Blog by Kenneth Lieblich

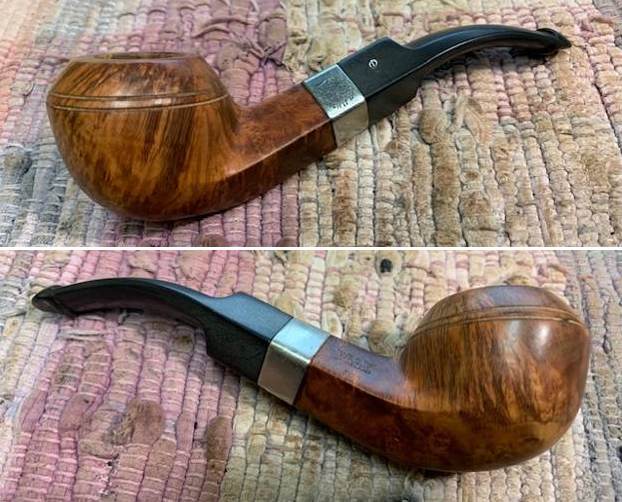

Next on the chopping block is this lovely Peterson Shamrock. I acquired it some time ago from Craigslist and I figured that it was time to honour the great patron of Ireland, Saint Patrick, with a pipe named for the Shamrock. This is a terrific pipe that simply looks a bit drab. Some special attention from me will bring out its best. This pipe shape is a classic billiard. This is a really pretty pipe and feels very comfortable in the hand.

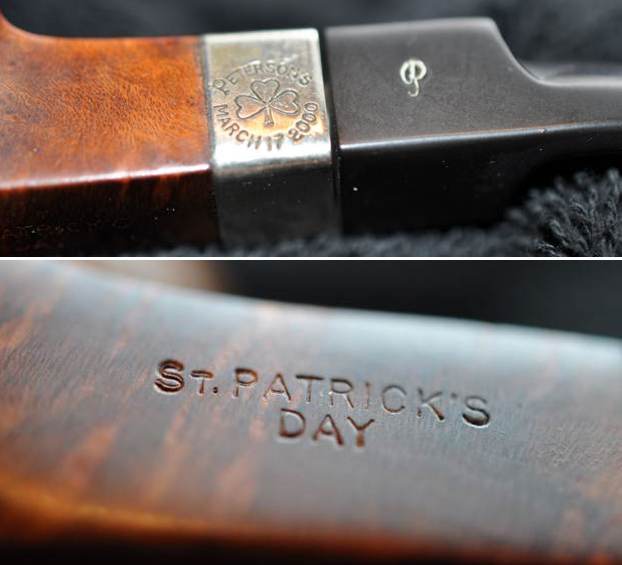

This pipe was made by the esteemed Irish pipe company, Peterson. Of course, Peterson is well known to most pipe smokers. For more information on the brand and its history, be sure to read the Pipedia article on them: https://pipedia.org/wiki/Peterson. The markings on the left-hand side of the shank read Shamrock and the left-hand side of the stem shows a capital S. The right-hand side of the shank reads “A. Peterson Product” [over] Made in the Rep. [over] of Ireland. Alongside this, the number 25 appears, the shape number.

This pipe was made by the esteemed Irish pipe company, Peterson. Of course, Peterson is well known to most pipe smokers. For more information on the brand and its history, be sure to read the Pipedia article on them: https://pipedia.org/wiki/Peterson. The markings on the left-hand side of the shank read Shamrock and the left-hand side of the stem shows a capital S. The right-hand side of the shank reads “A. Peterson Product” [over] Made in the Rep. [over] of Ireland. Alongside this, the number 25 appears, the shape number.

This “25” actually corresponds to the Peterson shape “455”, as explained over at Mark Irwin’s Peterson Pipe Notes:

This “25” actually corresponds to the Peterson shape “455”, as explained over at Mark Irwin’s Peterson Pipe Notes: Meanwhile, Mark Irwin and Gary Malmberg’s book, The Peterson Pipe provided some essential background information on Peterson’s Shamrock pipe. As you’ll see below, the nomenclature for dating doesn’t exactly correspond to what I have above, but still leads me to think that this pipe’s date is between 1948 and 1998. That’s a pretty wide range, but it will have to do! From The Peterson Pipe:

Meanwhile, Mark Irwin and Gary Malmberg’s book, The Peterson Pipe provided some essential background information on Peterson’s Shamrock pipe. As you’ll see below, the nomenclature for dating doesn’t exactly correspond to what I have above, but still leads me to think that this pipe’s date is between 1948 and 1998. That’s a pretty wide range, but it will have to do! From The Peterson Pipe:

Shamrock (c. 1941–2009) Originally stamped SHAMROCK with no brand name, an inexpensive line first described in George Yale (New York) mail order booklet in 1941, imported by Rogers Import. The line was actively promoted beginning in ’45, aggressively promoted in US by Rogers from early ‘50s when they registered the Shamrock logo with US Patent Office, claiming propriety since ’38. Over the years offered with P-lip or fishtail mouthpiece, with or without nickel band, with or without shamrock logo on the band, with or without S stamped in white or later in gold on mouthpiece. Appearing in 2008 as unstained smooth and rustic, fishtail mouthpiece with gold impressed P on the stem. COMS of MADE IN over IRELAND (c. 1945–1965), MADE IN IRELAND forming a circle (c. 1945–1965), “A PETERSON’S PRODUCT” over MADE IN IRELAND (c. 1945–1965), MADE IN THE over REPUBLIC over OF IRELAND (c. 1948–1998). Model is always difficult or impossible to date.

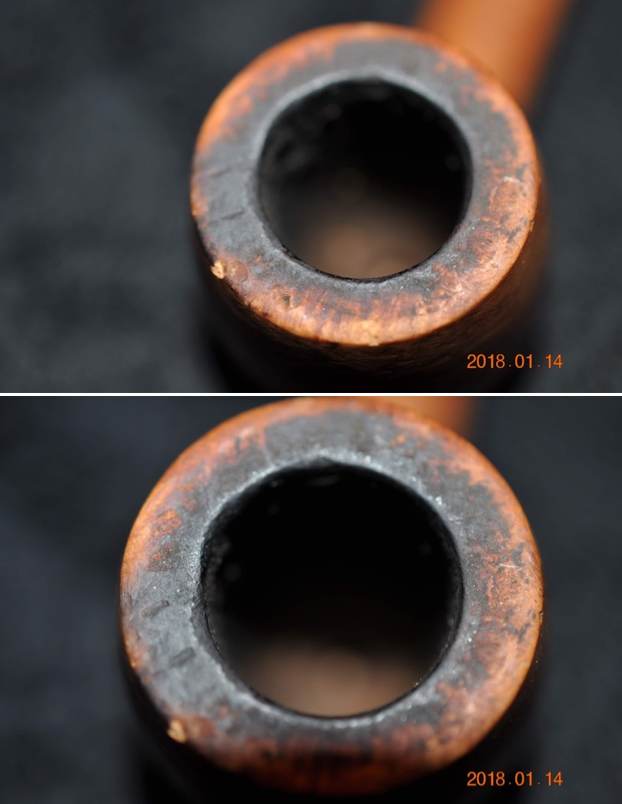

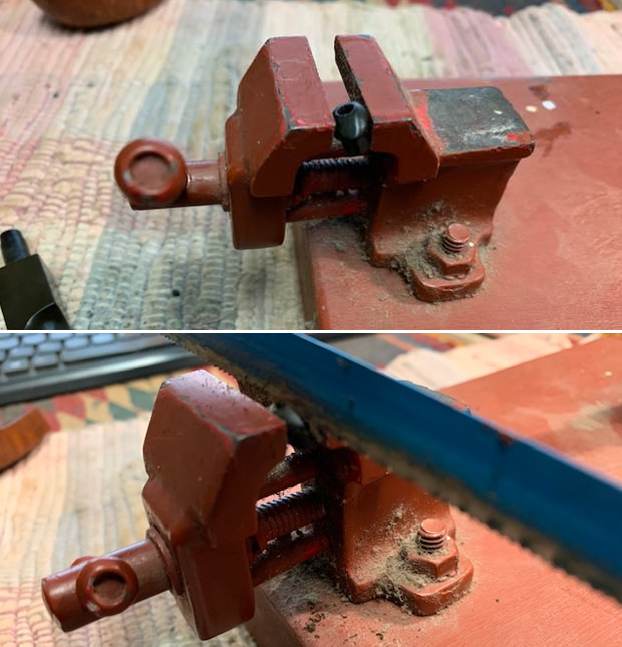

On to the pipe: it was in very nice condition, actually. The insides had already been cleaned fairly well by a previous owner. Annoyingly, the Craigslist seller claimed that the pipe was unsmoked, but this was clearly false (grrr). The stem had considerable oxidation, a few minor scrapes, but was otherwise in decent shape.

The stummel was also very nice. The outside of the bowl had only slight scratches and the overall colour was a bit dull. The insides would need to be cleaned a bit, but most of the work had already been done. Really, this pipe just needed a day at the salon in order to look its best.

The stummel was also very nice. The outside of the bowl had only slight scratches and the overall colour was a bit dull. The insides would need to be cleaned a bit, but most of the work had already been done. Really, this pipe just needed a day at the salon in order to look its best. The stem was first on my list. This stem has an inner tube in it, so, in order to clean it, I soaked it in some lemon-infused isopropyl alcohol. I let it sit for several hours and then cleaned it off and it looked much improved. I then buffed it with a microfibre cloth and moved on.

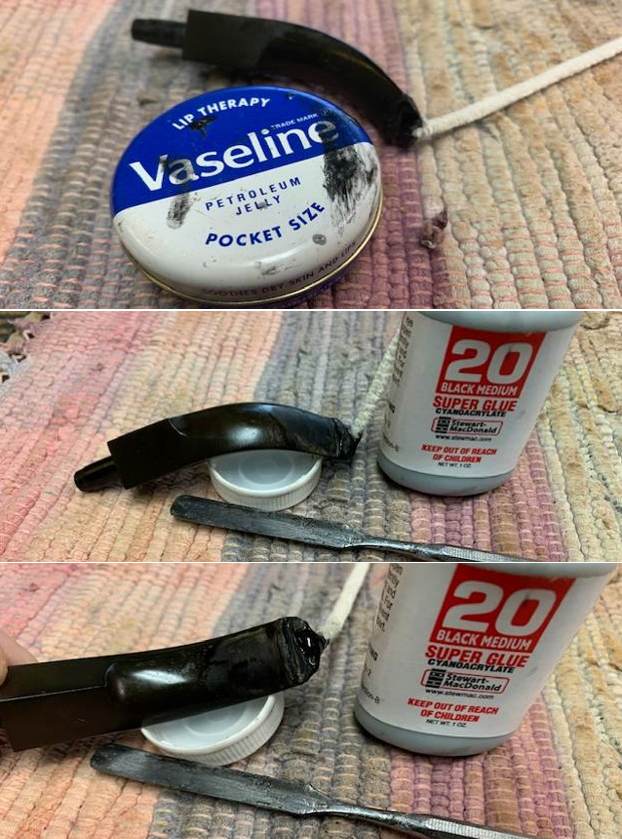

The stem was first on my list. This stem has an inner tube in it, so, in order to clean it, I soaked it in some lemon-infused isopropyl alcohol. I let it sit for several hours and then cleaned it off and it looked much improved. I then buffed it with a microfibre cloth and moved on. I took a BIC lighter and ‘painted’ the stem with its flame in order to lift any tiny bite marks. This was only modestly successful in raising the dents. Then, I cleaned out the insides of the stem with pipe cleaners and isopropyl alcohol. It was a bit dirty, but not too bad and I only went through a few pipe cleaners in order to clean it up. Once this process was done, the stem went for an overnight soak in the Pipe Stem Oxidation Remover. The following day, I cleaned all of the de-oxidizing mess off with alcohol, pipe cleaners, et cetera. The oxidation had migrated to the surface and would be fairly straightforward to remove. I scrubbed with SoftScrub on some cotton pads to remove the leftover oxidation.

I took a BIC lighter and ‘painted’ the stem with its flame in order to lift any tiny bite marks. This was only modestly successful in raising the dents. Then, I cleaned out the insides of the stem with pipe cleaners and isopropyl alcohol. It was a bit dirty, but not too bad and I only went through a few pipe cleaners in order to clean it up. Once this process was done, the stem went for an overnight soak in the Pipe Stem Oxidation Remover. The following day, I cleaned all of the de-oxidizing mess off with alcohol, pipe cleaners, et cetera. The oxidation had migrated to the surface and would be fairly straightforward to remove. I scrubbed with SoftScrub on some cotton pads to remove the leftover oxidation.

After this, I used some nail polish to restore the Shamrock “S” logo on the stem. I painted the area carefully and let it fully set before proceeding.

After this, I used some nail polish to restore the Shamrock “S” logo on the stem. I painted the area carefully and let it fully set before proceeding. I then sanded the stem with 220-, 400-, and 600-grit sandpapers to meld seamlessly into the stem. I then used all nine Micromesh pads (1,500 through 12,000 grit) to bring out the lovely black lustre on the stem. I also used Obsidian Pipe Stem Oil in between each pad scrubbing.

I then sanded the stem with 220-, 400-, and 600-grit sandpapers to meld seamlessly into the stem. I then used all nine Micromesh pads (1,500 through 12,000 grit) to bring out the lovely black lustre on the stem. I also used Obsidian Pipe Stem Oil in between each pad scrubbing.

On to the stummel, and most of the usual cleaning procedures were in order for this pipe. The bowl did not need to be reamed, so I was able to skip that. But I still inspected the bare briar to ensure there were no hidden flaws in the walls of the bowl. Fortunately, there were none. I then proceeded to clean out the insides of the shank with Q-tips, pipe cleaners, and isopropyl alcohol. There wasn’t too much nastiness inside this stummel – it only took a handful of pipe cleaners etc. to sort that out. I followed that up by cleaning the insides with some dish soap and tube brushes. I then moved on to cleaning the outside of the stummel with Murphy’s Oil Soap and some cotton pads. That removed any remaining dirt.

On to the stummel, and most of the usual cleaning procedures were in order for this pipe. The bowl did not need to be reamed, so I was able to skip that. But I still inspected the bare briar to ensure there were no hidden flaws in the walls of the bowl. Fortunately, there were none. I then proceeded to clean out the insides of the shank with Q-tips, pipe cleaners, and isopropyl alcohol. There wasn’t too much nastiness inside this stummel – it only took a handful of pipe cleaners etc. to sort that out. I followed that up by cleaning the insides with some dish soap and tube brushes. I then moved on to cleaning the outside of the stummel with Murphy’s Oil Soap and some cotton pads. That removed any remaining dirt.

Even though the pipe was quite clean, I figured that a de-ghosting session couldn’t hurt, so I thrust cotton balls in the bowl and the shank, and saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused any remaining oils, tars and smells to leech out into the cotton.

Even though the pipe was quite clean, I figured that a de-ghosting session couldn’t hurt, so I thrust cotton balls in the bowl and the shank, and saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused any remaining oils, tars and smells to leech out into the cotton. There was a slight mark on the rim of the stummel and, in order to remove it, I “topped” the pipe – that is to say, I gently and evenly sanded down the rim on a piece of 220-grit sandpaper. This effectively removed the marks, without altering the look of the pipe.

There was a slight mark on the rim of the stummel and, in order to remove it, I “topped” the pipe – that is to say, I gently and evenly sanded down the rim on a piece of 220-grit sandpaper. This effectively removed the marks, without altering the look of the pipe. Having completed that, I was able to address the small nicks on the stummel. I dug out my iron and a damp cloth to try and raise the nicks. The hot and moist steam can often cause the wood to swell slightly and return to shape. There was considerable movement! It looked a lot better as a result of the steam and I was pleased.

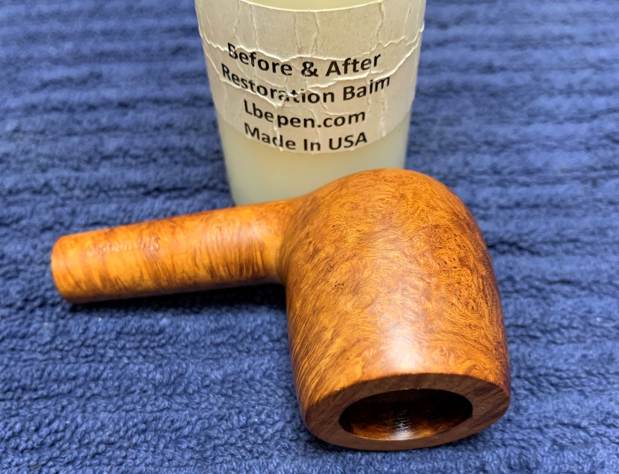

Having completed that, I was able to address the small nicks on the stummel. I dug out my iron and a damp cloth to try and raise the nicks. The hot and moist steam can often cause the wood to swell slightly and return to shape. There was considerable movement! It looked a lot better as a result of the steam and I was pleased. I took the opportunity to add a light application of Before & After Restoration Balm. I let it sit for 10–15 minutes and then gave it a buff. This made the beauty of the stummel’s grain really pop. No doubt about it – this is a really lovely pipe!

I took the opportunity to add a light application of Before & After Restoration Balm. I let it sit for 10–15 minutes and then gave it a buff. This made the beauty of the stummel’s grain really pop. No doubt about it – this is a really lovely pipe!

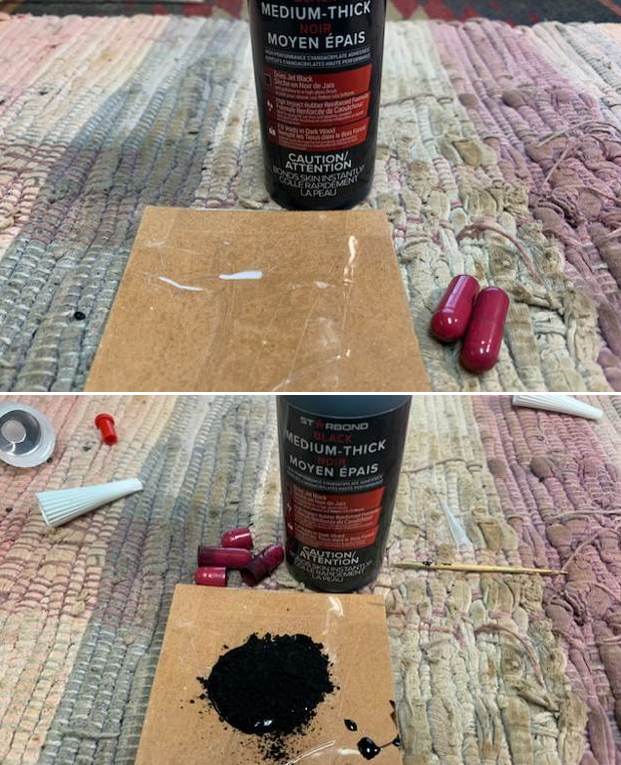

There was one tiny little dent remaining in the stummel. I lined it with cyanoacrylate adhesive. After letting it cure, I sanded the fill repair down with 200-, 400-, and 600-grit sandpaper. I then used all nine Micromesh pads (1,500 through 12,000 grit) on the stummel to finish it off.

There was one tiny little dent remaining in the stummel. I lined it with cyanoacrylate adhesive. After letting it cure, I sanded the fill repair down with 200-, 400-, and 600-grit sandpaper. I then used all nine Micromesh pads (1,500 through 12,000 grit) on the stummel to finish it off.

After that, I applied yet another application of Before & After Restoration Balm. Hubba hubba! This thing is looking better all the time.

After that, I applied yet another application of Before & After Restoration Balm. Hubba hubba! This thing is looking better all the time.

Then it was off for a trip to the buffer. A dose of White Diamond and a few coats of carnauba wax were just what this pipe needed. The lovely shine made the wood very attractive. This is a very handsome pipe and will provide many years of smoking pleasure.

Then it was off for a trip to the buffer. A dose of White Diamond and a few coats of carnauba wax were just what this pipe needed. The lovely shine made the wood very attractive. This is a very handsome pipe and will provide many years of smoking pleasure.

This Peterson Shamrock looks fantastic again and is ready to be enjoyed again by the next owner – just in time for St Patrick’s Day! I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the ‘Irish’ pipe section of the store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the pipe are as follows: length 5⅞ in. (150 mm); height 1⅝ in. (40 mm); bowl diameter 1⅛ in. (27 mm); chamber diameter ¾ in. (20 mm). The weight of the pipe is ⅞ oz. (26 g). I hope you enjoyed reading the story of this pipe’s restoration as much I as I did restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.

This Peterson Shamrock looks fantastic again and is ready to be enjoyed again by the next owner – just in time for St Patrick’s Day! I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the ‘Irish’ pipe section of the store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the pipe are as follows: length 5⅞ in. (150 mm); height 1⅝ in. (40 mm); bowl diameter 1⅛ in. (27 mm); chamber diameter ¾ in. (20 mm). The weight of the pipe is ⅞ oz. (26 g). I hope you enjoyed reading the story of this pipe’s restoration as much I as I did restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.