Blog by Steve Laug

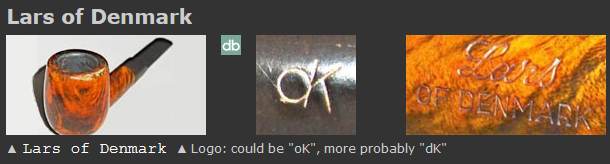

Jeff and I picked up four unsmoked, new old stock (NOS) pipes on Facebook that all are stamped on the left side and read Genuine Briar and on the right side Lars of Denmark. I took a photo of the foursome to show what they looked like. We knew that they were not pipes made by Lars Ivarsson when we bought them but the fact that they were interesting and unsmoked caught our attention. They are definitely not high end pipes they are a little higher in calibre than a basket pipe. They are well executed and the draught is good and the alignment of the entry of the airway into the bowl is centered at the bottom of the bowl. Each of the bowls has a carbon coating on the walls of the bowl that is neutral. All will need some simply refurbishing and polishing to smooth years of sitting unused in someone’s drawer or cabinet but none of them are damaged. The second one I am working on is bent Billiard though in the photo above it has a look of a Brandy. I have circled it in red in the photo above. The stem has a logo on the left side of the saddle that is a dk (Denmark I believe). The bowl was clean but had a bowl coating on the bowl walls. The rim top and bowl are clean but the finish is a little muddy with marks on the finish. There were a few fills (small and hidden) on the sides of the bowl. The vulcanite stem is lightly oxidized and has casting marks on the side of the stem ahead of the saddle portion. It is clean on the inside. The dk stamp on the left side is clear and readable. I took photos of the pipe before I started my work on it.

The second one I am working on is bent Billiard though in the photo above it has a look of a Brandy. I have circled it in red in the photo above. The stem has a logo on the left side of the saddle that is a dk (Denmark I believe). The bowl was clean but had a bowl coating on the bowl walls. The rim top and bowl are clean but the finish is a little muddy with marks on the finish. There were a few fills (small and hidden) on the sides of the bowl. The vulcanite stem is lightly oxidized and has casting marks on the side of the stem ahead of the saddle portion. It is clean on the inside. The dk stamp on the left side is clear and readable. I took photos of the pipe before I started my work on it.

I took a close up photo of the rim top to show some the scuff marks that were on it. The edges of the bowl looked very good. The stem was lightly oxidized and rough with casting marks on the sides of the blade but it was free of tooth marks and chatter.

I took a close up photo of the rim top to show some the scuff marks that were on it. The edges of the bowl looked very good. The stem was lightly oxidized and rough with casting marks on the sides of the blade but it was free of tooth marks and chatter. I took photos of the stamping on the sides of the shank. They are clear and readable as noted above. The logo stamp on the left side of the saddle bit is also clear.

I took photos of the stamping on the sides of the shank. They are clear and readable as noted above. The logo stamp on the left side of the saddle bit is also clear. I removed the stem from the shank and took a photo of the pipe from the side. It is a proportionally well made pipe. The tenon is tight and will need to be cleaned as will the dusty shank.

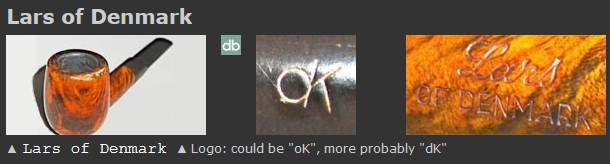

I removed the stem from the shank and took a photo of the pipe from the side. It is a proportionally well made pipe. The tenon is tight and will need to be cleaned as will the dusty shank. I knew next to nothing about the brand. I turned to Pipephil’s site and found some basic information and a photo of a pipe (http://pipephil.eu/logos/en/logo-l2.html). The only detail in the side bar was a note saying that this is not a pipe from Lars Mikael Ivarsson son of Sixten Ivarsson. Ah well, There was nothing else there and there was nothing on Pipedia either. It remains a mystery. I have included a screen capture of the pipe on Pipedia. It is stamped identically to the one on my table.

I knew next to nothing about the brand. I turned to Pipephil’s site and found some basic information and a photo of a pipe (http://pipephil.eu/logos/en/logo-l2.html). The only detail in the side bar was a note saying that this is not a pipe from Lars Mikael Ivarsson son of Sixten Ivarsson. Ah well, There was nothing else there and there was nothing on Pipedia either. It remains a mystery. I have included a screen capture of the pipe on Pipedia. It is stamped identically to the one on my table. I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth. It was looking better by the final three pads.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth. It was looking better by the final three pads.

With the polishing finished I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process. There are some flaws in the briar on both sides. There are small fills and some flaws in the wood.

With the polishing finished I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process. There are some flaws in the briar on both sides. There are small fills and some flaws in the wood.

The inside of the shank and mortise has a lot of stain inside which I assume came from dip staining the bowl. I cleaned it out with alcohol, pipe cleaners and cotton swabs until the came out clean. I cleaned the airway in the stem at the same time in the same way.

The inside of the shank and mortise has a lot of stain inside which I assume came from dip staining the bowl. I cleaned it out with alcohol, pipe cleaners and cotton swabs until the came out clean. I cleaned the airway in the stem at the same time in the same way. I sanded out the scratches and deep marks in the stem top, the casting marks on the stem sides and the oxidation on the underside of the stem.

I sanded out the scratches and deep marks in the stem top, the casting marks on the stem sides and the oxidation on the underside of the stem. I polished the vulcanite stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem and gave it a final coat of Obsidian Oil to finish it.

I polished the vulcanite stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem and gave it a final coat of Obsidian Oil to finish it.

This interesting Lars of Denmark Genuine Briar Bent Billiard turned out to be another nice looking pipe with the little extra TLC I put in once I received it. The rich oxblood finish hides the fills on the rim top and bowl quite well. The red finish with black under tones highlights the swirls of the grain and works well with the polished vulcanite stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Lars of Denmark Bent Billiard is a nice size pipe that I think will be a great smoker. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 47grams/ 1.66 ounces. Since it is unsmoked it is one you can break in with your tobacco of choice. I will be adding it to the Danish Pipe Makers Section of the rebornpipes store shortly. Let me know if you are interested in adding it to your collection. Thanks for reading this blog and my reflections on the pipe while I worked on it.

This interesting Lars of Denmark Genuine Briar Bent Billiard turned out to be another nice looking pipe with the little extra TLC I put in once I received it. The rich oxblood finish hides the fills on the rim top and bowl quite well. The red finish with black under tones highlights the swirls of the grain and works well with the polished vulcanite stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Lars of Denmark Bent Billiard is a nice size pipe that I think will be a great smoker. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 47grams/ 1.66 ounces. Since it is unsmoked it is one you can break in with your tobacco of choice. I will be adding it to the Danish Pipe Makers Section of the rebornpipes store shortly. Let me know if you are interested in adding it to your collection. Thanks for reading this blog and my reflections on the pipe while I worked on it.