By Steve Laug

A while back I received an email reaching out about a pipe that the writer, Anthony had acquired long ago and wanted to know if I had heard of it. He wrote the following email:

Hello, I am just wondering if in all your refurbishings you’ve come across any pipes stamped with the name John Crouch? I would love to send you photos but don’t see a way possible to do that. I’ve had this for 20 years and don’t really remember where I picked it up. Any help would be greatly appreciated. Thank you for your time.

I wrote him back and asked for photos of the pipe and the stamping so I had something to work with. For me this always helps in the hunt for the identity as generally it gives me a lot of information. Anthony wrote back and sent some photos for me.

Hi Steve, thank you for the quick response!! Here are a few shots I have of this beauty. It’s one of the only bulldogs I’ve seen without the double lines engraved into it. Like I said in my first message. I’ve had it for 20+ years. If I had to guess I picked it up in Colorado when I lived out there. I would love to hear what you think. Thanks again!!! ps. if you need more photos let me know.  The third photo he included gave a clear look at the stamping on the left side of the shank. It read John Crouch [over] HEAVYWEIGH [over] Italy. My initial thinking before doing any digging on the brand is that it was a pipe made for a pipe shop by someone like Savinelli (Italy). It is stamped with what I think is the shop name. I think that the “T” is missing on the end of HEAVYWEIGH as the shank is to short for the stamp. But some digging will clear that up.

The third photo he included gave a clear look at the stamping on the left side of the shank. It read John Crouch [over] HEAVYWEIGH [over] Italy. My initial thinking before doing any digging on the brand is that it was a pipe made for a pipe shop by someone like Savinelli (Italy). It is stamped with what I think is the shop name. I think that the “T” is missing on the end of HEAVYWEIGH as the shank is to short for the stamp. But some digging will clear that up. I wrote Anthony back with what I found. I was surprised that Pipedia included the brand but not surprised that it confirmed my suspicions about it being a pipe shop pipe. Here is my email:

I wrote Anthony back with what I found. I was surprised that Pipedia included the brand but not surprised that it confirmed my suspicions about it being a pipe shop pipe. Here is my email:

The pipe is a beauty Anthony. I did a bit of digging and found this information on https://pipedia.org/wiki/John_Crouch

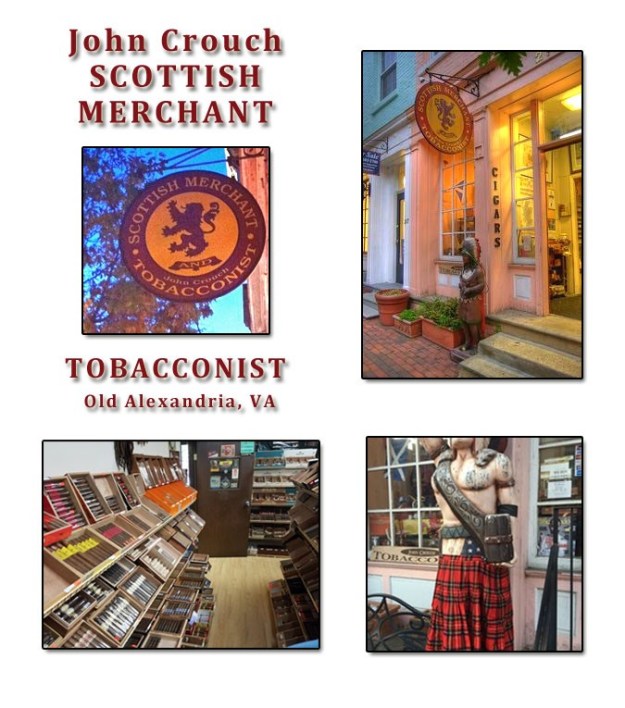

“John Crouch Tobacconist embodies the essence of Virginia. After all, tobacco is Virginia’s oldest industry. Years ago, tobacco was believed to have medical properties and a tobacconist was consulted in much of the same way that a pharmacist is today. In those days, a tobacconist would create a blend of tobacco products to ease an ailment. John Crouch Tobacconist has been home to the Washington areas’ nicest and largest humidor for over 30 years.” Apparently they also have pipes made for them under their name. I have also included photos from that listing. Hope that helps – Steve

I am including the following photos from Pipedia and the advertising page that Anthony sent as well as they give a clear picture of the manufacturer of the pipe and the shop it was made for. Now I really want to visit this shop!

Anthony wrote back and I include that below. I think his idea of calling or emailing them is perfect. He also asked if I would consider working on it if he chose to send it to me.

Anthony wrote back and I include that below. I think his idea of calling or emailing them is perfect. He also asked if I would consider working on it if he chose to send it to me.

Hey Steve, Thanks for the info. I, too, found this but didn’t think it was associated with the shop in Virginia!!! I guess I need to give them a call or email them to try to get to the bottom of this. Thanks for the help. Actually, two other things. 1.Is there a reason so few bulldogs lack the double engraved lines around the bowl? 2. If down the line what would a refurbishing run me? Rough estimate, nothing set in stone find of thing. Again. Thanks for your quick responses and your time.

I answered him that I would gladly take on the project for him for the chance to see the pipe up close and personal. I answered his other questions about the lack of rings around the bowl cap. Some time went by and he wrote again.

I also wanted to thank you for helping me figure out my John Crouch Heavyweigh pipe!! I contacted and talked with one of the guys down there in Alexandria, VA. He said, yes, back in the 70’s they in fact imported these Italian pipes then stamped and sold them. I would love to send you this pipe for a restoration. If you could send me your address I’ll send it off in the next few days. I should have ask first if you have time or backed up on restorations? Or when would be a good time to send it to you?

I look forward to seeing what you can do to this amazing pipe. I love how detailed your blog posts and restoration process are!!

Thank you again and hope to hear from you soon.

I answered and Anthony wrote that he had sent the pipe to me. He also included another piece of information that would be important in the restoration and repair.

Hey Steve… I should tell you I did break a chunk of the stem off. I slipped off a step as I was walking down then and unfortunately one of my reactions was to bite down and it broke the mouth piece of the stem. I think I have them still. If I can find the pieces should I send them?

Thank you in advance. I can’t wait to see the transformation and the documentation on the blog. All the best!! Anthony

The pipe arrived yesterday just as I finished the repair on the table that was ahead of it. Great timing! I opened the box and took photos of the pipe as I examined it to get a clear assessment of the work that lay ahead of me. Before I took the photos I removed the Softee Bit from the stem so I could see the damage on the stem top that Anthony had mentioned. I love the shape of the pipe – to me a Rhodesian without the rim cap rings but still the right shape. The pipe is well used and must be a great smoker. There was a moderate cake in the bowl and lava on the rim top. The inner edge of the bowl is rough and shows some reaming damage leaving it out of round a bit. The finish is dirty and there are some spots of varnish or shellac remaining around the bowl and shank. There are a few fills but they are solid. The pipe is stamped on the left side of the shank and reads as noted above. The stamp is clear and readable. I wonder if the HEAVYWEIGH stamp is missing the “T” but suppose we won’t know for sure. The stem is well fit but the damage on the topside was more extensive than I thought once I remove the Softee Bit. I have mad patches this big before but really never have been happy with the suspected lack of durability of them. I think this one would be better off with a new stem.

I took some closeup photos of the bowl and rim top to show the condition. You can see the damage on the inner edge and the generally roughness of the top and edge. The photos of the stem surface show the size of the damage. I hope you can see my rationale for restemming this one rather than making a patch that large.

I took some closeup photos of the bowl and rim top to show the condition. You can see the damage on the inner edge and the generally roughness of the top and edge. The photos of the stem surface show the size of the damage. I hope you can see my rationale for restemming this one rather than making a patch that large. I took a photo of the stamping on the shank. It is clear as noted. You can also see why I wondered if the HEAVYWEIGH portion is missing the T. You can also see the shellac or varnish on the shank in this photo. To give a sense of the proportion of the of the pipe I removed the stem and took a photo of it. This will help me when I choose a new stem for it.

I took a photo of the stamping on the shank. It is clear as noted. You can also see why I wondered if the HEAVYWEIGH portion is missing the T. You can also see the shellac or varnish on the shank in this photo. To give a sense of the proportion of the of the pipe I removed the stem and took a photo of it. This will help me when I choose a new stem for it. Now to work on the pipe itself. I started by reaming it with a PipNet Pipe Reamer. The bowl was large enough that I used the second and third cutting heads. I took the cake back to bare briar. I cleaned up the reaming with a Savinelli Fitsall Pipe Knife. I also scraped off the lava build up on the rim top with the knife. I sanded the bowl walls with 220 grit sandpaper wrapped around a dowel. I took it back to smooth walls. The walls looked very good with no sign of checking or burning.

Now to work on the pipe itself. I started by reaming it with a PipNet Pipe Reamer. The bowl was large enough that I used the second and third cutting heads. I took the cake back to bare briar. I cleaned up the reaming with a Savinelli Fitsall Pipe Knife. I also scraped off the lava build up on the rim top with the knife. I sanded the bowl walls with 220 grit sandpaper wrapped around a dowel. I took it back to smooth walls. The walls looked very good with no sign of checking or burning.

I cleaned out the shank, mortise and the airway in the bowl with pipe cleaners, cotton swabs and isopropyl alcohol. It took a lot of cleaners but I got the grime and oils out of the shank and though the pipe smelled of tobacco it was much cleaner smelling than previous to that. I chose not to clean the stem since I was going to replace it.

I cleaned out the shank, mortise and the airway in the bowl with pipe cleaners, cotton swabs and isopropyl alcohol. It took a lot of cleaners but I got the grime and oils out of the shank and though the pipe smelled of tobacco it was much cleaner smelling than previous to that. I chose not to clean the stem since I was going to replace it. With the internals cleaned I turned my attention to the rim top. I worked over the inner edge of the bowl and the rim top with a folded piece of 220 grit sandpaper. I then gently topped the bowl on a topping board with 220 grit sandpaper. I cleaned up the inner edge a bit more. The pipe looked amazingly good.

With the internals cleaned I turned my attention to the rim top. I worked over the inner edge of the bowl and the rim top with a folded piece of 220 grit sandpaper. I then gently topped the bowl on a topping board with 220 grit sandpaper. I cleaned up the inner edge a bit more. The pipe looked amazingly good.

I wiped down the bowl with acetone soaked cotton pads to remove the varnish/shellac coat. It was particularly heavy around the stamping on the shank – both sides. It took much work to remove the shiny coat.

I wiped down the bowl with acetone soaked cotton pads to remove the varnish/shellac coat. It was particularly heavy around the stamping on the shank – both sides. It took much work to remove the shiny coat.

I sanded the bowl with sanding pads – 320-3500 grit pads. I dry sanded it and wiped it down with a damp cloth after each pad. I was able to remove all of the shiny coat and the bowl began to take on a natural shine.

I sanded the bowl with sanding pads – 320-3500 grit pads. I dry sanded it and wiped it down with a damp cloth after each pad. I was able to remove all of the shiny coat and the bowl began to take on a natural shine.

I stained the rim top with a Cherry stain pen to match the rest of the briar. I also stained the lighter areas around the shank end. The rim top looked much better.

I stained the rim top with a Cherry stain pen to match the rest of the briar. I also stained the lighter areas around the shank end. The rim top looked much better. I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped it down after each sanding pad with a damp cloth to remove the sanding debris on the surface.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped it down after each sanding pad with a damp cloth to remove the sanding debris on the surface.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect it. I used a shoe brush to work it into the twin rings around the bowl cap. I let the balm sit for a little while and then buffed with a cotton cloth and shoe brush to raise the shine.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect it. I used a shoe brush to work it into the twin rings around the bowl cap. I let the balm sit for a little while and then buffed with a cotton cloth and shoe brush to raise the shine.

I set the bowl aside and turned my attention to a new stem. I found a blank in my can of stems that was close to the right diameter and just slightly longer. With a few adjustments to the tenon and the diameter at the shank the fit will be good. You can also see the large broken chunk missing on the original stem in the photo below. In the second photo below, I knocked off the casting debris with a Dremel and sanding drum in preparation for using my tenon turning tool.

I set the bowl aside and turned my attention to a new stem. I found a blank in my can of stems that was close to the right diameter and just slightly longer. With a few adjustments to the tenon and the diameter at the shank the fit will be good. You can also see the large broken chunk missing on the original stem in the photo below. In the second photo below, I knocked off the casting debris with a Dremel and sanding drum in preparation for using my tenon turning tool. I used the PIMO tenon turner to bring the tenon down close to the size that I wanted. I do this in stages as the tool can chip the tenon if you take too big a bite at one time. The second photo shows it getting closer. I paused mid turn to show how it cuts away material. Once I cleaned it up the fit was very close. Some sanding would make the fit perfect.

I used the PIMO tenon turner to bring the tenon down close to the size that I wanted. I do this in stages as the tool can chip the tenon if you take too big a bite at one time. The second photo shows it getting closer. I paused mid turn to show how it cuts away material. Once I cleaned it up the fit was very close. Some sanding would make the fit perfect.

I used a small flat file to remove the casting marks on the sides of the stem and fine tune the tenon fit in the bowl and took some photos of where it stands at this point.

I used a small flat file to remove the casting marks on the sides of the stem and fine tune the tenon fit in the bowl and took some photos of where it stands at this point. I started sanding the diameter of the stem to match the shank and then decided to give it a quick bend. I heated it with the flame of a lighter until the vulcanite was soft then bent the end to get the angle correct. I checked it against the original stem and the bend matched. Good to go!

I started sanding the diameter of the stem to match the shank and then decided to give it a quick bend. I heated it with the flame of a lighter until the vulcanite was soft then bent the end to get the angle correct. I checked it against the original stem and the bend matched. Good to go!

Now I had a lot of hand sanding to do to trim back the diameter to fit the shank. I do this next part all by hand with the stem removed and constantly putting it on the shank and checking progress. It is tedious so I can think of other things while sanding. It makes the process a bit of a respite. I can’t tell you how many hours of sanding this took but it is finally there. The fit is right and now it is time to polish it.

Now I had a lot of hand sanding to do to trim back the diameter to fit the shank. I do this next part all by hand with the stem removed and constantly putting it on the shank and checking progress. It is tedious so I can think of other things while sanding. It makes the process a bit of a respite. I can’t tell you how many hours of sanding this took but it is finally there. The fit is right and now it is time to polish it.

Once the fit was correct, I started polishing out the scratch marks and smoothing the stem with 320-3500 grit sanding pads. I wiped the stem down after each sanding pad with an Obsidian Oil impregnated cloth. It removes the dust and also gives the sanding pads some bite. By the final pad it was looking quite good.

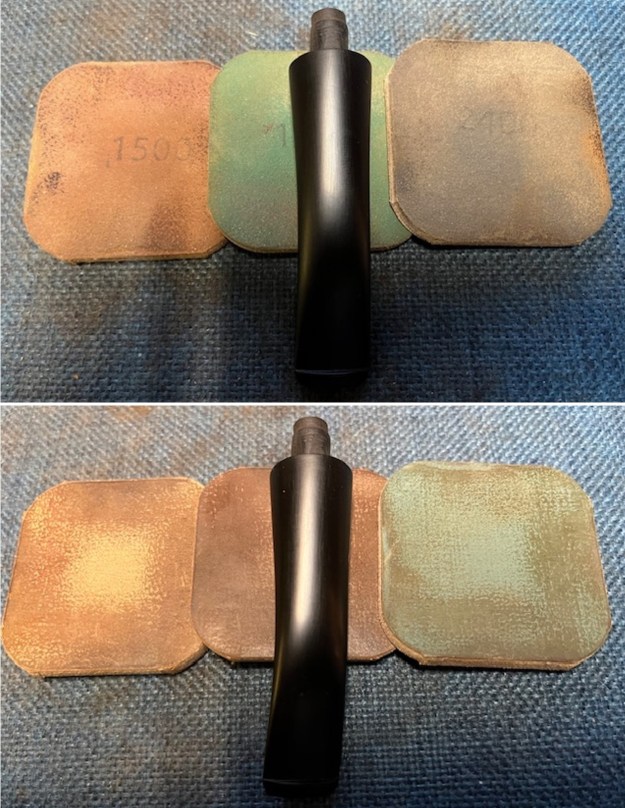

Once the fit was correct, I started polishing out the scratch marks and smoothing the stem with 320-3500 grit sanding pads. I wiped the stem down after each sanding pad with an Obsidian Oil impregnated cloth. It removes the dust and also gives the sanding pads some bite. By the final pad it was looking quite good. Following my usual process in restoration I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it further with Before & After Stem Polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil and set it aside to absorb the oil.

Following my usual process in restoration I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it further with Before & After Stem Polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil and set it aside to absorb the oil.

The John Crouch Heavyweigh(t) Rhodesian has been restemmed and is finished other than the final waxing and buffing. I polished the new stem with Blue Diamond to polish out the remaining small scratches and gave it several coats of carnauba. I buffed the pipe with a clean buffing pad on the buffer to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The finished pipe is shown in the photos below. The dimensions are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 45 grams/1.59 ounces. It does not feel heavy and the weight certainly does not put it in a heavy category for me. I will be sending it back to Anthony shortly. I look forward to hearing what he thinks of it once he has it in hand. If the condition was any indicator it is a good smoker. Thanks for walking through the restoration with me as I worked over this John Crouch Heavyweigh(t) Rhodesian.

The John Crouch Heavyweigh(t) Rhodesian has been restemmed and is finished other than the final waxing and buffing. I polished the new stem with Blue Diamond to polish out the remaining small scratches and gave it several coats of carnauba. I buffed the pipe with a clean buffing pad on the buffer to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The finished pipe is shown in the photos below. The dimensions are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 45 grams/1.59 ounces. It does not feel heavy and the weight certainly does not put it in a heavy category for me. I will be sending it back to Anthony shortly. I look forward to hearing what he thinks of it once he has it in hand. If the condition was any indicator it is a good smoker. Thanks for walking through the restoration with me as I worked over this John Crouch Heavyweigh(t) Rhodesian.