Blog by Steve Laug

The next pipe on the work table was purchased on 12/08/2021 from a seller on a Facebook auction from Durham, North Carolina, USA. The grain on this lovely Bent Billiard is what caught Jeff’s eye. It is a beautifully grained Bent Billiard with a vulcanite taper stem. The pipe is stamped on the left side and reads Ben Wade in script [over] Special Collection [over] London, England [over] the number 1. There was no other stamping on the shank. The finish had a lot of grime ground into the smooth finish on the bowl and some hand oils around the sides of the bowl. The bowl was thickly caked with an overflowing thick lava coat on the rim top and edges of the rim – heavier on the back top and edge. The stem was oxidized, dirty and had light tooth chatter and marks on the top and underside near the button. The top of the stem was stamped BEN [over] WADE in white. It had promise but it was very dirty. Jeff took some photos of the pipe before he started his cleanup work.

He took photos of the rim top and bowl to give a clear picture of the thickness of the cake and the overflow of lava on the rim top. He also took photos of the top and underside of the stem to show the light chatter and tooth marks. You can also see the light oxidation and calcification on the surface.

He took photos of the rim top and bowl to give a clear picture of the thickness of the cake and the overflow of lava on the rim top. He also took photos of the top and underside of the stem to show the light chatter and tooth marks. You can also see the light oxidation and calcification on the surface.

Jeff took photos of the sides and heel of the bowl to give a picture of what the briar around the pipe looked like. There is some stunning grain under the build up of grime.

Jeff took photos of the sides and heel of the bowl to give a picture of what the briar around the pipe looked like. There is some stunning grain under the build up of grime.

He took photos of the stamping on the sides of the shank and the stem. It reads as noted above and is clear and readable.

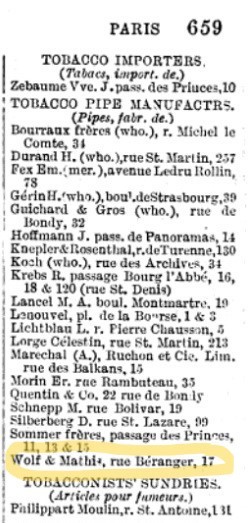

He took photos of the stamping on the sides of the shank and the stem. It reads as noted above and is clear and readable.  I turned to Pipedia (https://pipedia.org/wiki/Ben_Wade) and found a pipe that was stamped like the one that I am working on. The cursive font used on the Special Collection on both pipes is identical.The difference is that on this one it is stamped Made By Hand on the right side of the shank which is not seen on the one I have in hand. Mine is also stamped Ben Wade above the Special Collection stamp that was not seen on the pipe below. The pipes were made by Charatan.

I turned to Pipedia (https://pipedia.org/wiki/Ben_Wade) and found a pipe that was stamped like the one that I am working on. The cursive font used on the Special Collection on both pipes is identical.The difference is that on this one it is stamped Made By Hand on the right side of the shank which is not seen on the one I have in hand. Mine is also stamped Ben Wade above the Special Collection stamp that was not seen on the pipe below. The pipes were made by Charatan.

I am pretty certain it is one of the Ben Wade’s made by Charatan. The Special Collection stamp on the side and the London England stamp both make me also think of Charatan as the maker. Now it was time to work on the pipe.

I am pretty certain it is one of the Ben Wade’s made by Charatan. The Special Collection stamp on the side and the London England stamp both make me also think of Charatan as the maker. Now it was time to work on the pipe.

Jeff had cleaned up the pipe with his habitual process that delivers a very clean pipe to me for work. He reamed the pipe with a PipNet Pipe Reamer and cleaned up the remnants with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and pipe cleaners. He soaked the stem in Briarville’s Pipe Stem Deoxidizer and rinsed it off with warm water. I took photos of the pipe once I received it.

The rim top cleaned up well with the lava coat removed. The inner edge of the rim had a spot of burn on the back edge and a small sandpit on the rim top at the back left side. The stem surface looked very good with a few small tooth marks and chatter on both sides near the button. The Ben Wade mark on the top of the stem is faint and the white has washed out.

The rim top cleaned up well with the lava coat removed. The inner edge of the rim had a spot of burn on the back edge and a small sandpit on the rim top at the back left side. The stem surface looked very good with a few small tooth marks and chatter on both sides near the button. The Ben Wade mark on the top of the stem is faint and the white has washed out. I took a photo of the stamping on the shank. It reads as noted above and is clear and readable. I also took a photo of the pipe with the stem removed to give a sense of the shape and size.

I took a photo of the stamping on the shank. It reads as noted above and is clear and readable. I also took a photo of the pipe with the stem removed to give a sense of the shape and size. Now it was time to do my work on the pipe. I took the pipe to the desk top and started my work. I used a folded piece of 220 grit sandpaper to clean it up and remove the damage. It looked significantly better.

Now it was time to do my work on the pipe. I took the pipe to the desk top and started my work. I used a folded piece of 220 grit sandpaper to clean it up and remove the damage. It looked significantly better. Once I had cleaned up the rim top and edges I polished the bowl and the rim top, sides and shank with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping it down after each pad with a damp cloth. I think the flaw/sandpit in the rim top is the probable cause of it being a Ben Wade and not a Charatan, but it is beautiful.

Once I had cleaned up the rim top and edges I polished the bowl and the rim top, sides and shank with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping it down after each pad with a damp cloth. I think the flaw/sandpit in the rim top is the probable cause of it being a Ben Wade and not a Charatan, but it is beautiful.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for about ten minutes and then buffed it off with a cotton cloth to raise the shine.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for about ten minutes and then buffed it off with a cotton cloth to raise the shine.

I turned the bowl over in my hand at this point examining it carefully and enjoying shape and the flow of the grain around the bowl and shank. It is really quite beautiful. The sandpit on the back of the rim top bugged me. It just stood out and it was a spot that I could feel with my fingers and it extended a little bit into the bowl itself. It just was a blemish on an otherwise beautiful birdseye grain rim top. I just had to address it! I used a tooth pick to put a small drop of clear CA glue in the pit. It was not a huge drop but just enough to fill in the pit and the small part that extended about a 16th of an inch into the bowl. Once it dried I sanded it smooth with a 1500 grit micromesh sanding pad. I think it ended up looking better. I would buff it at the end of the clean up but I like it!

I turned the bowl over in my hand at this point examining it carefully and enjoying shape and the flow of the grain around the bowl and shank. It is really quite beautiful. The sandpit on the back of the rim top bugged me. It just stood out and it was a spot that I could feel with my fingers and it extended a little bit into the bowl itself. It just was a blemish on an otherwise beautiful birdseye grain rim top. I just had to address it! I used a tooth pick to put a small drop of clear CA glue in the pit. It was not a huge drop but just enough to fill in the pit and the small part that extended about a 16th of an inch into the bowl. Once it dried I sanded it smooth with a 1500 grit micromesh sanding pad. I think it ended up looking better. I would buff it at the end of the clean up but I like it!

I set the bowl aside and turned to work on the stem. I rubbed the stem down with Soft Scrub and cotton pads to remove the remaining oxidation in the surface. It looked much better than when I started.

I set the bowl aside and turned to work on the stem. I rubbed the stem down with Soft Scrub and cotton pads to remove the remaining oxidation in the surface. It looked much better than when I started. I painted the stem with the flame of a Bic lighter to lift the tooth marks. I was able to lift them significantly. I filled in what remained with black rubberized superglue. I set it aside to let the repairs cure. I used a file to flatten the repairs and start blending them into the surface. I sanded them with 220 grit sandpaper. (I tried to touch up the Ben Wade stamp with white acrylic nail polish but it did not work well.) I started polishing the stem with 600 grit wet dry sandpaper.

I painted the stem with the flame of a Bic lighter to lift the tooth marks. I was able to lift them significantly. I filled in what remained with black rubberized superglue. I set it aside to let the repairs cure. I used a file to flatten the repairs and start blending them into the surface. I sanded them with 220 grit sandpaper. (I tried to touch up the Ben Wade stamp with white acrylic nail polish but it did not work well.) I started polishing the stem with 600 grit wet dry sandpaper.

I polished the tooth marks and chatter out of the vulcanite stem surface with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad.

I polished the tooth marks and chatter out of the vulcanite stem surface with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad.

I finished my polishing with Before & After Pipe Stem Polish – both Fine and Extra-Fine polishes. I wiped it down with a final coat of Obsidian Oil and set aside.

I finished my polishing with Before & After Pipe Stem Polish – both Fine and Extra-Fine polishes. I wiped it down with a final coat of Obsidian Oil and set aside. This Ben Wade Special Collection London England Bent Billiard made by Charatan with a vulcanite taper stem is a great looking pipe now that it has been restored. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Ben Wade Special Collection Bent Billiard fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 3/8 inches, Chamber diameter: ¾ of an inch. The weight of the pipe 1.98 ounces/56 grams. I will be putting it on the rebornpipes store in the British Pipe Makers Section soon. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This Ben Wade Special Collection London England Bent Billiard made by Charatan with a vulcanite taper stem is a great looking pipe now that it has been restored. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Ben Wade Special Collection Bent Billiard fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 3/8 inches, Chamber diameter: ¾ of an inch. The weight of the pipe 1.98 ounces/56 grams. I will be putting it on the rebornpipes store in the British Pipe Makers Section soon. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.