by Steve LaugView post

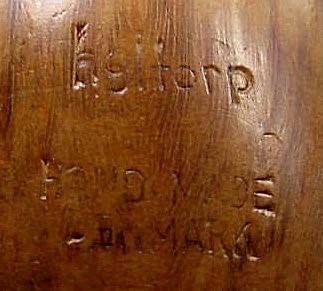

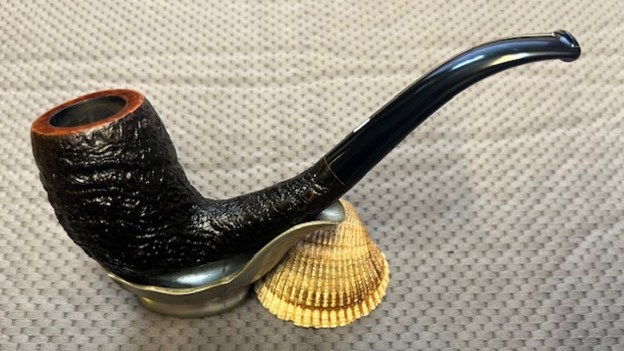

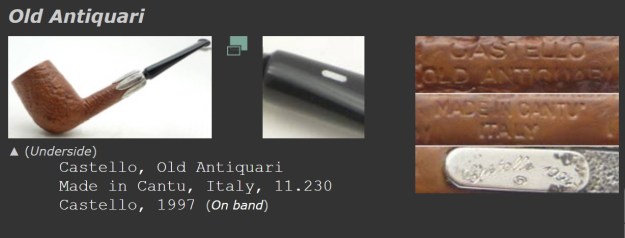

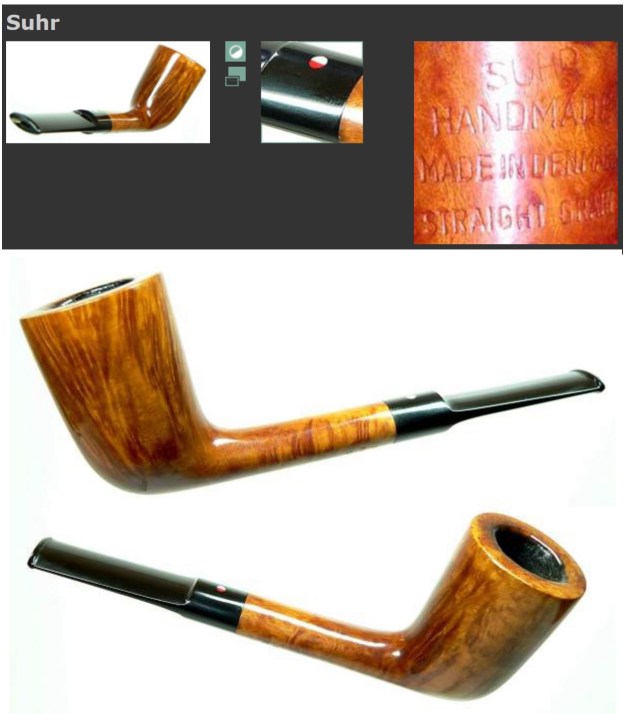

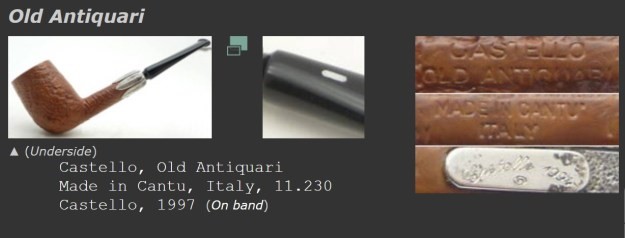

The next pipe on the table is another one that came to us from the seller in Caldwell, Idaho, USA on 07/12/2025. It is a Castello Rusticated Canadian with an acrylic taper stem with the faux diamond on the left side of the stem. It is in dirty but in good condition as can be seen in the photos below. It is stamped on a smooth panel on the underside of the shank and reads Castello [over] Old Antiquari [followed by] KK 32 [followed by] Hand Made [followed by] Made in Cantu [over] Italy [followed by] Carlo arched over Scotti in an oval. The stamping is clear and readable. The pipe has rich Tan and Brown stains on a deep rusticated finish and a dark stain flume around the rim top and down the bowl sides about ¼ inch. The finish was dusty and lightly dirty with grime in the nooks and crannies of the rugged, deep sandblast. The bowl had a moderate cake and there was tobacco debris in the bowl. The rim top had a thick lava coat in the sandblast rim top and edges. The original taper stem is dirty and oxidized. It has the crumpled diamond look to the logo. I took photos of the pipe before I started working on it.

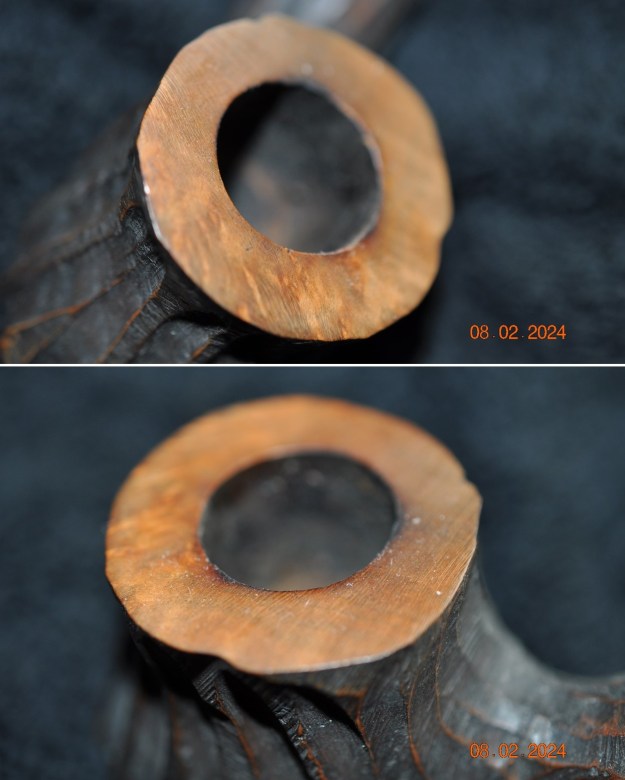

I took photos of the bowl and rim top to show the thickness of the cake and the lava coat on the rim top. There was some tobacco debris in the bottom of the bowl. The stem photos show the condition of the taper stem ahead of the button.

I took photos of the bowl and rim top to show the thickness of the cake and the lava coat on the rim top. There was some tobacco debris in the bottom of the bowl. The stem photos show the condition of the taper stem ahead of the button.  The stamping on the heel of the bowl is clear and readable as noted above. I took a photo of the pipe with the stem removed to give a sense of the proportions of the pipe. It is a real beauty. Interestingly, there was a clean foil inner tube in the tenon.

The stamping on the heel of the bowl is clear and readable as noted above. I took a photo of the pipe with the stem removed to give a sense of the proportions of the pipe. It is a real beauty. Interestingly, there was a clean foil inner tube in the tenon.

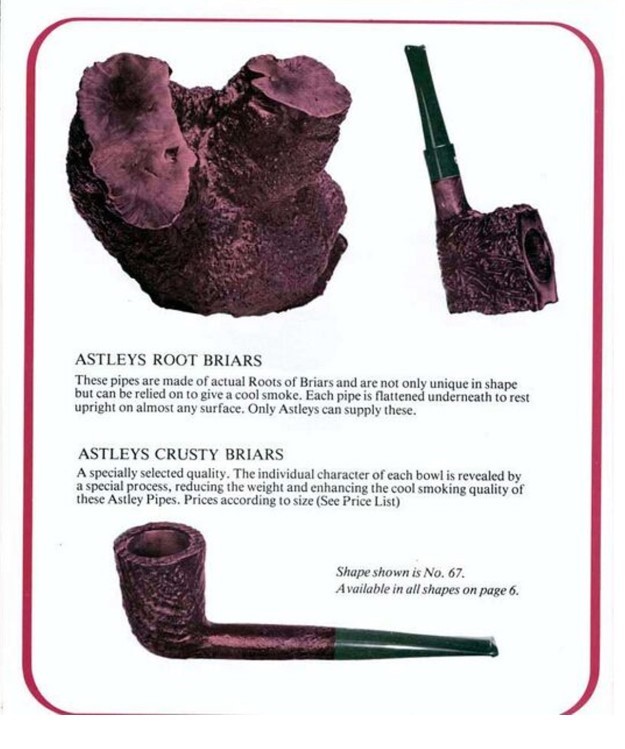

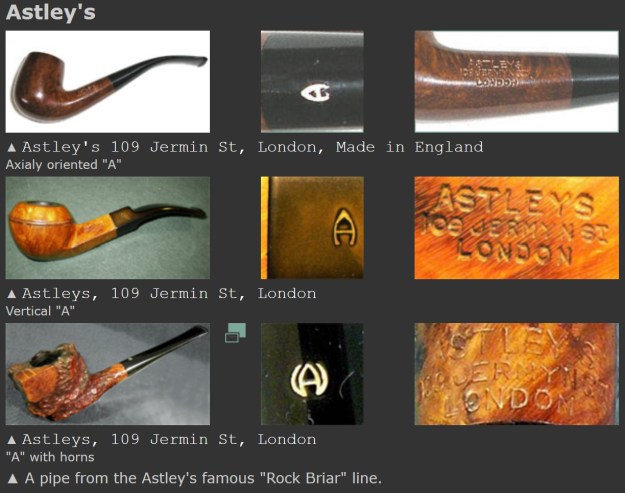

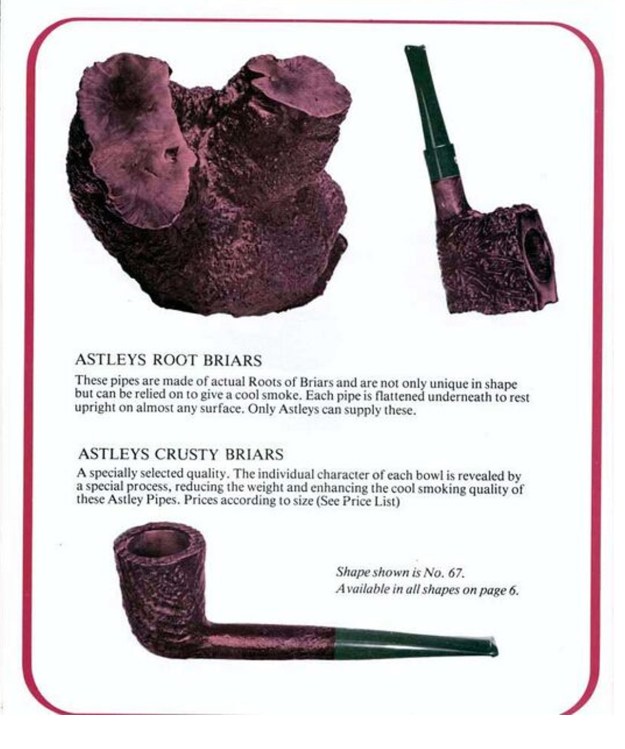

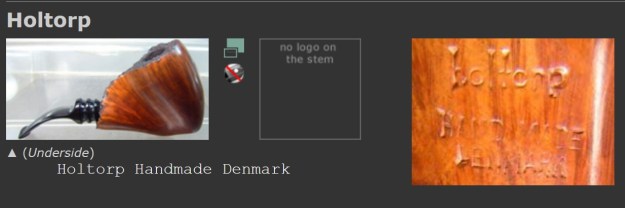

As usual I cannot seem to retain the details on Castello pipes in my head for long for some reason. The stamping on this one – Castello and the Carlo Scotti stamp left me with some questions that I need to answer before I began to work on the pipe. I turned first to the Pipephil site (http://www.pipephil.eu/logos/en/logo-castello.html) because of the general quick summary of information I get there along with a screen capture. Castello PIPA CASTELLO di Carlo Scotti & C. was founded in 1947 by Carlo Scotti († 1988). Franco Coppo (AKA “Kino”) who married Carlo Scotti’s daughter Savina, manages (2012) the corporate since 1985.

Castello PIPA CASTELLO di Carlo Scotti & C. was founded in 1947 by Carlo Scotti († 1988). Franco Coppo (AKA “Kino”) who married Carlo Scotti’s daughter Savina, manages (2012) the corporate since 1985.

The site also gave a good summary of the grading and sizes of the pipes. I quote that in full.

Sizes (ascending):

1K to 4K, G (Giant) and GG (Extra large)

Rusticated grading: SEA ROCK, OLD SEA ROCK, NATURAL VERGIN,

Sandblasted grading: ANTIQUARI, OLD ANTIQUARI

Smooth grading (ascending): TRADEMARK, CASTELLO, COLLECTION

Other stampings: Great Line (Non-standard or freestyle) Fiammata (Straight grain)

Production (2012): ~4000 pipes / year

I also found a note on the page that the Rhinestone logo was originally on pipes for the US market. It is occasionally used now.

I turned then to Pipedia for more information on the brand (https://pipedia.org/wiki/Castello). The majority of the information was what was already quoted above in abbreviated form.

…All carved Castello pipes are graded by the number of K’s that are stamped on each piece and are K-graded by SIZE. 1K is the smallest and fairly rare, 2K is small to medium, with 3K or 4K being the most common and ranges from medium to medium large. Large pieces are stamped “G” for giant and extra-large pieces are stamped “GG” for double giant. In addition to the number of K’s on a carved Sea Rock piece the shape number is almost always added. As a rule a Sea Rock Castello is stained Black, although recently there have been quite a few coming in stained deep brown and still stamped “Sea Rock”. American Logo’d Sea Rocks are all priced the same to the consumer, although most are 2 or 3 K’ed models. G/GG models are charged at a higher price on American pieces and are basically the same as their European counterparts.

The Castello Old Antiquari Briar KK 32 I was working on was definitely one made for the American Market with the Rhinestone in the stem. It had a brown or tan finish with a black flume around the top and the outer edge of the bowl. The Castello Old Antiquari in my hands was 2K graded. That told me that it is a mid-sized pipe. The number 32 makes it a short Canadian shape.

Now it was time to work on the pipe. I started my work by reaming the pipe. I scraped out the light cake with a Savinelli Fitsall Pipe Knife. I took the cake back to bare briar. I sanded the walls smooth with 220 grit sandpaper wrapped around a piece of dowel. The bowl walls looked very good with no burn damage or checking on the walls.

I worked over the rugged rustication on the rim top to remove the tars and lava on the rim top with a brass bristle wire brush.

I worked over the rugged rustication on the rim top to remove the tars and lava on the rim top with a brass bristle wire brush. I cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and both bristle and regular pipe cleaners.

I cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and both bristle and regular pipe cleaners.  I scrubbed the bowl and shank with a tooth brush and some undiluted Murphy’s Oil Soap. I rinsed it off with warm water to remove the dust and soap from the finish. I dried it off with a soft cloth. The rim top was still darkened in the grooves of the sandblast.

I scrubbed the bowl and shank with a tooth brush and some undiluted Murphy’s Oil Soap. I rinsed it off with warm water to remove the dust and soap from the finish. I dried it off with a soft cloth. The rim top was still darkened in the grooves of the sandblast.

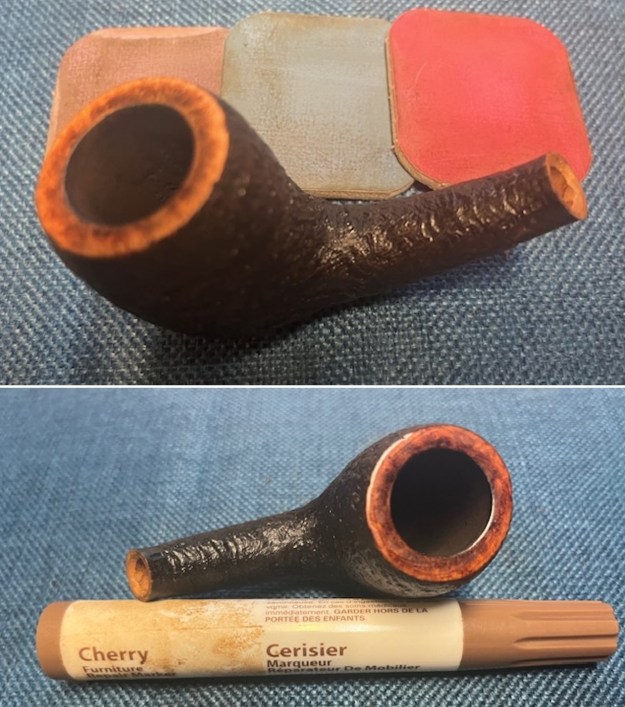

I touched up the black of the flume finish on the rim top and outer edge of the bowl with a black stain pen. It looked much better at this point with the finish cleaned of the dust and debris in the finish. It is a rich and rugged rustication.

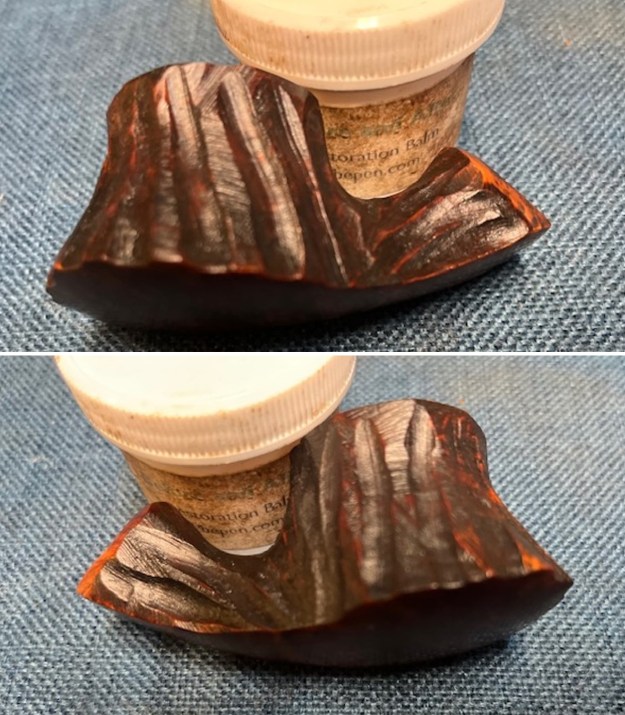

I touched up the black of the flume finish on the rim top and outer edge of the bowl with a black stain pen. It looked much better at this point with the finish cleaned of the dust and debris in the finish. It is a rich and rugged rustication. I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips and a horsehair shoe brush to work it into the nooks and crannies of the sandblast finish. The product works to clean, enliven and preserve the briar. I let it sit for 10 minutes then I buffed it with a cotton cloth to deepen the shine. The briar really comes alive with the balm.

I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips and a horsehair shoe brush to work it into the nooks and crannies of the sandblast finish. The product works to clean, enliven and preserve the briar. I let it sit for 10 minutes then I buffed it with a cotton cloth to deepen the shine. The briar really comes alive with the balm.

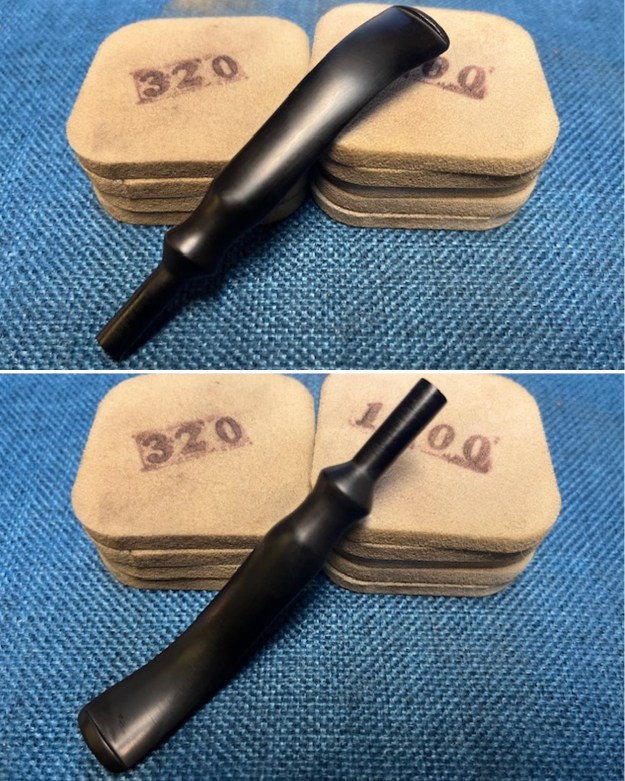

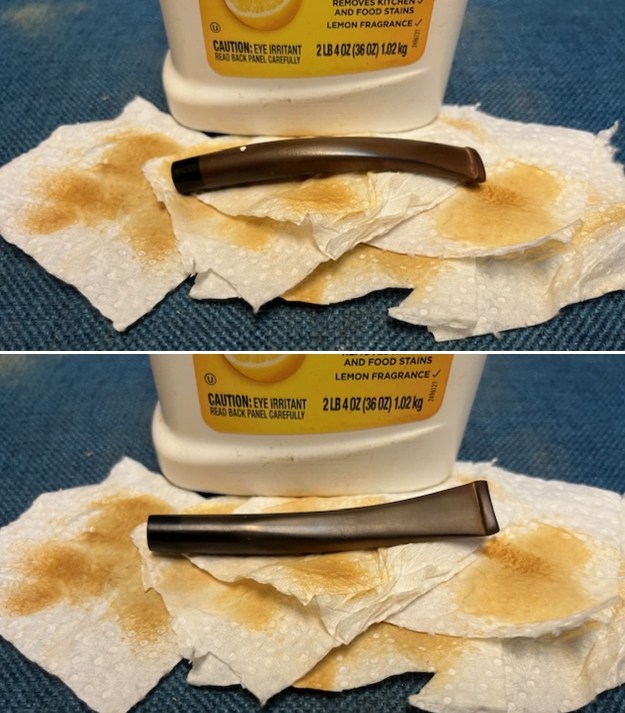

I set the bowl aside and worked on the stem. The stem was stamped on the underside and read TRADE MARK [over] CASTELLO [over] 7. I sanded the oxidation and the tooth marks and chatter with 220 grit sandpaper. I was able to remove all of the light tooth damage on the stem and the majority of the oxidation.

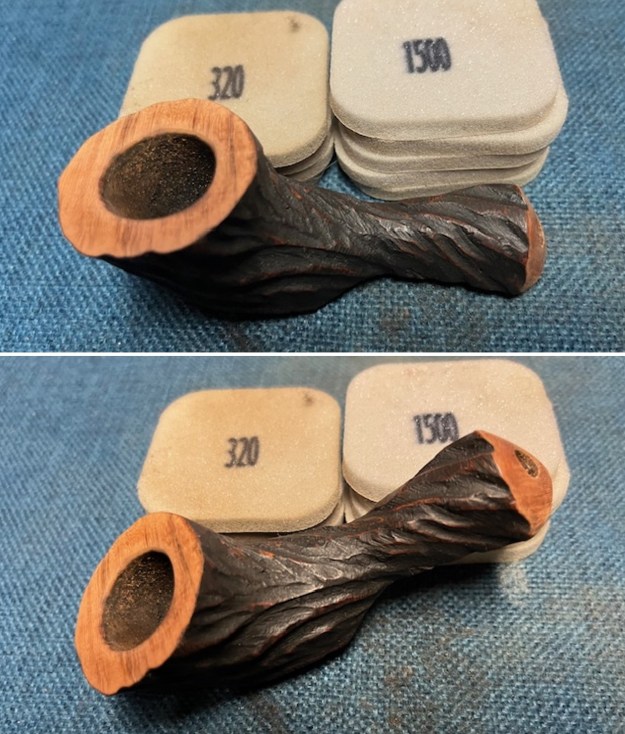

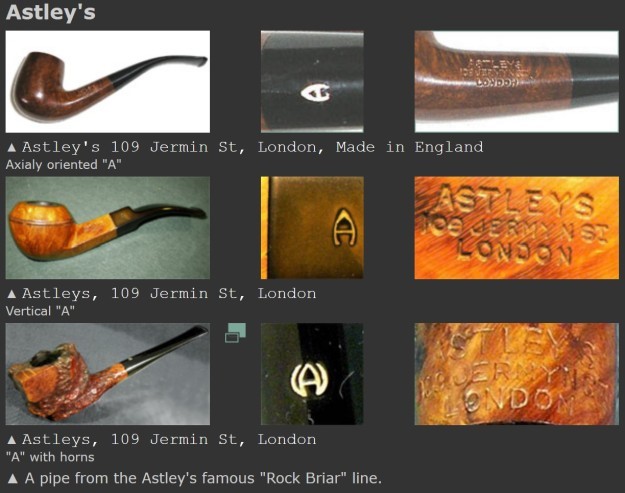

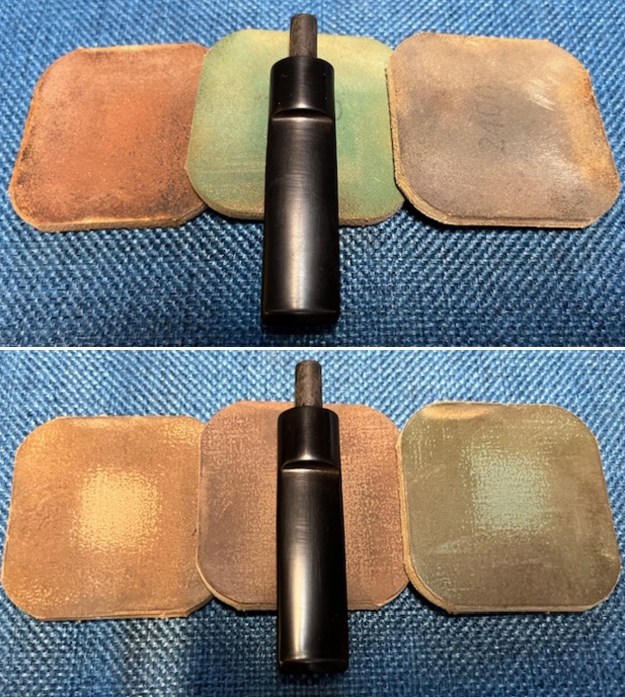

I set the bowl aside and worked on the stem. The stem was stamped on the underside and read TRADE MARK [over] CASTELLO [over] 7. I sanded the oxidation and the tooth marks and chatter with 220 grit sandpaper. I was able to remove all of the light tooth damage on the stem and the majority of the oxidation.  I sanded the stem and tenon surface with 320-3500 grit 2×2 inch pads. I wiped the stem down with an Obsidian Oil cloth after each sanding pad.

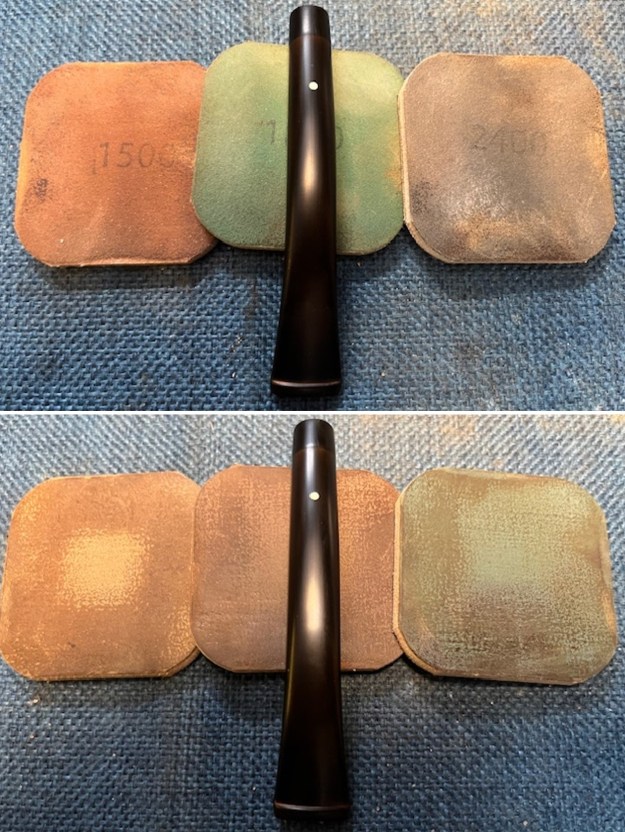

I sanded the stem and tenon surface with 320-3500 grit 2×2 inch pads. I wiped the stem down with an Obsidian Oil cloth after each sanding pad. I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This beautiful Castello Old Antiquari Rusticated Flumed Top KK 32 Short Canadian with a taper acrylic stem looks amazing after the work on it. The briar is clean and the deep rustication really came alive. The rich brown stains gave the finish a sense of depth with the polishing and waxing. The flumed black rim top and edges were a great contrast. The finish really popped. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Castello Old Antiquari Rusticated KK 32 Canadian really is a beauty and feels great in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 1/2 inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 47 grams/1.66 ounces. I will soon be putting this pipe on the rebornpipes store in the Italian Pipe Makers section. It should make a great smoker that the next steward will enjoy. Thanks for reading this blog and my reflections on the pipe while I worked on it. It was a fun one to work on.

This beautiful Castello Old Antiquari Rusticated Flumed Top KK 32 Short Canadian with a taper acrylic stem looks amazing after the work on it. The briar is clean and the deep rustication really came alive. The rich brown stains gave the finish a sense of depth with the polishing and waxing. The flumed black rim top and edges were a great contrast. The finish really popped. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Castello Old Antiquari Rusticated KK 32 Canadian really is a beauty and feels great in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 1/2 inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 47 grams/1.66 ounces. I will soon be putting this pipe on the rebornpipes store in the Italian Pipe Makers section. It should make a great smoker that the next steward will enjoy. Thanks for reading this blog and my reflections on the pipe while I worked on it. It was a fun one to work on.