Blog by Steve Laug

This is the second of the “Malaga” pipes that I am working on from Kathy’s Dad’s pipes. Last fall I received a contact email on rebornpipes from Kathy asking if I would be interested in purchasing her late Father, George Koch’s estate pipes. He was a lover of “Malaga” pipes – all shapes and sizes and she wanted to move them out as she cleaned up the estate. We emailed back and forth and I had my brother Jeff follow up with her as he also lives in the US and would make it simpler to carry out this transaction. The long and short of it is that we purchased her Dad’s “Malaga” pipes. There are some beautiful pipes in that lot. I have never seen this many “Malagas” together in one place in all of my years of pipe restoring and refurbishing. They varied from having almost pristine to gnawed and damaged stems that will need to be replaced. Many of the pipes already had replacement stems or maybe George had the staff at the Malaga shop in Michigan put Lucite stems on them because he was such a gnawer. I don’t know if we will ever know the answer to that as Kathy did not know for sure. She did know though that he loved the brand and that most of the pipes he smoked he purchased from the shop. These were some well used and obviously well loved pipes. Cleaning and restoring them will be a tribute to this pipeman. (Here is a link to some history of the Malaga Brand if you are interested: https://rebornpipes.com/tag/malaga-pipes/. There are also links there to a catalogue and the maker George Khoubesser.) To me knowing about the pipeman who held the pipes in trust before me gives another dimension to the restoration work. As I mentioned before, I may well be alone in this but when I know about the person it is almost as if he or she is with me work on his or her pipes. In this case Kathy was more than happy to send us not only information on her dad but also a photo of her Dad enjoying his “Malagas”. Once again, I am including that information so you can know a bit about the pipeman who held these pipes in trust before they are passed on to some of you. I include part of Kathy’s correspondence with my brother as well…

To me knowing about the pipeman who held the pipes in trust before me gives another dimension to the restoration work. As I mentioned before, I may well be alone in this but when I know about the person it is almost as if he or she is with me work on his or her pipes. In this case Kathy was more than happy to send us not only information on her dad but also a photo of her Dad enjoying his “Malagas”. Once again, I am including that information so you can know a bit about the pipeman who held these pipes in trust before they are passed on to some of you. I include part of Kathy’s correspondence with my brother as well…

Jeff…Here is a little about my dad, George P. Koch…I am sending a picture of him with a pipe also in a separate email.

Dad was born in 1926 and lived almost all his life in Springfield, Illinois. He was the youngest son of German immigrants and started grade school knowing no English. His father was a coal miner who died when Dad was about seven and his sixteen year old brother quit school to go to work to support the family. There was not much money, but that doesn’t ruin a good childhood, and dad had a good one, working many odd jobs, as a newspaper carrier, at a dairy, and at the newspaper printing press among others. He learned to fly even before he got his automobile driver’s license and carried his love of flying with him through life, recertifying his license in retirement and getting his instrumental license in his seventies and flying until he was grounded by the FAA in his early eighties due to their strict health requirements. (He was never happy with them about that.) He was in the Army Air Corps during World War II, trained to be a bomber, but the war ended before he was sent overseas. He ended service with them as a photographer and then earned his engineering degree from University of Illinois. He worked for Allis Chalmers manufacturing in Springfield until the early sixties, when he took a job at Massey Ferguson in Detroit, Michigan. We lived in Livonia, and that’s where his love for Malaga pipes began. After a few years he returned to Allis Chalmers and we moved back to Springfield. I remember that when we went back to Michigan to visit friends, Dad had to go to the Malaga store and acquire a few new pipes. Many a year I wrote to Malaga and they picked out a pipe for me to purchase that I could give Dad for a Christmas or birthday present. He was always pleased. His favorites were the straight stemmed medium sized bowl pipes, but he liked them all. He had some other pipes, but the Malagas were his favorites. I remember him smoking them sitting in his easy chair after work, with feet up on the ledge by the fire burning in the fireplace. Growing up it was my job to clean them and he liked the inner bowl and stem coated with Watkins vanilla, leaving a little of that liquid in the bowl to soak in when I put them back on the rack. Dad quit smoking later in life and so they’ve sat on the racks for many years unattended, a part of his area by his easy chair and fireplace. Dad passed whe n he was 89 years old and it finally is time for the pipes to move on. I’m very happy they are being restored by you and your brother and hope they find homes who enjoy them as much as Dad did. Thank-you for your care and interest. — Kathy, the oldest daughter

n he was 89 years old and it finally is time for the pipes to move on. I’m very happy they are being restored by you and your brother and hope they find homes who enjoy them as much as Dad did. Thank-you for your care and interest. — Kathy, the oldest daughter

Kathy, once again I thank you for providing this beautiful tribute to your Dad. We will appreciate your trust in allowing us to clean and restore these pipes. I am also trusting that those of you who are reading this might carry on the legacy of her Dad’s pipes as they will be added to the rebornpipes store once they are finished.

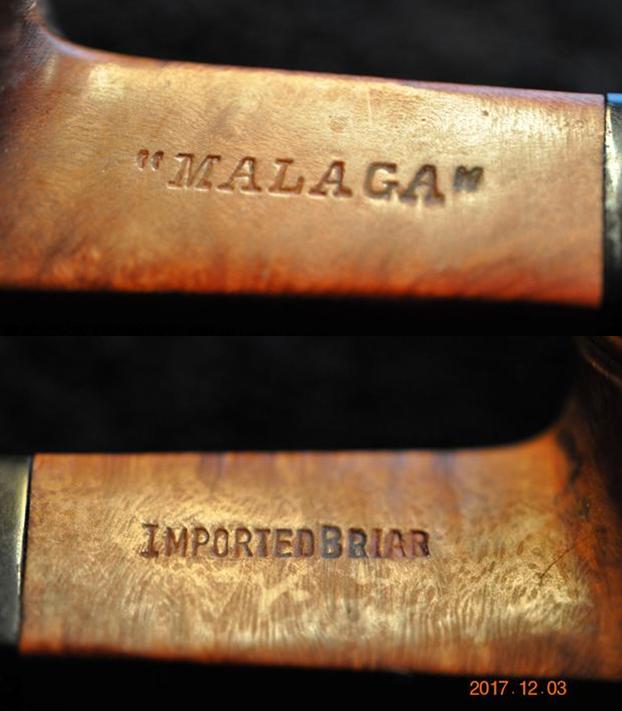

The second of the pipes that I chose to work on is a squat “Malaga” Bulldog with flattened panels on the front, right and left sides of the cap. It has a black Lucite saddle stem. It is another beautiful pipe underneath the grime and debris of the years. The warm brown finish on the bowl appeared to be good condition under the dust and tars of time. The rim top was covered with a light overflow of lava from the cake in the bowl. The inner and outer edge of the bowl had damage. There were some nicks on the cap of the bulldog. The outer edge and cap showed signs of being knocked against a hard surface to empty the dottle from the bowl. The twin rings around the top cap were dirty but solid. The stamping on the left side of the shank was clear and read “Malaga”. On the right side it was stamped Imported Briar. Once again there was no shape numbers on the pipe. The Lucite stem fit the shank quite well and was worn. There was tooth chatter and marks on both sides at the button. The interior of the pipe was dirty. I often talk about the wear and tear on the pipes I work on… this is not a bad thing. It actually shows that this was a well loved pipe and that the pipeman who used it held it often and enjoyed its company. Jeff took these photos before he started the cleanup work on the pipe.

He took close up photos of the bowl and rim to show the condition of the pipe before he started to work his magic on it. The exterior of the bowl and shank were dirty. You can see the lava on the rim, the cake in the bowl and the nicks on the bowl cap and the outer edge of the rim. It is dirty but in otherwise good condition. He also took a photo of the side of the bowl and the underside of the bowl and shank.

He took close up photos of the bowl and rim to show the condition of the pipe before he started to work his magic on it. The exterior of the bowl and shank were dirty. You can see the lava on the rim, the cake in the bowl and the nicks on the bowl cap and the outer edge of the rim. It is dirty but in otherwise good condition. He also took a photo of the side of the bowl and the underside of the bowl and shank.

He also took photos of the shank to show the stamping and the condition of the overall shank so you could have an idea of where things were at before he cleaned it up.

He also took photos of the shank to show the stamping and the condition of the overall shank so you could have an idea of where things were at before he cleaned it up. The photos of the stem show the fuzz of dust, calcification at the sharp edge of the button and the chatter and marks of teeth near the button. None of them are a real issue as much of the debris will wash away in the cleanup and the tooth chatter and marks will disappear in the restoration process.

The photos of the stem show the fuzz of dust, calcification at the sharp edge of the button and the chatter and marks of teeth near the button. None of them are a real issue as much of the debris will wash away in the cleanup and the tooth chatter and marks will disappear in the restoration process. Working on this second pipe reminds me yet again how much I have missed working on the pipes that Jeff has cleaned. The last little while I have been working on pipes that I had to clean up and it was a real nice change to work on these. Jeff reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and Murphy’s Oil Soap to remove the oils and tars on the bowl, rim and shank. He rinsed it under running water. He dried it off with a soft cloth. The lava mess on the rim was thoroughly removed without harming the finish underneath it. Once the grime was removed the finish actually looked it was in excellent condition. I took photos of the pipe to show its condition before I started my work on it.

Working on this second pipe reminds me yet again how much I have missed working on the pipes that Jeff has cleaned. The last little while I have been working on pipes that I had to clean up and it was a real nice change to work on these. Jeff reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and Murphy’s Oil Soap to remove the oils and tars on the bowl, rim and shank. He rinsed it under running water. He dried it off with a soft cloth. The lava mess on the rim was thoroughly removed without harming the finish underneath it. Once the grime was removed the finish actually looked it was in excellent condition. I took photos of the pipe to show its condition before I started my work on it.

I took a photo of the rim top to show the condition it was in after the cleanup. Jeff was able to remove all of the lava on the rim top and edges. There is still some darkening on the rim top.You can see the damage from knocking out the pipe on a hard surface on the top and outside edges of the bowl. There is general darkening and slight burn damage as well. The stem was clean and you can see the tooth chatter and marks on the surface near the button.

I took a photo of the rim top to show the condition it was in after the cleanup. Jeff was able to remove all of the lava on the rim top and edges. There is still some darkening on the rim top.You can see the damage from knocking out the pipe on a hard surface on the top and outside edges of the bowl. There is general darkening and slight burn damage as well. The stem was clean and you can see the tooth chatter and marks on the surface near the button. I lightly topped the bowl on my topping board using 220 grit sandpaper. It did not take too much work to remove the nicks and damage to the rim top and edges. Once it was complete I topped it on a medium grit sanding sponge to smooth the surface even more.

I lightly topped the bowl on my topping board using 220 grit sandpaper. It did not take too much work to remove the nicks and damage to the rim top and edges. Once it was complete I topped it on a medium grit sanding sponge to smooth the surface even more. I worked on the rim top and the inner edge of the bowl. I used a folded piece of 220 grit sandpaper to smooth out the damage around the edge. I gave the rim a light bevel to remove the damage on the front side of the bowl.

I worked on the rim top and the inner edge of the bowl. I used a folded piece of 220 grit sandpaper to smooth out the damage around the edge. I gave the rim a light bevel to remove the damage on the front side of the bowl.  I sanded the rim cap with 220 grit sandpaper to remove as much of the damage as I could. I forgot to take photos of that part of the process. I polished the briar with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the briar down after each pad with a damp cloth to remove the sanding dust.

I sanded the rim cap with 220 grit sandpaper to remove as much of the damage as I could. I forgot to take photos of that part of the process. I polished the briar with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the briar down after each pad with a damp cloth to remove the sanding dust.

I rubbed the bowl down with Before & After Restoration Balm to deep clean the pores and grain of the smooth finish as well as to enliven and protect the briar. I hand rubbed it with my fingers and wiped it off with a soft cloth. I buffed the bowl with a horsehair shoe brush to polish it. The briar really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration.

I rubbed the bowl down with Before & After Restoration Balm to deep clean the pores and grain of the smooth finish as well as to enliven and protect the briar. I hand rubbed it with my fingers and wiped it off with a soft cloth. I buffed the bowl with a horsehair shoe brush to polish it. The briar really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration.

I ran pipe cleaners dipped in alcohol through the airway in the stem to clean out the sanding dust. I cleaned out the slot and made sure the corners were all clean. I also ran pipe cleaners through the shank and used cotton swabs and alcohol in the mortise to remove any of the sanding dust from the rim work.

I ran pipe cleaners dipped in alcohol through the airway in the stem to clean out the sanding dust. I cleaned out the slot and made sure the corners were all clean. I also ran pipe cleaners through the shank and used cotton swabs and alcohol in the mortise to remove any of the sanding dust from the rim work. I sanded out the tooth chatter and tooth marks with 220 grit sandpaper to smooth and blend them into the surface of the rest of the stem. I sanded the surface of the button to remove the marks on the top and underside.

I sanded out the tooth chatter and tooth marks with 220 grit sandpaper to smooth and blend them into the surface of the rest of the stem. I sanded the surface of the button to remove the marks on the top and underside. I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the stem down after each pad with a damp cloth to remove the sanding dust.

I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the stem down after each pad with a damp cloth to remove the sanding dust.

With the stem polished I put it back on the pipe and buffed it with Blue Diamond. I gave the bowl and the stem several coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The finished pipe is shown in the photos below. This is the second of many “Malaga” pipes that I am restoring from Kathy’s Dad’s collection. I am looking forward to hearing what Kathy thinks once she sees the finished pipe on the blog. I will be posting it on the rebornpipes store very soon. It should make a nice addition to a new pipeman’s rack that can carry on the trust from her father. The dimensions are Length: 5 3/4 inches, Height: 1 1/2 inches, Outside diameter of the bowl: 1 3/4 inches, Chamber diameter: 3/4 inches. Thanks for walking through the restoration with me as I worked over this second Malaga of his estate. More will follow in a variety of shapes and sizes.

With the stem polished I put it back on the pipe and buffed it with Blue Diamond. I gave the bowl and the stem several coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The finished pipe is shown in the photos below. This is the second of many “Malaga” pipes that I am restoring from Kathy’s Dad’s collection. I am looking forward to hearing what Kathy thinks once she sees the finished pipe on the blog. I will be posting it on the rebornpipes store very soon. It should make a nice addition to a new pipeman’s rack that can carry on the trust from her father. The dimensions are Length: 5 3/4 inches, Height: 1 1/2 inches, Outside diameter of the bowl: 1 3/4 inches, Chamber diameter: 3/4 inches. Thanks for walking through the restoration with me as I worked over this second Malaga of his estate. More will follow in a variety of shapes and sizes.