Blog by Paresh Deshpande

The next pipe on my work table had all the traits/ signs of it being used by my grand old man; it was huge, it was solid with a nice hand fill, it was heavily caked with severe signs of being knocked around the rim edges, blocked shank and stem airways and the likes!! From the number of pipes that I have inherited from him, it appears that regular pipe cleaning and maintenance was an alien concept to him and whence a pipe fouled up, he just chucked it and got a new one- a very simple concept, to say the least!

The pipe that I decided to work on is a large full bent billiards with a P-lip stem. It is stamped on the left side of the shank as “YELLO-BOLE” over “REG. U.S. PAT. OFF” (Registered U.S. Patent Office) in block capital letters over “Imperial” in cursive script over “CURED WITH REAL HONEY”. To the left of these stampings towards the bowl, KBB is stamped in the clover leaf. The right of the shank bears the stamp of “ALGERIAN BRUYERE” over shape code “68C”. The shank end is adorned with a ferrule that bears the stamping of K B & B in a clover leaf over “NICKLE PLATED”. The stem bears the Yello-Bole logo in bright yellow circle. All the stampings are crisp and clear and is definitely surprising that it has survived over all these years!!  Researching a pipe is always an enriching learning and I look forward to the same on every pipe that I work. Having worked on a few Kaywoodies and also on Yello-Bole, I knew about the connection between the two. However, what intrigued me during the research is that both the brands also have shared the shape codes along the way, albeit at different points in time. Given below are extracts of the most relevant details from pipedia.com, specifically pertaining to this pipe on my work table, wherein I have highlighted information which merits attention:-

Researching a pipe is always an enriching learning and I look forward to the same on every pipe that I work. Having worked on a few Kaywoodies and also on Yello-Bole, I knew about the connection between the two. However, what intrigued me during the research is that both the brands also have shared the shape codes along the way, albeit at different points in time. Given below are extracts of the most relevant details from pipedia.com, specifically pertaining to this pipe on my work table, wherein I have highlighted information which merits attention:-

Tips for Dating Yello-Bole Pipes (https://pipedia.org/wiki/Yello-Bole#Tips_for_Dating_Yello-Bole_Pipes)

- KBB stamped in the clover leaf indicates it was made in 1955 or earlier as they stopped this stamping after being acquired by M. Frank.

- Pipes from 1933-1936 they were stamped “Honey Cured Briar”

- Post 1936 pipes were stamped “Cured with Real Honey”

- Pipe stems stamped with the propeller logo were made in the 1930’s or 1940’s – no propellers were used after the 1940’s.

- Yello-Bole used a 4 digit code stamped on the pipe in the 1930’s.

- Pipes with the Yello-Bole circle stamped on the shank it were made in the 1930’s, this stopped after 1939.

- Pipes stamped BRUYERE rather than BRIAR it was made in the 1930’s.

Thus, from the above tips it is evident that I am dealing with a pipe from the 1930s. However, when I visited the pipedia.com page on Collector’s Guide on Kaywoodie (https://pipedia.org/wiki/Collector%27s_Guide_to_Kaywoodie_Pipes#HINTS_ON_COLLECTING.2C_DATING_AND_PRICING_KAYWOODIES), under the heading “1947 Kaywoodie Shape Numbers and Descriptions”, I found the shape # 68C with the description as Extra Large Billiard, Full Bent which perfectly matched with the size and shape of the pipe on my work table.

Also on the same page, there is a picture of an advertisement flyer for CHESTERFIELD KAYWOODIE from 1947. The similarities between this Kaywoodie (read P-lip stem, large sump, massive size and shape) and the Yello-Bole that I am working on is striking.

Thus, the pipe that I am working on is from 1930s, specifically after 1936 as per the stampings seen on the pipe, however, the shape number and description matches with the Kaywoodie catalogue from 1947. Thus it is an interesting conflict as Yello- Bole was designed as an outlet for lower grade briars not used in Kaywoodie production, but the shape code and Chesterfield similarities were incorporated in Yello-Bole earlier than its introduction in Kaywoodie pipes!! I would be happy if anyone reader can clarify this conflict.

INITIAL VISUAL INSPECTION

The chamber is heavily caked with lava overflow on the rim top surface. The inner edge of the rim is severely damaged. Nicks and dings are also seen along the outer rim edge and chamber appears out of round. Chamber has strong odors of sweet smelling tobaccos. The condition of the inner walls of the chamber can be commented upon once the cake has been reamed down to the bare briar, but going by the solid feel of the external surface, I do not foresee any serious issues/ surprises with the chamber walls.

The stummel surface is covered in dust, dirt and grime of years of use and uncared for storage for the last 45 years when my grandfather quit smoking in the late 1970s. Oils and tars have overflowed over the stummel and have attracted dust giving a dull and lackluster appearance to the stummel. A number of minor dents and scratches are seen over the stummel, notably towards the front, foot and the bottom of the shank. Through all the dirt, some really stunning straight and bird’s eye grains are waiting to be exposed. The mortise is, well mildly put, clogged to hell and back!! That the sump is overflowing and overfilled with accumulated gunk is a fact that could be seen with the naked eyes. Believe you me readers, the pipe smells are too strong.

The stummel surface is covered in dust, dirt and grime of years of use and uncared for storage for the last 45 years when my grandfather quit smoking in the late 1970s. Oils and tars have overflowed over the stummel and have attracted dust giving a dull and lackluster appearance to the stummel. A number of minor dents and scratches are seen over the stummel, notably towards the front, foot and the bottom of the shank. Through all the dirt, some really stunning straight and bird’s eye grains are waiting to be exposed. The mortise is, well mildly put, clogged to hell and back!! That the sump is overflowing and overfilled with accumulated gunk is a fact that could be seen with the naked eyes. Believe you me readers, the pipe smells are too strong.

The large bent vulcanite stem exudes high quality and is heavily oxidized. The tenon is covered in a very thick coat of dried gunk and blobs of accumulated dried tars are seen inside the wide tenon opening. This also indicates the extreme clogging that can be expected in the expanded portion of the stem and in the stem air way. The lower button edge has a deep tooth indentation and tooth chatter in the bite zone. The button edge on the upper surface has worn down and would need to be sharpened. The lower end of the stem at the tenon end which enters the mortise shows severe scratch marks and chipped surface, the result of rubbing against the sharp edges of the ferrule at the shank end.

The large bent vulcanite stem exudes high quality and is heavily oxidized. The tenon is covered in a very thick coat of dried gunk and blobs of accumulated dried tars are seen inside the wide tenon opening. This also indicates the extreme clogging that can be expected in the expanded portion of the stem and in the stem air way. The lower button edge has a deep tooth indentation and tooth chatter in the bite zone. The button edge on the upper surface has worn down and would need to be sharpened. The lower end of the stem at the tenon end which enters the mortise shows severe scratch marks and chipped surface, the result of rubbing against the sharp edges of the ferrule at the shank end.

INITIAL CLEANING BY ABHA…

INITIAL CLEANING BY ABHA…

The initial cleaning on this pipe was done by Abha, my wife (she has cleaned up around 40-50 pipes and these have now reached me for further restoration). She reamed out the complete cake and further smoothed out the chamber walls with a folded piece of 220 grit sand paper. She further cleaned out the internals of the shank with pipe cleaners and alcohol and cotton buds. She followed the internal cleaning of the shank with external cleaning of the stummel using Murphy’s Oil soap and hard bristled tooth brush and dried it with paper napkins and cotton cloth.

Unfortunately, this time around, she could not clean the stem as it was too large to fit in to the container of the stem deoxidizer solution.

ONCE THE PIPE IS ON MY WORK TABLE…

The chamber is massive, that is what I noticed first when I got the cleaned up pipe on my work table. The wall of the chamber shows insignificant beginnings of heat fissure on the left and back of the chamber walls. Though insignificant now, if not addressed at this stage, these heat fissures may further lead to burn outs. I need to address this issue. The rim top surface is uneven and pock marked with dents and dings. The inner edge is severely damaged with dents and dings, some of them quite large. The chamber is significantly out of round, most notably on the left side in 10 o’clock direction. The rim repairs required are extensive. The nicely cleaned stummel looks exciting with beautiful transverse flowing straight grains on the sides of the stummel and shank and bird’s eye on the front of the stummel and extending to the bottom of the shank. Patches of old lacquer coat can still be seen in the fold between the bowl and shank and also along the bottom of the stummel. The dents and scratches to the front and at the foot of the stummel are now clearly visible. I intend to let them be as they are part of the pipe’s past and also since I wish to preserve the patina. Abha has painstakingly cleaned out the mortise and the sump. However, I could still see remnants of the gunk in the sump and the still strong odor is a pointer to the requirement of further sanitizing the internals of the stummel.

The nicely cleaned stummel looks exciting with beautiful transverse flowing straight grains on the sides of the stummel and shank and bird’s eye on the front of the stummel and extending to the bottom of the shank. Patches of old lacquer coat can still be seen in the fold between the bowl and shank and also along the bottom of the stummel. The dents and scratches to the front and at the foot of the stummel are now clearly visible. I intend to let them be as they are part of the pipe’s past and also since I wish to preserve the patina. Abha has painstakingly cleaned out the mortise and the sump. However, I could still see remnants of the gunk in the sump and the still strong odor is a pointer to the requirement of further sanitizing the internals of the stummel.

The ferrule at the end of the shank end came loose as I was inspecting the stummel. This gave me an opportunity to closely inspect the shank end for cracks or any damage. Lucky me, there are no such hidden gremlins here!! I did notice a fill at the base where the ferrule sat on the shank end (circled in yellow) that would need to be refreshed. The edges of the ferrule at the shank end have become very sharp (I did manage a nick during inspection) that had caused the damage observed on the tenon end of the stem. I need to address this issue.

The ferrule at the end of the shank end came loose as I was inspecting the stummel. This gave me an opportunity to closely inspect the shank end for cracks or any damage. Lucky me, there are no such hidden gremlins here!! I did notice a fill at the base where the ferrule sat on the shank end (circled in yellow) that would need to be refreshed. The edges of the ferrule at the shank end have become very sharp (I did manage a nick during inspection) that had caused the damage observed on the tenon end of the stem. I need to address this issue.

The unclean stem that came to me shows heavy scratches to the tenon end which seats in to the mortise and caused due to the sharp edges of the ferrule. I will address this issue by sanding the surface followed by a fill, if required. The upper surface and button edge of the P-lip shows damage and will have to sharpen the button while sanding and filling the surface. Similarly, the lower button edge has a deep tooth indentation and will need a fill to repair. The heavy oxidation will be a bear to get rid off given the size of the stem. The tenon is covered in a thick coat of dried gunk, not to mention the clogged the stem air way.

The unclean stem that came to me shows heavy scratches to the tenon end which seats in to the mortise and caused due to the sharp edges of the ferrule. I will address this issue by sanding the surface followed by a fill, if required. The upper surface and button edge of the P-lip shows damage and will have to sharpen the button while sanding and filling the surface. Similarly, the lower button edge has a deep tooth indentation and will need a fill to repair. The heavy oxidation will be a bear to get rid off given the size of the stem. The tenon is covered in a thick coat of dried gunk, not to mention the clogged the stem air way.

THE PROCESS

THE PROCESS

As is my norm, I started the process with stem cleaning and repairs. I cleaned the accumulated dried gunk from the insides of the tenon by scrapping it out with my dental tools followed by q-tips, pipe cleaners and isopropyl alcohol. I soon realized that no matter how many pipe cleaners and q-tips I used, the insides of the wide tenon will still keep throwing out dirty pipe cleaners. I would need to use a more invasive method. Using a shank brush and dish washing soap, I thoroughly cleaned out the gunk. I rinsed it under running warm water. Once satisfied with the internal cleaning, with my fabricated knife I scrapped off the dried oils and tars from the tenon surface. I wiped the tenon end with cotton swab and alcohol till clean. I also cleaned the stem air way and the slot end with pipe cleaners and alcohol. While I was working on the stem, a colleague had come visiting and was amazed at the patience and care being exhibited, traits which I am usually not associated with. He did crack a joke on this and clicked a couple of pictures which I have included here for posterity.

While I was working on the stem, a colleague had come visiting and was amazed at the patience and care being exhibited, traits which I am usually not associated with. He did crack a joke on this and clicked a couple of pictures which I have included here for posterity. I cleaned the stem surface with isopropyl alcohol on a cotton swab and followed it with a scrub using Murphy’s Oil soap and cotton swab. I also smooth the sharp edges of the ferrule with a folded piece of 150 grit sand paper.

I cleaned the stem surface with isopropyl alcohol on a cotton swab and followed it with a scrub using Murphy’s Oil soap and cotton swab. I also smooth the sharp edges of the ferrule with a folded piece of 150 grit sand paper.

I mix clear superglue and activated charcoal and paint the damaged tenon end surface and also applied it over the both button edges, upper P-lip surface and lower surface of the P-lip. I set the stem aside for the fills to cure.

I mix clear superglue and activated charcoal and paint the damaged tenon end surface and also applied it over the both button edges, upper P-lip surface and lower surface of the P-lip. I set the stem aside for the fills to cure.

I cleaned the stummel surface with acetone on a cotton swab to remove the patches of old lacquer. This cleaning further highlighted the beautiful grains on this pipe. This is sure going to be beautiful pipe in my collection.

I cleaned the stummel surface with acetone on a cotton swab to remove the patches of old lacquer. This cleaning further highlighted the beautiful grains on this pipe. This is sure going to be beautiful pipe in my collection.

Next I decided to address the issue of strong odor in the chamber. To eliminate the ghost smells from the pipe, I decided to treat it with salt and alcohol. I do not use Kosher salt as it is not readily available here and if available, it’s very expensive. I use cotton balls which is an at par substitute as I have realized over a period of time. I pack the sump with cotton and draw out a wick from the cotton and along with a folded regular pipe cleaner; insert it in to the mortise and through the draught hole in the chamber. I pack cotton balls in to the remaining portion of the mortise. Thereafter, I pack the chamber with cotton balls to about quarter of an inch below the rim inner edge. I soak the cotton balls with isopropyl alcohol up to the brim. About half an hour later, the level of alcohol has gone down, having being absorbed by the cotton. I top it up once again and set it aside overnight. By next afternoon, the cotton and alcohol has drawn out all the remaining oils and tars from the chamber, sump and mortise and the cotton and alcohol had fulfilled its intended task. I removed the cotton balls and the dirt can be gauged by the appearance and coloration of the cotton balls. With my fabricated knife and dental tools, I spent the next hour scrapping out the entire loosened gunk. I ran pipe cleaners through the mortise to clean out all the loosened tars and gunk that had lodged when I cleaned the sump and mortise. The chamber now smells clean, fresh and looks it too. I set the stummel to dry out naturally.

Next I decided to address the issue of strong odor in the chamber. To eliminate the ghost smells from the pipe, I decided to treat it with salt and alcohol. I do not use Kosher salt as it is not readily available here and if available, it’s very expensive. I use cotton balls which is an at par substitute as I have realized over a period of time. I pack the sump with cotton and draw out a wick from the cotton and along with a folded regular pipe cleaner; insert it in to the mortise and through the draught hole in the chamber. I pack cotton balls in to the remaining portion of the mortise. Thereafter, I pack the chamber with cotton balls to about quarter of an inch below the rim inner edge. I soak the cotton balls with isopropyl alcohol up to the brim. About half an hour later, the level of alcohol has gone down, having being absorbed by the cotton. I top it up once again and set it aside overnight. By next afternoon, the cotton and alcohol has drawn out all the remaining oils and tars from the chamber, sump and mortise and the cotton and alcohol had fulfilled its intended task. I removed the cotton balls and the dirt can be gauged by the appearance and coloration of the cotton balls. With my fabricated knife and dental tools, I spent the next hour scrapping out the entire loosened gunk. I ran pipe cleaners through the mortise to clean out all the loosened tars and gunk that had lodged when I cleaned the sump and mortise. The chamber now smells clean, fresh and looks it too. I set the stummel to dry out naturally.

By this time the stem fills had cured and with a flat head needle file, I sand these fills to achieve a rough match. I further fine tuned the match by sanding the filled area with a folded piece of 220 grit sand paper pinched between my thumb and forefinger. I followed it up by sanding the entire stem surface using 400, 600, 800 grit sand papers and finally with a piece of 0000 grade steel wool. This serves to remove the deep seated oxidation and also reduces the sanding marks of the more abrasive sand papers. I also sharpened the button edges while sanding. I wiped the stem with a cotton swab and alcohol to remove all the oxidation and sanding dust from the surface. I applied a little Extra Virgin Olive oil over the stem and set it aside to be absorbed by the vulcanite.

By this time the stem fills had cured and with a flat head needle file, I sand these fills to achieve a rough match. I further fine tuned the match by sanding the filled area with a folded piece of 220 grit sand paper pinched between my thumb and forefinger. I followed it up by sanding the entire stem surface using 400, 600, 800 grit sand papers and finally with a piece of 0000 grade steel wool. This serves to remove the deep seated oxidation and also reduces the sanding marks of the more abrasive sand papers. I also sharpened the button edges while sanding. I wiped the stem with a cotton swab and alcohol to remove all the oxidation and sanding dust from the surface. I applied a little Extra Virgin Olive oil over the stem and set it aside to be absorbed by the vulcanite. The next stummel issue to be addressed was that of the rim top surface damage. I topped the rim on a piece of 220 grit sand paper, checking frequently till I was satisfied that the charred surface was addressed to a great extent and the rim top surface is nice, smooth and even. The inner edge is still uneven, though much better than before topping, and shall be addressed next. With a folded piece of a 220 grit sand paper pinched between my thumb and forefinger, I created a slight bevel on the inner edge of the rim top surface. This helped to mask the out of round chamber and address the sever dents that had remained on the inner rim edge. It can never be perfect, it’s a repair after all, but the repairs sure looks great. I know I have scrapped the shank end while topping the rim, I should have been careful, but I noticed it early and will be under the ferrule, so no sweat!!

The next stummel issue to be addressed was that of the rim top surface damage. I topped the rim on a piece of 220 grit sand paper, checking frequently till I was satisfied that the charred surface was addressed to a great extent and the rim top surface is nice, smooth and even. The inner edge is still uneven, though much better than before topping, and shall be addressed next. With a folded piece of a 220 grit sand paper pinched between my thumb and forefinger, I created a slight bevel on the inner edge of the rim top surface. This helped to mask the out of round chamber and address the sever dents that had remained on the inner rim edge. It can never be perfect, it’s a repair after all, but the repairs sure looks great. I know I have scrapped the shank end while topping the rim, I should have been careful, but I noticed it early and will be under the ferrule, so no sweat!!

The one fill which was seen and readied for a fresh fill was patched up with a mix of briar dust and superglue and set aside to cure. Once the fill had hardened, and it was very quick indeed, I matched the fill with the rest of the stummel surface by sanding the fill with a flat head needle file followed by sanding the fill with a folded piece of 220 grit sand paper.

The one fill which was seen and readied for a fresh fill was patched up with a mix of briar dust and superglue and set aside to cure. Once the fill had hardened, and it was very quick indeed, I matched the fill with the rest of the stummel surface by sanding the fill with a flat head needle file followed by sanding the fill with a folded piece of 220 grit sand paper. To preserve the patina and bring a deeper shine, I polished the stummel with micromesh pads, dry sanding with 1500 to 12000 pads. I wiped the surface with a soft cloth at the end of the micromesh cycle. The stummel looks amazing with a deep shine and beautiful grains popping over the stummel surface. The massive size of the stummel helps accentuate these grains further.

To preserve the patina and bring a deeper shine, I polished the stummel with micromesh pads, dry sanding with 1500 to 12000 pads. I wiped the surface with a soft cloth at the end of the micromesh cycle. The stummel looks amazing with a deep shine and beautiful grains popping over the stummel surface. The massive size of the stummel helps accentuate these grains further.

The result of all the topping and subsequent micromesh polishing was that the rim top surface had a lighter hue as compared to the rest of the stummel surface. I matched the rim top surface with the rest of the stummel by staining the surface with a dark brown stain pen. I set it aside for the stain to cure.

The result of all the topping and subsequent micromesh polishing was that the rim top surface had a lighter hue as compared to the rest of the stummel surface. I matched the rim top surface with the rest of the stummel by staining the surface with a dark brown stain pen. I set it aside for the stain to cure. Turning my attention back to the stem, I decided to polish and shine up the stem surface. I wet sand the stem with 1500 to 12000 girt micromesh pads. Next I rub a small quantity of extra fine stem polish that I had got from Mark and set it aside to let the balm work its magic. After about 10 minutes, I hand buffed the stem with a microfiber cloth to a nice shine. I rub a small quantity of olive oil in to the stem surface to hydrate it and set it aside.

Turning my attention back to the stem, I decided to polish and shine up the stem surface. I wet sand the stem with 1500 to 12000 girt micromesh pads. Next I rub a small quantity of extra fine stem polish that I had got from Mark and set it aside to let the balm work its magic. After about 10 minutes, I hand buffed the stem with a microfiber cloth to a nice shine. I rub a small quantity of olive oil in to the stem surface to hydrate it and set it aside.

After the rim top surface stain had cured for about 6 hours, I rub a small quantity of “Before and After Restoration Balm” in to the briar with my finger tips and let it rest for a few minutes. I applied the balm over the rim top surface also. The balm almost immediately works its magic and the briar now has a nice vibrant appearance with the beautiful darkened grain patterns on full display. I further buff it with a horse hair shoe brush. I wiped it with a microfiber cloth. The rim top is now perfectly matched with the rest of the stummel dark coloration. I am very pleased with the blend.

After the rim top surface stain had cured for about 6 hours, I rub a small quantity of “Before and After Restoration Balm” in to the briar with my finger tips and let it rest for a few minutes. I applied the balm over the rim top surface also. The balm almost immediately works its magic and the briar now has a nice vibrant appearance with the beautiful darkened grain patterns on full display. I further buff it with a horse hair shoe brush. I wiped it with a microfiber cloth. The rim top is now perfectly matched with the rest of the stummel dark coloration. I am very pleased with the blend.

I mount a cotton cloth buffing wheel on to my hand held rotary tool and apply a coat of Blue Diamond to the stummel and the stem to polish out the minor scratches.

I mount a cotton cloth buffing wheel on to my hand held rotary tool and apply a coat of Blue Diamond to the stummel and the stem to polish out the minor scratches.  It was at this point in the process of restoration that I realized that I am yet to attach the ferrule at the shank end. I rub a small quantity of ‘Colgate’ toothpowder over the ferrule surface. Those who have not tried out this trick, you must try it out at least once, it works like magic and imparts a nice shine to the nickel plated (it works even better on Sterling Silver) ferrule. I apply superglue over the shank end, align the ferrule stamp with that on the shank and attach the ferrule over it. I press it down firmly for a couple of minutes to let the glue set. After the glue had completely cured, I tried the seating of the stem in to the mortise and realized that the stem surface still brushed against the sharp ferrule edge. With a needle file I sand the edges, frequently feeling for the sharpness with my fingers and checking the seating of the stem in to the mortise. Once the edges and seating were smooth, I applied a little petroleum jelly on the walls of the mortise as this reduces friction and moisturizes the briar and moved on to the home stretch.

It was at this point in the process of restoration that I realized that I am yet to attach the ferrule at the shank end. I rub a small quantity of ‘Colgate’ toothpowder over the ferrule surface. Those who have not tried out this trick, you must try it out at least once, it works like magic and imparts a nice shine to the nickel plated (it works even better on Sterling Silver) ferrule. I apply superglue over the shank end, align the ferrule stamp with that on the shank and attach the ferrule over it. I press it down firmly for a couple of minutes to let the glue set. After the glue had completely cured, I tried the seating of the stem in to the mortise and realized that the stem surface still brushed against the sharp ferrule edge. With a needle file I sand the edges, frequently feeling for the sharpness with my fingers and checking the seating of the stem in to the mortise. Once the edges and seating were smooth, I applied a little petroleum jelly on the walls of the mortise as this reduces friction and moisturizes the briar and moved on to the home stretch. With a cotton buffing wheel that I use for carnauba wax, I apply a coat of carnauba wax and continue to work on it till the complete coat of wax had been polished out. I mount a clean cotton cloth buffing wheel and give the entire pipe a once over buff. I finished the restoration by giving the entire pipe a rigorous hand buffing using a microfiber cloth to raise the shine further. The finished pipe looks beautiful.

With a cotton buffing wheel that I use for carnauba wax, I apply a coat of carnauba wax and continue to work on it till the complete coat of wax had been polished out. I mount a clean cotton cloth buffing wheel and give the entire pipe a once over buff. I finished the restoration by giving the entire pipe a rigorous hand buffing using a microfiber cloth to raise the shine further. The finished pipe looks beautiful.

Having addressed the cosmetic aspect of this pipe, I move on to address the functionality aspect by addressing the ridges and re-entrant formed at the draught hole as well as the minor/ insignificant heat fissures. I insert a petroleum jelly coated pipe cleaner in to the draught hole. I mix a small quantity of the contents from the two tubes of J B Weld in equal proportions and apply it evenly only over the damaged area near the draught hole with my fingers. I had to work deftly and fast as the compound starts to harden within 4 minutes. I set the stummel aside for the JB Weld coat to completely harden.

Having addressed the cosmetic aspect of this pipe, I move on to address the functionality aspect by addressing the ridges and re-entrant formed at the draught hole as well as the minor/ insignificant heat fissures. I insert a petroleum jelly coated pipe cleaner in to the draught hole. I mix a small quantity of the contents from the two tubes of J B Weld in equal proportions and apply it evenly only over the damaged area near the draught hole with my fingers. I had to work deftly and fast as the compound starts to harden within 4 minutes. I set the stummel aside for the JB Weld coat to completely harden. The next day, the compound had completely hardened. With a folded piece of 220 grit sand paper, I sanded the fill to as thin a layer as I thought would be just sufficient to protect the heel and ensure a smooth even surface for the pipe mud coating.

The next day, the compound had completely hardened. With a folded piece of 220 grit sand paper, I sanded the fill to as thin a layer as I thought would be just sufficient to protect the heel and ensure a smooth even surface for the pipe mud coating. Next I mixed activated charcoal and yogurt to a thick consistency and evenly applied it over the chamber walls and set it aside to dry out naturally. Once the coating had dried I buffed the pipe again with a microfiber cloth to a nice deep shine.

Next I mixed activated charcoal and yogurt to a thick consistency and evenly applied it over the chamber walls and set it aside to dry out naturally. Once the coating had dried I buffed the pipe again with a microfiber cloth to a nice deep shine.  P.S. This was a fun project and I absolutely loved and enjoyed working on it. It has some stunning grains and beats me that even though Yello-Bole was designed as an outlet for lower grade briars not used in Kaywoodie production, this beauty is anything but lower grade!! This would be joining my collection and I shall get to admire the beauty whenever I so desire.

P.S. This was a fun project and I absolutely loved and enjoyed working on it. It has some stunning grains and beats me that even though Yello-Bole was designed as an outlet for lower grade briars not used in Kaywoodie production, this beauty is anything but lower grade!! This would be joining my collection and I shall get to admire the beauty whenever I so desire.

Thank you all for sparing your valuable time in reading thus far and I would be happy to hear comments on the conflict that I find between Yello-Bole and Kaywoodie.

Jeff took photos of the bowl, rim top to show the thickness of the cake and the unique rustication on the surface of the rim and edges. There is some light lava on the inner edge but nothing too thick. He took photos of the top and underside of the vulcanite stem showing the oxidation, calcification, tooth marks, chatter and wear on the stem and button.

Jeff took photos of the bowl, rim top to show the thickness of the cake and the unique rustication on the surface of the rim and edges. There is some light lava on the inner edge but nothing too thick. He took photos of the top and underside of the vulcanite stem showing the oxidation, calcification, tooth marks, chatter and wear on the stem and button.

Jeff took a photo of the side and heel of the bowl to show the condition of the briar. You can see the beautiful shape of the bowl and the cut glass like rustication even through the dirt and debris of many years.

Jeff took a photo of the side and heel of the bowl to show the condition of the briar. You can see the beautiful shape of the bowl and the cut glass like rustication even through the dirt and debris of many years.  Jeff took photos of the stamping on the left side of the shank and the Yello-Bole circular yellow logo on the top of the stem.

Jeff took photos of the stamping on the left side of the shank and the Yello-Bole circular yellow logo on the top of the stem.

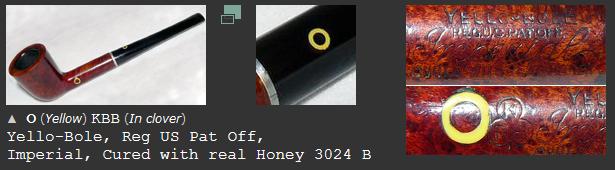

I turned to Pipephil’s site to see what I could find out about the brand and the timeline of the pipe (http://pipephil.eu/logos/en/logo-y.html). I found a photo of a pipe with the same stamping as the one that I am working on though it does not have the inlaid O on the briar shank. It is stamped exactly the way that the one I have – Yello-Bole, Reg US Pat Off, Imperial, Cured with Real Honey. I have included a screen capture below.

I turned to Pipephil’s site to see what I could find out about the brand and the timeline of the pipe (http://pipephil.eu/logos/en/logo-y.html). I found a photo of a pipe with the same stamping as the one that I am working on though it does not have the inlaid O on the briar shank. It is stamped exactly the way that the one I have – Yello-Bole, Reg US Pat Off, Imperial, Cured with Real Honey. I have included a screen capture below. I also have included a quote from the side bar on the site below.

I also have included a quote from the side bar on the site below.

I took some close up photos of the rim top and the stem surface. The top and inner and outer edge of the rim look to be in good condition. The bowl is a bit oval in shape rather than round but appears to have been made that way. The stem was clean of tooth marks and had light chatter on the button surface. There was some residual oxidation on the saddle area of the stem that would need to be dealt with.

I took some close up photos of the rim top and the stem surface. The top and inner and outer edge of the rim look to be in good condition. The bowl is a bit oval in shape rather than round but appears to have been made that way. The stem was clean of tooth marks and had light chatter on the button surface. There was some residual oxidation on the saddle area of the stem that would need to be dealt with.  I took a photo of the stamping on the side of the shank. It is readable and clear. The yellow circle on the top of the stem is inlaid and is in excellent condition.

I took a photo of the stamping on the side of the shank. It is readable and clear. The yellow circle on the top of the stem is inlaid and is in excellent condition. I removed the stem from the shank and took a photo of the parts of the pipe.

I removed the stem from the shank and took a photo of the parts of the pipe.  I started my work on the pipe by regluing the nickel band on the shank end. I dabbed the shank end with white all purpose glue and pressed the ferrule back in place and aligned it to the shank.

I started my work on the pipe by regluing the nickel band on the shank end. I dabbed the shank end with white all purpose glue and pressed the ferrule back in place and aligned it to the shank. I used a worn brass bristle brush to clean up the surface of the briar. I worked over the finish around the bowl and shank to remove any of the debris and the varnish coat on the briar.

I used a worn brass bristle brush to clean up the surface of the briar. I worked over the finish around the bowl and shank to remove any of the debris and the varnish coat on the briar.

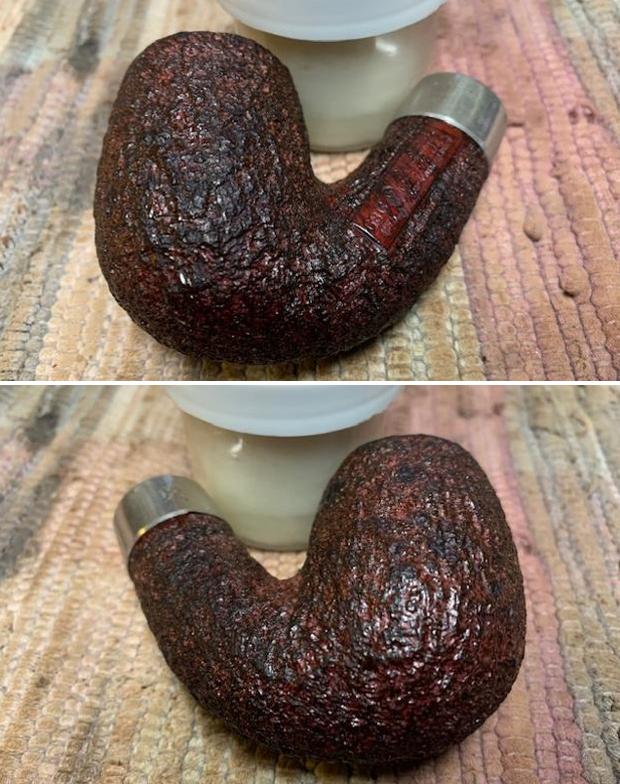

I worked some Before & After Restoration Balm into the surface of the bowl and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the bowl and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I set the bowl aside and turned my attention to the stem. I scrubbed the stem with Soft Scrub, a Scotch Brite scrubbing pad and cotton pads to remove the remaining oxidation on the stem. I coated the stem with the Soft Scrub and scoured it with the Scotch Brite scrubbing pad. I wiped it down with some more Soft Scrub and a cotton pads to remove the loosened oxidation.

I set the bowl aside and turned my attention to the stem. I scrubbed the stem with Soft Scrub, a Scotch Brite scrubbing pad and cotton pads to remove the remaining oxidation on the stem. I coated the stem with the Soft Scrub and scoured it with the Scotch Brite scrubbing pad. I wiped it down with some more Soft Scrub and a cotton pads to remove the loosened oxidation.  I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil.

With the bowl and the stem finished I put the beautiful and unusual KBB Rusticated Yello-Bole Imperial House Pipe back together and lightly buffed it on the wheel using Blue Diamond to give it a shine. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the wheel. I buffed it with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The rustication on this pipe really is a great looking and reminds me of cut glass. The dimensions of the pipe are – Length: 9 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: 7/8 of an inch. The weight of this large pipe is 3.14 ounces /89 grams. This KBB Yello-Bole Imperial House Pipe is another great find our hunts. It is much more beautiful in person than these photos can capture. I will be putting it on the rebornpipes store soon. If you would like to add it to your collection let me know. This is another pipe that has the possibility of transporting the pipe man or woman back to a slower paced time in history where you can enjoy a respite. Thanks for walking through the restoration with me.

With the bowl and the stem finished I put the beautiful and unusual KBB Rusticated Yello-Bole Imperial House Pipe back together and lightly buffed it on the wheel using Blue Diamond to give it a shine. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the wheel. I buffed it with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The rustication on this pipe really is a great looking and reminds me of cut glass. The dimensions of the pipe are – Length: 9 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: 7/8 of an inch. The weight of this large pipe is 3.14 ounces /89 grams. This KBB Yello-Bole Imperial House Pipe is another great find our hunts. It is much more beautiful in person than these photos can capture. I will be putting it on the rebornpipes store soon. If you would like to add it to your collection let me know. This is another pipe that has the possibility of transporting the pipe man or woman back to a slower paced time in history where you can enjoy a respite. Thanks for walking through the restoration with me.