Guest Blog by Robert M. Boughton

Member, North American Society of Pipe Collectors

http://www.naspc.org

http://www.roadrunnerpipes.com

http://about.me/boughtonrobert

Photos © the Author

Dedicated to Louis Arthur Hille (February 14, 1969-October 8, 2015)

“Part of me is afraid to get close to people because I’m afraid that they’re going to leave.” ― Brian Hugh Warner (a.k.a. Marilyn Manson), U.S. singer/songwriter/

performer/rock journalist/painter/actor, born January 5, 1969

INTRODUCTION

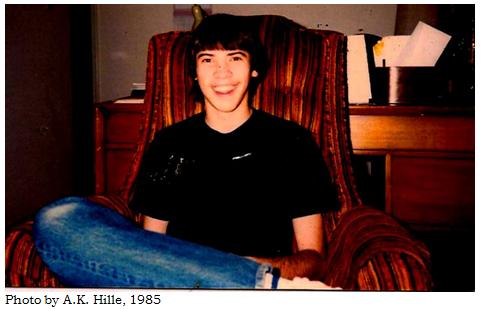

Like a panther, the young man caught in this rare snap-shot had the edge of menace in his pensive yet calm and subtly wild gaze and the firm set of his jaws. Though he seldom permitted the opportunity to penetrate the murky depths of his intellect long enough to preserve the moment in a photo, it shone through anyway. We were best friends and roommates for the past 15 years; I was his certified, consumer-directed caregiver during the last seven, and, in 2009, when his health took a big dive and he needed someone to protect him more than ever, he reluctantly made me his agent under a durable power of attorney. At the risk of being misunderstood (a possibility that really doesn’t threaten my hardy sense of self-identity in the least), we were soulmates.

The term snap-shot itself, as I may have noted before, originated as a hunting term: “A quick or hurried shot taken without deliberate aim, esp. one at a rising bird or quickly moving animal.” [Oxford English Dictionary] The word used in that sense dates at least to 1808, whereas the adoption by photographers appears to have started around 1860.

Louis told me, more times than I have mentioned in my blogs here how my dad was fond of saying I have a mind like a steel trap, that I would never meet anyone like him again. Once was well worth the almost manic-depressive ups and downs in near constant close quarters and proximity, but enough, if you can grok me. If my mind is a steel trap, Louis’ could go off when an ant happened upon it. To say Louis did not handle strict, unyielding strangers well, in particular those who could violate the sanctity of his room at will and in the hospital did so more or less constantly, and with apparent delight, is a gross understatement. He could and usually did revert to his five-year-old self and throw the kind of tantrums of which only an adult is capable. I’m sure the sole reason he was never put in four-point restraints, before the last year and a half or so when his hip and leg contractures became so bad that his knees were frozen up to his chin and made the heart’s desire of many a nurse and tech impossible, was the hospital staff’s well-founded fear of what I would have done.

A little more than a year before the serendipitous snapshot above, Louis celebrated his thirty-sixth birthday, on Valentine’s Day 2005, in a bed and hooked up to IV bags and monitors, during the second of many extended hospital stays. Before the end came last week, at home where he wanted to be, with his cats and me, Louis was to spend two more birthdays in hospitals, the most recent this year, on his 46th, and last. Celebrated, of course, is a modifier for birthdays that is worn thin by convention, and not at all the best choice in this case. In fact, the only way he lasted three months in that place was my gift to him his first full day of a large but portable CD/DVD player with headphones, as well as a couple of Stephen King’s better audio books and the latest Marilyn Manson release. That last would have been “The Golden Age of Grotesque”; this was two years before “East Me, Drink Me.” Yes, even Manson grew on me thanks to Louis’ knowledgeable and fervent guidance.

When I suspended the above moment in time, Louis had just recently been released (or, to be more honest, sprung by me) from the hospital full of quacks, imbeciles and ninnies. In their vast wisdom, which so often fuels a God complex, they mused at first over the likelihood of multiple sclerosis, given their myopic failure to get to the truth, so few years ago, that is now taught to pre-med students and even EMTs. Then they turned to lupus and several other look-alike possibilities. They even tested Louis for A.I.D.S. – not once, but twice, in case they missed it the first time.

This was how he often looked, for a time, after that quarter-year exercise in trial-and-error experiments that ended with our hectic, A.M.A., wheelchair career down several flights on the elevator and thence straight for the exit.

I have another favorite snapshot of Louis, taken with my cellphone when he had grown his hair back the way he liked it, which is to say very long. This one was taken around 2009-’10. It’s a favorite for æsthetic or artistic reasons as well as the way it shows the almost trancelike way he could stop in the middle of a step, having fallen into a reverie of contemplation that required stillness. I was surprised and pleased that he enjoyed this photo when I showed it to him after the barber had sheared off his beloved hair again.

It’s a favorite for æsthetic or artistic reasons as well as the way it shows the almost trancelike way he could stop in the middle of a step, having fallen into a reverie of contemplation that required stillness. I was surprised and pleased that he enjoyed this photo when I showed it to him after the barber had sheared off his beloved hair again.

The next year sometime, returning to my previous train of thought and meaning 2006 – I don’t recall the date but believe it was Spring – brought a surprise telephone call from Louis’ primary care physician.

I will never forget the similarity of the one-sided conversations, as I heard it from Louis’ side, and one of Bob Newhart’s hilarious 1960s “phone calls” from dead people, such as Abe Lincoln’s entreaty for help writing the Gettysburg Address – and Newhart’s deadpan response to one unheard complaint with something about how 87 years ago really wasn’t very snappy. Except that from my perspective, being able to “hear” what his doctor was saying based on Louis’ verbal responses, and in particular seeing the changes of his facial expressions, there was nothing to inspire laughter.

“Okay, then, I guess I’ll take the good news first,” Louis said after a moment’s exchange of niceties. Pause. “It’s not MS.” Pause. “That’s the good news?” Pause. “So what’s – the – bad news?” The last part was spoken as one word. “Oh.” Swallow. “It’s something different.” Pause. “Wait: neuro-what?” Repeating what the doctor told him, sound by sound. “Neuro-mye-litis op-ti-ca.” Nervous breathing, by both of us. “Oh. Yes, I heard you. MS isn’t fatal, but this is.”

And so the doctor did the unthinkable in a time when the pop medical practice remains to downplay the negative if not outright lie to the patient: he told the truth. Using the magnetic resonance imaging (MRI) scan photos from the big machine at the private hospital from which Louis escaped – the same kind of contraption that seemed to scare the devil out of Linda Blair in “The Exorcist,” only somewhat quieter – the head of the neurology department at our local university hospital spotted healed and unhealed wounds from the back of Louis’ neck and down his spine that gave her a good idea of what she was dealing with. She confirmed it with a blood test introduced the same year that differentiates the disease Louis had as a distinct and fatal entity from MS.

As it turned out, Louis was host to a genetic anomaly. In other words, the neuromyelitis optica (NMO, or Devic’s Disease) with which he was born – and which was just beginning, after 37 years of passing time slowly but methodically eating away at the myelin sheaths, fatty substances protecting Louis’ nerves, starting with those in the optic region, to thereby render him legally blind – had no precedence in his family. It was more along the lines of a ghastly fluke.

For those of you who have no idea where I’m going with this long account of Louis’ non-pipe-related demise (in fact, I even succeeded in getting him off cigarettes by supplying him with pipes and tobacco, although there was little chance he would ever live long enough to die of cancer), I will now clarify. Louis was by no means easy to get along with, but during the 15 years we were roommates, he – how should I put it? – grew on me as a good friend does, regardless of the many differences. Almost everyone who ever talked to him agreed on two points: one, he was a genius usually more capable than the listener to discuss complex issues of mathematics, science, world events, religious topics through the millennia, detailed weather phenomena and even the day’s stock market numbers. He was possessed of the ability to memorize the entire dialogues of movies, TV shows, commercials, popular and rock songs and more or less anything else – on a single viewing or hearing – and he could recite them for the rest of his life. The other general characteristic people who talked to Louis agreed on was that he could be a downright rude jerk. I’m not speaking ill of the dead, as should be apparent by the end of this unusual introduction; it was the simple truth, and he was never even aware of it despite my attempts to make him so. The fact is, he sounded like his mother, whom I knew. There was also the fact that his mind and spirit traveled at a speed comparable by mental comparison to the F-22 Raptor and was just as deadly with its offensive and defensive weapons loads. All of these factors tended to intimidate or just embarrass people.

Louis had theories far rarer than NMO, but as intricately informed as a spider’s web is spun, on such issues as the afterlife, prior lives, simultaneous lives, paranormal entities, abortion and other lively and nowadays popular and/or controversial concepts. Does a pattern emerge from these topics? Only now do I see it: Louis’ thriving thirst for life, before, during and after what most people would call his own. The thing about Louis is that he was out there way before it was cool to be out there.

The reason I stayed by Louis’ side almost as long as his parents, who kicked him out as an eighteenth birthday present, was that I could still see the same person I met the day after Thanksgiving in 2000. He was happy. He smiled and laughed and talked non-stop but coherently and cogently about almost anything, and when he couldn’t think of a name or a word or whatever, I was the only person who listened and understood where he was coming from and could fill in the missing spaces, and he could finish my thoughts, as well.

I miss those conversations at coffee houses or on buses or walking when I didn’t have a car, and he could still walk. I miss those good times not because we stopped having them after he grew sicker, but because they occurred less and less often, and now he is gone. All I ever wanted was to help him get better. Right now the only thing I have to replace that is working on pipes, trying to make them better.

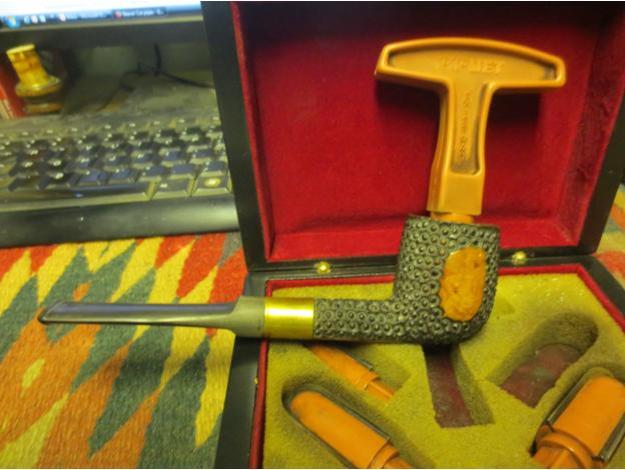

This one, like Louis, was really messed up when I got it, and the consensus among my pipe restorer friends was to lop off about a half an inch from the top of the bowl and reshape it. But I thought: nah! Been there, done that. This time I wanted to try something a little different. Two previous restorations came to mind. One is a Ben Wade with an enormous crack down one side of the bowl that required emergency surgery to amputate about two thirds of the tall billiard, and is still in recovery as a squat pot shop pipe. The other is a no-name Italian freehand that I call the Beak and thought was someone’s first attempt at pipe making because of several mistakes I had to correct, including the unmissable in the following photos.

Louis, I know you’re listening, and this one’s for you.

Louis, I know you’re listening, and this one’s for you.

RESTORATION

I am sure the reason my friends suggested the more drastic surgery is clear from these photos. Whoever put that gash in the rim ought to be brought up before the Pipe Court, have any other potential hostages he might be holding liberated and be forced to register as a pipe offender for the rest of his life, unless, of course, he can prove he is rehabilitated. The latter event is unlikely, as recidivism is high for this offense.

I am sure the reason my friends suggested the more drastic surgery is clear from these photos. Whoever put that gash in the rim ought to be brought up before the Pipe Court, have any other potential hostages he might be holding liberated and be forced to register as a pipe offender for the rest of his life, unless, of course, he can prove he is rehabilitated. The latter event is unlikely, as recidivism is high for this offense.

There are several not-so-easy to spot points. The traditional triangle with WDC, for William Demuth & Company (1862-1972), is missing, possibly from a previous owner gripping the bowl so tightly that it rubbed off altogether, or because of its original absence. Steve informs me that not all WDCs have the triangle. Also, the first few letters of Wellington are very faded, but the nomenclature type style is the same as other WDC Wellingtons, such as this System Billiard in the Peterson’s style that I restored a while back. Then there is the small STERLING mark on the close-up of the band, if you can make it out in the first group above.

Then there is the small STERLING mark on the close-up of the band, if you can make it out in the first group above.

At any rate, as much as the initial challenge appeared obvious – to see if I could pull off rounding the entire rim, thereby eliminating the horrid wound and hopefully leaving the rim even – I decided to clean and otherwise prepare the insides of the WDC first. The chamber appeared to have been well-cleaned, and all it needed was an easy sanding with 320-grit followed by 500. Then I remembered I needed a bit for the pipe and couldn’t even retort it until I found one! That’s okay, laugh all you like. I know I can be a bit spacey sometimes, and besides, laughing at the recollection now does me good.

What I wanted was about a three-inch tapered with the right diameter of the tenon end to fit flush with the shank, or a little bigger. Bigger, I can fix. In fact, considering I’m doing it the old-fashioned way, by hand and sand, so to speak, I’m becoming pretty adept. Of course, all I could find in tapered bits, even replacements (i.e., no brand marks) on other pipes awaiting restorations with which I am not above robbing Peter to pay Paul, had tenons that were way too small, or the diameters of the meeting points with the shank were too small. The pipe is banded, so neither of those options would do.

And so I turned to my sure supply of new saddle bits, which were just a touch shorter than I wanted but would do the trick. Here are shots of an uncut saddle bit next to the one I sanded down with coarse paper, identical except for the tenons, and the preliminary fit with the Wellington. Keep in mind that the condition of the pipe with the preliminary stem in it was taken after the next two steps, counting the basic fitting of bit to shank and the retort as finished.

Keep in mind that the condition of the pipe with the preliminary stem in it was taken after the next two steps, counting the basic fitting of bit to shank and the retort as finished.

I chose 200-grit paper for the task of rounding the rim so as to take more time and get the job done right with some extra work, but not overdo it with one fell swipe. I hope I’ve learned my lesson there! I was surprised at how easy it was to accomplish.

Here is the step I suggested above, under the photo of the pipe and bit, which made the wood look so inexplicably polished. Using 500-grit paper, I worked over the entire outer wood. I micro meshed from 1500-grit to 12000.

Here is the step I suggested above, under the photo of the pipe and bit, which made the wood look so inexplicably polished. Using 500-grit paper, I worked over the entire outer wood. I micro meshed from 1500-grit to 12000.

After a moment’s consideration of staining the wood below the rim a little darker, I concluded I would have to make it too dark for there to be any difference from the way it already was and opted to skip it. With that, I realized I only had to finish shaping the bit to the shank before buffing everything on the wheels.

After a moment’s consideration of staining the wood below the rim a little darker, I concluded I would have to make it too dark for there to be any difference from the way it already was and opted to skip it. With that, I realized I only had to finish shaping the bit to the shank before buffing everything on the wheels.

That was when something really creepy happened. I had searched high and low for a tapered bit without luck, but in the meantime did a little straightening up in my office-shop. I had been working on the pipe in the living room with my mobile restoration cart handy and the couch much more comfortable. While looking for an upgrade DVD to an invaluable computer program that remains misplaced, I searched through a large plastic trash bag stuffed willy-nilly with papers, electronic gadgets and whatnot. I came across a nice, black wooden cigar display case with a hinged lid and clasp that I picked up at my tobacconist. No, there was nothing special in the box; it was empty, unfortunately. Then the thought occurred to me how it would make the perfect place to put my loose oddball bits scattered. Most of them were in one place on the bottom shelf, but I had come across some others all over the cart.

Back in the living room, I sat down on the edge of the couch with the box open on the floor in front of me and began to organize the bits in the box, tossing a few that could never be of any use as I went. At last I thought I had them all but checked the top shelf again, as I had before while looking for a tapered bit. I was about to call it quits when I spied two bit lips poking out from under a piece of sandpaper, and…well, I could not believe my eyes. One of them was tapered and appeared to have about the right size tenon. With near reverence, I tried it in the Wellington. The fit was a little loose – just enough to add a layer of black Super Glue, I figured. All it needed other than that was the slightest of sanding just below the lip with 320-grit paper, micro meshing and buffing on the wheel with red and white Tripoli.

Knowing it would be a perfect fit when the glue dried, I still could not stand having to wait another night to see. Of course that’s a figure of speech relating to patience, which I am normally all about, and so I physically survived the night. I was so worn out I even slept like a baby until morning came, and my first thought, like a kid at Christmas, was the present waiting for me on the cart. All I can add is that the black Super Glue had dried on the tenon in perfect shape, and the bit twisted to an exact, flush match with the shank.

Some of you may think this foolish, but I found breathing difficult. Emotion welled up in me again, and to fight it off I closed my eyes. I said out loud, “I’ll be darned [or another similar word]! Thank you, Louis.” He thought I didn’t believe in anything he ever talked about but told me many times he would be keeping an eye on me after he died. I believe he is.

Ready to finish this relaxing project, I buffed the bowl with red and white Tripoli, White Diamond and carnauba, using the dry wheel as usual between each, and then rubbed down the whole thing with a soft cotton cloth.

CONCLUSION

CONCLUSION

His vision, from the constantly passing bars,

has grown so weary that it cannot hold

anything else. It seems to him there are

a thousand bars; and behind the bars, no world.

As he paces in cramped circles, over and over,

the movement of his powerful soft strides

is like a ritual dance around a center

in which a mighty will stands paralyzed.

Only at times, the curtain of the pupils

lifts, quietly–. An image enters in,

rushes down through the tensed, arrested muscles,

plunges into the heart and is gone.

― Rainer Maria Rilke (1875-1926), Austro-Hungarian poet, in “The Panther”

This was one of Louis’ favorite poems. I was surprised when he revealed this insight into his personality, oh so long ago it seems now, back in the happy autumn days that are no more, to paraphrase another poet’s description of the feeling of ennui. Louis liked those somewhat morose lines of verse, also, the first time I spoke them to him from memory, and several times later asked me to repeat them. I used to recite the words in gushy, over-dramatic tones dripping with the contempt I thought I had for them. But in verbal repetition, I overcame that bad habit, for there was a reason I could recall the brilliant if brief sample of prose from a high school sophomore lit class that really was a long time ago.

For most of the 15 years I knew him, Louis had an intense fear of dying appropriate to someone with an equally free spirit of the simple joy of living that was stolen from him. I tried to reassure Louis, over and over again, that he was not there yet based on my knowledge of the progressively more horrible stages of the disease he came to face almost every waking hour. My mistake was not expecting the unnatural, man-made obstacles that hastened, for him, the day no one truly wishes to see. I am beginning to be at peace with the knowledge that Louis no longer suffers as he did for so long – that he is in a better place, despite my best efforts; and I am still here, to enjoy my life the way my friend wanted me to do, and to fight the good battles. Now I understand that tears are seldom idle.

Just a few more words with some illustrations to sum up: compare the photos below, one antique and the other still fresh. That’s Rilke – somewhere.

That’s Rilke – somewhere.

And just one more photo of Louis, age 16, happy at home with his parents.

MARILYN MANSON LINKS

http://www.rollingstone.com/culture/news/columbine-whose-fault-is-it-19990624

https://www.youtube.com/watch?v=9vyZK_CKkZo Marilyn Manson’s first David Letterman appearance – yes, he was invited back…and back!

I took a close up photo of the rim on each of the pipes. The first photo below shows the rim on the Prince and the second shows the rim on the Billiard. The buildup and the uneven cake are visible in both pipes. It is hard to see the bevel on the rim in the Prince but it matches the one on the rim of the Billiard.

I took a close up photo of the rim on each of the pipes. The first photo below shows the rim on the Prince and the second shows the rim on the Billiard. The buildup and the uneven cake are visible in both pipes. It is hard to see the bevel on the rim in the Prince but it matches the one on the rim of the Billiard.

I also took some close up photos of the stems on both pipes to show the state of the stem. The first two photos show the stem on the Prince. You can see the damage of the broken area on the side of the button and the cut off button. You can also see the groove or divot that had been cut in the stem to make the pipe useable. The third and fourth photos show the stem on the Billiard and you can see the tooth marks and chatter on the stem surface. It is also clear that it does not fit well against the side of the band.

I also took some close up photos of the stems on both pipes to show the state of the stem. The first two photos show the stem on the Prince. You can see the damage of the broken area on the side of the button and the cut off button. You can also see the groove or divot that had been cut in the stem to make the pipe useable. The third and fourth photos show the stem on the Billiard and you can see the tooth marks and chatter on the stem surface. It is also clear that it does not fit well against the side of the band.

I decided to restem the Prince so I found a stem in my can of stems that was the same diameter as the shank and slightly longer than the broken stem to account for the missing button. I turned the tenon with a sanding drum on a Dremel to get a close fit and then hand sanded until it push snuggly into the mortise.

I decided to restem the Prince so I found a stem in my can of stems that was the same diameter as the shank and slightly longer than the broken stem to account for the missing button. I turned the tenon with a sanding drum on a Dremel to get a close fit and then hand sanded until it push snuggly into the mortise. To deal with the badly fit shank band I cleaned the area with a dental pick and then pressed briar dust into the groove just ahead of the band. I dripped clear super glue into the briar dust and then as it settled add more glue and more briar dust. I wanted the transition between the shank and the band to be smooth. I sanded the repair with a folded piece of 220 grit sandpaper and then with a medium and a fine grit sanding sponge to smooth out the scratches in the surface.

To deal with the badly fit shank band I cleaned the area with a dental pick and then pressed briar dust into the groove just ahead of the band. I dripped clear super glue into the briar dust and then as it settled add more glue and more briar dust. I wanted the transition between the shank and the band to be smooth. I sanded the repair with a folded piece of 220 grit sandpaper and then with a medium and a fine grit sanding sponge to smooth out the scratches in the surface. I reamed both bowls back to bare wood with a PipNet reamer. I sanded the beveled rim on the Prince to clean off the oils and lava and to show the bevel. More work would need to be done on both rims.

I reamed both bowls back to bare wood with a PipNet reamer. I sanded the beveled rim on the Prince to clean off the oils and lava and to show the bevel. More work would need to be done on both rims.

I worked on the bevel of the rims with 220 grit sandpaper to remove the buildup and also to smooth out the bevel. It took quite a bit of sanding on both rims to get the angle consistent all the way around the bowl and also to remove the burn damage on the inner edge of both. I sanded both with a medium and fine grit sanding sponge to finish the cleanup.

I worked on the bevel of the rims with 220 grit sandpaper to remove the buildup and also to smooth out the bevel. It took quite a bit of sanding on both rims to get the angle consistent all the way around the bowl and also to remove the burn damage on the inner edge of both. I sanded both with a medium and fine grit sanding sponge to finish the cleanup. I stained the newly cleaned surfaces of the rim with a light brown stain pen to approximate the colour on the smooth portions on the bowl sides and bottom of the shank.

I stained the newly cleaned surfaces of the rim with a light brown stain pen to approximate the colour on the smooth portions on the bowl sides and bottom of the shank. I sanded them both with 400 grit wet dry sandpaper to smooth out the remaining scratches that showed up with the stain. It also lightened the stain enough that the match was perfect.

I sanded them both with 400 grit wet dry sandpaper to smooth out the remaining scratches that showed up with the stain. It also lightened the stain enough that the match was perfect.

With the rims finished it was time to scrub the rustication. I used Murphy’s Oil Soap and a tooth brush to scour the rustication pattern on both bowls. I scrubbed them and then rinsed them under warm running water.

With the rims finished it was time to scrub the rustication. I used Murphy’s Oil Soap and a tooth brush to scour the rustication pattern on both bowls. I scrubbed them and then rinsed them under warm running water.

To address the difference in diameter of the stem and the band on the shank on the Billiard I used a Dremel and sanding drum to take down the top, bottom and right side of the saddle stem. I repeatedly checked the fit until I had it very close then I finished adjusting the fit by hand with 220 grit sandpaper. I sanded the stem on the Prince with 220 grit sandpaper to remove the oxidation and the calcification on the end of the stem.

To address the difference in diameter of the stem and the band on the shank on the Billiard I used a Dremel and sanding drum to take down the top, bottom and right side of the saddle stem. I repeatedly checked the fit until I had it very close then I finished adjusting the fit by hand with 220 grit sandpaper. I sanded the stem on the Prince with 220 grit sandpaper to remove the oxidation and the calcification on the end of the stem.

With the fit finished on the stems it was time to clean out the internals of the stems and shanks. I used alcohol, cotton swabs and pipe cleaners to scrub the insides until they were clean.

With the fit finished on the stems it was time to clean out the internals of the stems and shanks. I used alcohol, cotton swabs and pipe cleaners to scrub the insides until they were clean.

I wet sanded the stem and the brass with a 1500 grit micromesh sanding pad for the first round of sanding on both. It worked to remove many of the scratches and marks in the brass and the vulcanite.

I wet sanded the stem and the brass with a 1500 grit micromesh sanding pad for the first round of sanding on both. It worked to remove many of the scratches and marks in the brass and the vulcanite. I worked on the stem with the micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I rubbed the stem down with Obsidian Oil between each set of three pads. When I finished sanding with the 12000 grit pad I let the oil dry on the stem.

I worked on the stem with the micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I rubbed the stem down with Obsidian Oil between each set of three pads. When I finished sanding with the 12000 grit pad I let the oil dry on the stem.

In the final sanding I sanded the brass and it carried over onto the top portion of each stem giving it a bit of a brown look in the next photo. This all came off when I buffed the stem with red Tripoli and White Diamond.

In the final sanding I sanded the brass and it carried over onto the top portion of each stem giving it a bit of a brown look in the next photo. This all came off when I buffed the stem with red Tripoli and White Diamond. I heated the stem on the Prince and gave it a slight bend to give it a more finished looked. I buffed the stems and rims with White Diamond and Blue Diamond and then gave them multiple coats of carnauba wax. I also waxed the smooth portions on the bowl sides, shank bottoms and the rims. I buffed these with Blue Diamond as well. I wiped the rustication down with a light coat of olive oil to bring some life back to the briar. The finished sisters are shown below.

I heated the stem on the Prince and gave it a slight bend to give it a more finished looked. I buffed the stems and rims with White Diamond and Blue Diamond and then gave them multiple coats of carnauba wax. I also waxed the smooth portions on the bowl sides, shank bottoms and the rims. I buffed these with Blue Diamond as well. I wiped the rustication down with a light coat of olive oil to bring some life back to the briar. The finished sisters are shown below.

Thanks for looking. Does anyone have any information about this brand? It would be great to be able to get a little information. Please post anything you know in the comments below. Thanks.

Thanks for looking. Does anyone have any information about this brand? It would be great to be able to get a little information. Please post anything you know in the comments below. Thanks.