Blog by Steve Laug

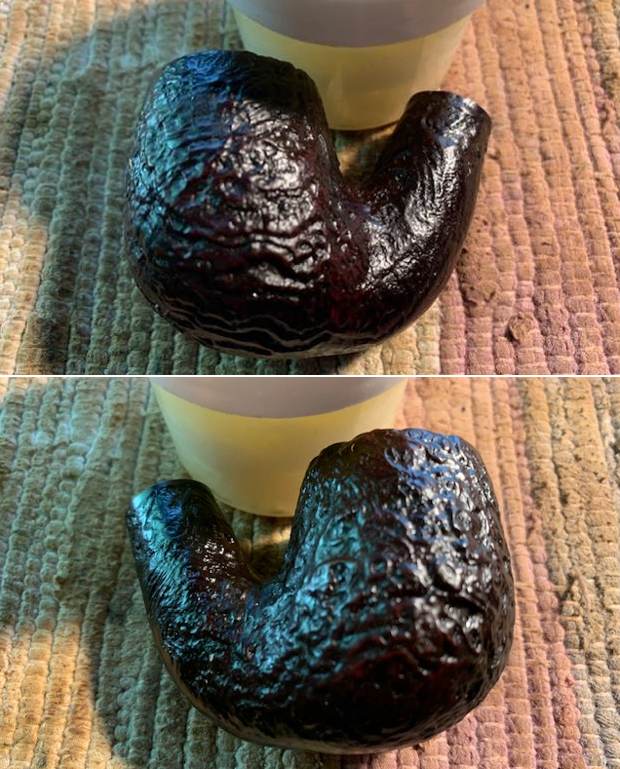

This next pipe is another that has been here for a very long time. I have no idea where I purchased it or whether it came to me in a trade for labour. I don’t remember. I have worked on quite a few of these Comoy’s made The Everyman Pipes over the years and find that they are well made and quite nice. The pipe is stamped on the underside and reads The [over] Everyman [over] London Pipe [over] the shape number 215. That is followed by Made in London [over] England. This particular pipe has a rugged and deep sandblast around the bowl and shank. It has been stained with a dark brown stain. The bowl had been well reamed but there was some lava on the rim top blast. It was slightly out of round with some damage on the back inner edge of the bowl. Internally it smelled like an aromatic tobacco like Half and Half. The stem was oxidized, calcified and had some tooth chatter and marks on the top and underside ahead of the button. I took some photos of the pipe to give a sense of what I saw before I started my clean up work.

I took photos of the rim top and inner edge of the bowl to show the lava coat in the sandblast rim top and some burn damage and darkening on the inner edge of the bowl. The photos of the stem show the oxidation, calcification and the tooth marks and chatter on both sides ahead of the button.

I took photos of the rim top and inner edge of the bowl to show the lava coat in the sandblast rim top and some burn damage and darkening on the inner edge of the bowl. The photos of the stem show the oxidation, calcification and the tooth marks and chatter on both sides ahead of the button.  I took a photo of the stamping on the underside of the shank. It is clear and readable as noted above.

I took a photo of the stamping on the underside of the shank. It is clear and readable as noted above.  I removed the stem from the shank and took a photo of the pipe to give a sense of the proportion.

I removed the stem from the shank and took a photo of the pipe to give a sense of the proportion.  Before starting my cleanup work on the pipe I turned my favourite go to sites on background of brands. The first is Pipephil’s site (http://www.pipephil.eu/logos/en/logo-e4.html). There I looked up The Everyman brand and confirmed what I remembered about it being made by Comoy’s.

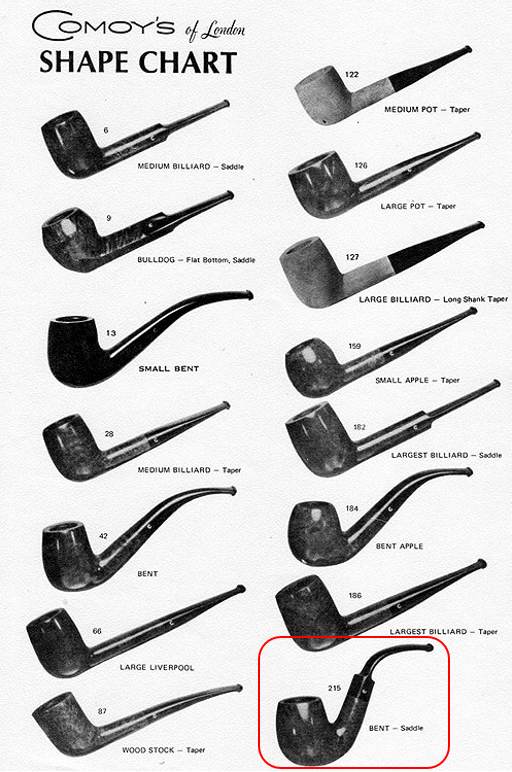

Before starting my cleanup work on the pipe I turned my favourite go to sites on background of brands. The first is Pipephil’s site (http://www.pipephil.eu/logos/en/logo-e4.html). There I looked up The Everyman brand and confirmed what I remembered about it being made by Comoy’s.  From there I turned to Pipedia (https://pipedia.org/wiki/Comoy%27s). I went directly to the section on Comoy’s pipes. At the bottom of the article I found links for a shape list and also a shape chart. I have included both of them below. The shape number 215 is shown as a small ½ Bent Billiard.

From there I turned to Pipedia (https://pipedia.org/wiki/Comoy%27s). I went directly to the section on Comoy’s pipes. At the bottom of the article I found links for a shape list and also a shape chart. I have included both of them below. The shape number 215 is shown as a small ½ Bent Billiard.![]() I have circled the 215 shape in the Comoy’s shape chart below.

I have circled the 215 shape in the Comoy’s shape chart below. Now it was time to work on the pipe. I decided to address the stench in the pipe first so I could work on a clean pipe. The pipe bowl had been reamed and it was quite clean so I turned to clean the mortise and the airway in the shank and stem. I scrubbed the out with pipe cleaners, cotton swabs and Isopropyl 99% alcohol. Many pipe cleaners and much time passed and the draught was clean and open in both the stem and the shank.

Now it was time to work on the pipe. I decided to address the stench in the pipe first so I could work on a clean pipe. The pipe bowl had been reamed and it was quite clean so I turned to clean the mortise and the airway in the shank and stem. I scrubbed the out with pipe cleaners, cotton swabs and Isopropyl 99% alcohol. Many pipe cleaners and much time passed and the draught was clean and open in both the stem and the shank.  With that done I worked on the lava build up on the rim top and the burn damage and darkening on the inner edge of the rim. I worked over the rim top with a brass bristle wire brush and two dental picks to clean out the grooves of the sandblast. I rusticated the sandblasted rim to further rough up the surface and remove the tars. I used a small conical burr to remove the damaged areas and reshape the rim top.

With that done I worked on the lava build up on the rim top and the burn damage and darkening on the inner edge of the rim. I worked over the rim top with a brass bristle wire brush and two dental picks to clean out the grooves of the sandblast. I rusticated the sandblasted rim to further rough up the surface and remove the tars. I used a small conical burr to remove the damaged areas and reshape the rim top.  I used a Walnut Stain pen to stain the rim top rustication to match the other parts of the blasted rim top. I actually looks quite good.

I used a Walnut Stain pen to stain the rim top rustication to match the other parts of the blasted rim top. I actually looks quite good.  I used a folded piece of 220 grit sandpaper to give the edge a light bevel to minimize the damage and bring the bowl back to round.

I used a folded piece of 220 grit sandpaper to give the edge a light bevel to minimize the damage and bring the bowl back to round.  With that part of the work done I decided it was time to address the ghost in pipe with alcohol and cotton bolls. I stuffed the bowl with cotton bolls and twisted one into a plug that I pushed into the shank end. I set the bowl upright in an old ice cube tray and filled it with alcohol using an ear syringe. I set it aside to do its work over night.

With that part of the work done I decided it was time to address the ghost in pipe with alcohol and cotton bolls. I stuffed the bowl with cotton bolls and twisted one into a plug that I pushed into the shank end. I set the bowl upright in an old ice cube tray and filled it with alcohol using an ear syringe. I set it aside to do its work over night.

I worked some Before & After Restoration Balm into finish of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The Restoration Balm really makes the grain stands out beautifully.

I worked some Before & After Restoration Balm into finish of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The Restoration Balm really makes the grain stands out beautifully.

I cleaned the exterior of the stem with some Soft Scrub All Purpose cleanser and cotton pads. I was able to remove a lot of oxidation and calcification from the stem surface.

I cleaned the exterior of the stem with some Soft Scrub All Purpose cleanser and cotton pads. I was able to remove a lot of oxidation and calcification from the stem surface.  I set the bowl aside and turned my attention to the stem. I used the flame of a Bic lighter to “paint” the surface of the stem to lift the tooth marks on both sides of the stem. The heat lifted many of the marks. I filled in what remained with clear CA glue and set it aside to harden.

I set the bowl aside and turned my attention to the stem. I used the flame of a Bic lighter to “paint” the surface of the stem to lift the tooth marks on both sides of the stem. The heat lifted many of the marks. I filled in what remained with clear CA glue and set it aside to harden.

Once the repairs cured on the top and underside of the stem I filed them flat and recut the button edge with a small file. I sanded them with a folded piece of 220 sandpaper. I started polishing the stem with 400 grit wet dry sandpaper.

Once the repairs cured on the top and underside of the stem I filed them flat and recut the button edge with a small file. I sanded them with a folded piece of 220 sandpaper. I started polishing the stem with 400 grit wet dry sandpaper.

I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the stem down after each pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both fine and extra fine and buffed it with a cotton pad. I gave it a final coat of Obsidian Oil and set it aside to dry.

I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the stem down after each pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both fine and extra fine and buffed it with a cotton pad. I gave it a final coat of Obsidian Oil and set it aside to dry.

The Everyman London Pipe 215 Bent Billiard was finished. I polished the bowl and stem with Blue Diamond to polish out the remaining small scratches. I used a very light touch so as not to damage the stamping on the shank. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The depths of the sandblast came alive with the buffing and works well with the polished black vulcanite saddle stem. Altogether the pipe has a rich look. The finished pipe is shown in the photos below. The shape, finish and flow of the pipe and stem are very well done. The dimensions are Length: 5 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.55 ounces/45 grams. I will be putting it on the rebornpipes store in the British Pipemakers Section soon. If you are interested in adding it to your collection let me. I have one of these and they are a cool dry smoke. Thanks for walking through the restoration of this fine old Comoy’s made pipe. It was a pleasure to work on.

The Everyman London Pipe 215 Bent Billiard was finished. I polished the bowl and stem with Blue Diamond to polish out the remaining small scratches. I used a very light touch so as not to damage the stamping on the shank. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The depths of the sandblast came alive with the buffing and works well with the polished black vulcanite saddle stem. Altogether the pipe has a rich look. The finished pipe is shown in the photos below. The shape, finish and flow of the pipe and stem are very well done. The dimensions are Length: 5 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.55 ounces/45 grams. I will be putting it on the rebornpipes store in the British Pipemakers Section soon. If you are interested in adding it to your collection let me. I have one of these and they are a cool dry smoke. Thanks for walking through the restoration of this fine old Comoy’s made pipe. It was a pleasure to work on.