Blog by Steve Laug

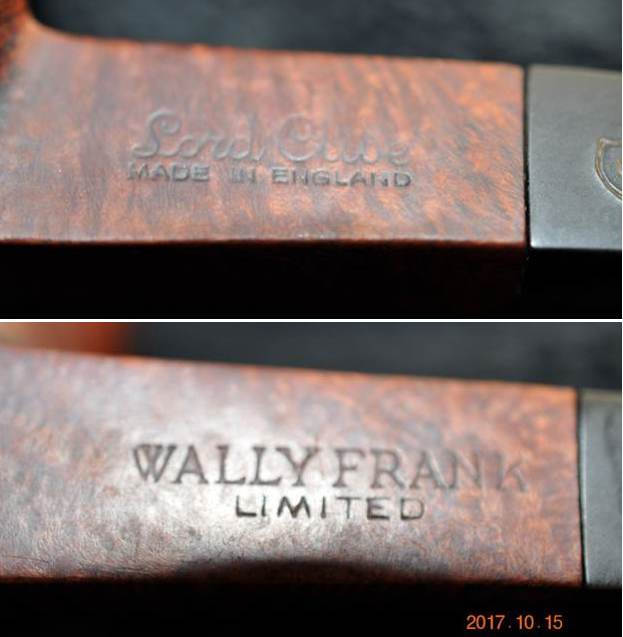

The next pipe is one that Jeff picked up from an antique store on 10/14/17 in Pocatello, Idaho, USA. The store is no longer there so it is a memory that we both share having bought pipes from them over the years. This one is a very English looking straight Bulldog with a taper stem. It is stamped on the top left of the diamond shank and reads Lord Clive in script [over] MADE IN ENGLAND. On the left underside of the shank it is stamped WALLY FRANK [over] LIMITED. On the top right side of the diamond shank it is stamped with the shape number 827. The finish is very dirty with a thick cake and lava overflow on the rim top. There are some nicks in the surface of the briar as well. The twin rings around the cap are in good condition which is a blessing as these are often chipped and damaged. The stem has shield with a C in the middle stamped in gold on the left top side of the diamond taper. It is lightly oxidized and has tooth marks and chatter on both sides ahead of the button. There is also a chip on the right underside of the button that will need to be addressed. It is a proportionally pleasing looking pipe with some interesting grain poking through the grime. Jeff took photos of the pipe before he started his cleanup and I have included them below.

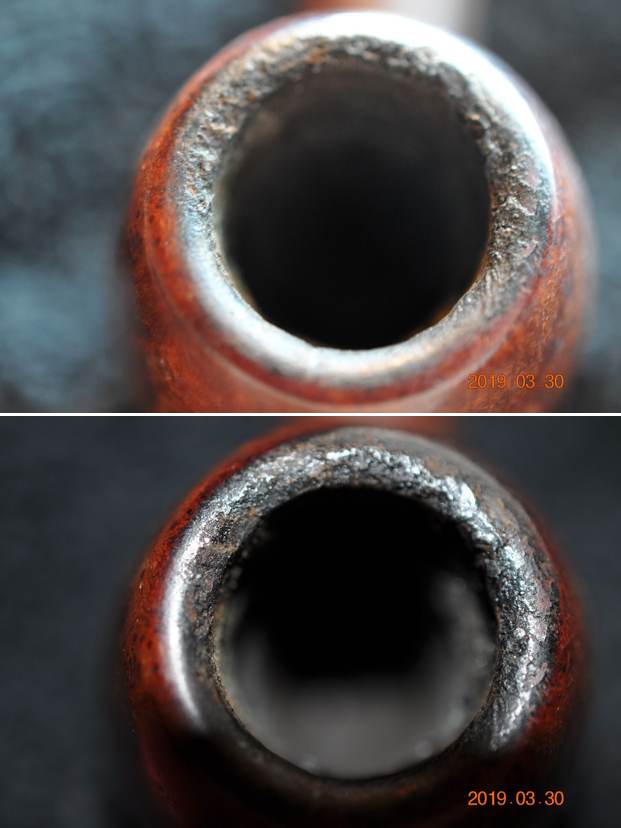

Jeff took photos of the rim top and stem to give a clear picture of the condition of the bowl, rim top and stem. You can see the thick cake in the bowl and the lava build up on the crowned rim top. There are some nicks and damage but it is hard to know what is under the lava coat and cake. The photos of the stem show the damage on the right underside button and the area ahead of it. It almost makes the tooth marks and chatter in the stem invisible. But believe me they are very present.

Jeff took photos of the rim top and stem to give a clear picture of the condition of the bowl, rim top and stem. You can see the thick cake in the bowl and the lava build up on the crowned rim top. There are some nicks and damage but it is hard to know what is under the lava coat and cake. The photos of the stem show the damage on the right underside button and the area ahead of it. It almost makes the tooth marks and chatter in the stem invisible. But believe me they are very present.

He captured the grain on the side of the bowl as well as the deep gouge in the next photo. It is a nice piece of briar.

He captured the grain on the side of the bowl as well as the deep gouge in the next photo. It is a nice piece of briar.  Jeff took a few photos of the stamping on the shank and stem to capture it for me. The photos show the stamp on the left upper and lower diamond shank and stem as well as the upper right side of the shank. It is clear and readable as noted above.

Jeff took a few photos of the stamping on the shank and stem to capture it for me. The photos show the stamp on the left upper and lower diamond shank and stem as well as the upper right side of the shank. It is clear and readable as noted above.

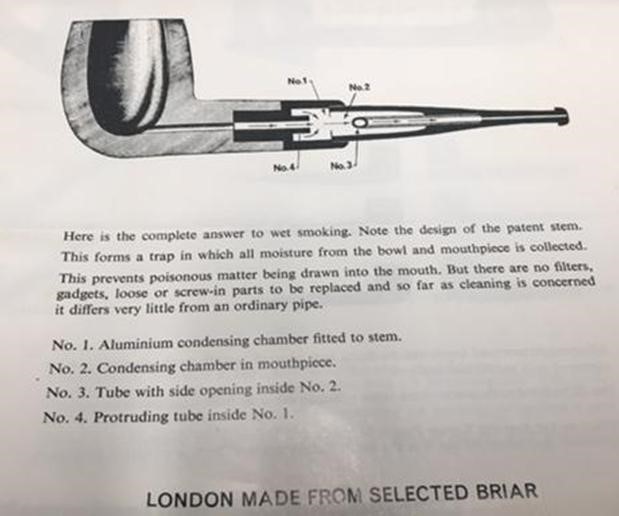

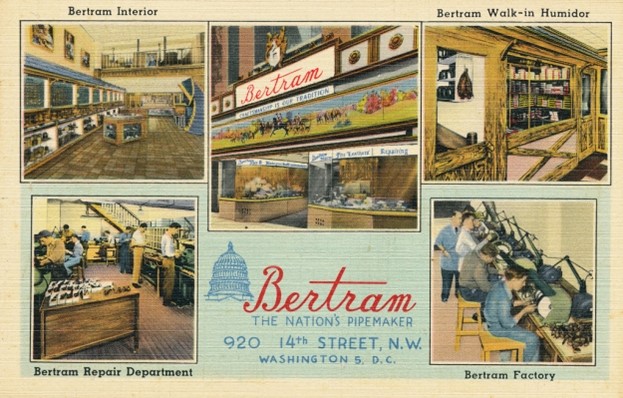

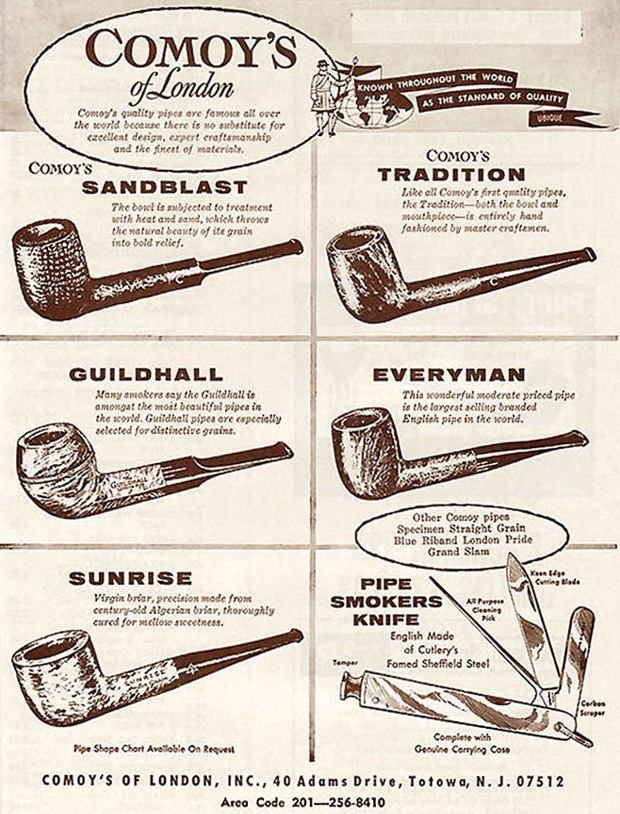

The look of the pipe, the shape number and the Made in England stamp all reminded me of Comoy’s made pipes. I turned to Pipephil to see what I could learn there about the brand and its provenance (http://pipephil.eu/logos/en/logo-l6.html). Sure enough the site had a listing which I have captured in the next two photos. All of the stamping looks precisely the way the one I am working on looks minus the Wally Frank LTD stamp. Sure enough the pipe is made by Comoy’s so my guess was not wrong.

The look of the pipe, the shape number and the Made in England stamp all reminded me of Comoy’s made pipes. I turned to Pipephil to see what I could learn there about the brand and its provenance (http://pipephil.eu/logos/en/logo-l6.html). Sure enough the site had a listing which I have captured in the next two photos. All of the stamping looks precisely the way the one I am working on looks minus the Wally Frank LTD stamp. Sure enough the pipe is made by Comoy’s so my guess was not wrong.

I then turned to Pipedia for more information. There was nothing listed under Lord Clive so I turned to the section on Comoy’s (https://pipedia.org/wiki/Comoy%27s). I scrolled through the great historical information sections of the wiki until I came the section I have included below. In the list of names I found Lord Clive and have marked it in red.

I then turned to Pipedia for more information. There was nothing listed under Lord Clive so I turned to the section on Comoy’s (https://pipedia.org/wiki/Comoy%27s). I scrolled through the great historical information sections of the wiki until I came the section I have included below. In the list of names I found Lord Clive and have marked it in red.

Seconds made by Comoy’s – Academy Award, Ace of spades, Ancestor, Astor, Ayres, Britannia, Canadian Club, Carlyle, Charles Cross, Claridge, Coronet?, Cromwell, Damman?, Dorchester, Dunbar, Drury Lane, Emerson, Everyman, Festival of Britain, Golden Arrow, Grand Master, Gresham, Guildhall, Hamilton (according to Who Made That Pipe), Kingsway, Lion’s Head, Lord Clive, Lumberman, Hyde Park, Lloyds, Mc Gahey, Moorgate, Newcastle, Oxford, O’Gorman, Rosebery Extra, Royal Falcon, Royal Guard, Royal Lane, Scotland Yard, St James, Sunrise, Super Sports, Sussex, The Academy Award, The Golden Arrow, The Mansion House, The Exmoor Pipe, Treaty Bond, Throgmorton, Tinder Box Royal Coachman, Townhall, Trident, Trocadero, Westminster, Wilshire

I now knew I was dealing a pipe that Comoy’s had made for Wally Frank Ltd. It was classic shaped Comoy’s 827 straight Bulldog with a taper stem. But I still wanted to know “Who is Lord Clive?”.

So I continued my exploration of the web and turned to Wikipedia to see what I could learn about the person (https://en.wikipedia.org › wiki › Robert_Clive). I quote a summary below and also include a photo.

Major-General Robert Clive, 1st Baron Clive, KB, FRS (29 September 1725 – 22 November 1774), also known as Clive of India, was the first British Governor of the Bengal Presidency. Clive has been widely credited for laying the foundation of the British East India Company rule in Bengal.

That short summary told me what I needed to know. It also said more than was written. To the British he was a hero and to the people of India he was an oppressor. But it is interesting to know a bit about him.

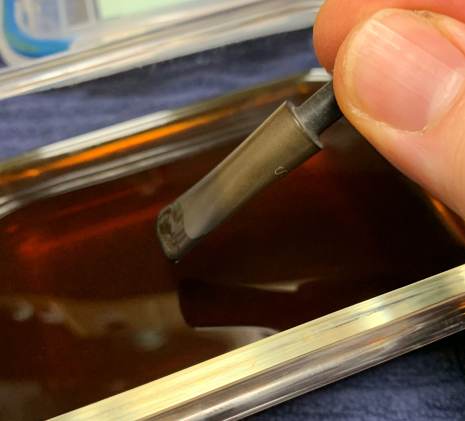

Jeff reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and undiluted Murphy’s Oil Soap to remove the lava, oils and tars on the rim and the grime on the finish of the bowl. He rinsed it under running water. He dried it off with a soft cloth. He was able to remove lava build up on the rim top and you could see the great condition of the bowl top and edges of the rim. There was still some darkening to the rim top toward the back of the bowl. He soaked the stem in Before & After Deoxidizer to remove the oxidation. I took photos of the pipe before I started my work on it.

I took a close up photo of the rim top to show the condition of the bowl and rim after Jeff had cleaned up the grime and lava. The crowned rim top had some darkening on the whole rim top though darker on the backside of the rim and there were dings and nicks in the surface. The stem photos show that the oxidation is gone. The tooth marks and chatter are eclipsed by the missing chunk of the stem on the right edge of the button and up the stem.

I took a close up photo of the rim top to show the condition of the bowl and rim after Jeff had cleaned up the grime and lava. The crowned rim top had some darkening on the whole rim top though darker on the backside of the rim and there were dings and nicks in the surface. The stem photos show that the oxidation is gone. The tooth marks and chatter are eclipsed by the missing chunk of the stem on the right edge of the button and up the stem.  I took photos of the stamping on the sides of the diamond shank showing how it was laid out. I was also able to capture the C in the shield on the left topside of the taper stem.

I took photos of the stamping on the sides of the diamond shank showing how it was laid out. I was also able to capture the C in the shield on the left topside of the taper stem.  I removed the stem from the shank and took a photo of the pipe to show the proportions and the look of the grain on the bowl. I also show the damage to the side of the stem in both photos. The first one shows the top right and the second the bottom right. The pipe really is a beauty!

I removed the stem from the shank and took a photo of the pipe to show the proportions and the look of the grain on the bowl. I also show the damage to the side of the stem in both photos. The first one shows the top right and the second the bottom right. The pipe really is a beauty!  I sanded the top of the rim with a folded piece of 220 grit sandpaper to remove the damage and the darkening. I would polish it later and think it would look very good. The photo shows how the rim looked at this point.

I sanded the top of the rim with a folded piece of 220 grit sandpaper to remove the damage and the darkening. I would polish it later and think it would look very good. The photo shows how the rim looked at this point.  I repaired the deep gouges on the bowl sides with clear CA glue. Once they cured I sanded them smooth with 220 grit sandpaper to blend them in and reduce the shininess of the repair. I am happy with how it looks.

I repaired the deep gouges on the bowl sides with clear CA glue. Once they cured I sanded them smooth with 220 grit sandpaper to blend them in and reduce the shininess of the repair. I am happy with how it looks.

I polished the bowl and rim top with micromesh sanding pads – dry sanding it with 1500-12000 grit pads. I wiped the bowl down with a damp cloth after each pad to remove the sanding debris. After the final sanding pad I hand buffed it with a cotton cloth to raise a shine.

I polished the bowl and rim top with micromesh sanding pads – dry sanding it with 1500-12000 grit pads. I wiped the bowl down with a damp cloth after each pad to remove the sanding debris. After the final sanding pad I hand buffed it with a cotton cloth to raise a shine.

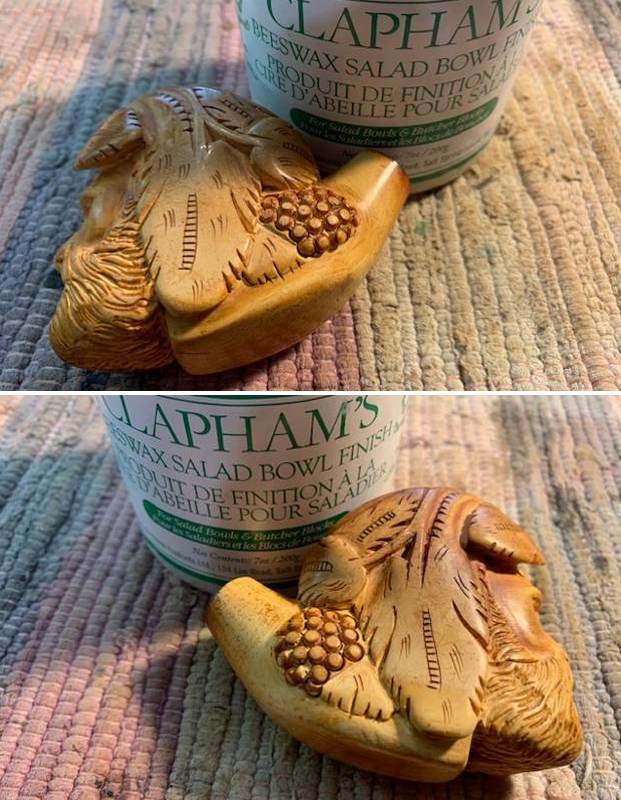

I worked some Before & After Restoration Balm into finish of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The Restoration Balm really makes the grain stands out beautifully.

I worked some Before & After Restoration Balm into finish of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The Restoration Balm really makes the grain stands out beautifully.

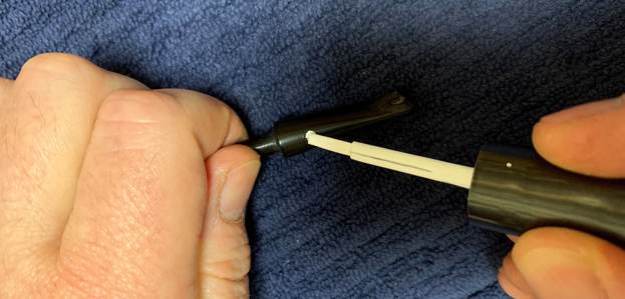

I set the bowl aside and turned my attention to the stem. I greased a pipe cleaner with Vaseline and inserted it in the slot. I used some very thick black CA glue and worked it into the damaged area on the button and stem using a dental spatula. I set it aside to let it cure.

I set the bowl aside and turned my attention to the stem. I greased a pipe cleaner with Vaseline and inserted it in the slot. I used some very thick black CA glue and worked it into the damaged area on the button and stem using a dental spatula. I set it aside to let it cure.

Once it cured I used a small file to redefine the button edge and flatten out the surface of the stem. Once I had removed the largest part of the fills I used clear CA glue to fill in the air bubbles and work on the repaired edge shape. I then used the file to flatten and reshape those repairs.

Once it cured I used a small file to redefine the button edge and flatten out the surface of the stem. Once I had removed the largest part of the fills I used clear CA glue to fill in the air bubbles and work on the repaired edge shape. I then used the file to flatten and reshape those repairs.

I used a folded piece of 220 grit sandpaper to blend the repairs into the surface of the stem. I started polishing the stem with a folded piece of 400 grit sandpaper. I wiped the stem down with Obsidian Oil.

I used a folded piece of 220 grit sandpaper to blend the repairs into the surface of the stem. I started polishing the stem with a folded piece of 400 grit sandpaper. I wiped the stem down with Obsidian Oil.  I polished the stem with micromesh sanding pads – dry sanding it with 1500-12000 grit pads. I wiped the stem down with Obsidian Oil after each pad. I polished it with Before & After Pipe Polish – both Fine and Extra Fine and gave it a final coat and set it aside to dry.

I polished the stem with micromesh sanding pads – dry sanding it with 1500-12000 grit pads. I wiped the stem down with Obsidian Oil after each pad. I polished it with Before & After Pipe Polish – both Fine and Extra Fine and gave it a final coat and set it aside to dry.

I put the stem back on the Comoy’s Made Lord Clive 827 Bulldog and buffed the pipe with Blue Diamond on the buffing wheel. I polished the briar and the vulcanite of the stem until there was a rich shine. This classic English straight Bulldog shape and finish really highlights some amazing grain on a proportionally well carved pipe. Once I buffed the pipe the briar came alive and the mixture of grain – straight, flame and birdseye – popped with polishing. The repaired black vulcanite stem had a rich glow. This Lord Clive 827 Bulldog fits well in the hand and sits right in the mouth. Have a look at it with the photos below. The dimensions are Length: 5 ¾ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.45 ounces/41 grams. This beauty will be going on the rebornpipes online store in the English Pipemakers Section. If you are interested let me know. Thanks for walking through the restoration with me as it was a pleasure to work on.

I put the stem back on the Comoy’s Made Lord Clive 827 Bulldog and buffed the pipe with Blue Diamond on the buffing wheel. I polished the briar and the vulcanite of the stem until there was a rich shine. This classic English straight Bulldog shape and finish really highlights some amazing grain on a proportionally well carved pipe. Once I buffed the pipe the briar came alive and the mixture of grain – straight, flame and birdseye – popped with polishing. The repaired black vulcanite stem had a rich glow. This Lord Clive 827 Bulldog fits well in the hand and sits right in the mouth. Have a look at it with the photos below. The dimensions are Length: 5 ¾ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.45 ounces/41 grams. This beauty will be going on the rebornpipes online store in the English Pipemakers Section. If you are interested let me know. Thanks for walking through the restoration with me as it was a pleasure to work on.