oxidation to the stem surface. I attack this initial layer with 000 steel wool and then use 240 grit paper to address the minor tooth chatter – I take pictures of bit top and bottom before starting to show progress. In order to have a good match between the mortise and the stem, I want to eyeball what the fit looks like before I proceed further. As I suspected, with all the superglue applied to the mortise area, the fit between mortise end and stem was not flush. I took the stummel back to the topping board and gently rotated the shank end on the board to regain a flush docking between stummel and stem. After a few rotation cycles and testings to eyeball things, I am satisfied.

Before starting the micromesh cycles for the stem finishing, I need to remove the lip that I discovered with the shank end over the stem. With the topping of the shank end, I enlarged the circumference of the end just a bit so that it was a bit larger than the circumference of the stem shoulder – primarily on the lower side of the shank. I use 240 grit paper to even out the difference between the shank and stem – leaving the stem in place to assure a good, smooth transition! I am careful to use my thumb to cover and protect the nomenclature as I move around the shank with the sanding paper.

Before starting the micromesh cycles for the stem finishing, I need to remove the lip that I discovered with the shank end over the stem. With the topping of the shank end, I enlarged the circumference of the end just a bit so that it was a bit larger than the circumference of the stem shoulder – primarily on the lower side of the shank. I use 240 grit paper to even out the difference between the shank and stem – leaving the stem in place to assure a good, smooth transition! I am careful to use my thumb to cover and protect the nomenclature as I move around the shank with the sanding paper. Now to the panel repair below the rim. Using 240 grit sanding paper I bring the hardened superglue and briar dust mixture down to the bowl surface careful to maintain a rounded surface and not to flatten out the area of sanding focus. The pictures show the progress.

Now to the panel repair below the rim. Using 240 grit sanding paper I bring the hardened superglue and briar dust mixture down to the bowl surface careful to maintain a rounded surface and not to flatten out the area of sanding focus. The pictures show the progress.

I like the panel patch and it will blend with a darker stain. On a roll, I launch into the clean-up of the stummel and especially the ‘flame murals’ which are filled with grit and dust. I use a tooth brush with Murphy’s Wood Soap undiluted and work over the entire stummel with special focus in the fire sculpting to remove the surface finish. I follow this with rubbing down the stummel using cotton pads and tooth brush with acetone to remove the finish deep in the grain of the briar. I finish my clean-up of the surface by picking the carved crevices with a dental tool. Using micromesh sanding pads, I sand the high points of the stummel. Using 1500-2400 I wet sand. Following, 3200-4000 dry sand and finishing dry-sanding with 6000-12000. The pictures show the progress – I’m liking the briar grain the micromesh process is bringing out.

At this point, I have two questions about how to proceed before staining the stummel. First, I need to clean out the ‘flame’ sculpting and use a black fine tipped permanent marker to darken the flames to give more contrast after the stain is applied. The other question was how do I treat the stampings of the WDC Milano – Hesson Guard? Do I protect it from the stain? Do I cover them with Vaseline? What? Upon closer inspection, I notice that the left side stamping, Hesson Guard, appeared to have gold left over in the ‘Hesson’ lettering – the rest having worn off (picture below) after the crack repair. After a quick email to Steve, his input revealed that both sides would have originally born the gold lettering. So, from my model kit (I’ve been involved in a project for several years building the USS Constitution sailing ship) I discover a bottle of Testors Gold Enamel Model Paint and my wife finds a small brush which I trim with my knife to create a more distinct point. With Steve’s counsel stored in my mind, I applied the paint over the lettering and wiped off the excess. To my relief and joy, the gold paint adhered to the crevices of the lettering and the overflow came off with the paper towel. My first stamping restoration with paint worked well! Steve also said that there was no need to worry about the new lettering during staining – that the gold paint would repel the stain. Careful to avoid the new gold lettering, I clean the bowl with isopropyl using a tooth brush to get rid of the residue from the sanding and then I move to highlighting the flame sculpts to bring greater definition to the paneled murals in the finished pipe. The pictures tell the story.

At this point, I have two questions about how to proceed before staining the stummel. First, I need to clean out the ‘flame’ sculpting and use a black fine tipped permanent marker to darken the flames to give more contrast after the stain is applied. The other question was how do I treat the stampings of the WDC Milano – Hesson Guard? Do I protect it from the stain? Do I cover them with Vaseline? What? Upon closer inspection, I notice that the left side stamping, Hesson Guard, appeared to have gold left over in the ‘Hesson’ lettering – the rest having worn off (picture below) after the crack repair. After a quick email to Steve, his input revealed that both sides would have originally born the gold lettering. So, from my model kit (I’ve been involved in a project for several years building the USS Constitution sailing ship) I discover a bottle of Testors Gold Enamel Model Paint and my wife finds a small brush which I trim with my knife to create a more distinct point. With Steve’s counsel stored in my mind, I applied the paint over the lettering and wiped off the excess. To my relief and joy, the gold paint adhered to the crevices of the lettering and the overflow came off with the paper towel. My first stamping restoration with paint worked well! Steve also said that there was no need to worry about the new lettering during staining – that the gold paint would repel the stain. Careful to avoid the new gold lettering, I clean the bowl with isopropyl using a tooth brush to get rid of the residue from the sanding and then I move to highlighting the flame sculpts to bring greater definition to the paneled murals in the finished pipe. The pictures tell the story.

Time to stain and I decide to use a mixture of an alcohol-based Italian stain I found here in Bulgaria with a color description of dark nut. I want this as the base, but I mix it with a mahogany color water based stain to bring out a slightly more redish tone in the briar. I think the red will work with the flame sculpting motif and I think this will look good – but of course the briar does what it will with the hues! After mixing the stains in the shot glass, I apply the mixture to the stummel mounted on the cork and candle stick with cotton balls making sure to cover everything and getting a good thick coverage. After applying stain, I use the butane lighter to flame the stain. With the mixture that I made, the alcohol content was too low to ‘flame’ so I evenly moved the lighter flame across the surface to evaporate the alcohol setting the dye in the grain of the briar. I repeated the process again and set the stummel aside to dry.

Time to stain and I decide to use a mixture of an alcohol-based Italian stain I found here in Bulgaria with a color description of dark nut. I want this as the base, but I mix it with a mahogany color water based stain to bring out a slightly more redish tone in the briar. I think the red will work with the flame sculpting motif and I think this will look good – but of course the briar does what it will with the hues! After mixing the stains in the shot glass, I apply the mixture to the stummel mounted on the cork and candle stick with cotton balls making sure to cover everything and getting a good thick coverage. After applying stain, I use the butane lighter to flame the stain. With the mixture that I made, the alcohol content was too low to ‘flame’ so I evenly moved the lighter flame across the surface to evaporate the alcohol setting the dye in the grain of the briar. I repeated the process again and set the stummel aside to dry. With the stummel put aside, I turn again to the stem. I re-inspect the button area after the earlier sanding to remove the teeth chatter. I decide that the button needed a little more attention. I use 240 grit sanding paper and a needle file to fine-tune the shape of the button before starting on the micromesh cycles. I wet-sand the stem using 1500-2400 and complete the cycle by applying Obsidian Oil. While still wet from the oil I continue to dry sand with 3200-4000 micromesh pads, again concluding the cycle by applying Obsidian Oil. The final cycle, 6000-12000 is used and a final coat of Obsidian Oil and I put the stem aside to dry. I love watching the shine of the stem progressively make it to the surface getting that final wet, reflective look in the stem. Nice! The stem pops. The pictures capture the progress!

With the stummel put aside, I turn again to the stem. I re-inspect the button area after the earlier sanding to remove the teeth chatter. I decide that the button needed a little more attention. I use 240 grit sanding paper and a needle file to fine-tune the shape of the button before starting on the micromesh cycles. I wet-sand the stem using 1500-2400 and complete the cycle by applying Obsidian Oil. While still wet from the oil I continue to dry sand with 3200-4000 micromesh pads, again concluding the cycle by applying Obsidian Oil. The final cycle, 6000-12000 is used and a final coat of Obsidian Oil and I put the stem aside to dry. I love watching the shine of the stem progressively make it to the surface getting that final wet, reflective look in the stem. Nice! The stem pops. The pictures capture the progress!

For me, beginning the process of finishing the stummel after the staining dries, is like opening a Christmas present. The anticipation is to see what actually is under the crust of flamed stain and what the briar grain will reveal. With the Dremel tool, I begin to remove the ‘wrapping’ using a felt wheel. Also with a felt wheel I polish beginning with Tripoli and then move to Blue Diamond. I focus on bringing out the contrast of briar ‘flames’ showcased in the three panels. I switch to a cotton cloth wheel and apply carnauba wax to both stummel and stem. After several coats of carnauba, I complete the job by giving the pipe a clean cotton cloth wheel buff followed by a rigorous buffing with a micro-fiber cloth to bring out the deep tones of the briar.

For me, beginning the process of finishing the stummel after the staining dries, is like opening a Christmas present. The anticipation is to see what actually is under the crust of flamed stain and what the briar grain will reveal. With the Dremel tool, I begin to remove the ‘wrapping’ using a felt wheel. Also with a felt wheel I polish beginning with Tripoli and then move to Blue Diamond. I focus on bringing out the contrast of briar ‘flames’ showcased in the three panels. I switch to a cotton cloth wheel and apply carnauba wax to both stummel and stem. After several coats of carnauba, I complete the job by giving the pipe a clean cotton cloth wheel buff followed by a rigorous buffing with a micro-fiber cloth to bring out the deep tones of the briar.

I’m pleased with the revitalization of ‘The Professor’, WDC Milano Hesson Guard. I think Professor Freundt, if he were alive today to comment, would agree. The rich dark tones of the briar, with the hints of deep reds, reminds me of the myriads of leather bindings and books that filled his hazy office. I’m pleased with the results. Thanks for joining me!

I’m pleased with the revitalization of ‘The Professor’, WDC Milano Hesson Guard. I think Professor Freundt, if he were alive today to comment, would agree. The rich dark tones of the briar, with the hints of deep reds, reminds me of the myriads of leather bindings and books that filled his hazy office. I’m pleased with the results. Thanks for joining me!

There is a brass spacer between the base and the briar bowl and at some time in its life the spacer had been reversed and the sharper edges scarred the bowl. The Bakelite is actually notched to receive the sharp turned down edges of the spacer. The bowl had lots of dents and scars – character marks that I wish could talk and tell the story of the travels of this old pipe. The brass rim had long since come loose and was easily removed but for some reason never disappeared as it clung to the rim of the pipe. In the next photo you can see the rim top and the porcelain bottom of the bowl… it almost looks like the old milk glass that my grandmother collected.

There is a brass spacer between the base and the briar bowl and at some time in its life the spacer had been reversed and the sharper edges scarred the bowl. The Bakelite is actually notched to receive the sharp turned down edges of the spacer. The bowl had lots of dents and scars – character marks that I wish could talk and tell the story of the travels of this old pipe. The brass rim had long since come loose and was easily removed but for some reason never disappeared as it clung to the rim of the pipe. In the next photo you can see the rim top and the porcelain bottom of the bowl… it almost looks like the old milk glass that my grandmother collected. After looking at the two pictures above that came from my brother I was looking forward to seeing the pipe in person. When it arrived and I finally took it out to work on it was all that I had expected. The stem was over clocked so that would need to be addressed but I lined things up and took the next set of photos to show what the pipe looked like after my brother did an amazing job cleaning it. (It is great to have him work with me – it really speeds up the process on the restoration. He reams and cleans the pipes and does the dirty work of reaming and removing the debris of the years.) I looked it over to see if there were identifying marks. What I thought was brass may all be what is stamped on the right side of the band – 14K Gold Plated. The left side of the band bears the inverted WDC triangle logo.

After looking at the two pictures above that came from my brother I was looking forward to seeing the pipe in person. When it arrived and I finally took it out to work on it was all that I had expected. The stem was over clocked so that would need to be addressed but I lined things up and took the next set of photos to show what the pipe looked like after my brother did an amazing job cleaning it. (It is great to have him work with me – it really speeds up the process on the restoration. He reams and cleans the pipes and does the dirty work of reaming and removing the debris of the years.) I looked it over to see if there were identifying marks. What I thought was brass may all be what is stamped on the right side of the band – 14K Gold Plated. The left side of the band bears the inverted WDC triangle logo.

I took a close up photo of the rim top to show the dents, scratches and scars on the surface. The photo also shows the porcelain cup in the bottom of the bowl. It has three round air holes for directing the smoke into the bottom chamber and into the stem.

I took a close up photo of the rim top to show the dents, scratches and scars on the surface. The photo also shows the porcelain cup in the bottom of the bowl. It has three round air holes for directing the smoke into the bottom chamber and into the stem. I dismantled the pipe to show the many parts that went into its construction. The photo below shows the broken down pipe.

I dismantled the pipe to show the many parts that went into its construction. The photo below shows the broken down pipe. The next photos show the over clocked stem. (I had removed the loose band at this point in the process.) Once the base was screwed onto the stem it was grossly overturned. The metal tenon was set in the stem so it would need to be heated to be able to repair this.

The next photos show the over clocked stem. (I had removed the loose band at this point in the process.) Once the base was screwed onto the stem it was grossly overturned. The metal tenon was set in the stem so it would need to be heated to be able to repair this. I heated the metal tenon with a lighter and once the glue softened I was able to align the stem and shank very easily. Underneath the band the number 43 had been scratched into the Bakelite shank. I am not sure if that is the shape number or if it is the “autograph” of the assembler of the pipe. Either way it is something that remained hidden for many years.

I heated the metal tenon with a lighter and once the glue softened I was able to align the stem and shank very easily. Underneath the band the number 43 had been scratched into the Bakelite shank. I am not sure if that is the shape number or if it is the “autograph” of the assembler of the pipe. Either way it is something that remained hidden for many years.  I set the base aside and worked on the bowl. I removed the rim cap and cleaned off the glue that remained behind on the top of the bowl. It was rough and I was thinking that it was reason that the cap was no longer smooth. I scrubbed out the glue residue in the inside of the rim cap as well with alcohol and cotton swabs. I used a flat blade screw driver to smooth out the interior flat surface of the cap. I wiped down the bowl with acetone to remove the remnants of the finish and then glued the rim cap back in place with an all-purpose glue. I polish the rim with some micromesh and metal polish. I decided to leave some of the dents and dings as to me it gave the pipe character.

I set the base aside and worked on the bowl. I removed the rim cap and cleaned off the glue that remained behind on the top of the bowl. It was rough and I was thinking that it was reason that the cap was no longer smooth. I scrubbed out the glue residue in the inside of the rim cap as well with alcohol and cotton swabs. I used a flat blade screw driver to smooth out the interior flat surface of the cap. I wiped down the bowl with acetone to remove the remnants of the finish and then glued the rim cap back in place with an all-purpose glue. I polish the rim with some micromesh and metal polish. I decided to leave some of the dents and dings as to me it gave the pipe character.

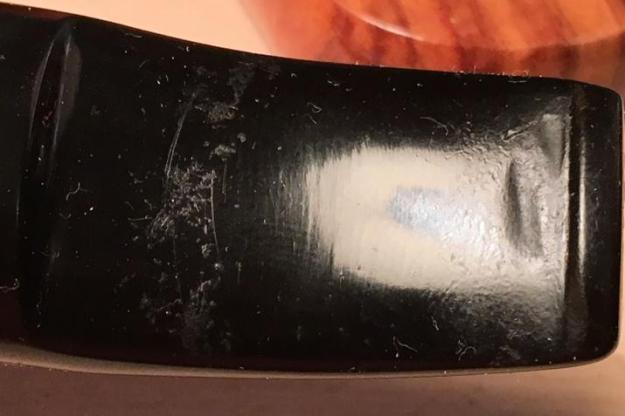

I cleaned the surface of the Bakelite base and sanded the whole base with micromesh sanding pads from 1500-12000 grit. I rubbed the base down with Obsidian Oil several times throughout the process to give the micromesh some bite as I polished the base.

I cleaned the surface of the Bakelite base and sanded the whole base with micromesh sanding pads from 1500-12000 grit. I rubbed the base down with Obsidian Oil several times throughout the process to give the micromesh some bite as I polished the base.

I gave the internals a quick clean with alcohol and cotton swabs to remove any of the sanding dust that might have found its way into the bowl base and shank. I also cleaned the airway in the stem at the same time with alcohol and pipe cleaners.

I gave the internals a quick clean with alcohol and cotton swabs to remove any of the sanding dust that might have found its way into the bowl base and shank. I also cleaned the airway in the stem at the same time with alcohol and pipe cleaners. I roughened the area on the base that would be underneath the band to give the glue something to bind to. I used an all-purpose glue and applied it sparingly to the shank. I had previously polished the band with metal polish to remove any tarnish and give it a shine. I pressed it in place and laid the base aside for the glue to set.

I roughened the area on the base that would be underneath the band to give the glue something to bind to. I used an all-purpose glue and applied it sparingly to the shank. I had previously polished the band with metal polish to remove any tarnish and give it a shine. I pressed it in place and laid the base aside for the glue to set. I cleaned the inside of the space plate with alcohol and cotton swabs to remove the debris of the years. The spacer appeared not to have been glued in place so I left it that way. I polished it with micromesh sanding pads 1500-4000 grit until it gleamed. I laid it aside until I was ready to put the pipe back together.

I cleaned the inside of the space plate with alcohol and cotton swabs to remove the debris of the years. The spacer appeared not to have been glued in place so I left it that way. I polished it with micromesh sanding pads 1500-4000 grit until it gleamed. I laid it aside until I was ready to put the pipe back together. I turned my attention to the stem. There were some light tooth marks on the underside of the stem near the button. I sanded these out with 220 grit sandpaper. I wet sanded the stem with 1500-2400 grit micromesh sanding pads. I wiped the stem down with a damp cotton pad and dry sanded it with 3200-12000 grit pads. I gave the stem a final wipe down with the damp pad.

I turned my attention to the stem. There were some light tooth marks on the underside of the stem near the button. I sanded these out with 220 grit sandpaper. I wet sanded the stem with 1500-2400 grit micromesh sanding pads. I wiped the stem down with a damp cotton pad and dry sanded it with 3200-12000 grit pads. I gave the stem a final wipe down with the damp pad.

With the stem finished and the glued band dried I put the base and stem back together. I would still need to buff the entirety with Blue Diamond on the buffing wheel.

With the stem finished and the glued band dried I put the base and stem back together. I would still need to buff the entirety with Blue Diamond on the buffing wheel.

I used a medium brown stain pen to stain the bowl. I heated the briar and then applied the stain with the pen. I repeated the staining until the coverage was smooth and even.

I used a medium brown stain pen to stain the bowl. I heated the briar and then applied the stain with the pen. I repeated the staining until the coverage was smooth and even. I gave the bowl several coats of Conservator’s Wax and hand buffed it to raise the shine with a microfibre cloth.

I gave the bowl several coats of Conservator’s Wax and hand buffed it to raise the shine with a microfibre cloth.

With all the parts finished I took a final photo of the bowl and the base before putting it back together.

With all the parts finished I took a final photo of the bowl and the base before putting it back together. I buffed the completed pipe with Blue Diamond to polish out some of the scratches in the base and the stem. I was not able to remove all of them so I left a few behind to tell the story. I gave the pipe several coats of carnauba wax and buffed it with a clean buffing pad. I hand buffed it with a microfibre cloth. The finished pipe is shown in the photos below. I am really pleased with the finished pipe and how it looks. Thanks for looking.

I buffed the completed pipe with Blue Diamond to polish out some of the scratches in the base and the stem. I was not able to remove all of them so I left a few behind to tell the story. I gave the pipe several coats of carnauba wax and buffed it with a clean buffing pad. I hand buffed it with a microfibre cloth. The finished pipe is shown in the photos below. I am really pleased with the finished pipe and how it looks. Thanks for looking.

The fourth and fifth pictures remove the mystery of the knurled edge on the bottom of the bowl that showed in the first photo. You can see in that photo of the bowl bottom that the silver disk looks like it was made to be rotated. We talked and my brother bid and won the pipe (I can’t wait for the pipe to get here so I can check this out). The fifth photo shows the inside of the bowl. The top of the disk appears to be a cup intruding into the bowl bottom. It was really odd looking.

The fourth and fifth pictures remove the mystery of the knurled edge on the bottom of the bowl that showed in the first photo. You can see in that photo of the bowl bottom that the silver disk looks like it was made to be rotated. We talked and my brother bid and won the pipe (I can’t wait for the pipe to get here so I can check this out). The fifth photo shows the inside of the bowl. The top of the disk appears to be a cup intruding into the bowl bottom. It was really odd looking.

That information was helpful on many levels. He did not however have any photos or drawings of the pipe or pictures of the advertisements. I wanted to know if the bottom “sump” as he called it was pressure fit or threaded and screwed into the briar. I wanted to know if the bottom of the bowl was damaged or if the “sump” sat as it was supposed to flush with the bottom. It was hard to tell from the photos. I wanted to know was the “wads” were that sat in the sump. From the look of the bowl bottom it appeared that the “wads” may well have been lozenges that fit in the curved cup and then sat flat in the bottom of the bowl. But what did they look like? More research would be needed to answer these questions. But at least the mystery of the knurled edge peaking from the first photo was solved. It was a single unit with a cup on the inside of the bowl. I could not wait to see this in person and “fiddle” with it.

That information was helpful on many levels. He did not however have any photos or drawings of the pipe or pictures of the advertisements. I wanted to know if the bottom “sump” as he called it was pressure fit or threaded and screwed into the briar. I wanted to know if the bottom of the bowl was damaged or if the “sump” sat as it was supposed to flush with the bottom. It was hard to tell from the photos. I wanted to know was the “wads” were that sat in the sump. From the look of the bowl bottom it appeared that the “wads” may well have been lozenges that fit in the curved cup and then sat flat in the bottom of the bowl. But what did they look like? More research would be needed to answer these questions. But at least the mystery of the knurled edge peaking from the first photo was solved. It was a single unit with a cup on the inside of the bowl. I could not wait to see this in person and “fiddle” with it. He gave the dimensions of the pipe as follows: overall length: 5 ½ inches, bowl height: 1 ½ inches, diameter of the bowl: 1 5/8 inches, bore diameter: 7/8 inches, bore depth: 1 1/8 inches and the weight: 44 grams or 1.6 ounces

He gave the dimensions of the pipe as follows: overall length: 5 ½ inches, bowl height: 1 ½ inches, diameter of the bowl: 1 5/8 inches, bore diameter: 7/8 inches, bore depth: 1 1/8 inches and the weight: 44 grams or 1.6 ounces I took it out of the alcohol bath and heated the disk with the flame of a lighter. I used a pair of pliers to hold tightly to the edge of the disk and I was able to twist it out of the bowl. Once it popped free I could undo it by hand. The first photo below shows the inside of the silver disk. The second shows the knurled outside.

I took it out of the alcohol bath and heated the disk with the flame of a lighter. I used a pair of pliers to hold tightly to the edge of the disk and I was able to twist it out of the bowl. Once it popped free I could undo it by hand. The first photo below shows the inside of the silver disk. The second shows the knurled outside. To remove the damage to the rim top and edges I topped the bowl on a topping board with 220 grit sandpaper.

To remove the damage to the rim top and edges I topped the bowl on a topping board with 220 grit sandpaper. There were some nicks around the hole in the bottom of the bowl so I sanded those smooth with sandpaper and then cleaned out the threads in the briar with a cotton swab and alcohol.

There were some nicks around the hole in the bottom of the bowl so I sanded those smooth with sandpaper and then cleaned out the threads in the briar with a cotton swab and alcohol. I used the brass bristle brush to scrub the threads and the cup on the disk. I cleaned it afterwards with cotton swabs and alcohol.

I used the brass bristle brush to scrub the threads and the cup on the disk. I cleaned it afterwards with cotton swabs and alcohol. I used a cotton swab to coat the threads on the disk with Vaseline and turned it into the bottom of the bowl. I wanted to make sure that I could easily turn the disk by hand.

I used a cotton swab to coat the threads on the disk with Vaseline and turned it into the bottom of the bowl. I wanted to make sure that I could easily turn the disk by hand. I cleaned out the internals with pipe cleaners, cotton swabs and alcohol. It was pretty clean thanks to my brother. It did not take too many to clean it out.

I cleaned out the internals with pipe cleaners, cotton swabs and alcohol. It was pretty clean thanks to my brother. It did not take too many to clean it out. I sanded the bowl and stem with a medium and a fine grit sanding block. The pipe is beginning to look really good. I had to make a decision how far to sand the bowl and how many of the original dings and dents to remove without changing the “story” and character of this old timer.

I sanded the bowl and stem with a medium and a fine grit sanding block. The pipe is beginning to look really good. I had to make a decision how far to sand the bowl and how many of the original dings and dents to remove without changing the “story” and character of this old timer. I heated the briar and then stained it with dark brown aniline stain cut by 50% with isopropyl alcohol. I flamed it to set the stain and repeated the process.

I heated the briar and then stained it with dark brown aniline stain cut by 50% with isopropyl alcohol. I flamed it to set the stain and repeated the process. I wiped down the stain with alcohol dampened cotton pads to make it more transparent and make the grain stand out. At this point the fills stood out and I would need to address them a bit differently.

I wiped down the stain with alcohol dampened cotton pads to make it more transparent and make the grain stand out. At this point the fills stood out and I would need to address them a bit differently.

I used a black Sharpie Permanent Marker to draw some lines across the fills and blend them into the grain on the pipe. I then chose to give the bowl a second contrast staining using a Cherry Danish Oil stain. I find that the combination of the black marker and the cherry stain blends the fills better than a brown stain. The combination of the brown and the cherry stains gives depth to the finish so I like using them together.

I used a black Sharpie Permanent Marker to draw some lines across the fills and blend them into the grain on the pipe. I then chose to give the bowl a second contrast staining using a Cherry Danish Oil stain. I find that the combination of the black marker and the cherry stain blends the fills better than a brown stain. The combination of the brown and the cherry stains gives depth to the finish so I like using them together. Once the cherry Danish Oil stain dried (overnight) I buffed it lightly on the wheel with Blue Diamond and then gave the bowl a coat of carnauba wax. I hand buffed it with a microfibre cloth. You can see the small dings that I left in the bowl sides rather than change the look. I polished the silver disk with a silver polishing cloth. The next series of photos shows the bowl at this point in the process.

Once the cherry Danish Oil stain dried (overnight) I buffed it lightly on the wheel with Blue Diamond and then gave the bowl a coat of carnauba wax. I hand buffed it with a microfibre cloth. You can see the small dings that I left in the bowl sides rather than change the look. I polished the silver disk with a silver polishing cloth. The next series of photos shows the bowl at this point in the process.

I set the bowl aside and worked on the stem. The old hard rubber that was used on this stem was good quality. There was very little oxidation if any on it. The main issue was the pitting that covered the surface of the stem. I sanded it with 220 grit sandpaper to address the pitting and smooth out the surface and then began my normal sequence of micromesh sanding pads. Between each set of three grits (1500-2400, 3200-4000, 6000-12000) I rubbed the stem down with Obsidian Oil. I gave it a final coat of the oil and let it dry before I buffed the pipe.

I set the bowl aside and worked on the stem. The old hard rubber that was used on this stem was good quality. There was very little oxidation if any on it. The main issue was the pitting that covered the surface of the stem. I sanded it with 220 grit sandpaper to address the pitting and smooth out the surface and then began my normal sequence of micromesh sanding pads. Between each set of three grits (1500-2400, 3200-4000, 6000-12000) I rubbed the stem down with Obsidian Oil. I gave it a final coat of the oil and let it dry before I buffed the pipe.

I buffed the pipe and stem with Blue Diamond and gave it several coats of carnauba wax. I buffed it with a clean buffing pad to raise the shine. I hand buffed it with a microfibre cloth to put the finishing touches on the pipe. The finished pipe is shown in the photos below. Thanks for looking.

I buffed the pipe and stem with Blue Diamond and gave it several coats of carnauba wax. I buffed it with a clean buffing pad to raise the shine. I hand buffed it with a microfibre cloth to put the finishing touches on the pipe. The finished pipe is shown in the photos below. Thanks for looking.