Blog by Steve Laug

I just finished cleaning up another of the old pipes I picked up in my antique mall grab bag. It is a dainty pipe with an oval shank. When it came out of the grab bag it had a cracked shank and did not have a stem in the shank so I assumed it was a Canadian. When I went over the stems in the bag I found that one of them was stamped Old Pal. It fit the shank well and the look was quite unique. The stem was broken at the button with a large chunk on one side missing. The overall length is 5 ¾ inches and the weight is negligible. It is stamped on top of the shank in arc – Old Pal, over an Eagle with spread wings and then underneath Made in France.

On the underside of the shank it is stamped 396 which I assume is the shape number. The shape number appears to be a GBD number but it is not included in the list on the Perdua shape number website. The stamping is faint but still readable. I wrote about the history of the brand in a previous post (https://rebornpipes.wordpress.com/2014/04/19/restemming-and-refurbishing-a-planter-opera-pipe/) But will summarize it again here for those who may not go back and read it.

On the underside of the shank it is stamped 396 which I assume is the shape number. The shape number appears to be a GBD number but it is not included in the list on the Perdua shape number website. The stamping is faint but still readable. I wrote about the history of the brand in a previous post (https://rebornpipes.wordpress.com/2014/04/19/restemming-and-refurbishing-a-planter-opera-pipe/) But will summarize it again here for those who may not go back and read it.

“Who Made That Pipe” states that there were two French makers for Old Pal. The first of those is Marechal Ruchon and Cie. (Incidentally it is the company that owned the GBD brand). The second maker listed is Rubinovich & Haskell Ltd. The bird emblem is probably the key, but I can find no reference to it. My own thinking is that the brand was made by Marechal Ruchon & Cie. I was able to dig up this brief summary of the MR&C brand. Ganeval, Bondier and Donninger began making pipes in 1850 and rapidly gained prominence in briar pipe making. Of the three, Bondier survived the others by 30 years, but new partners took their places. The name of the company changed to Bondier Ulrich & Cie, then Bine Marechal & Cie and finally to A Marechal, Ruchon & Cie. August Marechal and Ferdinand Ruchon saw the firm into the 20th century, their names being used for the company for well over 50 years.

Prior to 1899, Marechal, Ruchon & Co. became A. Oppenhiemer’s sole agent for cigarette papers but still remained in the pipe making business. Then in 1902, Marechal, Ruchon & Co., owners of GBD and referred to as French pipe makers, merged with A. Oppenhiemer. In the 1915 London Directory of briar pipe makers one will find: “”Marechal, Ruchon & Co. – 38 Finsbury Sq. E.C.; London works, 15 & 16 Featherstone St. E.C. and Oppenhiemer, A. & Co. – 38 Finsbury Sq. E.C. listed separately.

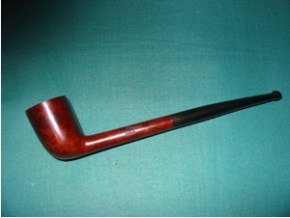

As before with that background information remembered I worked on this old pipe to clean it up and restore it. When I picked it up the bowl was badly caked. The rim was dirty and the outer edge had been knocked about pretty hard to remove the dottle of the past. The inner bevel was tarred but still in pretty good shape. The right side of the pipe had no fills or real damage. It was a nice birdseye under the grime. The left side had two fills of pink putty in the midst of some very nice grain. The grain on the rest of the bowl was a mix of cross grain and swirling grain. The finish was worn with some paint marks on the top of the shank. The stem was oxidized and had been broken with a large chunk missing at the button on the right side. The shank was cracked but the joint with the stem was smooth and tight. The tenon fit snug in the mortise with no gap in the junction. The shank and airway were dirty and tarry.

I have included the photo below as it clearly shows the crack in the shank, the broken stem and the stamping on the shank of the pipe.

I debated whether to cut off the stem or to just restem the pipe with a Canadian stem. I looked at it with a small stem and then with this stem and decided to cut off the stem. I used a Dremel and a sanding drum to remove the broken part of the stem and even out the line of the end of the stem.

I took it back to the work table and reamed the bowl with a PipNet reamer. I reamed the cake back to bare briar so that I could work on the damage to the inner edge of the rim.

I took out my box of assorted nickel bands and found one that was the correct diameter and squeezed it until it was an oval. I dripped super glue into the open crack and pressed it together to dry. Then I heated the band with a heat gun and pressed it on to the cracked shank.

I used a folded piece of sandpaper to sand the tenon slightly so that it fit snugly in the shank. The fit of the stem to the band and shank looked good so that part of the job was finished.

I set up the topping board and the 220 grit sandpaper and topped the bowl to remove the damaged rim. I used a folded piece of sandpaper to bevel the inner edge of the rim inward like it had been originally.

I wiped the bowl down with acetone to remove the finish and the spots of white paint that were on the top of the shank. I repeated the wash until the finish was clean and then wiped it down again with isopropyl alcohol.

With work on the bowl at a good stopping point I decided to do some work on the stem. I had to cut a new button and taper the stem toward the new button. There would have to be shaping done as well opening the slot on the end of the stem. I used a rasp to cut the edge on the lip of the button and to sand down the taper of the stem. I used a series of needle files to further shape the button and the taper.

I cleaned up the taper and the button with a sanding board that I picked up at a beauty supply house. It makes the edge clean and works well to even the taper on the stem.

The hole in the end of the new button was elongated and oval but needed to be opened more and made into a “Y” shaped slot whose inner edges tapered toward the airway and the slot shaped like an eye – open enough to take a pipe cleaner without any difficulty. I used three different needle files to open the slot. The first was a round file, followed by an oval file and ending with a flat oval that worked well to cut the edges of the slot.

I sanded the stem with a medium and a fine grit sanding sponge to smooth out the surface on the stem and also to bevel the edge of the button toward the slot.

With the interesting grain pattern and the fills on the side of the bowl I decided to use a dark brown aniline stain. I applied it with a dauber and then flamed it. I applied it and flamed it a second time to make sure the coverage was even.

When the stain was dry I wiped down the bowl and shank with isopropyl alcohol on cotton pads to remove the top coats of the stain and make it more transparent.

I sanded the bowl with a fine grit sanding sponge and then wiped it again with the alcohol to clean off the dust. I gave it a second coat of a medium walnut stain as a top coat.

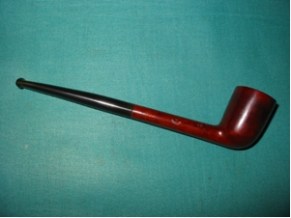

I buffed the top coat of stain with White Diamond and then brought it back to the work table and took the following pictures. The angles on the stem are looking good. The shape of the button and the taper of the stem worked well with the pipe.

I sanded the stem with medium and fine grit sanding pads and then applied some liquid white out to the stamping on the stem to try to make it stand out more clearly. I sanded the stem with my usual array of micromesh sanding pads – wet sanding with 1500-2400 and dry sanding with 3200-12000 grit pads.

I rubbed the stem down with Obsidian Oil and when it was dry buffed the stem and bowl with White Diamond and gave it multiple coats of carnauba wax to protect and preserve it. I finished by buffing it with a soft, flannel buff. The finished pipe is shown in the photos below. The newly shaped stem came out fairly well. I like the overall look of the finish and the band on the pipe. It is ready to join the other Old Pal in the rack.