Blog by Steve Laug

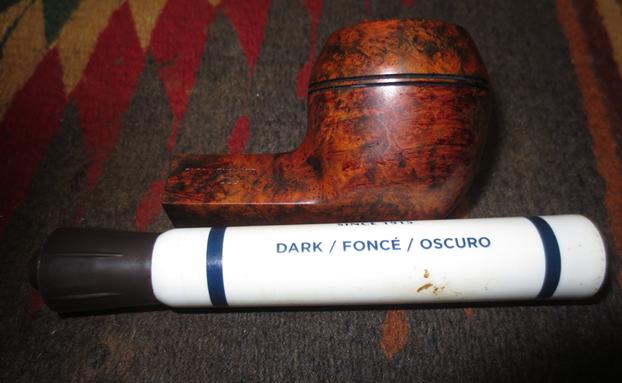

The next pipe on the work table came to us 2018 from a fellow in Pocatello, Idaho, USA. It is a nice looking Billiard with cross grain and birdseye grain and has a Fancy Lucite half saddle stem. The Lucite stem fits the name on the left side Oscar Lucite. The bowl has a rich reddish brown colour combination that highlights grain. The pipe has some grime ground into the surface of the briar. The finish had a few small fills around the sides but they blended in fairly well. This pipe is stamped on the sides of the shank. On the left it reads Oscar [over] Lucite. On the right it has a Savinelli “S” Shield and next to that was the shape number 111KS [over] Italy. There is a thick cake in the bowl and an overflow of lava on the top beveled inner edge of the bowl. The rim top looks good but it is hard to be certain with the lava coat. There were some light tooth marks and chatter on both sides of the Lucite stem near the button. The pipe looks to be in good condition under the grime. Jeff took photos of the pipe before he started his cleanup.

He took photos of the rim top to show the thick cake and the thick lava coat. It is hard to know what the condition of the rim top and edges is like under that thick lava. It is an incredibly dirty pipe but obviously one that was a great smoker. The acrylic half saddle stem had light tooth marks and chatter on both sides ahead of the button.

He took photos of the rim top to show the thick cake and the thick lava coat. It is hard to know what the condition of the rim top and edges is like under that thick lava. It is an incredibly dirty pipe but obviously one that was a great smoker. The acrylic half saddle stem had light tooth marks and chatter on both sides ahead of the button.

He took a photo of the sides and heel of the bowl to show the beautiful grain around the bowl and the condition of the pipe. You can see the grime ground into the surface of the briar.

He took a photo of the sides and heel of the bowl to show the beautiful grain around the bowl and the condition of the pipe. You can see the grime ground into the surface of the briar.  He took a photo of the stamping on the left side of the shank. It is clear and readable as noted above. On the underside of the shank it is stamped Savinelli Product.

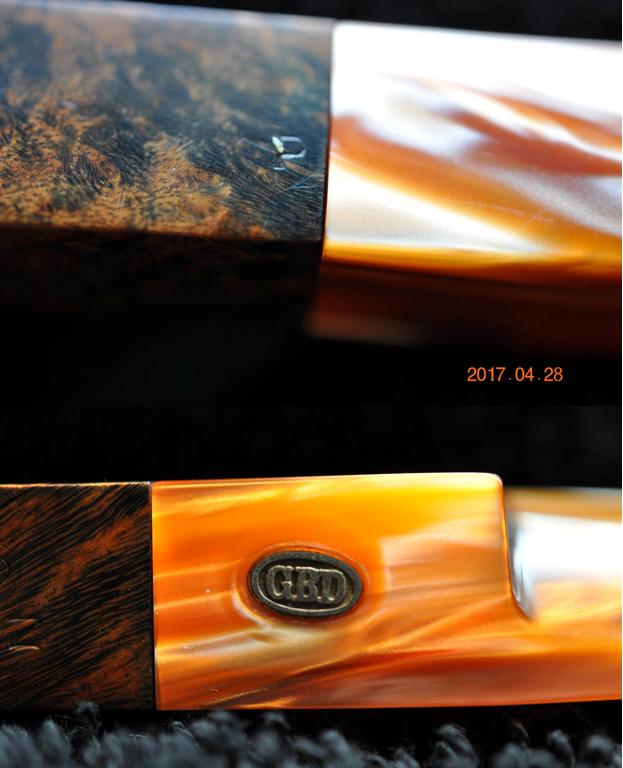

He took a photo of the stamping on the left side of the shank. It is clear and readable as noted above. On the underside of the shank it is stamped Savinelli Product.  I turned first to Pipephil’s site to look at the Savinelli write up there and see if I could learn anything about the Oscar Lucite line (http://www.pipephil.eu/logos/en/logo-savinelli3.html). There was a listing for the Oscar Lucite and I did a screen capture of the pertinent section.

I turned first to Pipephil’s site to look at the Savinelli write up there and see if I could learn anything about the Oscar Lucite line (http://www.pipephil.eu/logos/en/logo-savinelli3.html). There was a listing for the Oscar Lucite and I did a screen capture of the pertinent section. I looked up the Savinelli brand on Pipedia to see if I could find the Oscar Lucite line and the 111KS Shape (https://pipedia.org/wiki/Savinelli). There was nothing that tied directly to the line I am working on. There is a detailed history of the brand there that is a good read. I also captured the shape chart and boxed in the 111KS shape in red. The shape is identical to the one that I am working on. The stem on this one is the original shape that was on the Lucite Line but there was no shooting star logo on the left side.

I looked up the Savinelli brand on Pipedia to see if I could find the Oscar Lucite line and the 111KS Shape (https://pipedia.org/wiki/Savinelli). There was nothing that tied directly to the line I am working on. There is a detailed history of the brand there that is a good read. I also captured the shape chart and boxed in the 111KS shape in red. The shape is identical to the one that I am working on. The stem on this one is the original shape that was on the Lucite Line but there was no shooting star logo on the left side. It was time to work on the pipe. As usual Jeff had done a thorough cleanup on the pipe. He reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and Murphy’s Oil Soap to remove the oils and tars on the rim and the grime on the finish of the bowl. He rinsed it under running water. One of the benefits of this scrub is that it also tends to lift some of the scratches and nicks in the surface of the briar. He dried it off with a soft cloth. He cleaned the internals and externals of the stem with alcohol, pipe cleaners and cotton swabs. He scrubbed the stem with Soft Scrub all-purpose cleanser and rinsed it off with warm water and cleaned out the airway in the stem with alcohol. Other than the damaged rim top the pipe looked good.

It was time to work on the pipe. As usual Jeff had done a thorough cleanup on the pipe. He reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and Murphy’s Oil Soap to remove the oils and tars on the rim and the grime on the finish of the bowl. He rinsed it under running water. One of the benefits of this scrub is that it also tends to lift some of the scratches and nicks in the surface of the briar. He dried it off with a soft cloth. He cleaned the internals and externals of the stem with alcohol, pipe cleaners and cotton swabs. He scrubbed the stem with Soft Scrub all-purpose cleanser and rinsed it off with warm water and cleaned out the airway in the stem with alcohol. Other than the damaged rim top the pipe looked good.

I took a photo of the rim top and stem to show the condition. The rim top was in very rough condition. The rim top and the edges of the bowl had darkening, burn marks and some nicking. The Lucite half saddle stem had light tooth chatter and marks on both sides ahead of the button and on the button edges.

I took a photo of the rim top and stem to show the condition. The rim top was in very rough condition. The rim top and the edges of the bowl had darkening, burn marks and some nicking. The Lucite half saddle stem had light tooth chatter and marks on both sides ahead of the button and on the button edges.  The stamping on the sides of the shank is clear and readable as noted above.

The stamping on the sides of the shank is clear and readable as noted above.  I removed the stem from the shank and took a photo of the pipe to give a sense of the whole. It is a nice looking billiard that should clean up very well.

I removed the stem from the shank and took a photo of the pipe to give a sense of the whole. It is a nice looking billiard that should clean up very well.  I started working on the pipe by dealing with the damaged rim top and edges. I topped the bowl with 220 grit sandpaper on a topping board. I worked over the rim top and inner bevel of the rim with 220 grit sandpaper. I smooth out the damage and gave the rim top and edge a clean look that would polish out nicely. I wiped the rim top down with a damp cloth to remove the dust and debris.

I started working on the pipe by dealing with the damaged rim top and edges. I topped the bowl with 220 grit sandpaper on a topping board. I worked over the rim top and inner bevel of the rim with 220 grit sandpaper. I smooth out the damage and gave the rim top and edge a clean look that would polish out nicely. I wiped the rim top down with a damp cloth to remove the dust and debris.

I polished the briar with micromesh sanding pads – wet sanding with 1500-12000 grit pads and wiped down the bowl after each sanding pad.

I polished the briar with micromesh sanding pads – wet sanding with 1500-12000 grit pads and wiped down the bowl after each sanding pad.

I stained the rim top with an Oak stain pen to match the rest of the bowl. Once I buffed and polished the bowl it would be a perfect match.

I stained the rim top with an Oak stain pen to match the rest of the bowl. Once I buffed and polished the bowl it would be a perfect match.  I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The Balm did its magic and the grain stood out.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The Balm did its magic and the grain stood out.

I polished the Lucite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. The photo below shows the polished stem.

I polished the Lucite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. The photo below shows the polished stem.

This nicely grained Savinelli Made Oscar Lucite 11KS Billiard with Lucite half saddle stem is a great looking pipe now that it has been restored. The briar is clean and really came alive. The rich reddish, brown stains gave the grain a sense of depth with the polishing and waxing. The grain really popped. I put the vulcanite stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Oscar Lucite Billiard is a beauty and feels great in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ¾ inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 46grams/1.62oz.Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This nicely grained Savinelli Made Oscar Lucite 11KS Billiard with Lucite half saddle stem is a great looking pipe now that it has been restored. The briar is clean and really came alive. The rich reddish, brown stains gave the grain a sense of depth with the polishing and waxing. The grain really popped. I put the vulcanite stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Oscar Lucite Billiard is a beauty and feels great in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ¾ inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 46grams/1.62oz.Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

I ran a pipe cleaner through the airway in the stem and the shank and they were very clean. I used a cotton swab to clean around the step down on the tenon and in the mortise. These too were clean.

I ran a pipe cleaner through the airway in the stem and the shank and they were very clean. I used a cotton swab to clean around the step down on the tenon and in the mortise. These too were clean.