Blog by Steve Laug

A good friend of mine stopped by for a bowl the other day and to drop off some pipes he was donating to the Nepal Pipe Project. He has given quite a few already and some of you have benefited from his generosity. This time he had a couple of surprises with him as well. He had two of his favourite pipes with him that needed some attention. The first was a handmade Gepetto Canadian made by Ser Jacopo. It was a shape #37 and had a rusticated finish. It was a beautiful pipe. He had been twisting the stem out of the shank and it was stuck. One little twist too much and the tenon snapped in the shank. It broke off quite deep in the shank and was solidly stuck in place. I would need to pull the tenon, drill out the stem and insert a new tenon.

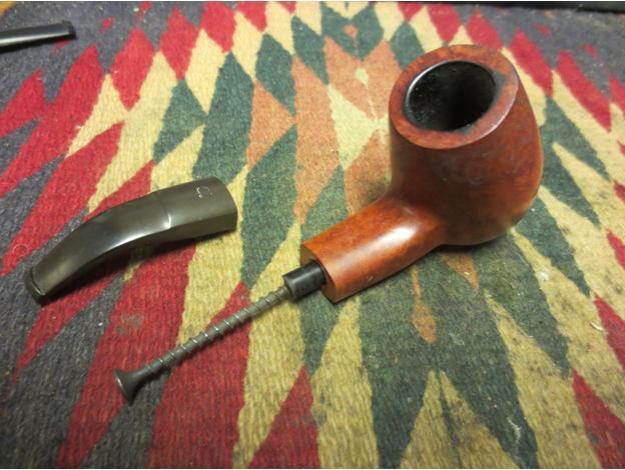

I used my drywall screw and twisted it into the airway of the broken tenon until it caught hold and then wiggled it loose. With careful wiggling and pulling the broken tenon came free of the shank.

I used my drywall screw and twisted it into the airway of the broken tenon until it caught hold and then wiggled it loose. With careful wiggling and pulling the broken tenon came free of the shank.

I used the Dremel and sanding drum to take off the majority of the remaining broken tenon on the stem itself. I faced it on the topping board with 220 grit sandpaper until it was flat against the rest of the stem face.

I used the Dremel and sanding drum to take off the majority of the remaining broken tenon on the stem itself. I faced it on the topping board with 220 grit sandpaper until it was flat against the rest of the stem face.

The stem is Lucite and the original tenon was an integral part of the stem. I did not have any Lucite tenon and also no Delrin tenons. So once again I decided to do some improvisation. I turned down the tenon on an old thin vulcanite stem that I had in my stem can until it was a snug fit in the mortise of the shank. I wanted it to sit as deeply as the previous tenon so I turned it down accordingly with the Dremel and sanding drum. When the fit was correct I left it in place in the shank and carefully cut off the stem with a hacksaw. I left enough of the new tenon to sit in the hole I would drill in the stem face.

The stem is Lucite and the original tenon was an integral part of the stem. I did not have any Lucite tenon and also no Delrin tenons. So once again I decided to do some improvisation. I turned down the tenon on an old thin vulcanite stem that I had in my stem can until it was a snug fit in the mortise of the shank. I wanted it to sit as deeply as the previous tenon so I turned it down accordingly with the Dremel and sanding drum. When the fit was correct I left it in place in the shank and carefully cut off the stem with a hacksaw. I left enough of the new tenon to sit in the hole I would drill in the stem face. I set up a drill and turned the stem onto the drill bit by hand until it was deep enough to hold the new tenon but not too deep because of the sharp taper of the stem. If it was too deep it would have broken through the top and bottom side of the taper. I measured the depth I had to work with and drilled only that depth in the stem. I started out using a drill bit slightly larger than the airway in the stem and worked my way up to a ¼ inch bit. I used a round needle file to clean up the inside edges of the drilled out stem. I turned the end of the tenon down until it slid snugly into the hole. Once I had a good fit I coated the end of the tenon with super glue and pressed it into the hole. I did this carefully to keep the tenon straight both horizontally and vertically.

I set up a drill and turned the stem onto the drill bit by hand until it was deep enough to hold the new tenon but not too deep because of the sharp taper of the stem. If it was too deep it would have broken through the top and bottom side of the taper. I measured the depth I had to work with and drilled only that depth in the stem. I started out using a drill bit slightly larger than the airway in the stem and worked my way up to a ¼ inch bit. I used a round needle file to clean up the inside edges of the drilled out stem. I turned the end of the tenon down until it slid snugly into the hole. Once I had a good fit I coated the end of the tenon with super glue and pressed it into the hole. I did this carefully to keep the tenon straight both horizontally and vertically.  Once the glue set on the new tenon I cleaned it up with some sandpaper and then pushed it into the mortise of the pipe. The fit was good and the taper lined up correctly on the top, sides and bottom of the shank. The stem needed to be sanded to clean it up and polish it. I sanded it with 220 grit sandpaper to smooth out the edges and around the button.

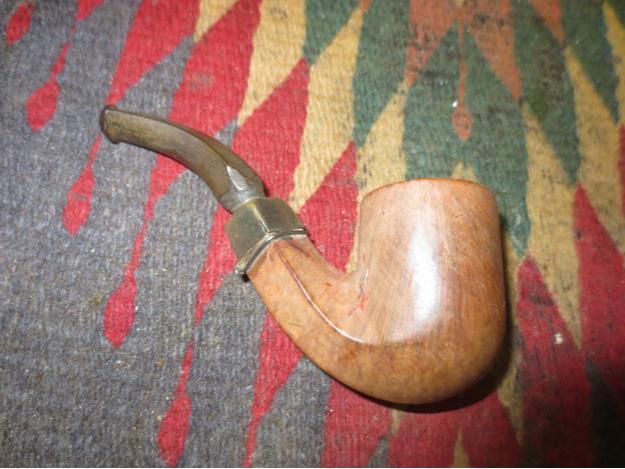

Once the glue set on the new tenon I cleaned it up with some sandpaper and then pushed it into the mortise of the pipe. The fit was good and the taper lined up correctly on the top, sides and bottom of the shank. The stem needed to be sanded to clean it up and polish it. I sanded it with 220 grit sandpaper to smooth out the edges and around the button.

I continued to sand it with a medium and a fine grit sanding sponge. The fit against shank on the underside had a slight gap so I needed to do some adjustments. I heated the tenon and then pushed it in place and held it against the shank until it cooled and set. The fit was better.

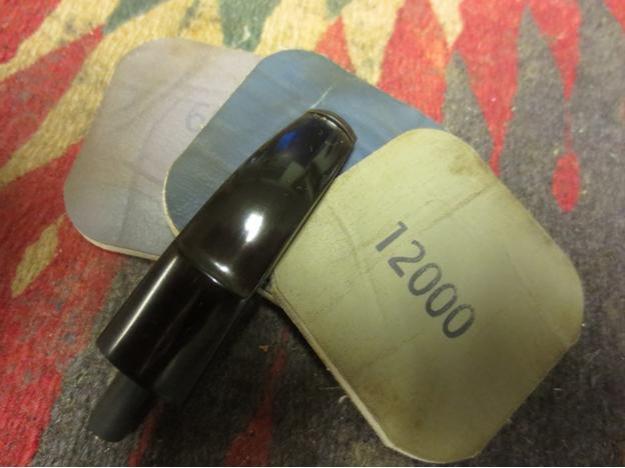

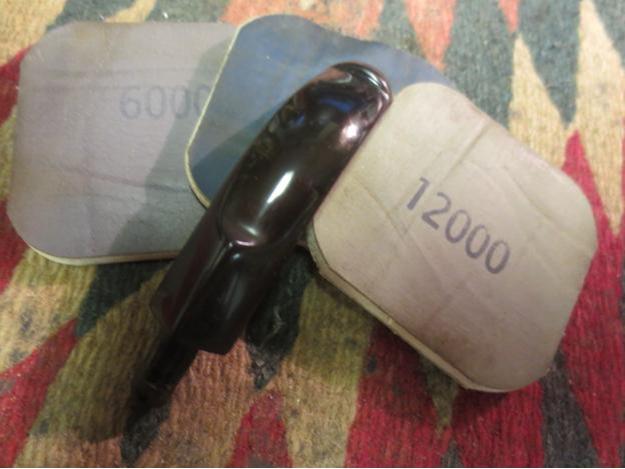

I continued to sand it with a medium and a fine grit sanding sponge. The fit against shank on the underside had a slight gap so I needed to do some adjustments. I heated the tenon and then pushed it in place and held it against the shank until it cooled and set. The fit was better. I wet sanded the stem with 1500-2400 grit micromesh pads and then used some mineral oil to give the next grits of micromesh some bite. I then dry sanded with 3200-4000 grit pads and repeated the oil and then finished with 6000-12000 grit pads. I put the stem on the pipe and buffed it with Blue Diamond.

I wet sanded the stem with 1500-2400 grit micromesh pads and then used some mineral oil to give the next grits of micromesh some bite. I then dry sanded with 3200-4000 grit pads and repeated the oil and then finished with 6000-12000 grit pads. I put the stem on the pipe and buffed it with Blue Diamond.

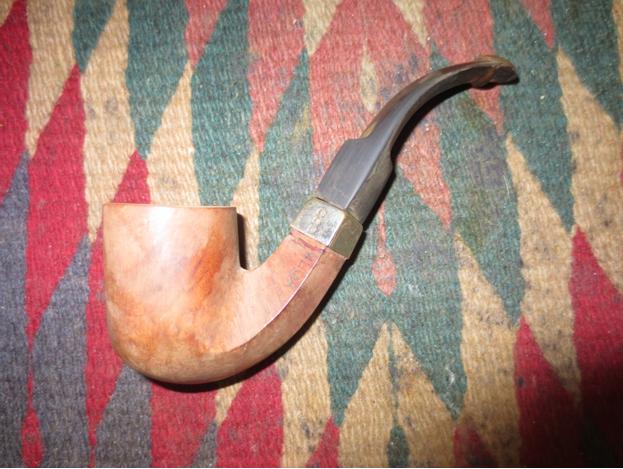

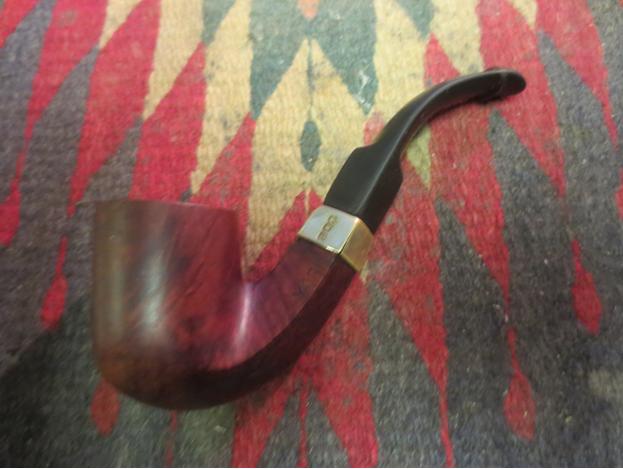

The rim had some build up of tars on the back top edge so I cleaned that off and then buffed the rim the rim to polish it. I lightly buffed the entire bowl. I used carnauba wax on the rim and the smooth portions of the pipe as well as the stem. I buffed it with a clean flannel buff and then buffed it by hand with a microfibre cloth. The finished pipe is shown below. It should be back in my friend’s hands soon and he can enjoy it once again. Thanks for looking.

The rim had some build up of tars on the back top edge so I cleaned that off and then buffed the rim the rim to polish it. I lightly buffed the entire bowl. I used carnauba wax on the rim and the smooth portions of the pipe as well as the stem. I buffed it with a clean flannel buff and then buffed it by hand with a microfibre cloth. The finished pipe is shown below. It should be back in my friend’s hands soon and he can enjoy it once again. Thanks for looking.