by Steve Laug

I am excited to be working on another uniquely beautiful pipe stamped JHW. But maybe you don’t know why I am excited about a pipe stamped with these three initials, Well I have to tell you right up front that JHW is Jack H. Weinberger. Who is that? That does not help either? Jack H. Weinberger was a pipe maker in West Caldwell, New Jersey. Still not helping? He hired young lads from the local high school to help him out as he carved 10-12 hours a day. Two of these were none other than Curt Rollar and Mark Tinsky who went on to become the American Pipe Company. There was a long list of pipe carving luminaries who came through Jack’s shop and JHW pipes but these two you probably have heard of. So JHW or Jack H. Weinberger was an important part of the American Pipemaking scene and gave many carvers a start and they have continued to this day. Now maybe you understand my excitement – being able to work on another of Jack’s pipes and bring it back to its former glory.

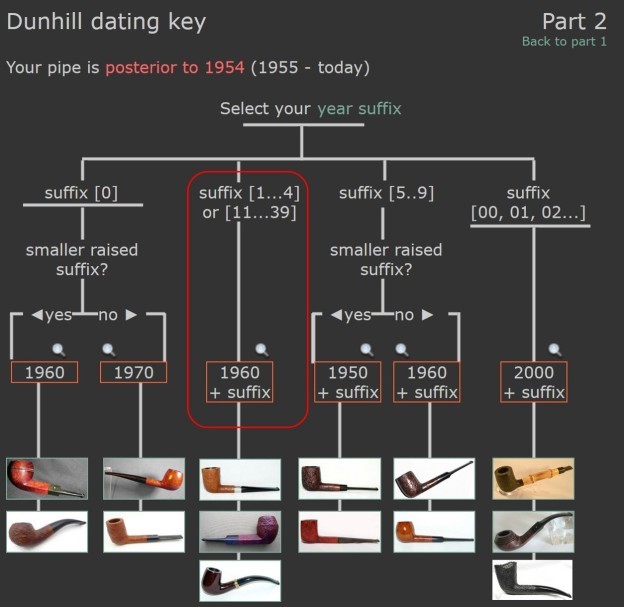

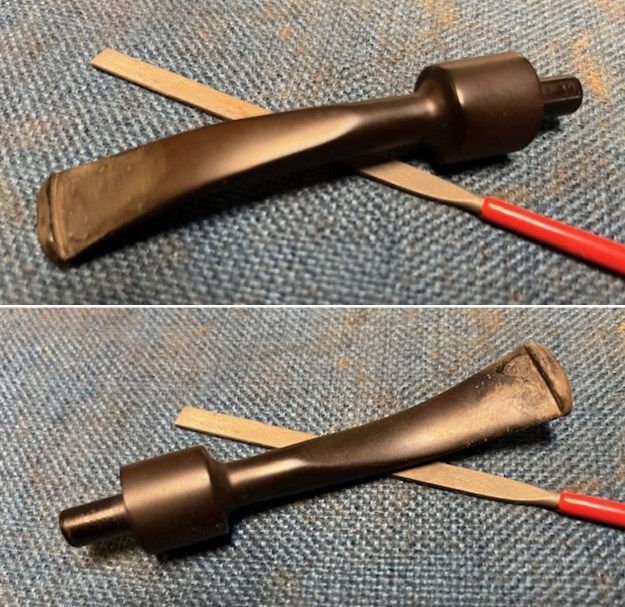

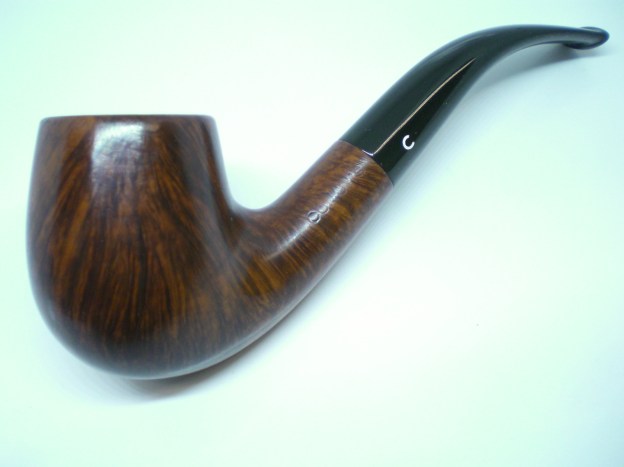

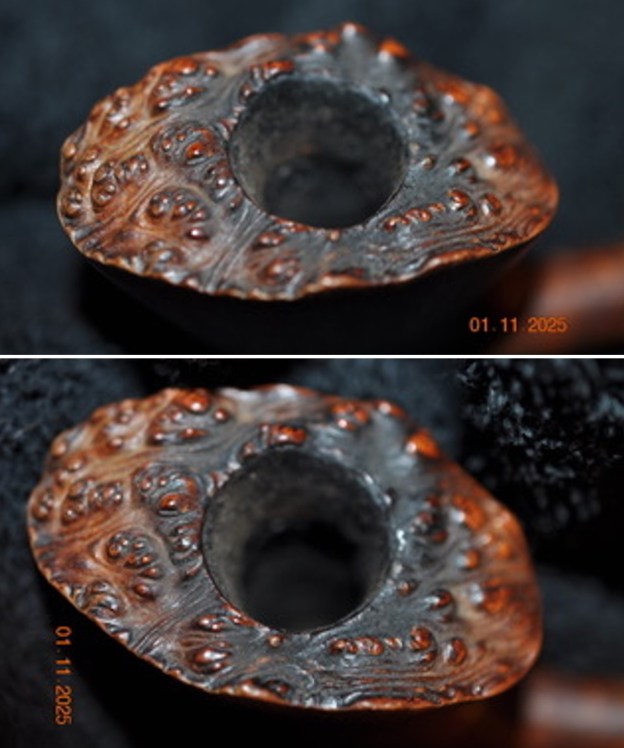

This pipe I chose to work on was another unusual one. It came to us from a seller in Santa Cruz, California, USA on 05/28/2024. It is a great piece of briar with great straight grain all the way around the bowl and shank and a plateau rim top on the bowl. It is a beautiful piece of briar! He made a carved, fan shaped Freehand pipe. The front, back and sides of the bowl have some nice straight grain. Very unique but something just calls out to you. When the pipe came to us it was dirty with grime ground into the finish. There was a thick cake in the bowl and heavy lava in the valleys of the plateau rim top and inner edge. There was grime and oils darkening the sides of the bowl. It was dirty but that did not hide the beauty of the grain on this briar. The stem is a saddle made out of vulcanite. There were tooth marks and light chatter on both sides just ahead of the button. Jeff took photos of the pipe as a whole before he started his cleanup work. I include them below.  Jeff took some close up shots of the rim top to show the bowl and cake. You can see the cake in the bowl and the thick lava on the rim top and the inner edge. The stem photos also show the condition it was in when we received it. Lots of promise with the pipe but some work too!

Jeff took some close up shots of the rim top to show the bowl and cake. You can see the cake in the bowl and the thick lava on the rim top and the inner edge. The stem photos also show the condition it was in when we received it. Lots of promise with the pipe but some work too!

Jeff took some photos of the sides – left and right sides and the heel of the bowl to give a sense of the lay of the pipe on the block of briar. It is certainly beautiful.

Jeff took some photos of the sides – left and right sides and the heel of the bowl to give a sense of the lay of the pipe on the block of briar. It is certainly beautiful.

Here are some photos of the stamping on the left side of the shank. I think this must be an older stamp of JHW as the J is a part of the uppercase HW. It is the only one I have that has this stamping. Otherwise the J is a stylized pipe followed by the HW.

Here are some photos of the stamping on the left side of the shank. I think this must be an older stamp of JHW as the J is a part of the uppercase HW. It is the only one I have that has this stamping. Otherwise the J is a stylized pipe followed by the HW. Take some time to read the great writeup on Pipedia and JHW pipes and influence the carver had on the American pipe making scene. It is a well written and enjoyable read. Here is the link: (https://pipedia.org/wiki/JHW_Pipes).

Take some time to read the great writeup on Pipedia and JHW pipes and influence the carver had on the American pipe making scene. It is a well written and enjoyable read. Here is the link: (https://pipedia.org/wiki/JHW_Pipes).

Armed with that information I turned to work on the pipe itself. Jeff had cleaned up the pipe with his usual thoroughness. He reamed the pipe with a PipNet pipe reamer and removed the rest of it with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and pipe cleaners and shank brushes. He soaked the stem in Briarville’s Pipe Stem Deoxidizer and rinsed it off with warm water. I took photos of the pipe before I started my part of the restoration work.

The rim top cleaned up really well. The rim top and inner edge of the bowl look good. The plateau rim top looks very good. There is a slight darkening on the inner edge of the bowl. The bowl itself was very clean and the pipe smelled fresh. The stem surface had light tooth chatter on both sides near the button.

The rim top cleaned up really well. The rim top and inner edge of the bowl look good. The plateau rim top looks very good. There is a slight darkening on the inner edge of the bowl. The bowl itself was very clean and the pipe smelled fresh. The stem surface had light tooth chatter on both sides near the button. The stamping on the left side of the shank is faint but still readable. It is stamped as noted above. I removed the stem and took a photo of the pipe to give a sense of the whole.

The stamping on the left side of the shank is faint but still readable. It is stamped as noted above. I removed the stem and took a photo of the pipe to give a sense of the whole. I wiped the bowl down with some acetone to see if I could lighten the darkening around the bowl sides. It worked quite well.

I wiped the bowl down with some acetone to see if I could lighten the darkening around the bowl sides. It worked quite well.

I sanded the sides of the bowl and shank with 320-3500 grit sanding pads. There were also some scratches in the briar on the sides, but nothing too deep so this process would take care of the issues.

I sanded the sides of the bowl and shank with 320-3500 grit sanding pads. There were also some scratches in the briar on the sides, but nothing too deep so this process would take care of the issues.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each pad. I take photos of the three groups of pads for my own viewing primarily as I am looking for progress in polishing. Once again, by the end of the process it looked quite good.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each pad. I take photos of the three groups of pads for my own viewing primarily as I am looking for progress in polishing. Once again, by the end of the process it looked quite good.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips. i worked it into the plateau on the rim top with a shoe brush. The product works to clean, enliven and protect the briar. I let the balm sit for 15 minutes and buffed with a cotton cloth to raise the shine. The grain came alive.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips. i worked it into the plateau on the rim top with a shoe brush. The product works to clean, enliven and protect the briar. I let the balm sit for 15 minutes and buffed with a cotton cloth to raise the shine. The grain came alive.

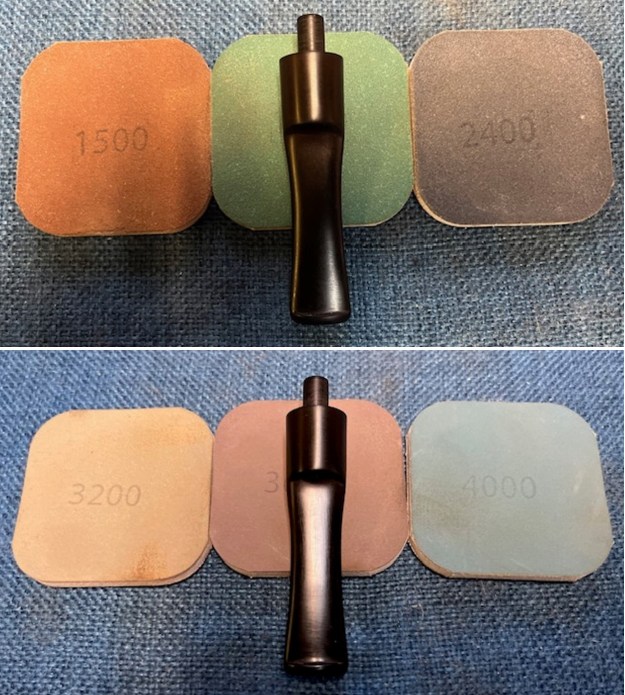

I set the bowl aside and turned my attention to the stem. I “painted” the surface of the stem to raise the tooth marks on the vulcanite. I filled in what remained in the surface with black CA glue and set it aside to cure. Once the repair cured I used a flat needle file to smooth out the repairs on the stem surface. I followed that up with a folded piece of 220 grit sandpaper to blend them into the surface of the stem.

I set the bowl aside and turned my attention to the stem. I “painted” the surface of the stem to raise the tooth marks on the vulcanite. I filled in what remained in the surface with black CA glue and set it aside to cure. Once the repair cured I used a flat needle file to smooth out the repairs on the stem surface. I followed that up with a folded piece of 220 grit sandpaper to blend them into the surface of the stem.

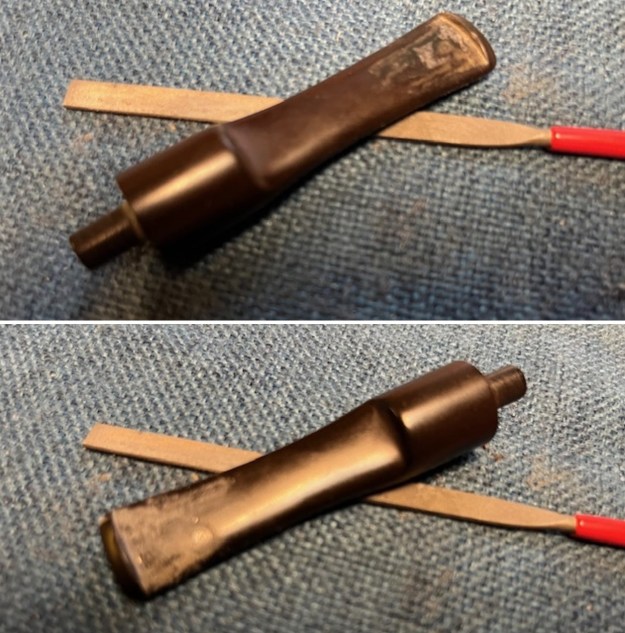

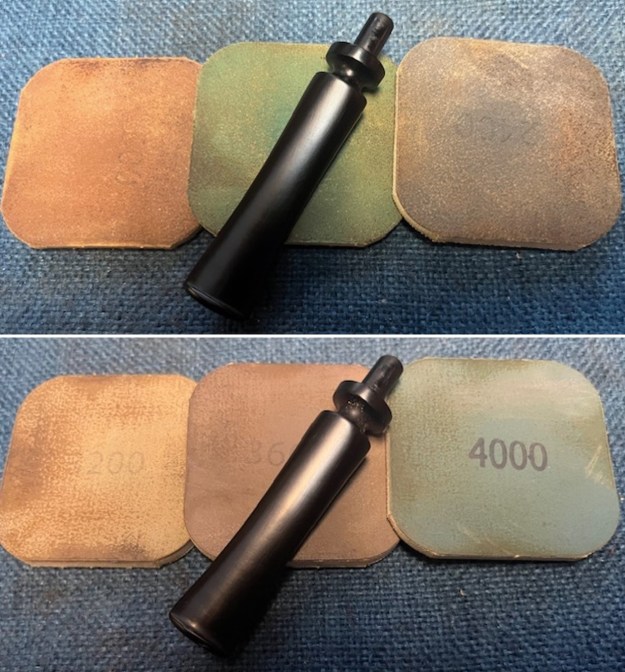

I sanded the stem with 320-3500 grit sanding pads. I wiped the stem down after each pad with an Obsidian Oil soaked cloth. The process helped remove the lingering oxidation.

I sanded the stem with 320-3500 grit sanding pads. I wiped the stem down after each pad with an Obsidian Oil soaked cloth. The process helped remove the lingering oxidation. I polished the stem with micromesh sanding pads – 1500-12000 grit pads to remove them. I wiped the stem down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. I rubbed it down with a final coat of Obsidian Oil and let it dry.

I polished the stem with micromesh sanding pads – 1500-12000 grit pads to remove them. I wiped the stem down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. I rubbed it down with a final coat of Obsidian Oil and let it dry.

This Jack H. Weinberger (JHW) Fan Shape Oval Freehand with a vulcanite saddle stem is a great looking pipe with some beautiful grain around the front and sides of the bowl. The grain around the bowl is quite stunning and works well with both the shape and the polished vulcanite saddle stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the wheel and followed by buffing the pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Jack H. Weinberger (JHW) Fan Freehand fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 ½ inches, Height: 3 inches, Outside diameter of the bowl: 2 ½ inches long x 1 ½ inches wide, Chamber diameter: ¾ of an inch. The weight of the pipe is 2.26 ounces/64 grams. I will be putting it on the rebornpipes store in the American Pipemakers Section shortly. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. I appreciate your support and time!

This Jack H. Weinberger (JHW) Fan Shape Oval Freehand with a vulcanite saddle stem is a great looking pipe with some beautiful grain around the front and sides of the bowl. The grain around the bowl is quite stunning and works well with both the shape and the polished vulcanite saddle stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the wheel and followed by buffing the pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Jack H. Weinberger (JHW) Fan Freehand fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 ½ inches, Height: 3 inches, Outside diameter of the bowl: 2 ½ inches long x 1 ½ inches wide, Chamber diameter: ¾ of an inch. The weight of the pipe is 2.26 ounces/64 grams. I will be putting it on the rebornpipes store in the American Pipemakers Section shortly. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. I appreciate your support and time!