Blog by Steve Laug

The next pipe on the table is one that Jeff picked up from an auction in Bridgton, Maine, USA in November of 2018 for so it has been sitting here for a long time. It is a very different looking bent Billiard with a faux horn shank ring. The stem is a fancy saddle that looks very good. The stamping on the underside of the shank read Nording [over] Made in Denmark. It was sandblasted on the lower half of the bowl and the entire shank. There is a smooth band around the top half of the bowl on the front and both sides. But it is not totally smooth as it appears that the sandblast was sanded in that area. It is unique for sure and oddly attractive. There was a lot of grime and grit ground into the finish of the bowl. There was a heavy cake in the bowl and a heavy overflow of lava on the sandblast rim top. The fit of the stem in the shank was smooth and flawless. The faux horn shank ring was quite stunning. On the left side of the saddle the “N” logo had been stamped. It was clear and readable but did not have the white colour in it. The stem was vulcanite and it was oxidized, calcified and had some wear on both sides near the button.

Jeff took photos of the bowl and rim top to show the cake in the bowl. The sandblast rim top showed thick coat of lava that filled in the rim top and hopefully protected the edges from damage. He took photos of the top and underside of the stem showing the tooth chatter, scratching, oxidation and calcification on the stem surface and wear on the edges of the button.

Jeff took photos of the bowl and rim top to show the cake in the bowl. The sandblast rim top showed thick coat of lava that filled in the rim top and hopefully protected the edges from damage. He took photos of the top and underside of the stem showing the tooth chatter, scratching, oxidation and calcification on the stem surface and wear on the edges of the button.

Jeff took photos of the sides and heel of the bowl to show the condition of the finish. You can see the well done shape and the interesting grain pattern under the sandblast. Even under the dirt and debris of the years it looked very good.

Jeff took photos of the sides and heel of the bowl to show the condition of the finish. You can see the well done shape and the interesting grain pattern under the sandblast. Even under the dirt and debris of the years it looked very good. The stamping is clear and readable as noted above. The honey coloured finish even looks good under the grime and the pipe really is a Grand Luxe!

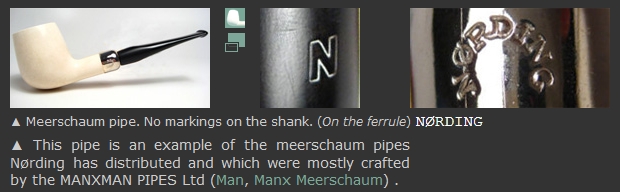

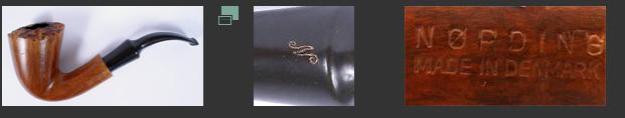

The stamping is clear and readable as noted above. The honey coloured finish even looks good under the grime and the pipe really is a Grand Luxe! I turned first to Pipephil to get a quick review of the brand (http://pipephil.eu/logos/en/logo-n2.html). The pipe was carved by Erik Nording. Nording is a prolific carver who continues to make pipes and sell them globally. The screen capture below shows a Nording with stamping like the one I am working on.

I turned first to Pipephil to get a quick review of the brand (http://pipephil.eu/logos/en/logo-n2.html). The pipe was carved by Erik Nording. Nording is a prolific carver who continues to make pipes and sell them globally. The screen capture below shows a Nording with stamping like the one I am working on. I then turned to Pipedia to have a look at the history of the Nording brand and see if there were any pipes like the one in hand (https://pipedia.org/wiki/N%C3%B8rding). The history was worth a read, though there were no photos of the pipe that I had.

I then turned to Pipedia to have a look at the history of the Nording brand and see if there were any pipes like the one in hand (https://pipedia.org/wiki/N%C3%B8rding). The history was worth a read, though there were no photos of the pipe that I had.

With the information I learned in the above articles I had the background on the pipe. Now it was time to work on it.

I am really happy to have Jeff’s help on cleaning up the pipes that we pick up along the way. He reamed the bowl with a PipNet pipe reamer and cleaned up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed out the internals with alcohol, pipe cleaners and cotton swabs until the pipe was clean. He scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime and grit on the briar and the lava on the rim top. The finish looks much better and the rim top was actually very visible and it looked good. There were also remnants of varnish or shellac on the exterior of the bowl (more on the right than front and left side). Jeff scrubbed the stem with Soft Scrub All Purpose Cleaner to remove the majority of the grime. When the pipe arrived here in Vancouver it looked very good.

I took some close up photos of the rim top and the stem surface. The rim top looked very good and the sandblast on the finish was worn but clean. I took close up photos of the stem to show the condition of the surface and button. The stem was very clean with tooth chatter on both sides near the button.

I took some close up photos of the rim top and the stem surface. The rim top looked very good and the sandblast on the finish was worn but clean. I took close up photos of the stem to show the condition of the surface and button. The stem was very clean with tooth chatter on both sides near the button.  I took a photo of the stamping on the underside of the shank You can see that it is stamped as noted above. It is clear and readable.

I took a photo of the stamping on the underside of the shank You can see that it is stamped as noted above. It is clear and readable.  I took the pipe apart and took a photo of the pipe. It is a good looking pipe and has some great grain on the bowl and shank.

I took the pipe apart and took a photo of the pipe. It is a good looking pipe and has some great grain on the bowl and shank.  I decided to start my restoration work on this one by working to remove the varnish coat. I rubbed the bowl down with acetone on cotton pads to remove the finish. It did not work very well. So I sanded the finish lightly with 1500 grit micromesh sanding pads to break the shiny top coat on the briar. I then wiped it down again with acetone and was happy with the results.

I decided to start my restoration work on this one by working to remove the varnish coat. I rubbed the bowl down with acetone on cotton pads to remove the finish. It did not work very well. So I sanded the finish lightly with 1500 grit micromesh sanding pads to break the shiny top coat on the briar. I then wiped it down again with acetone and was happy with the results.

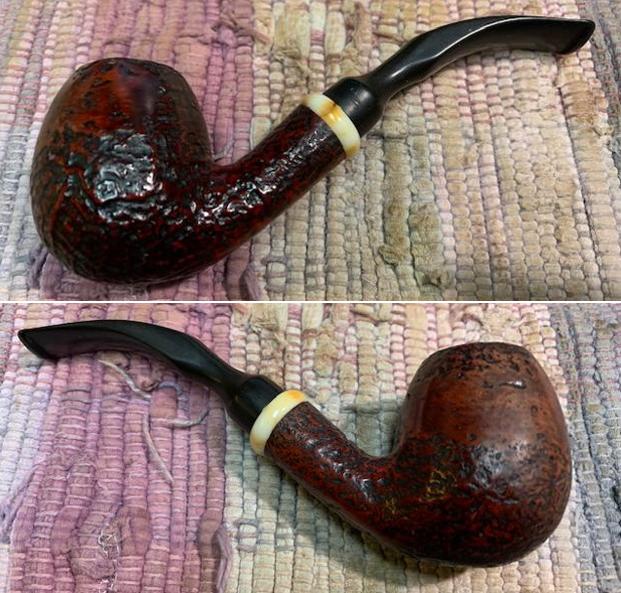

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips and a horsehair shoe brush to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips and a horsehair shoe brush to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

With that done the bowl was finished other than the final buffing. I set it aside and turned my attention to the stem. I looked at the worn areas on the stem and decided to sand them out with 220 grit sandpaper and start polishing it with 400 grit wet dry sandpaper.

With that done the bowl was finished other than the final buffing. I set it aside and turned my attention to the stem. I looked at the worn areas on the stem and decided to sand them out with 220 grit sandpaper and start polishing it with 400 grit wet dry sandpaper.  I touched up the N stamp with Rub’n Buff Antique Gold. I rubbed it onto the surface and into the N with a toothpick. I buffed it off with a soft cloth and the look is very good.

I touched up the N stamp with Rub’n Buff Antique Gold. I rubbed it onto the surface and into the N with a toothpick. I buffed it off with a soft cloth and the look is very good. I polished the stem with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine.

I polished the stem with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine.

It is fun to come to end of the restoration of the Nording Mixed Finish Danish Bent Billiard. It turned out to be a nice looking pipe. The finish came alive with the work I had done on it. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with the polished shank ring and black vulcanite saddle stem. It really was beautiful. This Nording made Bent Billiard is nice looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 52grams/1.83ounces. It is a beautiful pipe that I will soon put on the rebornpipes store in the Danish Pipe Makers section. If you are interested in adding it to your collection let me know. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of the next pipeman or woman.

It is fun to come to end of the restoration of the Nording Mixed Finish Danish Bent Billiard. It turned out to be a nice looking pipe. The finish came alive with the work I had done on it. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with the polished shank ring and black vulcanite saddle stem. It really was beautiful. This Nording made Bent Billiard is nice looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 52grams/1.83ounces. It is a beautiful pipe that I will soon put on the rebornpipes store in the Danish Pipe Makers section. If you are interested in adding it to your collection let me know. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of the next pipeman or woman.