Blog by Paresh

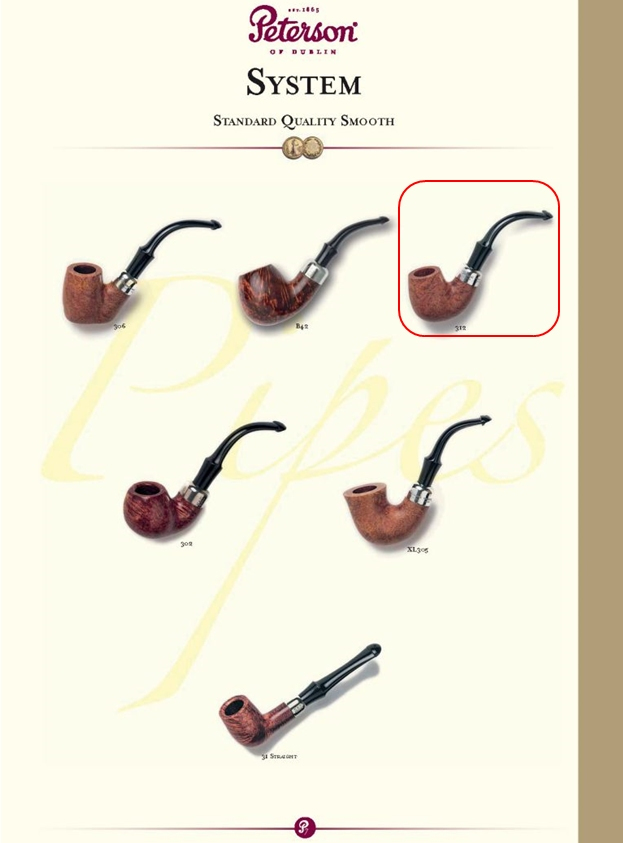

While going through the second box of my inherited pipes, I came across a beautiful delicate Calabash shaped pipe which called out to me for restoration. That this would be a Peterson’s pipe came as a surprise since it did not have the patented Peterson’s P-lip and obviously, it was not a System pipe. I remembered that one of the first pipes from my inheritance that I had sent to Steve for restoration had been a Peterson’s rusticated petite Calabash pipe. I revisited the blog and memories of my early association with Steve, the gentleman, a great friend and now my Guru and constant companion on my journey in to the beautiful world of pipe restorations, came flooding back. I cherish his friendship and our association. Here is the link to the write up he had done on that rusticated tiny Calabash pipe (https://rebornpipes.com/2018/04/22/pareshs-grandfathers-pipe-5-a-tiny-peterson-bent-calabash-pipe/).

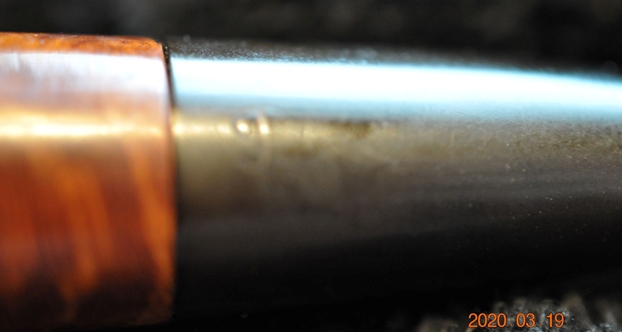

I have researched and worked on a few vintage as well as new Peterson’s and seeing the stampings on this calabash, I knew this had to be an old Peterson’s. The stummel has a nice spread of mixed grains all around and a nice feel in the hand. It is stamped on the left side of the shank as “PETERSON’S” in an arch with a forked ‘P’ over “OF DUBLIN”. The right of the shank bears the COM stamp “LONDON MADE” over “ENGLAND”. The familiar script “P” on the saddle adorns the left side of the saddle stem.  While dating a Peterson’s pipe, I always fall back to my under mentioned favorite site; http://thepetersonpipeproject.blogspot.com/2007/07/dating-peterons-pipes.html

While dating a Peterson’s pipe, I always fall back to my under mentioned favorite site; http://thepetersonpipeproject.blogspot.com/2007/07/dating-peterons-pipes.html

I quote from the above site

“English made Peterson pipes actually span between the pre-Republic and Republic eras. In 1895, Peterson opened a shop in London England that lasted until the late 1950s or early 1960s. So the English Era, for a simplified date, will be from 1895 through 1959. The stamps Peterson used in London and that we have seen are:

Made in England – block format

Made in England – circle format

Made in London

Made in London England

Simply, London England

Great Britain

Though there are a couple of more, the above will give one the general idea. We believe the earliest stamp of this era was the “Made in England” in a block format since Peterson was using the “Made in Ireland” block format at about the same time on their Irish production pipes. The “Made in England” circle format was used during the same time frame as the “Made in Eire” and “Made in Ireland” circle formats.

From the start of the Patent Era until somewhere in the early 1930s, Peterson used the “Old Style” lettering that used a forked tail “P” in Peterson.

From the start of the Patent Era until somewhere in the early 1930s, Peterson used the “Old Style” lettering that used a forked tail “P” in Peterson.

Thus from the above, it can be concluded that the pipe on my work table is from the English Era and dates from the period 1895 to1930s.

Initial Input By Abha About The Condition Of The Pipe

As is her habit, Abha my wife, had not taken any pictures of the pipe before she carried out her initial cleaning of the pipe and the only remembrance about this pipe she had was that there was a very heavy build up of cake in the chamber that had spilled over the rim top and over the stummel surface. The mortise was choked and the stem did not sit flush with the shank end. The stem was deeply oxidized.

Initial Cleaning By Abha…

The initial cleaning on this pipe was done by Abha, my wife (she has cleaned up around 60 pipes for my further restoration and I am gradually inching forward completing these pipes). She reamed out the complete cake and further smoothed out the chamber walls with a folded piece of 220 grit sand paper. She further cleaned out the internals of the shank with pipe cleaners and alcohol and cotton buds. She followed the internal cleaning of the shank with external cleaning of the stummel using Murphy’s Oil soap and hard bristled tooth brush and dried it with paper napkins and cotton cloth.

Next she cleaned out the internals of the stem air way and immersed it in “Before and After Deoxidizer” solution along with the stem of other pipes in line for restoration. Once the stem had soaked overnight, she cleaned the stem under running warm water and scrubbed the raised oxidation from the stem surface using scotch brite pad. She further removed the oxidation by scrubbing the stem with 0000 grade steel wool and applied a little olive oil to rehydrate the stem.

Once The Pipe Is On My Work Table…

The cleaned up pipes presents a very clear picture of what needs to be done to restore this pipe to a pristine and smokable condition. I really cannot thank Abha, my wife, enough for all the help and support that she extends me in my pursuance of this hobby. I proceed to carry out my appreciation of the work that needs to be done on this pipe to restore it.

The chamber is of a decent size with a depth of about 1.8 inches. The wide flared out mouth of the chamber tapers down towards the heel, giving the pipe its classic calabash shape. The walls of the chamber are in pristine condition with no signs of heat lines or fissures. The rim top surface is uneven, scratched and darkened. The inner edge has a couple of minor dents and dings and is slightly charred on the left side in 7 o’clock direction. Close observation of the outer edge under magnification shows what appears to be a hairline crack in the 12 o’clock direction (encircled in red). The chamber smells clean and fresh, thanks to the thorough cleaning by Abha. The hairline crack, hopefully, is superficial and may be addressed when the rim is topped on a sandpaper to remove the scratches, dings to the inner edge and the darkening over the rim surface. The nicely cleaned stummel looks solid with nice mixed grains and swirls all around. There is not a single fill in the entire stummel surface, signifying excellent briar selection by Peterson’s carvers. Abha had painstakingly cleaned out the mortise and the sump. The briar looks dark, dull and lifeless. A nice polish and revitalizing the briar with “Before and After” restoration balm will rejuvenate the briar and make things interesting!!

The nicely cleaned stummel looks solid with nice mixed grains and swirls all around. There is not a single fill in the entire stummel surface, signifying excellent briar selection by Peterson’s carvers. Abha had painstakingly cleaned out the mortise and the sump. The briar looks dark, dull and lifeless. A nice polish and revitalizing the briar with “Before and After” restoration balm will rejuvenate the briar and make things interesting!!

The cleaned up stem that came to me shows bite marks to the upper surface and button edge and there is a need to sharpen the button first by filling and then sanding the surface. Similarly, the lower button edge has a few tooth chatter and indentations and will need a fill to repair.

The cleaned up stem that came to me shows bite marks to the upper surface and button edge and there is a need to sharpen the button first by filling and then sanding the surface. Similarly, the lower button edge has a few tooth chatter and indentations and will need a fill to repair.  The Process

The Process

I started this project by sanding the stem surface with a 220 grit sand paper to address the issue of tooth chatter. I wiped the stem with alcohol on a cotton swab to remove all the sanding dust from the stem surface. I followed it up by wiping the surface with Murphy’s Oil soap. This step also helps to remove the oxidation from the stem’s surface. The tooth chatter and the tooth indentations from both the upper and lower surface have been greatly reduced. The remaining tooth indentations and the button edges will need to be filled with charcoal and superglue.

I mix clear superglue and activated charcoal and applied it over the both button edges, upper P-lip surface and lower surface of the P-lip. I set the stem aside for the fills to cure.

I mix clear superglue and activated charcoal and applied it over the both button edges, upper P-lip surface and lower surface of the P-lip. I set the stem aside for the fills to cure. Once the stem fills had hardened considerably, with a flat head needle file, I sand these fills to achieve a rough match. I further fine tuned the match by sanding the filled area with a folded piece of 220 grit sand paper pinched between my thumb and forefinger. I followed it up by sanding the entire stem surface using 320, 600, 800 grit sand papers and finally with a piece of 1000 grit sandpaper. This serves to remove the deep seated oxidation and also reduces the sanding marks of the more abrasive sand papers. I also sharpened the button edges while sanding. I wiped the stem with a cotton swab and alcohol to remove all the oxidation and sanding dust from the surface. I applied a little Extra Virgin Olive oil over the stem and set it aside to be absorbed by the vulcanite.

Once the stem fills had hardened considerably, with a flat head needle file, I sand these fills to achieve a rough match. I further fine tuned the match by sanding the filled area with a folded piece of 220 grit sand paper pinched between my thumb and forefinger. I followed it up by sanding the entire stem surface using 320, 600, 800 grit sand papers and finally with a piece of 1000 grit sandpaper. This serves to remove the deep seated oxidation and also reduces the sanding marks of the more abrasive sand papers. I also sharpened the button edges while sanding. I wiped the stem with a cotton swab and alcohol to remove all the oxidation and sanding dust from the surface. I applied a little Extra Virgin Olive oil over the stem and set it aside to be absorbed by the vulcanite.

The next issue that I addressed was that of the rim top surface damage. I topped the rim on a piece of 220 grit sand paper, checking frequently till I was satisfied that the charred inner rim edge on the left side in 7 o’clock direction was addressed to a great extent and the rim top surface is nice, smooth and even. The inner edge is still uneven, though much better than before topping, and shall be addressed next.

The next issue that I addressed was that of the rim top surface damage. I topped the rim on a piece of 220 grit sand paper, checking frequently till I was satisfied that the charred inner rim edge on the left side in 7 o’clock direction was addressed to a great extent and the rim top surface is nice, smooth and even. The inner edge is still uneven, though much better than before topping, and shall be addressed next.

With a folded piece of a 220 grit sand paper pinched between my thumb and forefinger, I created a slight bevel on the inner edge of the rim top surface. This helped to mask the out of round chamber and address the minor dents that had remained on the inner rim edge. It can never be perfect; it’s a repair after all, but the repairs sure looks good.

With a folded piece of a 220 grit sand paper pinched between my thumb and forefinger, I created a slight bevel on the inner edge of the rim top surface. This helped to mask the out of round chamber and address the minor dents that had remained on the inner rim edge. It can never be perfect; it’s a repair after all, but the repairs sure looks good.

I was very happy by the way the rim surface appeared at this stage in restoration. The crack that was observed under camera magnification, is neither visible to the naked eye nor in the pictures that I had clicked of the rim surface after topping. However, I wanted to be doubly sure that the hairline crack was only superficial and had been addressed with topping the rim surface. I increased the magnification of my mobile phone camera to 5x and sure enough, I could make out the crack (indicated with blue arrow). Just on a haunch, I traced the path of the crack over the stummel surface and sure enough, it extended below the outer rim edge for about ¼ of an inch, though very thin (indicated with blue arrow). Ahhhhh… What a pain that revelation was!! Though it’s a very fine hairline crack, I would address it to prevent it from enlarging and expanding over the rest of the stummel surface and /or the rim top. Just to be sure that the crack had not penetrated inside the chamber, I double checked and traced the extent of the crack over the inner edge and in to the chamber. Thankfully, the corresponding inner edge and chamber walls are sans any damage (enclosed in green).

I was very happy by the way the rim surface appeared at this stage in restoration. The crack that was observed under camera magnification, is neither visible to the naked eye nor in the pictures that I had clicked of the rim surface after topping. However, I wanted to be doubly sure that the hairline crack was only superficial and had been addressed with topping the rim surface. I increased the magnification of my mobile phone camera to 5x and sure enough, I could make out the crack (indicated with blue arrow). Just on a haunch, I traced the path of the crack over the stummel surface and sure enough, it extended below the outer rim edge for about ¼ of an inch, though very thin (indicated with blue arrow). Ahhhhh… What a pain that revelation was!! Though it’s a very fine hairline crack, I would address it to prevent it from enlarging and expanding over the rest of the stummel surface and /or the rim top. Just to be sure that the crack had not penetrated inside the chamber, I double checked and traced the extent of the crack over the inner edge and in to the chamber. Thankfully, the corresponding inner edge and chamber walls are sans any damage (enclosed in green).

I now address the crack that is seen to the front of the stummel in 12 o’clock direction. Firstly, I clean off all the dirt from the stummel surface by sanding it to reveal the extent of the crack. I follow up this cleaning of the crack by marking the end points and turning points of the crack with a sharp dental pick. These marks also help to guide the drill bit when drilling the counter hole. I take care that the drill is just sufficiently deep enough to arrest the further spread of the crack and not a through hole. I generally drill two counter holes; first at the exact end point of the crack and second at the suspected/ likely progression end of the crack.

I now address the crack that is seen to the front of the stummel in 12 o’clock direction. Firstly, I clean off all the dirt from the stummel surface by sanding it to reveal the extent of the crack. I follow up this cleaning of the crack by marking the end points and turning points of the crack with a sharp dental pick. These marks also help to guide the drill bit when drilling the counter hole. I take care that the drill is just sufficiently deep enough to arrest the further spread of the crack and not a through hole. I generally drill two counter holes; first at the exact end point of the crack and second at the suspected/ likely progression end of the crack.

I fill this crack and the counter holes with a mix of CA superglue and briar dust. Once the fill has cured for couple of hours, I sand it down with a flat needle file to achieve a rough match with the rest of the stummel surface. I fine tune the match with a piece of 220 sand paper.

I fill this crack and the counter holes with a mix of CA superglue and briar dust. Once the fill has cured for couple of hours, I sand it down with a flat needle file to achieve a rough match with the rest of the stummel surface. I fine tune the match with a piece of 220 sand paper.

I continued the stummel repairs by sanding the fill and the entire stummel with a folded piece of 220 grit sand paper. I was especially very careful around the stummel stampings, least I obliterate it by sanding.

I continued the stummel repairs by sanding the fill and the entire stummel with a folded piece of 220 grit sand paper. I was especially very careful around the stummel stampings, least I obliterate it by sanding.

Turning my attention back to the stem, I decided to polish and shine up the stem surface. I wet sand the stem with 1500 to 12000 grit micromesh pads. Next I rub a small quantity of extra fine stem polish that I had got from Mark and set it aside to let the balm work its magic. After about 10 minutes, I hand buffed the stem with a microfiber cloth to a nice shine. I rub a small quantity of olive oil in to the stem surface to hydrate it and set it aside.

Turning my attention back to the stem, I decided to polish and shine up the stem surface. I wet sand the stem with 1500 to 12000 grit micromesh pads. Next I rub a small quantity of extra fine stem polish that I had got from Mark and set it aside to let the balm work its magic. After about 10 minutes, I hand buffed the stem with a microfiber cloth to a nice shine. I rub a small quantity of olive oil in to the stem surface to hydrate it and set it aside.  Next, I polished the stummel with micromesh pads, dry sanding with 1500 to 12000 pads. I polished the freshly topped rim surface and the newly created inner rim bevel. I wiped the surface with a soft cloth at the end of the micromesh cycle. The stummel looks amazing with a deep shine and beautiful grains popping over the stummel surface. I am surprised that the rim top surface has the same deep brown coloration as the rest of the stummel surface and use of stain pen was not required.

Next, I polished the stummel with micromesh pads, dry sanding with 1500 to 12000 pads. I polished the freshly topped rim surface and the newly created inner rim bevel. I wiped the surface with a soft cloth at the end of the micromesh cycle. The stummel looks amazing with a deep shine and beautiful grains popping over the stummel surface. I am surprised that the rim top surface has the same deep brown coloration as the rest of the stummel surface and use of stain pen was not required.

I massaged a small quantity of “Before and After Restoration Balm” with my fingers into the briar. The immediate and incredible transformation that takes place is a worthy reward for all the efforts!! I let the balm sit on the surface to be absorbed in to the briar for about 20 minutes. The bowl now looks fresh and attractive with the grains popping out any which way you look at the briar; it feels somewhat like DIWALI, the festival of lights celebrated here in India. I polished off the balm with a soft cloth to a lovely shine.

I massaged a small quantity of “Before and After Restoration Balm” with my fingers into the briar. The immediate and incredible transformation that takes place is a worthy reward for all the efforts!! I let the balm sit on the surface to be absorbed in to the briar for about 20 minutes. The bowl now looks fresh and attractive with the grains popping out any which way you look at the briar; it feels somewhat like DIWALI, the festival of lights celebrated here in India. I polished off the balm with a soft cloth to a lovely shine.

Before I could move on to polishing with Blue Diamond and carnauba wax, there was one issue yet to be addressed; that of refreshing the stem logo. I coated the stem logo with the ink of white correction pen and set it to dry out.

Before I could move on to polishing with Blue Diamond and carnauba wax, there was one issue yet to be addressed; that of refreshing the stem logo. I coated the stem logo with the ink of white correction pen and set it to dry out. I mount a cotton cloth buffing wheel on to my hand held rotary tool and apply a coat of Blue Diamond to the stummel and the stem to polish out the minor scratches.

I mount a cotton cloth buffing wheel on to my hand held rotary tool and apply a coat of Blue Diamond to the stummel and the stem to polish out the minor scratches.  With a cotton buffing wheel that I use for carnauba wax, I apply a coat of carnauba wax and continue to work on it till the complete coat of wax had been polished out. I mount a clean cotton cloth buffing wheel and give the entire pipe a once over buff. I finished the restoration by giving the entire pipe a rigorous hand buffing using a microfiber cloth to raise the shine further. The finished pipe looks beautiful and will be an addition to my collection of Peterson’s pipes!!

With a cotton buffing wheel that I use for carnauba wax, I apply a coat of carnauba wax and continue to work on it till the complete coat of wax had been polished out. I mount a clean cotton cloth buffing wheel and give the entire pipe a once over buff. I finished the restoration by giving the entire pipe a rigorous hand buffing using a microfiber cloth to raise the shine further. The finished pipe looks beautiful and will be an addition to my collection of Peterson’s pipes!!

P.S. The stem logo did not turn out to be as crisp as it usually does!! Maybe, the stamping was not as deep as I thought it would be.

P.S. The stem logo did not turn out to be as crisp as it usually does!! Maybe, the stamping was not as deep as I thought it would be.

This project presented me with an unexpected repair work. The crack, even though a fine hairline crack it may have been, has the potential for developing in to a much more serious issue of a burnout. The counter holes stand out against the highly polished stummel surface and I have let them be. The only way to mask these was to resort to staining the entire stummel which would be at the cost of the beautiful natural briar color and not to mention the grains.

Sincere gratitude to all the readers who have shared this part of my journey in to the world of pipe restoration…Cheers!!