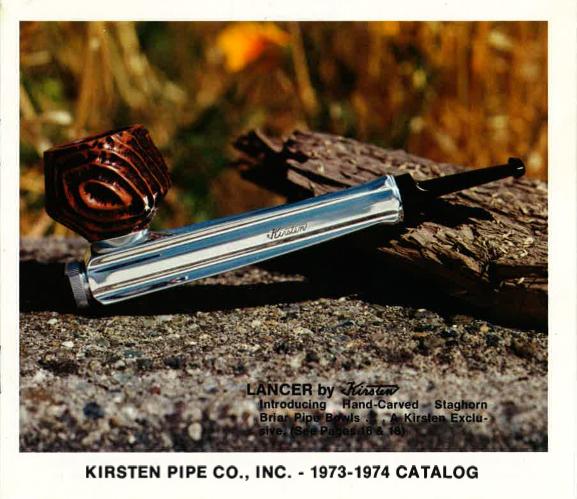

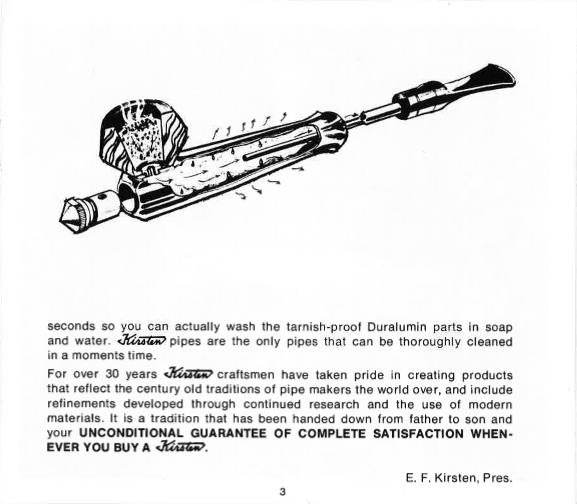

This is the second of the Kirsten Pipe Company Catalogues. While there are some similarities between the first one I posted and this one notice the subtle changes in colour, in bowl shapes offered and of course in prices. I have two more catalogues to scan from the years that follow and I find this kind of thing fascinating to read. If you are like me in this then enjoy!

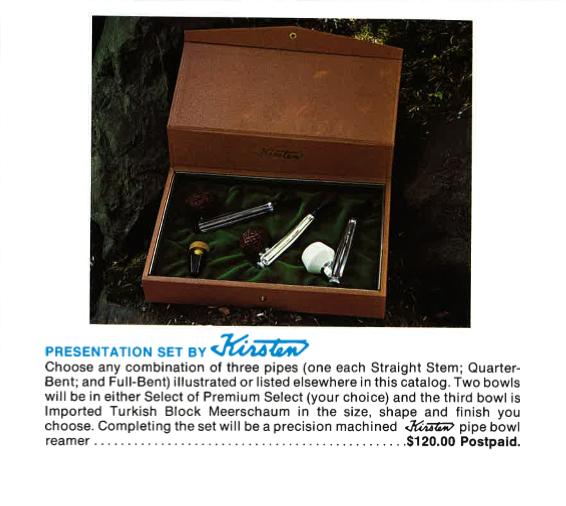

Inserted in the cover was a Kirsten Meerschaum bowl and pipe leaflet as well as advertisement for a boxed set of pipes.

Inserted in the cover was a Kirsten Meerschaum bowl and pipe leaflet as well as advertisement for a boxed set of pipes.

Tag Archives: Kirsten pipes

1974-1975 Kirsten Pipe Company Catalog

I received an email while I was traveling to my mom’s 90th birthday from a reader who was selling 6 Kirsten pipes and wanted to know if I was interested in buying them. He sent a photo and to my surprise they included not only the pipe but some parts, boxes, extra bowls and some catalogs. This is the first of them – a 1974-1975 Catalog. I thought you all might be interested in having a look.

Restoring a Kirsten Generation 1 Medium Straight Pipe

Blog by Steve Laug

My brother continues to look for Kirsten estate pipes. He picked up this Kirsten because it looked like an old-timer. When I received it I could see that he was right about it being an older one. All the signs were there. The bowl was threaded directly on the barrel of the pipe and bottom cap that is on new models was not present. When the stem was removed there were no O rings on the end of the insert. The valve cap was stuck in the end of the shank and it could not be turned. The rim had a lava overflow on it and there was a heavy cake in the bowl. The screw mount in the bottom of the bowl was caked over to the point that it was stuck in the bowl. The metal barrel was oxidized and pitted. It had no shine left but looked like a well-worn pipe. The stem was oxidized and a dirty brown colour. There were tooth marks next to the button on the top and the bottom sides of the stem. The rod that ran through the barrel was dirty and coated with tars and oils that had hardened.

The left side of the barrel is stamped Kirsten in script. The underside is stamped Pats. & Pats. Pend. USA M. The stamping along with the absence of O rings, the bowl screwed directly on top of the barrel pointed to a Generation 1 Kirsten which dated it between the years 1936-1958. In a previous blog I spelled out the features of each generation of Kirsten pipes that were released. https://rebornpipes.com/2012/11/03/kirsten-generation-1-1-5-2-3/ I quote the following from there: The wooden bowl on this generation connects directly to the metal barrel and there is no metal cup spacer. It is a pretty flush fit that goes flat against the barrel. On the underside of the metal barrel it is stamped with one or more of the following “Pat. Appl. For” (1936-38) and “Pats. & Pats. Pending” (1938-1958) over “Made in USA” – S” (or applicable size – S, M, L). There are no O-rings on the bit or metal shank insert. The M stamp on the pipe identifies it as a Medium sized pipe.

The left side of the barrel is stamped Kirsten in script. The underside is stamped Pats. & Pats. Pend. USA M. The stamping along with the absence of O rings, the bowl screwed directly on top of the barrel pointed to a Generation 1 Kirsten which dated it between the years 1936-1958. In a previous blog I spelled out the features of each generation of Kirsten pipes that were released. https://rebornpipes.com/2012/11/03/kirsten-generation-1-1-5-2-3/ I quote the following from there: The wooden bowl on this generation connects directly to the metal barrel and there is no metal cup spacer. It is a pretty flush fit that goes flat against the barrel. On the underside of the metal barrel it is stamped with one or more of the following “Pat. Appl. For” (1936-38) and “Pats. & Pats. Pending” (1938-1958) over “Made in USA” – S” (or applicable size – S, M, L). There are no O-rings on the bit or metal shank insert. The M stamp on the pipe identifies it as a Medium sized pipe.

So I armed with that information I knew that the pipe I had, came from the time period of 1936-1958 and the lack of O rings on the mouthpiece and I assumed on the valve once I was able to remove confirmed that. I was ready to get to work on the pipe. I heated the valve insert with a heat gun to loosen the tars that held the cap in place. It did not take too long and I was able to insert a screw driver in the barrel and tap on the valve. The next photo shows the pipe taken apart. The condition of all of the parts is clear – dirty but functional. The knurled edges on the valve were damaged by previous attempts by someone else to remove the valve with pliers. In the photo above there are pliers present but I did not use them on the end cap.

The next photo shows the pipe taken apart. The condition of all of the parts is clear – dirty but functional. The knurled edges on the valve were damaged by previous attempts by someone else to remove the valve with pliers. In the photo above there are pliers present but I did not use them on the end cap. The screw in the bottom of the bowl was held in place by the cake in the bowl. The photo also shows the condition of the bowl and the rim. The other close-up photos show the stem and the tooth marks on both sides near the button.

The screw in the bottom of the bowl was held in place by the cake in the bowl. The photo also shows the condition of the bowl and the rim. The other close-up photos show the stem and the tooth marks on both sides near the button.

I sanded the stem with 180 and 220 grit sandpaper to remove the oxidation and the tooth marks. I was able to blend the tooth damage into the flow of the stem because fortunately they were not deep.

I sanded the stem with 180 and 220 grit sandpaper to remove the oxidation and the tooth marks. I was able to blend the tooth damage into the flow of the stem because fortunately they were not deep. I lightly topped the bowl on the topping board to remove the damage to the rim and the build-up.

I lightly topped the bowl on the topping board to remove the damage to the rim and the build-up. I reamed the bowl with the Savinelli Pipe Knife and took the cake back to bare briar. I sanded the inside of the bowl with a piece of sandpaper to clean out the remaining cake.

I reamed the bowl with the Savinelli Pipe Knife and took the cake back to bare briar. I sanded the inside of the bowl with a piece of sandpaper to clean out the remaining cake. I scrubbed the exterior of the bowl with cotton pads and acetone to remove the grime and the remaining finish.

I scrubbed the exterior of the bowl with cotton pads and acetone to remove the grime and the remaining finish.

I scrubbed the rod on the stem unit with acetone to remove the tars and oils. I did the same with the exterior of the valve.

I scrubbed the rod on the stem unit with acetone to remove the tars and oils. I did the same with the exterior of the valve. I cleaned out the tarry build-up in the valve/end cap with cotton swabs and alcohol.

I cleaned out the tarry build-up in the valve/end cap with cotton swabs and alcohol. I cleaned out the barrel with cotton swabs and rolled cotton pads and alcohol pushed through the opening with a screw driver. I also pushed a rolled piece of 0000 steel wool through the barrel to polish the inside. I used pipe cleaners to clean out the threads in the opening on the top of the barrel.

I cleaned out the barrel with cotton swabs and rolled cotton pads and alcohol pushed through the opening with a screw driver. I also pushed a rolled piece of 0000 steel wool through the barrel to polish the inside. I used pipe cleaners to clean out the threads in the opening on the top of the barrel. I cleaned up the screw and the airway through the screw with a dental pick, pipe cleaners and alcohol. I cleaned the threads on the screw with cotton swabs and alcohol.

I cleaned up the screw and the airway through the screw with a dental pick, pipe cleaners and alcohol. I cleaned the threads on the screw with cotton swabs and alcohol. I polished the aluminum barrel with Meguiar’s Scratch X2.0 and cotton swabs.

I polished the aluminum barrel with Meguiar’s Scratch X2.0 and cotton swabs. I restained the bowl with a dark brown stain pen.

I restained the bowl with a dark brown stain pen.  I put the bowl on the barrel buffed them with Blue Diamond on the wheel to polish the stain and even out the coat on the bowl as well as polish the aluminum. The next photos show the bowl and barrel at this point in the process.

I put the bowl on the barrel buffed them with Blue Diamond on the wheel to polish the stain and even out the coat on the bowl as well as polish the aluminum. The next photos show the bowl and barrel at this point in the process.

I cleaned out the airway in the stem with pipe cleaners and alcohol and then worked on the stem with micromesh sanding pads. I wet sanded with 1500-2400 grit pads and gave it a coat of Obsidian Oil. I dry sanded with 3200-4000 grit pads and gave it another coat of oil. I finished sanding with 6000-12000 grit pads and gave it a final coat of Obsidian Oil. I set the stem aside to dry.

I cleaned out the airway in the stem with pipe cleaners and alcohol and then worked on the stem with micromesh sanding pads. I wet sanded with 1500-2400 grit pads and gave it a coat of Obsidian Oil. I dry sanded with 3200-4000 grit pads and gave it another coat of oil. I finished sanding with 6000-12000 grit pads and gave it a final coat of Obsidian Oil. I set the stem aside to dry.

I gave the pipe and stem multiple coats of carnauba wax and buffed the barrel, bowl and stem with a clean buffing pad to raise the shine. I hand buffed it with a microfibre cloth to add depth to the shine. The photos below show the finished pipe. This one will also go on the store soon. If you are interested in it let me know. Thanks for looking.

I gave the pipe and stem multiple coats of carnauba wax and buffed the barrel, bowl and stem with a clean buffing pad to raise the shine. I hand buffed it with a microfibre cloth to add depth to the shine. The photos below show the finished pipe. This one will also go on the store soon. If you are interested in it let me know. Thanks for looking.

Breathing new life into a Kirsten S with a Unique Bell Bowl

Blog by Steve Laug

My brother picked up this Kirsten because he really liked the look of the bowl. I have never seen a Kirsten bowl this shape so I don’t know if it is an aftermarket bowl or one of Kirsten’s own. In the long run it does not matter because not only is the shape attractive but the briar is stunning. The rim has a slight bevel inward and the curve into the metal base cap looks great and feels great in the hand. The bowl had a heavy cake and the screw mount in the bottom of the bowl was caked over to the point that it was stuck in the bowl. The metal barrel was oxidized and pitted. It had no shine left but looked like a well-worn pipe. The stem was oxidized but there were no tooth marks or chatter on the stem. The rod that ran through the barrel was dirty and coated with tars and oils that had harden. The adjustable valve on the end of the barrel was stuck and could not be turn or adjusted. It was actually stuck closed so there was no airflow through the barrel.

I put the pipe in an alcohol bath to let it soak for a day while I was at work. When I came home in the evening I was able to take it apart. The alcohol had softened the tars and the stem came out easily and I was able to use a screw driver and a light tap on the handle to knock out the stuck valve. The bowl came off the barrel but the screw was still stuck in the bottom of the bowl. When I had it apart I realized I was dealing with a Generation 2 Kirsten. It was made between 1958-1985. I quote from a previous blog on the site with the information that leads me to the conclusion that I was dealing with a Generation 2. “Markings on underside of metal shank “Made in USA XL” (or app. size) and “Pat. & Pats. Pending”. The presence of O rings on both the valve and the mouthpiece and the metal cup spacer under bowl are the biggest thing that separates the Generation 1 from the Generation 2 pipes. These O rings help provide a tighter seal when the stem and apparatus are inserted into the radiator stem. Instead of “O” rings, the machining of the Generation 1 pipes was so precise the fit was exact.” https://rebornpipes.com/2012/11/03/kirsten-generation-1-1-5-2-3/ The blog also identifies the S stamp on the bottom of the shank as the Sportsman Model from that era.

I put the pipe in an alcohol bath to let it soak for a day while I was at work. When I came home in the evening I was able to take it apart. The alcohol had softened the tars and the stem came out easily and I was able to use a screw driver and a light tap on the handle to knock out the stuck valve. The bowl came off the barrel but the screw was still stuck in the bottom of the bowl. When I had it apart I realized I was dealing with a Generation 2 Kirsten. It was made between 1958-1985. I quote from a previous blog on the site with the information that leads me to the conclusion that I was dealing with a Generation 2. “Markings on underside of metal shank “Made in USA XL” (or app. size) and “Pat. & Pats. Pending”. The presence of O rings on both the valve and the mouthpiece and the metal cup spacer under bowl are the biggest thing that separates the Generation 1 from the Generation 2 pipes. These O rings help provide a tighter seal when the stem and apparatus are inserted into the radiator stem. Instead of “O” rings, the machining of the Generation 1 pipes was so precise the fit was exact.” https://rebornpipes.com/2012/11/03/kirsten-generation-1-1-5-2-3/ The blog also identifies the S stamp on the bottom of the shank as the Sportsman Model from that era.

So I knew that the pipe I had, came from the time period of 1958-1985 and that the O rings on both the valve and the mouthpiece confirmed that. The S stamp also fits the pipe squarely within that date range. Armed with that information I began to work on refurbishing the Kirsten. I reamed the bowl with the Savinelli Pipe Knife and was able to clean out the cake enough that I could use a flat blade screwdriver to loosen the screw from the bottom of the bowl. Once the screw was removed I cleaned out the bowl with sandpaper to take the cake back to bare briar.

I reamed the bowl with the Savinelli Pipe Knife and was able to clean out the cake enough that I could use a flat blade screwdriver to loosen the screw from the bottom of the bowl. Once the screw was removed I cleaned out the bowl with sandpaper to take the cake back to bare briar. I scrubbed the rim with a cotton pad and saliva and was able to remove the majority of the tars and oils. I used micromesh sanding pads to further clean up the rim top. The briar was beautiful once the grime was removed. I wiped down the outside of the bowl and rim with alcohol and the finish was in very decent shape.

I scrubbed the rim with a cotton pad and saliva and was able to remove the majority of the tars and oils. I used micromesh sanding pads to further clean up the rim top. The briar was beautiful once the grime was removed. I wiped down the outside of the bowl and rim with alcohol and the finish was in very decent shape. I scrubbed the oxidized finish with Meguiar’s Scratch X2.0 and cotton pads and cotton swabs and was able to remove the worn and oxidized build up on the surface. Underneath the oxidation was a shiny metal finish. It would not take too much scrubbing to remove all of the damage.

I scrubbed the oxidized finish with Meguiar’s Scratch X2.0 and cotton pads and cotton swabs and was able to remove the worn and oxidized build up on the surface. Underneath the oxidation was a shiny metal finish. It would not take too much scrubbing to remove all of the damage. I soaked some cotton pads in alcohol and pushed them through the barrel and also scrubbed the inside of the barrel with cotton swabs and alcohol to remove the tars and oils there. I cleaned out the inside of the valve and the outside of the insert end.

I soaked some cotton pads in alcohol and pushed them through the barrel and also scrubbed the inside of the barrel with cotton swabs and alcohol to remove the tars and oils there. I cleaned out the inside of the valve and the outside of the insert end.  I cleaned out the airway in the stem with alcohol and pipe cleaners. I sanded the metal rod with micromesh sanding pads to remove the build up and tars on the metal surface. I scrubbed it with alcohol to clean it and polished it with the Meguiar’s.

I cleaned out the airway in the stem with alcohol and pipe cleaners. I sanded the metal rod with micromesh sanding pads to remove the build up and tars on the metal surface. I scrubbed it with alcohol to clean it and polished it with the Meguiar’s. With the internals cleaned, the bowl reamed and cleaned, the barrel polished and cleaned it was time to polish the stem. I scrubbed it with Soft Scrub cleanser to remove the oxidation. Once I broke through it I used the Meguiar’s Scratch X2.0 to further polish the stem. I decided to try to see if I could successfully use Charles’ method of cleaning oxidation with the Meguiar’s.

With the internals cleaned, the bowl reamed and cleaned, the barrel polished and cleaned it was time to polish the stem. I scrubbed it with Soft Scrub cleanser to remove the oxidation. Once I broke through it I used the Meguiar’s Scratch X2.0 to further polish the stem. I decided to try to see if I could successfully use Charles’ method of cleaning oxidation with the Meguiar’s.

I was pretty amazed with the results. The finish glowed and the polish actually removed all of the oxidation. It just took repeated scrubbings and polishing until finally no more oxidation came off with the polish. I buffed the pipe with Blue Diamond on the wheel to polish the briar, barrel and the stem. I gave the pipe multiple coats of carnauba wax and buffed it with a clean buffing pad to polish it. I hand buffed it with a microfibre cloth to deepen the shine. The finished pipe looks like new and it just glows with warmth and a shine that must have originally graced the pipe. It is a beautiful Kirsten and should grace someone’s pipe rack for years to come. The finished pipe is shown in the photos below. If you are interested in this pipe let me know. Thanks for looking.

I was pretty amazed with the results. The finish glowed and the polish actually removed all of the oxidation. It just took repeated scrubbings and polishing until finally no more oxidation came off with the polish. I buffed the pipe with Blue Diamond on the wheel to polish the briar, barrel and the stem. I gave the pipe multiple coats of carnauba wax and buffed it with a clean buffing pad to polish it. I hand buffed it with a microfibre cloth to deepen the shine. The finished pipe looks like new and it just glows with warmth and a shine that must have originally graced the pipe. It is a beautiful Kirsten and should grace someone’s pipe rack for years to come. The finished pipe is shown in the photos below. If you are interested in this pipe let me know. Thanks for looking.

Found an Old Patents Pending Generation 1 Kirsten A

Blog by Steve Laug

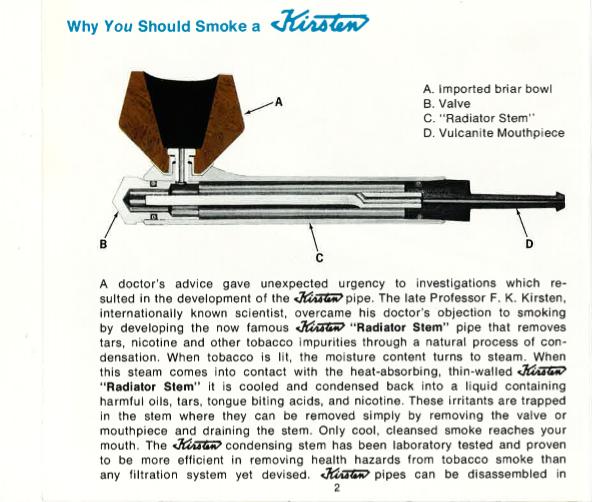

Another pipe from the treasure trove my brother Jeff sent me was an early Kirsten. The metal barrel is stamped Kirsten in script on the left side of the barrel and on the underside it is stamped Pats. & Pats. Pend. – A. When I received it the bowl would unscrew from the barrel and it had no metal cap on the bottom. It was a wooden bowl without the cap which along with the stamping pointed to an early Kirsten. The stem and rod were stuck in the barrel and the adjustable valve on the front of the barrel was frozen solid. The valve had evidently been frozen for some time as someone had used pliers on it to try to remove it. They had left behind the tooth marks of the pliers on the aluminum valve cover. Because of the vulcanite lip on the stem that sat against the barrel that there would not be a rubber grommet between the stem and the barrel. The bowl had a thick, rock hard cake and the bottom of the bowl was not visible to see what the condition of the screw head was like. I have no idea how the pipe man ever drew air through this pipe as the bottom of the bowl was solid. The finish on the bowl was dull and lifeless with no grain visible through the grime. The top of the rim was covered with over flow from the cake in the bowl. It was a large bowl initially so once the cake was gone it would be an inch in diameter. I looked up information to see if I could find a cut away drawing of the Kirsten and found this one and a bit of history and information on the concept of the Kirsten pipe. The following is from the Kirsten website https://www.kirstenpipe.com/page_pipestyles.shtml and https://www.kirstenpipe.com/page ourstory.shtml

I looked up information to see if I could find a cut away drawing of the Kirsten and found this one and a bit of history and information on the concept of the Kirsten pipe. The following is from the Kirsten website https://www.kirstenpipe.com/page_pipestyles.shtml and https://www.kirstenpipe.com/page ourstory.shtml “It is by no means merely puffery to say that Professor Frederick K. Kirsten was a genuine American original. He first sailed to this country in 1902, as a cabin boy from Hamburg, Germany. After successfully rounding the Horn and eluding the shanghai gangs of the West Coast, he navigated the educational system at the University of Washington to become a Professor of Aeronautical Engineering. Here, his inventive spirit took wing. He created the world-famous Kirsten Wind Tunnel, Air-washing equipment for factories, an air-cooled Utopian Bed, and, most notably, a revolutionary propeller which enables boats to stop and turn on a dime. Today, in the same waters where he jumped ship almost 100 years ago, ocean-going vessels are landed by sturdy tugs driven by Kirsten cycloidal propellers, piloted by equally sturdy captains smoking cool Kirsten pipes.”

“It is by no means merely puffery to say that Professor Frederick K. Kirsten was a genuine American original. He first sailed to this country in 1902, as a cabin boy from Hamburg, Germany. After successfully rounding the Horn and eluding the shanghai gangs of the West Coast, he navigated the educational system at the University of Washington to become a Professor of Aeronautical Engineering. Here, his inventive spirit took wing. He created the world-famous Kirsten Wind Tunnel, Air-washing equipment for factories, an air-cooled Utopian Bed, and, most notably, a revolutionary propeller which enables boats to stop and turn on a dime. Today, in the same waters where he jumped ship almost 100 years ago, ocean-going vessels are landed by sturdy tugs driven by Kirsten cycloidal propellers, piloted by equally sturdy captains smoking cool Kirsten pipes.”

“Rightly called the coolest pipe in the world, this latter innovation came about when a doctor advised Professor Kirsten to switch from cigarettes. He quickly dreamed up a way to trap the moisture, tars and tongue-biting acids which attack the users of briar pipes. After 50 years and counting, Kirsten pipes are still produced by the Kirsten family, faithfully following the basic designs of this father of invention.”

“Professor Kirsten revolutionized pipesmoking by creating the Radiator stem. When tobacco, which is 30% to 60% moisture, is lit in the bowl, it creates steam. As the smoke is drawn through the stem, the steam is cooled and condenses into a liquid. This bitter-tasting liquid is trapped in the stem, along with tars, nicotine and tongue-biting acids.”

“Only clean, cool, moisture-free smoke passes through the intake tube to the mouthpiece. To remove the trapped liquid, you simply remove the valve. You can clean a KIRSTEN in seconds by pushing a tissue through the bore of the stem, exactly as you would clean a gun barrel.”

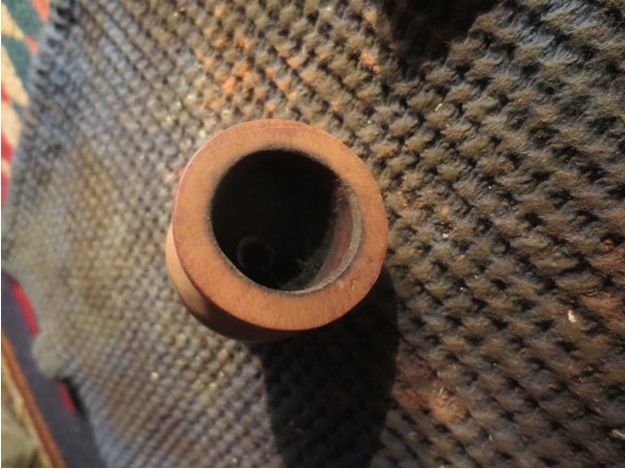

The cleaning in seconds must not have been something that the previous owner of this pipe ever read or understood. I decided to work on the bowl first as it was the only part of the pipe that I could remove at that point in the process. I took the photo below to give an idea of the thickness of the cake and the minimal size of the air hole at the bottom of the bowl. You can see that it is virtually clogged and the airflow would be very restricted. The lack of a cap on the bottom of the bowl can be seen in the next three photos. The first two photos show the state of the finish. In the second one you can see the grain peeking through the grime on the finish. In the third photo you can see the stamping on the bottom of the bowl. It reads Kirsten Pats Appl For.

The lack of a cap on the bottom of the bowl can be seen in the next three photos. The first two photos show the state of the finish. In the second one you can see the grain peeking through the grime on the finish. In the third photo you can see the stamping on the bottom of the bowl. It reads Kirsten Pats Appl For.

I put the barrel and stem in an alcohol bath to soak overnight to try to loosen the frozen stem and rod.

I put the barrel and stem in an alcohol bath to soak overnight to try to loosen the frozen stem and rod. I reamed the bowl with the largest cutting head on the PipNet reamer and took the cake back to bare briar. I used a pen knife to work on the bottom of the bowl and was finally able to see the characteristic Kirsten screw. I sanded the inside of the bowl with 220 grit sandpaper and used an ice pick to remove the screw. From the underside of the bowl I inserted the ice pick into the drilled centre of the screw and tapped it gently and the screw came free from the bowl.

I reamed the bowl with the largest cutting head on the PipNet reamer and took the cake back to bare briar. I used a pen knife to work on the bottom of the bowl and was finally able to see the characteristic Kirsten screw. I sanded the inside of the bowl with 220 grit sandpaper and used an ice pick to remove the screw. From the underside of the bowl I inserted the ice pick into the drilled centre of the screw and tapped it gently and the screw came free from the bowl.

I lightly topped the rim on a topping board to remove the damage and the build up on that surface.

I lightly topped the rim on a topping board to remove the damage and the build up on that surface.

I scrubbed down the exterior of the bowl and rim with acetone on cotton pads to remove the grime and the remaining finish. I was quite pleasantly surprised by the grain that was revealed in the process.

I scrubbed down the exterior of the bowl and rim with acetone on cotton pads to remove the grime and the remaining finish. I was quite pleasantly surprised by the grain that was revealed in the process.

I cleaned the inside and the outside of the screw with a tooth brush and alcohol until it shone.

I cleaned the inside and the outside of the screw with a tooth brush and alcohol until it shone.

I sanded the bowl with a medium and a fine grit sanding block to clean up the scratches and smooth out the finish on the sides and top of the bowl.

I sanded the bowl with a medium and a fine grit sanding block to clean up the scratches and smooth out the finish on the sides and top of the bowl. I wet sanded the bowl with micromesh sanding pads from 1500-2400 grit and dry sanded with 3200-12000 grit pads.

I wet sanded the bowl with micromesh sanding pads from 1500-2400 grit and dry sanded with 3200-12000 grit pads.

I took the barrel out of the bath and put it in a cup of boiling water. I dipped both ends into the boiling water hoping to break one of the frozen ends loose. I was able to remove the stem and the rod assembly after the alcohol bath and the boiling water dip. The stem and the rod were quite brown with the shellac of old tobacco juices. Of course dipping the stem in the boiling water caused the oxidation on the stem to come to the surface.

I took the barrel out of the bath and put it in a cup of boiling water. I dipped both ends into the boiling water hoping to break one of the frozen ends loose. I was able to remove the stem and the rod assembly after the alcohol bath and the boiling water dip. The stem and the rod were quite brown with the shellac of old tobacco juices. Of course dipping the stem in the boiling water caused the oxidation on the stem to come to the surface.

I scrubbed the rod assembly with 0000 steel wool and alcohol to remove the shellac coat that had built up and polish it. There was some corrosion that came to light at the middle of the rod. I would need to work on that once I had cleaned up the stem.

I scrubbed the rod assembly with 0000 steel wool and alcohol to remove the shellac coat that had built up and polish it. There was some corrosion that came to light at the middle of the rod. I would need to work on that once I had cleaned up the stem. I sanded the stem and rod with 220 grit sandpaper and then with a medium and fine grit sanding sponge to remove the scratches.

I sanded the stem and rod with 220 grit sandpaper and then with a medium and fine grit sanding sponge to remove the scratches.

I worked on the stem and rod with micromesh sanding pads – wet sanding with 1500-2400 grit pads and then rubbing down the stem with Obsidian Oil. The micromesh pads removed the last of the corrosion on the rod and polished it. I dry sanded with 3200-4000 grit pads and gave the stem another coat of oil. I finished sanding it with 6000-12000 grit pads and gave it a final coat of Obsidian Oil. I failed to take photos of the final steps in the micromesh process but it is the typical procedure and each successive grit of pads gave more of a polish to the vulcanite.

I worked on the stem and rod with micromesh sanding pads – wet sanding with 1500-2400 grit pads and then rubbing down the stem with Obsidian Oil. The micromesh pads removed the last of the corrosion on the rod and polished it. I dry sanded with 3200-4000 grit pads and gave the stem another coat of oil. I finished sanding it with 6000-12000 grit pads and gave it a final coat of Obsidian Oil. I failed to take photos of the final steps in the micromesh process but it is the typical procedure and each successive grit of pads gave more of a polish to the vulcanite. I cleaned out the stem and tenon with alcohol and pipe cleaners inserted from both ends. I was able to clean out all of the oils and tars and the cleaners came out clean.

I cleaned out the stem and tenon with alcohol and pipe cleaners inserted from both ends. I was able to clean out all of the oils and tars and the cleaners came out clean. Now the bowl and the stem unit were cleaned, polished and ready to go once I was able to remove the valve from the end of the barrel. This was proving a very difficult task. I had put the barrel in the freezer overnight hoping to loosen the valve – no luck. I had boiled it multiple times – no luck. I had given it several alcohol baths – no luck. I let it sit with penetrating oil in the barrel to try to loosen the valve end. I tried to drive it out with a round end file and a small hammer. Nothing worked. I posted that on rebornpipes and got a response from Old Man in the Cave suggesting that I heat it with a heat gun.

Now the bowl and the stem unit were cleaned, polished and ready to go once I was able to remove the valve from the end of the barrel. This was proving a very difficult task. I had put the barrel in the freezer overnight hoping to loosen the valve – no luck. I had boiled it multiple times – no luck. I had given it several alcohol baths – no luck. I let it sit with penetrating oil in the barrel to try to loosen the valve end. I tried to drive it out with a round end file and a small hammer. Nothing worked. I posted that on rebornpipes and got a response from Old Man in the Cave suggesting that I heat it with a heat gun.

I geared up for the process. He had suggested setting the barrel in a wood vise which is a tool I don’t have yet. I chose instead to hold the barrel with some insulated leather gloves over the heat gun. I heated the barrel with gun until it was hot. Then I used a pair of pliers that had cotton pads on the jaws and gave it a light twist and the valve came free. I don’t know if the heat from the gun finally did what I should have done in the first place or if the combination of methods finally came together and it worked. It does not matter as the valve finally came free. I now know why the later models of Kirsten pipes came with a rubber o-ring around the valve and the stem so that it provided something between the two metal pieces and the barrel. Somehow the combination of tobacco juice and saliva left to sit becomes shellac or lacquer that is almost impossible to break free. Thanks to Old Man in the Cave the valve is free and I could finally clean out the barrel and put the pipe back together. The next photos show the condition of the valve once I was able to remove it from the barrel. You can see the tapered angle of the top portion of the valve (on the right below the cap). The lacquer or shellac that bound the valve in the barrel is also very evident. I am guessing that there would have been much more if it had not been sitting in alcohol and been heated so much. But even that little band held the valve tightly in place.

I scrubbed the valve and the inside of the barrel with 0000 steel wool. I ran the steel wool through the barrel to clean out the build up inside and then used a wooden dowel to push alcohol soak cotton pads through the barrel to clean it until it shone. I cleaned out the inside of the valve with alcohol and cotton swabs. I was able to get everything shining again. It took some work to remove some of the tooth marks that were on the valve end from previous owners who had attempted to turn it but I was able to sand them smooth with micromesh sanding pads. They are still present but not as obvious.

I scrubbed the valve and the inside of the barrel with 0000 steel wool. I ran the steel wool through the barrel to clean out the build up inside and then used a wooden dowel to push alcohol soak cotton pads through the barrel to clean it until it shone. I cleaned out the inside of the valve with alcohol and cotton swabs. I was able to get everything shining again. It took some work to remove some of the tooth marks that were on the valve end from previous owners who had attempted to turn it but I was able to sand them smooth with micromesh sanding pads. They are still present but not as obvious.

Once all the parts were clean and polished I greased the valve and the end of the stem and rod unit with Vaseline so that it would slide into the barrel with less resistance. I know that it will not stop the buildup of tars but it will at least slow it down. The next photos show the disassembled pipe and then the pipe put back together. The valve turned easily and I aligned the hole in the valve with the hole in the top of the barrel where the bowl screwed in place. The airflow was clear and unrestricted.

I hand buffed the barrel with Meguiar’s Scratch X2.0 to remove the scratches and give it a shine. I rubbed on some Conservators Wax and then hand buffed the barrel with a shoe brush. I buffed the briar bowl with Blue Diamond on the wheel and then gave it multiple coats of carnauba wax and buffed it with a clean flannel buff. Once I had finished I screwed the bowl in place and buffed it a microfibre cloth. The finished pipe is shown in the photos below.

I hand buffed the barrel with Meguiar’s Scratch X2.0 to remove the scratches and give it a shine. I rubbed on some Conservators Wax and then hand buffed the barrel with a shoe brush. I buffed the briar bowl with Blue Diamond on the wheel and then gave it multiple coats of carnauba wax and buffed it with a clean flannel buff. Once I had finished I screwed the bowl in place and buffed it a microfibre cloth. The finished pipe is shown in the photos below.

I took the pipe apart so that I could take the next two pictures to show the cleaned and polished parts. Everything is once again in working order. It was clear looking at all of the parts that I was dealing with a Generation 1 Kirsten. These were made between the years 1936-1958. The wooden bowl on this generation connects directly to the metal barrel and there is no metal cup spacer. It is a pretty flush fit that goes flat against the barrel. On the underside of the metal barrel it is stamped with one or more of the following “Pat. Appl. For” (1936-38) and “Pats. & Pats. Pending” (1938-1958) over “Made in USA” – S” (or applicable size – S, M, L). There are no O-rings on the bit or metal shank insert.

I took the pipe apart so that I could take the next two pictures to show the cleaned and polished parts. Everything is once again in working order. It was clear looking at all of the parts that I was dealing with a Generation 1 Kirsten. These were made between the years 1936-1958. The wooden bowl on this generation connects directly to the metal barrel and there is no metal cup spacer. It is a pretty flush fit that goes flat against the barrel. On the underside of the metal barrel it is stamped with one or more of the following “Pat. Appl. For” (1936-38) and “Pats. & Pats. Pending” (1938-1958) over “Made in USA” – S” (or applicable size – S, M, L). There are no O-rings on the bit or metal shank insert.

NEPAL PROJECT PIPE SALE 7 –Restoring a Kirsten K – Companion Generation 2

Blog by Steve Laug

This is the seventh pipe from the box of pipes that I was gifted by a good friend of mine with the instructed purpose of cleaning them up and selling them with all of the proceeds going to the aid of earthquake victims in Nepal. Once again all funds raised will all go to the SA Foundation, and organization that has worked in Nepal for over 15 years helping provide recovery, housing and job training for women who are victims of sexual exploitation and trafficking. The ongoing earthquakes (over 300) that continue to shake Nepal have left much in ruins. The SA Foundation Project there was able to find new housing for the women and help with staff as well. Every dollar raised from the sale of these pipes will go to the work in Nepal.

It is a Kirsten metal pipe with a briar Dublin bowl. It is stamped on the left side of the shank, Kirsten in a cursive script. On the underside it is stamped Made in U.S.A. – K. These pipes were made for a long period of time in the Seattle, Washington area of the US. They came in four generations or iterations – Generation 1, 1.5, 2 and 3. The stamping on this one, the absence of a metal cap to hold the bowl, and the presence of the rubber O rings on the metal valve and on the stem insert, point to it being a Generation 1.5 pipe or a transitional one.

Documentation that I quote on an earlier blog from Dave Whitney shows the following information on the Generation 1.5 – transitional period – mid to late 50’s. This was an experimental stage. Kirsten realized that the bit and insert were prone to seizure as the condensate dried. This model always has O-rings on the metal insert, and later models can have O-rings on both. Same markings, as I remember it. There is no metal cup spacer under the bowl. This generation has O rings either on the valve or mouthpiece but no O rings on the other end. This transitional period is stamped “Pat. Pending” and “Pats. & Pats. Pending” some with “Made in U.S.A. It seems like the company was using surplus parts to combine into this series of pipes. This particular pipe is stamped K after the U.S.A. thus making it a Companion.

When I brought this one to the work table the stem was frozen in the shank and the valve on the end was also frozen. The bowl could not be turned off by hand as my other Kirsten’s can. The bowl had a layer of cake and the screw in the bottom of the bowl was also caked and dirty. The rim was dirty and the metal was barrel was dull and soiled. The stem was not only stuck but it also had tooth marks on the top and underside of the stem near the button. There was also some discoloration and sticky buildup on the stem.

I cleaned out the slot on the screw in the bottom of the bowl and was able to remove it with a flat blade screwdriver. The valve at the end of the barrel also came out when I used a pair of pliers that I had taped the end on so that it would not damage the aluminum of the valve. It was very tight and the tobacco oils acted like dried varnish on the rubber gasket and the aluminum almost welding it to the barrel. By carefully working it back and forth I was finally able to remove it.

I cleaned out the slot on the screw in the bottom of the bowl and was able to remove it with a flat blade screwdriver. The valve at the end of the barrel also came out when I used a pair of pliers that I had taped the end on so that it would not damage the aluminum of the valve. It was very tight and the tobacco oils acted like dried varnish on the rubber gasket and the aluminum almost welding it to the barrel. By carefully working it back and forth I was finally able to remove it. The stem would not budge so I dropped the barrel stem down in my alcohol bath and let it soak overnight. I dropped the bowl into the bath at the same time to soften the cake in it and also make the cleanup of the rim and bowl easier.

The stem would not budge so I dropped the barrel stem down in my alcohol bath and let it soak overnight. I dropped the bowl into the bath at the same time to soften the cake in it and also make the cleanup of the rim and bowl easier. I filled a small cap with alcohol and put the valve and the screw into the small bath overnight as well. I figured a good soak would make the clean up process much simpler.

I filled a small cap with alcohol and put the valve and the screw into the small bath overnight as well. I figured a good soak would make the clean up process much simpler. In the morning I was able to remove the stem and rod apparatus from the barrel with ease. It was caked with the same kind of varnish from the tars and oils of the tobacco.

In the morning I was able to remove the stem and rod apparatus from the barrel with ease. It was caked with the same kind of varnish from the tars and oils of the tobacco. I took a photograph down the barrel to show what the inside looked like once the stem was removed.

I took a photograph down the barrel to show what the inside looked like once the stem was removed. I took the bowl out of the bath as well and laid out the parts of the pipe side by side for the photos before I cleaned them up.

I took the bowl out of the bath as well and laid out the parts of the pipe side by side for the photos before I cleaned them up. Using a piece of 0000 steel wool I scrubbed the rod and the bowl down to clean up the grime and buildup. I also scrubbed the screw and the valve as well with the steel wool. It did not take much effort to remove that from the metal or the briar. The photo below shows the cleaned up parts.

Using a piece of 0000 steel wool I scrubbed the rod and the bowl down to clean up the grime and buildup. I also scrubbed the screw and the valve as well with the steel wool. It did not take much effort to remove that from the metal or the briar. The photo below shows the cleaned up parts. I scrubbed out the barrel with cotton swabs and alcohol as far as I could reach. I pushed it through the threaded connector for the bowl as well to remove all of the oils and tar.

I scrubbed out the barrel with cotton swabs and alcohol as far as I could reach. I pushed it through the threaded connector for the bowl as well to remove all of the oils and tar. I took the next photo of the barrel to show the inside and how much cleaner it was. I still needed to clean it more so I twisted some tissue into a cord and turned it into the barrel until it came out the other end. I move it back and forth to scrub out the inside of the barrel. Once it was out the inside of the barrel shone.

I took the next photo of the barrel to show the inside and how much cleaner it was. I still needed to clean it more so I twisted some tissue into a cord and turned it into the barrel until it came out the other end. I move it back and forth to scrub out the inside of the barrel. Once it was out the inside of the barrel shone.

I reamed the bowl using a sharp pen knife paying particular attention to the seat at the bottom of the bowl which held the screw flat against the bowl bottom. I cut the cake back to a very thin coat along the walls. I then used some Vaseline on the threads of the screw and put it through the bottom of the bowl and used the screw driver to turn it into the barrel. I still needed to polish the grooves on the barrel and the valve but the pipe was beginning to look very good.

I reamed the bowl using a sharp pen knife paying particular attention to the seat at the bottom of the bowl which held the screw flat against the bowl bottom. I cut the cake back to a very thin coat along the walls. I then used some Vaseline on the threads of the screw and put it through the bottom of the bowl and used the screw driver to turn it into the barrel. I still needed to polish the grooves on the barrel and the valve but the pipe was beginning to look very good.

I sanded the tooth marks on the stem with 220 grit sandpaper to remove as much of them as I could without thinning the surface of the stem or leaving behind a groove. I was able to remove both marks on the top and bottom of the stem.

I sanded the tooth marks on the stem with 220 grit sandpaper to remove as much of them as I could without thinning the surface of the stem or leaving behind a groove. I was able to remove both marks on the top and bottom of the stem.

I used micromesh sanding pads to polish the stem and bring back the shine. I wet sanded with 1500-2400 grit pads and then rubbed the stem down with Obsidian Oil and then dry sanded with 3200-4000 grit pads and gave it another coat of oil. Finally I sanded with the 6000-12,000 grit pads and then gave it a final coat of oil and let it dry.

I used micromesh sanding pads to polish the stem and bring back the shine. I wet sanded with 1500-2400 grit pads and then rubbed the stem down with Obsidian Oil and then dry sanded with 3200-4000 grit pads and gave it another coat of oil. Finally I sanded with the 6000-12,000 grit pads and then gave it a final coat of oil and let it dry.

I buffed the stem with Blue Diamond Plastic Polish on the wheel and brought out a deep shine. I then gave the stem multiple coats of carnauba wax and buffed it with a clean, soft flannel buffing pad to raise the shine.

I buffed the stem with Blue Diamond Plastic Polish on the wheel and brought out a deep shine. I then gave the stem multiple coats of carnauba wax and buffed it with a clean, soft flannel buffing pad to raise the shine.

I buffed the barrel lightly with the Blue Diamond and also buffed the bowl. I gave the bowl and barrel several coats of carnauba wax and then lightly buffed it with a clean flannel buffing pad to raise the shine. The finished pipe is shown in the photos below. It is ready for someone who has been looking for one of these to pick it up and add it to their rack and help out the women of Nepal at the same time.

I buffed the barrel lightly with the Blue Diamond and also buffed the bowl. I gave the bowl and barrel several coats of carnauba wax and then lightly buffed it with a clean flannel buffing pad to raise the shine. The finished pipe is shown in the photos below. It is ready for someone who has been looking for one of these to pick it up and add it to their rack and help out the women of Nepal at the same time.

This older Kirsten Companion K is a great looking pipe and the Dublin bowl gives it a distinctive look. As I said above, it should make someone a great addition. If you are interested in this pipe email me with an offer at slaug@uniserve.com and we can discuss it. The entirety of the sale price will go to the Nepal project. I will pay the postage so that does not get taken off the proceeds. If you are interested in reading about the SA Foundation you can look at their website at http://www.safoundation.com.

This older Kirsten Companion K is a great looking pipe and the Dublin bowl gives it a distinctive look. As I said above, it should make someone a great addition. If you are interested in this pipe email me with an offer at slaug@uniserve.com and we can discuss it. The entirety of the sale price will go to the Nepal project. I will pay the postage so that does not get taken off the proceeds. If you are interested in reading about the SA Foundation you can look at their website at http://www.safoundation.com.

Thanks for looking.

Converting an Old Briar Bowl to fit a Kirsten

Blog by Steve Laug

After I finished fitting the old Maplewood bowl for my son-in-law’s Kirsten I took another bowl from my pipe parts box. This was another old bowl with the airway drilled on the bottom of the bowl and having a nipple fitting. This bowl came from part of an old hookah type set up. I had picked it up in the same bag of parts as the maple bowl. It had a rubber fitting that the bowl sat in and a glass pipette that extended from the bottom of the fitting. I removed the bowl from the rubber and then stripped it with acetone on a cotton pad and wiped it down until the finish was gone. I sanded the surface of the bowl with 220 grit sandpaper to remove the remnants of the finish. There were also fills in the bowl on two sides. Some of them had shrunken and needed to be refilled. I sanded the surface to clean up around the fills. I filled them with super glue and briar dust and sanded them flush against the surface of the bowl.

There were also fills in the bowl on two sides. Some of them had shrunken and needed to be refilled. I sanded the surface to clean up around the fills. I filled them with super glue and briar dust and sanded them flush against the surface of the bowl.

The underside of the bowl also had several fills. The nipple actually was not part of the briar bowl but was made out of maple. It was inserted in the bottom of the bowl. I wiped it clean to show the connections. I also topped the bowl on a topping board with 220 grit sandpaper to smooth out the surface.

The underside of the bowl also had several fills. The nipple actually was not part of the briar bowl but was made out of maple. It was inserted in the bottom of the bowl. I wiped it clean to show the connections. I also topped the bowl on a topping board with 220 grit sandpaper to smooth out the surface.

I used a hacksaw to cut the nipple off the bottom of the bowl. Once I had the wood portion of the nipple cut all the way through it came off the bowl. In the middle was a brass tube that ran the length of the nipple and went into the bottom of the bowl where it was flared against the inside bottom. I used a small hammer to drive the tube into the bowl.

I used a hacksaw to cut the nipple off the bottom of the bowl. Once I had the wood portion of the nipple cut all the way through it came off the bowl. In the middle was a brass tube that ran the length of the nipple and went into the bottom of the bowl where it was flared against the inside bottom. I used a small hammer to drive the tube into the bowl.

When I had removed the tube I sanded the bottom of the bowl to smooth out the surface. Once it was clean I could see that the maple was inset into the bottom of the bowl. It is distinguishable in that it is white in the photos below. On one side of the white maple insert were two flaws in the briar that had originally been filled. One of the fills fell out of the bowl bottom when I drove out the metal tube.

When I had removed the tube I sanded the bottom of the bowl to smooth out the surface. Once it was clean I could see that the maple was inset into the bottom of the bowl. It is distinguishable in that it is white in the photos below. On one side of the white maple insert were two flaws in the briar that had originally been filled. One of the fills fell out of the bowl bottom when I drove out the metal tube. I drilled the airway in the bottom of the bowl larger with a drill bit the same size as the metal bottom cap that is part of the Kirsten bowl system. The cap would sit in the hole and a drilled screw would be inserted into the cap from inside the bowl. When I drilled out the hole the maple insert came out of the bottom. It left an inset area on the bottom that would be removed when I sanded the bottom of the bowl for the cap to sit flush against the bottom.

I drilled the airway in the bottom of the bowl larger with a drill bit the same size as the metal bottom cap that is part of the Kirsten bowl system. The cap would sit in the hole and a drilled screw would be inserted into the cap from inside the bowl. When I drilled out the hole the maple insert came out of the bottom. It left an inset area on the bottom that would be removed when I sanded the bottom of the bowl for the cap to sit flush against the bottom. I used super glue and briar dust to repair the two flaws in the bottom of the bowl. I dripped the glue into the holes and then pushed super glue into the flaws with a dental pick.

I used super glue and briar dust to repair the two flaws in the bottom of the bowl. I dripped the glue into the holes and then pushed super glue into the flaws with a dental pick. I sanded the bottom of the bowl with a Dremel and sanding drum to shape the bottom edges of the bowl to fit on the Kirsten shank. I sanded the bottom edges of the bowl at a sharper angle to give it a more defined shape.

I sanded the bottom of the bowl with a Dremel and sanding drum to shape the bottom edges of the bowl to fit on the Kirsten shank. I sanded the bottom edges of the bowl at a sharper angle to give it a more defined shape.

I used the Dremel and sanding drum to deepen the bottom of the bowl and give the internal screw a flat surface to seat against. I also used a PipNet reamer with the largest cutting head to flatten out the bottom of the bowl and smooth out the surface. Once it was smooth I inserted the screw into the bowl bottom and threaded it onto the bottom cap. Once I had the cap inserted and tightened with a Philips screwdriver I screwed it onto the Kirsten shank. The next four photos show the newly shaped cauldron bowl on the Kirsten.

I used the Dremel and sanding drum to deepen the bottom of the bowl and give the internal screw a flat surface to seat against. I also used a PipNet reamer with the largest cutting head to flatten out the bottom of the bowl and smooth out the surface. Once it was smooth I inserted the screw into the bowl bottom and threaded it onto the bottom cap. Once I had the cap inserted and tightened with a Philips screwdriver I screwed it onto the Kirsten shank. The next four photos show the newly shaped cauldron bowl on the Kirsten.

I took the cap and screw off the bowl and wiped it down a final time before staining it with a dark brown aniline stain. I applied the stain and then flamed it to set it in the briar. I restained and reflamed it until the coverage was even.

I took the cap and screw off the bowl and wiped it down a final time before staining it with a dark brown aniline stain. I applied the stain and then flamed it to set it in the briar. I restained and reflamed it until the coverage was even.

I buffed the bowl with red Tripoli and White Diamond to polish the stain and give it a shine. In doing so the fills were highlighted. I used a permanent marker to cover the fills and then gave the bowl multiple coats of carnauba wax and buffed it with a soft flannel buff. I put the cap and screw in place and tightened it down. The photos below show the finished bowl.

I buffed the bowl with red Tripoli and White Diamond to polish the stain and give it a shine. In doing so the fills were highlighted. I used a permanent marker to cover the fills and then gave the bowl multiple coats of carnauba wax and buffed it with a soft flannel buff. I put the cap and screw in place and tightened it down. The photos below show the finished bowl.

I buffed the bowl with several new coats of carnauba wax and polished it to a shine with a soft flannel buffing pad. The finished cauldron bowl is shown in place on the pipe below. It looks really good on the Kirsten stem. It provides a second bowl for one of my other Kirsten pipes. I like the overall look of the piece and it is great to have a repurposed bowl to use. I look forward to loading it up and giving it an inaugural smoke.

I buffed the bowl with several new coats of carnauba wax and polished it to a shine with a soft flannel buffing pad. The finished cauldron bowl is shown in place on the pipe below. It looks really good on the Kirsten stem. It provides a second bowl for one of my other Kirsten pipes. I like the overall look of the piece and it is great to have a repurposed bowl to use. I look forward to loading it up and giving it an inaugural smoke.

Fitting a Maplewood Bowl to fit a Kirsten Pipe Shank

Blog by Steve Laug

My son-in-law brought his Kirsten with him on the pipe hunt we went on recently and mentioned that the bowl was too small to his liking. We were talking about hunting for a bowl that had a airway drilled in the bottom of the bowl that could be modified to accept the fitting – screw and cap – on a Kirsten bowl. These fittings hold the bowl on the shank. I remembered that I had a Maplewood bowl in my box of pipe parts that could work really well. It had a nipple on the bottom of the bowl. The nipple ended at a rounded cap and then steps up to the bowl. The original bowl can be seen in the photo below. The bowl was clean and unsmoked. There was a varnish finish on the bowl and the wood was quite rough. Around the hip at the base of the bowl there was a rough band around one side of the bowl. The bowl had some really interesting grain on it. Around the top third of the bowl the grain went around the bowl horizontally. Below that there was some vertical grain. The combination was attractive. This bowl would work well once I modified it to fit the pipe. I sawed the nipple off the bottom of the bowl with a hacksaw. I sawed it flat against the bottom of the bowl to make that surface flush.

I sawed the nipple off the bottom of the bowl with a hacksaw. I sawed it flat against the bottom of the bowl to make that surface flush. With the nipple removed it was clear that the airway was slightly off centre and would need to be adjusted once I drilled it to open it up to hold the bottom cap from the Kirsten.

With the nipple removed it was clear that the airway was slightly off centre and would need to be adjusted once I drilled it to open it up to hold the bottom cap from the Kirsten. I measure the diameter and the length of the insert to figure out how much of the bottom of the bowl I would need to remove. I drilled it out with a drill bit the same size as the insert on the Kirsten cap. I used a knife to open the air hole and move it more toward the centre of the bottom of the bowl.

I measure the diameter and the length of the insert to figure out how much of the bottom of the bowl I would need to remove. I drilled it out with a drill bit the same size as the insert on the Kirsten cap. I used a knife to open the air hole and move it more toward the centre of the bottom of the bowl. I used the Dremel with a sanding drum to shape the bottom of the bowl. I had to remove about ¼ of an inch or more from the bottom of the bowl. I sanded it bring it down and begin to round the edges. The next three photos show the progress of shaping the bowl bottom. The third photo shows the bowl after I also sanded it with 180 and 220 grit sandpaper.

I used the Dremel with a sanding drum to shape the bottom of the bowl. I had to remove about ¼ of an inch or more from the bottom of the bowl. I sanded it bring it down and begin to round the edges. The next three photos show the progress of shaping the bowl bottom. The third photo shows the bowl after I also sanded it with 180 and 220 grit sandpaper.

I sanded it with a medium grit sanding sponge to smooth out the scratches. I fitted the bottom cap to the bowl to see what more I would need to remove for a proper fit between the bowl and the shank. I fit the screw into the bottom cap and used a Philips screwdriver to tighten it in place.

I sanded it with a medium grit sanding sponge to smooth out the scratches. I fitted the bottom cap to the bowl to see what more I would need to remove for a proper fit between the bowl and the shank. I fit the screw into the bottom cap and used a Philips screwdriver to tighten it in place.

I sanded the bowl more to remove the finish and fine tune the shaping the bottom of the bowl. I wanted the finished bowl to look like a brandy glass shape.

I sanded the bowl more to remove the finish and fine tune the shaping the bottom of the bowl. I wanted the finished bowl to look like a brandy glass shape.

When I had fine tuned the bowl shape and the bottom of the bowl I fit it on a Kirsten shank from one of my pipes. The fit was pretty accurate and the look of the shape worked well with the pipe. I would need to sand the bowl some more, remove the remaining varnish and then stain the bowl once finished. I topped the bowl on a topping board with 220 grit sandpaper to smooth out the rim. Though the pipe was unsmoked the rim was roughly finished.

When I had fine tuned the bowl shape and the bottom of the bowl I fit it on a Kirsten shank from one of my pipes. The fit was pretty accurate and the look of the shape worked well with the pipe. I would need to sand the bowl some more, remove the remaining varnish and then stain the bowl once finished. I topped the bowl on a topping board with 220 grit sandpaper to smooth out the rim. Though the pipe was unsmoked the rim was roughly finished.

I took the bowl apart and prepared it for staining. I wiped it down with acetone to remove the remaining varnish and dust from the bowl. I used a dark brown aniline stain to colour the bowl. I stained it and flamed it with a lighter. I reapplied and reflamed the bowl several more times until the coverage was even.

I took the bowl apart and prepared it for staining. I wiped it down with acetone to remove the remaining varnish and dust from the bowl. I used a dark brown aniline stain to colour the bowl. I stained it and flamed it with a lighter. I reapplied and reflamed the bowl several more times until the coverage was even.

I wanted the finish to be light brown in colour with dark grain patterns on the bowl. I wiped it down with alcohol on cotton pads to thin down the finish. I continued to wipe it until the underlying maple showed through and the grain patterns were darkened.

I wanted the finish to be light brown in colour with dark grain patterns on the bowl. I wiped it down with alcohol on cotton pads to thin down the finish. I continued to wipe it until the underlying maple showed through and the grain patterns were darkened. I buffed the bowl with red Tripoli and also White Diamond. Once it was finished I sanded it with 1500-3200 grit micromesh sanding pads to smooth it out. I rubbed it down with a light coat of olive oil and rubbed it into the finish. The bowl was complete at this point – I fit it back on the shank and took the next set of photos to show the look I was aiming for.

I buffed the bowl with red Tripoli and also White Diamond. Once it was finished I sanded it with 1500-3200 grit micromesh sanding pads to smooth it out. I rubbed it down with a light coat of olive oil and rubbed it into the finish. The bowl was complete at this point – I fit it back on the shank and took the next set of photos to show the look I was aiming for.

I took the bowl off the shank and buffed it with White Diamond once more. I gave it multiple coats of carnauba wax and buffed it with a soft flannel buff. The dark brown aniline stain had brought out the grain and contrasted nicely with the rest of the bowl. The horizontal and vertical graining makes this a nice looking pipe bowl.

I took the bowl off the shank and buffed it with White Diamond once more. I gave it multiple coats of carnauba wax and buffed it with a soft flannel buff. The dark brown aniline stain had brought out the grain and contrasted nicely with the rest of the bowl. The horizontal and vertical graining makes this a nice looking pipe bowl.

I put the bowl back on the Kirsten shank and took the next set of photos to show the finished bowl and shank. It certainly fit the shank well and the larger bowl should meet my son-in-laws request for a longer smoking bowl for his Kirsten. He is away with my daughter for the weekend but when he returns home I look forward to seeing what he thinks of his new bowl.

I put the bowl back on the Kirsten shank and took the next set of photos to show the finished bowl and shank. It certainly fit the shank well and the larger bowl should meet my son-in-laws request for a longer smoking bowl for his Kirsten. He is away with my daughter for the weekend but when he returns home I look forward to seeing what he thinks of his new bowl.

Addendum: I was working my way through Ebay UK when I found a pipe that had the same bowl as the one used in this article. It is a tourist pipe from the Smokey Mountains National Park. It looks to be the same pipe bowl and looks identical to the one I used.

Restoring a Frozen Kirsten Companion K Straight Pipe

Blog by Steve Laug

The last pipe I picked up on my recent Alberta trip was a Kirsten style straight pipe. The metal shank is stamped on the left side Companion and on the underside it is stamped Made in U.S.A and then K. On the top of the shank the previous owner scratched in his initials FWE. The bowl was stuck on the shank. The finish on the bowl was worn and dirty. The rim of the bowl had a thick tarry buildup and had some deep dents in the surface. There was a thick cake build up on the inside of the bowl that was shaped like a cone – the bottom was very narrow and the top was wide open. Normally the bowl on Kirsten pipes are more U-shaped with the walls similarly open to the bottom of the bowl where the drilled screw goes through. The stem had a tooth mark on the top and the bottom side near the button. The stem was frozen in the metal shank and I could not twist it at all. The airflow adjustment end cap that normally twists to either open or dampen the airflow was also frozen in place. The metal barrel and end cap had scratches and marks on it. The end cap ridges were worn and looked like someone had used a pair of pliers on it to try to break it free.

I was able to twist the bowl off the barrel by carefully turning it back and forth slightly to break it free. The tars in the barrel threads and on the drilled out screw in the bowl were really gummed up and dirty.

I was able to twist the bowl off the barrel by carefully turning it back and forth slightly to break it free. The tars in the barrel threads and on the drilled out screw in the bowl were really gummed up and dirty. I put the barrel in the freezer and left it there during dinner. After dinner I took it out and was able to twist the stem from the barrel. Once I removed the stem and the metal tube plunger it was extremely tarred and sticky. The second photo below shows the black tars of the interior of the barrel and plunger.

I put the barrel in the freezer and left it there during dinner. After dinner I took it out and was able to twist the stem from the barrel. Once I removed the stem and the metal tube plunger it was extremely tarred and sticky. The second photo below shows the black tars of the interior of the barrel and plunger.

The end cap was still frozen in the barrel. I filled the barrel with alcohol and set it in an ice-cube try to let it soak. I knew that the tars on the plunger were also what held the end cap in place binding the metal of the barrel and the cap to each other. Typically the end cap had a rubber grommet on it that held it in place with a friction fit. In this case it appeared that the rubber grommet was compressed against the metal on the inside of the barrel and bound it in place.

The end cap was still frozen in the barrel. I filled the barrel with alcohol and set it in an ice-cube try to let it soak. I knew that the tars on the plunger were also what held the end cap in place binding the metal of the barrel and the cap to each other. Typically the end cap had a rubber grommet on it that held it in place with a friction fit. In this case it appeared that the rubber grommet was compressed against the metal on the inside of the barrel and bound it in place. I cleaned the plunger and sanded the stem with 220 grit sandpaper to remove the hard tarry build up on it. I wiped it down with alcohol and then sanded it until the plunger was shiny and clean. I cleaned out the inside of the stem and the plunger with both bristle and regular pipe cleaners.

I cleaned the plunger and sanded the stem with 220 grit sandpaper to remove the hard tarry build up on it. I wiped it down with alcohol and then sanded it until the plunger was shiny and clean. I cleaned out the inside of the stem and the plunger with both bristle and regular pipe cleaners.

I reamed the bowl with a PipNet reamer and used all sizes of the cutting heads to ream back the carbon build up in the bowl.

I reamed the bowl with a PipNet reamer and used all sizes of the cutting heads to ream back the carbon build up in the bowl.

The bowl was badly dinged and hammered leaving some deep denting. I topped the rim with a topping board to clean up the damaged top edge.

The bowl was badly dinged and hammered leaving some deep denting. I topped the rim with a topping board to clean up the damaged top edge.

I wiped down the bowl with alcohol on cotton pads and then used a flat blade screwdriver to remove the screw from the bottom of the bowl and remove bottom cap on the bowl. I wiped down the inside of the cap and cleaned the screw with a brass bristle tire brush. I wiped it down with alcohol and then sanded the outside of the cap and screw with 1500-2400 grit micromesh sanding pads to polish them.

I wiped down the bowl with alcohol on cotton pads and then used a flat blade screwdriver to remove the screw from the bottom of the bowl and remove bottom cap on the bowl. I wiped down the inside of the cap and cleaned the screw with a brass bristle tire brush. I wiped it down with alcohol and then sanded the outside of the cap and screw with 1500-2400 grit micromesh sanding pads to polish them.

The rim had two rather large fills that needed to be hidden with stain. I used the stain pens to restain the rim and the bowl. I started with the lightest colour pen and finished with the darkest colour.

The rim had two rather large fills that needed to be hidden with stain. I used the stain pens to restain the rim and the bowl. I started with the lightest colour pen and finished with the darkest colour. I buffed the bowl with White Diamond and then gave it several coats of carnauba wax. I put the metal cap back in place and turned the screw into the bottom of the bowl.

I buffed the bowl with White Diamond and then gave it several coats of carnauba wax. I put the metal cap back in place and turned the screw into the bottom of the bowl.

The end cap still did not come off after I had soaked it with alcohol. I used a Robertson head screw driver with a long shank and inserted it in the barrel. I hammered the end with a hammer and tried to drive it out of the barrel. It cam half way out but I could not budge it further. I boiled a cup of water and let the barrel and end cap sit in it to see if I could loosen the tars. I repeated this three times with the cooling of the water. I then inserted the screw driver and was able to drive out the cap. It was covered with a black tar build up and the inside of the barrel was also thickly coated. I cleaned out the inside of the end cap and the barrel with cotton swabs, pipe cleaners and alcohol. I rubbed down the rubber grommet on the stem and the end cap with Vaseline to soften them again and then inserted them in place in the barrel.

The end cap still did not come off after I had soaked it with alcohol. I used a Robertson head screw driver with a long shank and inserted it in the barrel. I hammered the end with a hammer and tried to drive it out of the barrel. It cam half way out but I could not budge it further. I boiled a cup of water and let the barrel and end cap sit in it to see if I could loosen the tars. I repeated this three times with the cooling of the water. I then inserted the screw driver and was able to drive out the cap. It was covered with a black tar build up and the inside of the barrel was also thickly coated. I cleaned out the inside of the end cap and the barrel with cotton swabs, pipe cleaners and alcohol. I rubbed down the rubber grommet on the stem and the end cap with Vaseline to soften them again and then inserted them in place in the barrel. I sanded the stem with 220 grit sandpaper and then medium and fine grit sanding sponges to remove the tooth marks and the oxidation. I then sanded it with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding 3200-12,000 grit pads. I rubbed the stem down with Obsidian Oil between each set of three pads. I gave the stem a final buff with White Diamond and then gave it several coats of carnauba wax to give it a shine.

I sanded the stem with 220 grit sandpaper and then medium and fine grit sanding sponges to remove the tooth marks and the oxidation. I then sanded it with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding 3200-12,000 grit pads. I rubbed the stem down with Obsidian Oil between each set of three pads. I gave the stem a final buff with White Diamond and then gave it several coats of carnauba wax to give it a shine.

The finished pipe is shown below. I rubbed the stem down with some Conservator’s Wax – a microcrystalline wax and hand buffed it with a shoe brush. I avoid using the buffer on metal as it turns the pads black and does not shine the metal. I put it back together and it is ready for its inaugural smoke. I have two other Kirstens that are great smokers and this one with be added to that number until the day I pass it on to someone along the way.

The finished pipe is shown below. I rubbed the stem down with some Conservator’s Wax – a microcrystalline wax and hand buffed it with a shoe brush. I avoid using the buffer on metal as it turns the pads black and does not shine the metal. I put it back together and it is ready for its inaugural smoke. I have two other Kirstens that are great smokers and this one with be added to that number until the day I pass it on to someone along the way.

Modifying an Old Meerschaum Bowl to Fit a Kirsten Pipe Barrel

In a lot I picked up off EBay was a nice older meerschaum pipe bowl. I think it was originally made either for the WDC base that came in the lot or for a different metal or Bakelite pipe. The threads on the pedestal base were stripped out. As I was looking at it I thought, “Why not see if I can modify it to fit the Kirsten stem and barrel that I have waiting for a bowl”. In the first photo below is the lot of bowls I picked up on EBay. The Meerschaum bowl is in the bottom right corner. The base or nipple is visible in this photo.

The next series of four photos show the bowl before I began work on it I wanted to line it up and see if it would possibly work on the Kirsten. I wanted to see if it was awkward looking or would look feasible. I took photos of the bowl and pipe from different angles to get a feel for the look of the bowl on the pipe.

I decided to try the same process I use in topping a bowl to remove the nipple or base. I set up my sandpaper on a flat board and sanded the nipple to flatten it out. It seemed like it was going to take a long time to remove it so I took it to my Dremel and quickly removed most of it and then came back to the sanding board to finish it up. The next three photos show the process of removing the meer nipple.

Now the bowl needed to be cleaned up and shaped to fit the barrel of the Kirsten. I sanded the bowl with a medium grit sanding sponge to remove the tar and finish of the bowl. Since I was going to reshape the bowl bottom I wanted to remove the old patina and dents as much as possible to make matching the bowl bottom simpler. The next three photos show the sanding of the bowl.

After sanding the bowl surface I used my Dremel to remove the material from the bottom of the bowl and to reshape the bowl to fit the Kirsten. It was a slow and repetitive process as one thing I have learned it you can always remove more material but you cannot put it back. I wanted to shape the bowl with a more rounded bottom on it and give the overall look of a brandy shape. The next three photos show the new shape of the bowl after the Dremel had done its work.

The next step in the process was to open up the hole in the bottom of the bowl in order to receive the bottom plate on the outside and the hollow screw on the inside. Kirsten bowls have a brass or vulcanite bottom plate that is inserted into the bottom of the bowl. This adapter or plate is cupped so I matched the bowl bottom to the cup on the plate. I had to drill slowly with increasingly larger drill bits until I had opened the airway enough for the plate to fit. Then I needed to open the bowl bottom enough to take the screw head. This particular bowl was a bit tapered so I needed to drill it so that the bottom was more flat on the inside so that the screw head would rest evenly on the bottom of the bowl. The outside drilling was ¼ inch when finished. The inside drilling was a ½ inch to let the screw sit evenly. The next three photos give an idea of the drilling and the end product. In the last of the three photos I placed the plate/adapter and the screw in the photo so that you can see where I was going with my drilling.

After drilling the bowl to fit the pieces I put it together to see if it all worked. The first three photos below show the bottom plate and the screw attached. I tried to photograph the bowl from a variety of angles in order to show the fit and feel of the bottom plate. The top down photo shows the placement of the screw. The other two photos show the fitted bottom plate. The last photo of the three shows the view from the bottom of the bowl with the screw centered in the bottom plate and the bowl ready to place on the shank.