Blog by Steve Laug

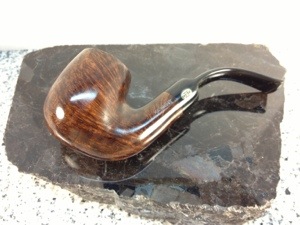

I love old GBD pipes no matter what era they come from. I gave my brother a list of pipes to keep an eye open for in his treasure hunts as he travels and on his eBay forays as well. GBD has been at the top of that list. He found a newer generation GBD recently and sent it my way. It is a nicely grained apple that is stamped GBD in the oval over MIDNIGHT on the top of the shank. On the underside it is stamped London England over 788 which is the shape number for an oval shank apple. The stem is a green swirled Lucite saddle shape with the GBD Oval stamped on the top of the saddle portion. The pipe was in decent shape. The finish was dirty and there was a buildup of cake in the bowl that had overflowed onto the rim. There were some dents in the outer edge of the rim on the back left side and some nicks and scratches on the left side of the bowl. The stem was another one that Jaws had gotten a hold of just like the Estella Non Pareil that I just finished and wrote about (https://rebornpipes.com/2016/12/06/jaws-and-an-estella-non-pareil-%c2%bc-bent-9606-stack-by-savinelli/). The top side had some deep dents and the underside had them as well. There were better situated in that they were in the blacker portion of the stem so blending in the repairs would be simpler. The photos my brother Jeff sent me really show the grain on the pipe. It has some stunning swirls of grain on the sides and some stunning birdseye on the top and the bottom of the shank and bowl.

The photos my brother Jeff sent me really show the grain on the pipe. It has some stunning swirls of grain on the sides and some stunning birdseye on the top and the bottom of the shank and bowl.

The next photos show some close ups of the rim and the bowl bottom. The top of the rim was thickly coated with the overflowing cake in the bowl. The birdseye on the bowl bottom is stunning.

The next photos show some close ups of the rim and the bowl bottom. The top of the rim was thickly coated with the overflowing cake in the bowl. The birdseye on the bowl bottom is stunning. The stamping on the shank and the stem was clear though lighter to the right edge on the topside of the shank. The fit of the stem to the shank was messy due to the build up of tars and oils in the shank and the mortise. I was pretty certain that once the pipe was cleaned up the fit would be back to normal.

The stamping on the shank and the stem was clear though lighter to the right edge on the topside of the shank. The fit of the stem to the shank was messy due to the build up of tars and oils in the shank and the mortise. I was pretty certain that once the pipe was cleaned up the fit would be back to normal. The next two photos show the work of Jaws on the Lucite. I can only say that I am thankful that the stem was not vulcanite or it would have been destroyed!

The next two photos show the work of Jaws on the Lucite. I can only say that I am thankful that the stem was not vulcanite or it would have been destroyed! My brother did his usual thorough clean up and was able to remove all of the tars and oils from the rim and the cake from the bowl. He scrubbed the grime and oils from the finish with Murphy’s Oil Soap and cleaned out the internals with alcohol, cotton swabs and pipe cleaners. The next four photos show the pipe when it arrived on my work table in Vancouver. I am getting spoiled by him doing all the grunt work of reaming and scrubbing. The pipes I get are all cleaned and reamed and ready to be restored. It is a great arrangement!

My brother did his usual thorough clean up and was able to remove all of the tars and oils from the rim and the cake from the bowl. He scrubbed the grime and oils from the finish with Murphy’s Oil Soap and cleaned out the internals with alcohol, cotton swabs and pipe cleaners. The next four photos show the pipe when it arrived on my work table in Vancouver. I am getting spoiled by him doing all the grunt work of reaming and scrubbing. The pipes I get are all cleaned and reamed and ready to be restored. It is a great arrangement!

I took a close up photo of the bowl and rim to show how clean it was when it got to me.

I took a close up photo of the bowl and rim to show how clean it was when it got to me. The tooth dents in the stem are shown in the next two photos. After the stem had been cleaned up they did not look as daunting as the ones in the Estella. The button had been worn down some as well by the chomper.

The tooth dents in the stem are shown in the next two photos. After the stem had been cleaned up they did not look as daunting as the ones in the Estella. The button had been worn down some as well by the chomper. I “painted” the dents in the stem with the flame from a Bic lighter. I was able to raise them quite a bit on this stem. On the top side only one deep tooth mark remained and on the underside there were three left.

I “painted” the dents in the stem with the flame from a Bic lighter. I was able to raise them quite a bit on this stem. On the top side only one deep tooth mark remained and on the underside there were three left. I sanded the dented areas with 220 grit sandpaper to smooth out the surface around the dents. I washed it down with alcohol on a cotton swab to make sure I did not leave any of the white sanding dust in the tooth marks. I decided to use black superglue to fill in the tooth dents as they were in the darker portion of the stem. I filled them in and let the glue dry.

I sanded the dented areas with 220 grit sandpaper to smooth out the surface around the dents. I washed it down with alcohol on a cotton swab to make sure I did not leave any of the white sanding dust in the tooth marks. I decided to use black superglue to fill in the tooth dents as they were in the darker portion of the stem. I filled them in and let the glue dry. Once the glue had dried I sanded the patches smooth with 220 grit sandpaper to blend them into the surface of the stem. The patch on the topside disappeared into the dark green/black of the rest of the stem. The ones on the underside were a little more temperamental and showed some light areas on some small parts of the patches.

Once the glue had dried I sanded the patches smooth with 220 grit sandpaper to blend them into the surface of the stem. The patch on the topside disappeared into the dark green/black of the rest of the stem. The ones on the underside were a little more temperamental and showed some light areas on some small parts of the patches. I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the stem down with a damp cotton pad after each set of three pads.

I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the stem down with a damp cotton pad after each set of three pads.

I set the stem aside and worked on the bowl. I used 1500-2400 grit micromesh sanding pads to work over the nicks in the rim and on the left side of the bowl. I was able to minimise them so that they blended into the briar better. I stained the bowl with a dark brown aniline stain cut 50/50 with isopropyl alcohol and flamed it with a lighter. I repeated the process until the coverage was even on all sides of the bowl.

I set the stem aside and worked on the bowl. I used 1500-2400 grit micromesh sanding pads to work over the nicks in the rim and on the left side of the bowl. I was able to minimise them so that they blended into the briar better. I stained the bowl with a dark brown aniline stain cut 50/50 with isopropyl alcohol and flamed it with a lighter. I repeated the process until the coverage was even on all sides of the bowl. I buffed the bowl and stem with Blue Diamond on the buffing wheel and gave the pipe multiple coats of carnauba wax to protect it. I buffed it with a clean buffing pad to polish the carnauba and give it a shine. I hand buffed the pipe with a microfibre cloth to deepen the shine. The finished pipe is shown in the photos below. The rich brown of the stain is a great contrast to the green of the Lucite stem. The overall look of the pipe is rich and the feel in the hand is perfect. This one will be available on the store in the days ahead. Thanks for journeying with me in this refurb.

I buffed the bowl and stem with Blue Diamond on the buffing wheel and gave the pipe multiple coats of carnauba wax to protect it. I buffed it with a clean buffing pad to polish the carnauba and give it a shine. I hand buffed the pipe with a microfibre cloth to deepen the shine. The finished pipe is shown in the photos below. The rich brown of the stain is a great contrast to the green of the Lucite stem. The overall look of the pipe is rich and the feel in the hand is perfect. This one will be available on the store in the days ahead. Thanks for journeying with me in this refurb.