Blog by Steve Laug

The next pipe on the worktable is from an American Importer and Distributor called Mastercraft. I will give more information on the brand later in the blog. This one is a classic rusticated finish Bulldog with a diamond shaped vulcanite saddle stem. It has a tight rustication pattern all the way around the bowl and shank. There is a smooth panel on the left underside of the shank. Jeff purchased from an antique store in Centerville, Iowa, USA. The pipe is stamped on the left underside of the shank and reads Mastercraft [over] Birdseye Grain. On the end of the shank on that smooth panel it is also stamped France. The left side of the saddle stem also has MC in and oval stamped into the vulcanite. The pipe is dirty with a thick cake in the bowl and a lava overflow and dusty in the rustication of the rim top. The inner edge of the rim looks very good. The finish was dusty with grime ground into the finish around the sides of the bowl. The black vulcanite stem is oxidized, calcified and has tooth marks and chatter on the top and underside near the button. Jeff took some photos of the pipe before he started his cleanup work.  He took a photo of the bowl and rim top to show their general condition. You can see the lava on the rim top and the thick cake in the bowl. There is damage on the rear inner edge of the bowl. The stem is oxidized, calcified and has tooth marks and chatter on both sides near the button.

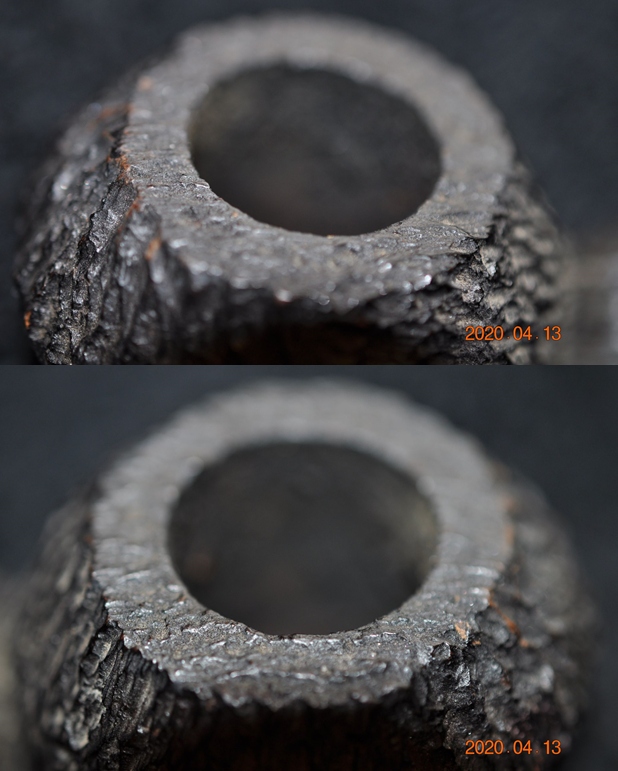

He took a photo of the bowl and rim top to show their general condition. You can see the lava on the rim top and the thick cake in the bowl. There is damage on the rear inner edge of the bowl. The stem is oxidized, calcified and has tooth marks and chatter on both sides near the button.

Jeff took some photos of the sides and heel of the bowl to give an idea of the tight rusticated finish around the bowl. I cannot wait to see what it looks like once it is cleaned and polished.

Jeff took some photos of the sides and heel of the bowl to give an idea of the tight rusticated finish around the bowl. I cannot wait to see what it looks like once it is cleaned and polished.

He took a photo of the stamping on the sides of the shank to capture it for me. It is clear and readable.

He took a photo of the stamping on the sides of the shank to capture it for me. It is clear and readable.

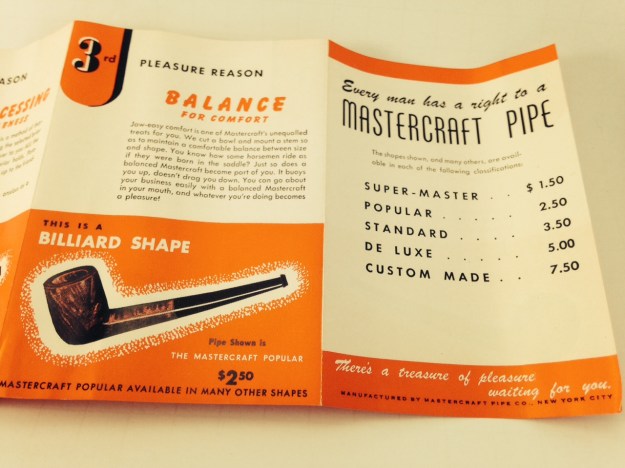

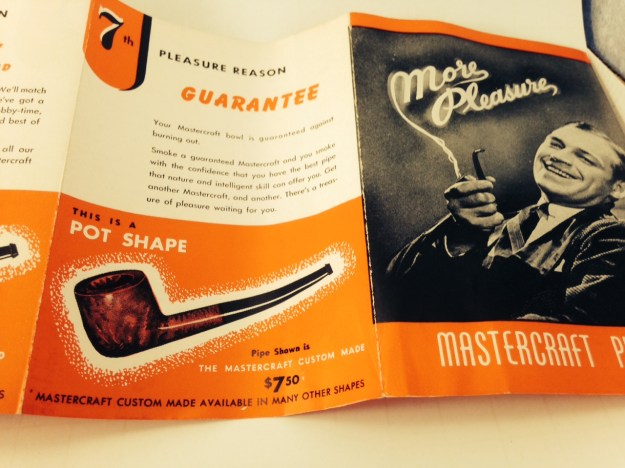

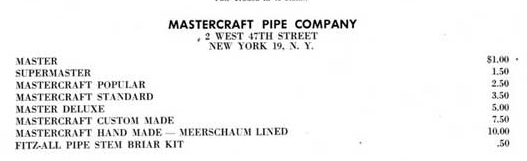

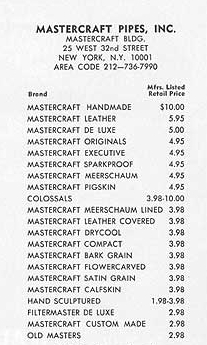

I turned to Pipephil to get a feel for the history of the brand and have included a screen capture of the pertinent section on the site below (http://www.pipephil.eu/logos/en/logo-m3.html). I quote: Mastercraft started in 1941 and belongs to Lane Ltd. Group.

I turned to Pipephil to get a feel for the history of the brand and have included a screen capture of the pertinent section on the site below (http://www.pipephil.eu/logos/en/logo-m3.html). I quote: Mastercraft started in 1941 and belongs to Lane Ltd. Group. I turned to Pipedia for any additional information (https://pipedia.org/wiki/Mastercraft). The article gave and expanded history of the brand. For all intents and purposes Mastercraft was an importer of pipes and pipe related merchandise rather than a maker. I know that the stamping on the pipe identifies it as French made but I am not sure of the manufacturer.

I turned to Pipedia for any additional information (https://pipedia.org/wiki/Mastercraft). The article gave and expanded history of the brand. For all intents and purposes Mastercraft was an importer of pipes and pipe related merchandise rather than a maker. I know that the stamping on the pipe identifies it as French made but I am not sure of the manufacturer.

Now I had a pretty good idea of how the pipe was stamped and made. With that information I moved forward to work on the pipe itself and see what I had to do with it. Jeff had done an amazing job in removing all of the cake and the lava on the rim top. He had reamed the bowl with a PipNet Pipe Reamer and cleaned up the remnants with a Savinelli Fitsall Pipe Knife. He took the cake back to bare briar so we could check the walls for damage. He scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime on the bowl and rim and was able to remove the lava and dirt. He cleaned out the interior of the bowl and shank with pipe cleaners, cotton swabs and alcohol until they came out clean. He cleaned the stem with Soft Scrub to remove the grime on the exterior and cleaned out the airway with alcohol, cotton swabs and pipe cleaners. He soaked the stem in Before & After Deoxidizer and rinsed if off and recleaned the inside of the stem with alcohol and pipe cleaners. I took photos of the pipe before I started my part of the restoration.

I took some photos of the rim top and stem. The rim top and inner edge of the bowl looks very good. The close up photos of the stem shows that there are tooth marks and chatter on the top and underside of the stem near the button.

I took some photos of the rim top and stem. The rim top and inner edge of the bowl looks very good. The close up photos of the stem shows that there are tooth marks and chatter on the top and underside of the stem near the button.  I took a photo of the stamping on the underside of the shank to show the stamping. It is clear and readable. The second photo shows the MC logo on the left side of the saddle stem.

I took a photo of the stamping on the underside of the shank to show the stamping. It is clear and readable. The second photo shows the MC logo on the left side of the saddle stem.  I removed the stem from the shank and took a photo of the pipe at this point. You can clearly see the condition, size and shape of the pipe.

I removed the stem from the shank and took a photo of the pipe at this point. You can clearly see the condition, size and shape of the pipe. The bowl was in excellent condition as was the finish of the bowl after Jeff’s cleanup. I started my cleanup by working some Before & After Restoration Balm into the surface of the briar with my fingertips and a horsehair shoe brush to clean, enliven and protect the briar. I let the balm sit for about ten minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

The bowl was in excellent condition as was the finish of the bowl after Jeff’s cleanup. I started my cleanup by working some Before & After Restoration Balm into the surface of the briar with my fingertips and a horsehair shoe brush to clean, enliven and protect the briar. I let the balm sit for about ten minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I set the bowl aside and turned my attention to the stem. I “painted” the surface of the vulcanite with the flame to lift the tooth marks in the top and underside. I was able to lift many of them. I filled the remaining tooth marks with black super glue and set it aside to cure.

I set the bowl aside and turned my attention to the stem. I “painted” the surface of the vulcanite with the flame to lift the tooth marks in the top and underside. I was able to lift many of them. I filled the remaining tooth marks with black super glue and set it aside to cure.

I used a needle file to smooth out the repairs. I blended it into the surface of the vulcanite beginning with the file. I followed that up with 220 grit sandpaper and started the polishing with 400 grit wet dry sandpaper.

I used a needle file to smooth out the repairs. I blended it into the surface of the vulcanite beginning with the file. I followed that up with 220 grit sandpaper and started the polishing with 400 grit wet dry sandpaper.

I used some liquid paper to touch up what remained of the stamp on the saddle stem. The MC was readable though the oval surrounding it was damaged.

I used some liquid paper to touch up what remained of the stamp on the saddle stem. The MC was readable though the oval surrounding it was damaged. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with a cloth containing some Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with a cloth containing some Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth.

This Mastercraft Birdseye Grain Rusticated Bulldog is a nice looking pipe. The finish looks very good and the rustication is tight and sharp. I put the stem back on the bowl and buffed the pipe lightly with Blue Diamond on the buffing wheel. I carefully avoided the stamping on the shank sides during the process. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the buffing wheel. I buffed it with a clean buffing pad on the buffer. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished pipe is an excellent example of the tightly rusticated Mastercraft pipes from France that was distributed by Mastercraft. The rustication follows the shape very well. Give the finished pipe a look in the photos below. I can only tell you that it is much prettier in person than the photos capture. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ½ Chamber diameter: ¾ of an inch. This interesting MasterCraft Bent Bulldog that is stamped Birdseye Grain is a great looking pipe in excellent condition. Thanks for walking through the restoration with me as I worked over another beautiful pipe. I will be adding it to the rebornpipes store soon. If you want to add it to your collection send me an email or a message! Thanks for your time.

This Mastercraft Birdseye Grain Rusticated Bulldog is a nice looking pipe. The finish looks very good and the rustication is tight and sharp. I put the stem back on the bowl and buffed the pipe lightly with Blue Diamond on the buffing wheel. I carefully avoided the stamping on the shank sides during the process. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the buffing wheel. I buffed it with a clean buffing pad on the buffer. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished pipe is an excellent example of the tightly rusticated Mastercraft pipes from France that was distributed by Mastercraft. The rustication follows the shape very well. Give the finished pipe a look in the photos below. I can only tell you that it is much prettier in person than the photos capture. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ½ Chamber diameter: ¾ of an inch. This interesting MasterCraft Bent Bulldog that is stamped Birdseye Grain is a great looking pipe in excellent condition. Thanks for walking through the restoration with me as I worked over another beautiful pipe. I will be adding it to the rebornpipes store soon. If you want to add it to your collection send me an email or a message! Thanks for your time.