by Steve Laug

I was recently contacted by a fellow here in Vancouver about some pipes he had. He was referred to me by a local pipe shop. I was unclear if he wanted them cleaned or exactly what. When he came on the weekend he brought six pipes in two pipe boxes for me to have a look at. I spoke with him about the cost of restoring them. It finally became clear to me (I guess I am slow) that he wanted to sell the pipes. He was tasked with the job by his sister in law as the pipes were from her late husband’s collection. As I unpacked them it was clear that they were some nice pipes and some were higher grade. All but one was smoked and had the heavy smell of fruity aromatics to them. Some had cake in the bowl and lava on the rim. Of the six, four of them had significant rim damage – bowls out of round, burn marks, cut marks. The saddest part is that the damage was most significant on the higher end pipes. Most of them had tooth marks in the stems. Obviously, they had been his late brother in laws favourites and he had enjoyed them. He left them with me and I went over them, researched the brands and wrote up an offer for him to present to his sister in law. By the end of the day we had a deal. The six pipes now have a new home and the fruity smell needs to be exorcised! I am turning my attention to the fifth of the six pipes I purchased. The bottom right pipe of the six is unsmoked. The last of the five that needed work is just above the unsmoked one. It is another beautiful looking pipe that looks to be Danish Made. It is a straight Brandy stamped on the underside of the shank and reads JULS [over] Freehand. The bowl had beautiful straight grain around sides. The shape is impeccably done. The finish was dirty but otherwise all was good it appeared. The rim top was clean of cake and lava. The inner edge of the bowl was damaged all the way around and was slightly out of round. The bowl had been recently reamed and it was clean. Like the others, there was a pipe cleaner trough from the entrance of the airway into the bowl but much less prominent. It could have been caused by an overzealous reaming that left the bottom damaged. The stem was slightly oxidized and had light tooth marks and chatter on both sides of the stem ahead of the button. The stem had what looked like an Ebony wood inlay toward the shank end of the stem spaced between vulcanite at the tenon and the rest of the blade. The transition between the wood and the vulcanite was not smooth on either end. The JS engraving on the topside of the stem was faded but still readable. It also came with a soft felt pipe sock that had a Johs stamp on it.

I am turning my attention to the fifth of the six pipes I purchased. The bottom right pipe of the six is unsmoked. The last of the five that needed work is just above the unsmoked one. It is another beautiful looking pipe that looks to be Danish Made. It is a straight Brandy stamped on the underside of the shank and reads JULS [over] Freehand. The bowl had beautiful straight grain around sides. The shape is impeccably done. The finish was dirty but otherwise all was good it appeared. The rim top was clean of cake and lava. The inner edge of the bowl was damaged all the way around and was slightly out of round. The bowl had been recently reamed and it was clean. Like the others, there was a pipe cleaner trough from the entrance of the airway into the bowl but much less prominent. It could have been caused by an overzealous reaming that left the bottom damaged. The stem was slightly oxidized and had light tooth marks and chatter on both sides of the stem ahead of the button. The stem had what looked like an Ebony wood inlay toward the shank end of the stem spaced between vulcanite at the tenon and the rest of the blade. The transition between the wood and the vulcanite was not smooth on either end. The JS engraving on the topside of the stem was faded but still readable. It also came with a soft felt pipe sock that had a Johs stamp on it.

I took photos of the bowl and rim top to give you an idea of what I see. Once again it is too bad that Word does now allow for the inclusion of smells because this sweet vanilla is filling my work area. I have a candle going to mask the smell a bit. You can see the damage to the rim top and inner edge of the bowl. The bowl is lightly caked. The stem is lightly oxidized and has light tooth marks and chatter on both sides ahead of the button. There is also a faint stamp on the top of the stamp.

I took photos of the bowl and rim top to give you an idea of what I see. Once again it is too bad that Word does now allow for the inclusion of smells because this sweet vanilla is filling my work area. I have a candle going to mask the smell a bit. You can see the damage to the rim top and inner edge of the bowl. The bowl is lightly caked. The stem is lightly oxidized and has light tooth marks and chatter on both sides ahead of the button. There is also a faint stamp on the top of the stamp. I took a photo of the stamping on the underside of the shank. It is faint but readable with a lens as noted above. The stamp on the top of the stem is a JS etched on the top by hand. I took a photo of the bowl with the stem removed to give a sense of the proportion and appearance of the pipe.

I took a photo of the stamping on the underside of the shank. It is faint but readable with a lens as noted above. The stamp on the top of the stem is a JS etched on the top by hand. I took a photo of the bowl with the stem removed to give a sense of the proportion and appearance of the pipe.

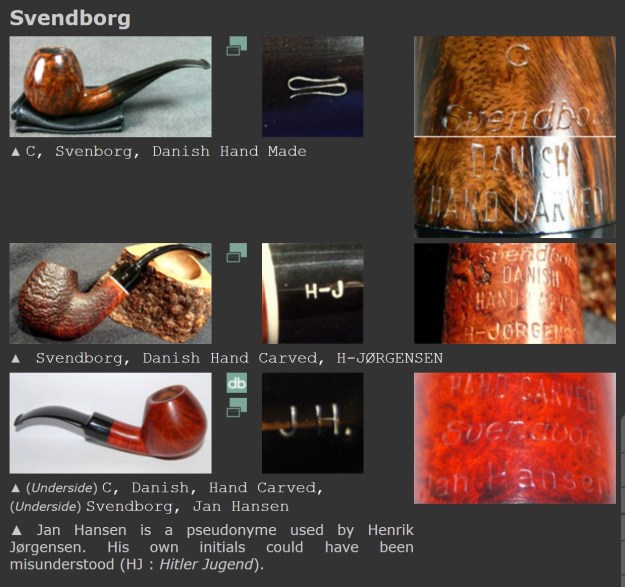

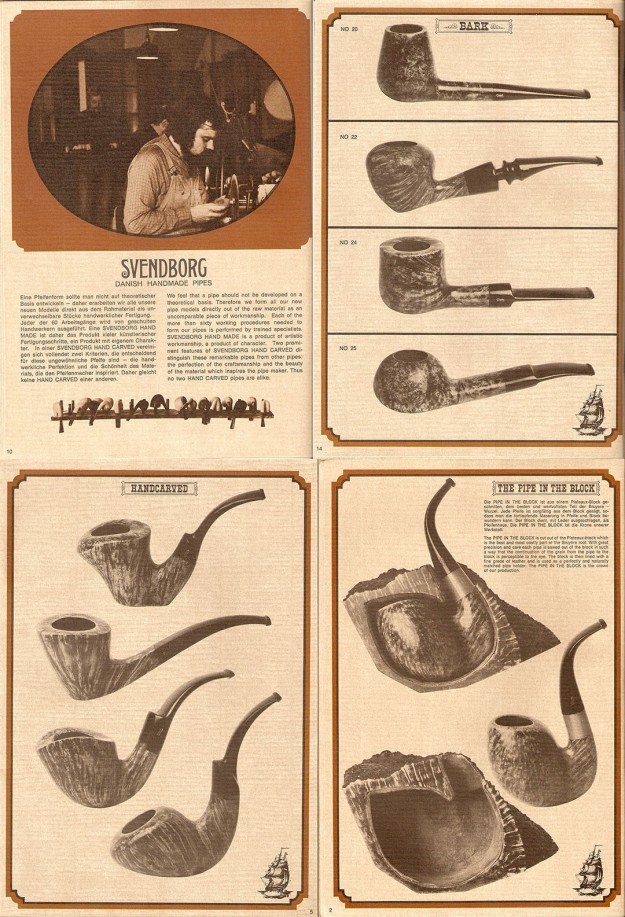

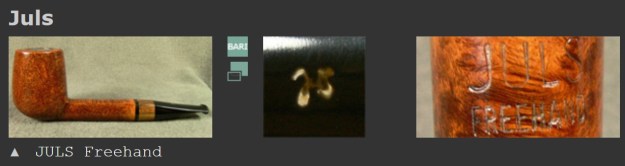

To help me understand the stamping a bit more I turned to Pipephil’s site and read what it said about Svendborg Hand Carved pipes (http://pipephil.eu/logos/en/logo-j4.html). I have included a screen capture of the section below as well as the side bar information below the capture.

To help me understand the stamping a bit more I turned to Pipephil’s site and read what it said about Svendborg Hand Carved pipes (http://pipephil.eu/logos/en/logo-j4.html). I have included a screen capture of the section below as well as the side bar information below the capture.  Artisan: Julian Schäffer. He began carving pipes in 1982 and almost stopped the job in the early 90s. His 2001 collection brought 14 high grade pipes together.

Artisan: Julian Schäffer. He began carving pipes in 1982 and almost stopped the job in the early 90s. His 2001 collection brought 14 high grade pipes together.

From the information I found that the pipe was carved by Julian Schäffer during the 8 years that he carved pipes – 1982-1990. He was known to carve high grade pipes.

Next, I turned to Pipedia for more information and detail (https://pipedia.org/wiki/Juls). I find that the articles there often fill in some more information on the relationships and history of a given brand. In this case I found that also true. The article is very brief and quotes Pipes, Artisans and Trademarks, by José Manuel Lopes I quote it in full below.

JULS pipes are by the German artisan Julian Schäffer, who began carving pipes in 1982, and worked with Former and Rainer Barbi. Influenced by Danish design, his pieces are both with and without 9mm filters, and have ebonite stems. They are collectors’ items today. The brand ran from 1982 to the beginning of the 1990s, when Julian ceased production, and moved on to other activities. Stamp: JULS

I turned to Google and found several listings for JULS pipes that were selling on the estate portion of smokingpipes.com. There was a brief description of a Billiard for sale there that gave more information as well that was further confirmation concerning the brand. Here is the link (https://www.smokingpipes.com/pipes/estate/germany/moreinfo.cfm?product_id=612079). I quote:

Crafted by German artisan Julian Schäffer, Juls pipes were heavily influenced by Danish design sensibilities, with Schäffer having worked with carvers such as Former and Rainer Barbi. Juls pipes began production in 1982, with Schäffer ending his production around the early 1990s. This Billiard from the German carver illustrates his deft understanding of Danish design, its composition replete with soft, sleek line work. The bowl stands tall with an upright posture, formed by smooth, supple walls rising high from the rounded heel toward the flat rim. From a defined transition, a sturdy shank emerges from the bowl, punctuated by a broad accent of dark wood at the shank end as its meets a slender stem with a trim expansion ring at its base. A warm, hazelnut stain dresses the stummel, showcasing whorls of birdseye across the bowl’s left flank. – Joshua Carroll

Now I knew that the carver was Julian Schaffer and that his pipes had an obvious Danish design look to them. He had trained with Hans Former and Rainier Barbi in Germany, both who were master carvers. I also knew that the pipe was made in the short period between 1982-1990 when he stopped carving.

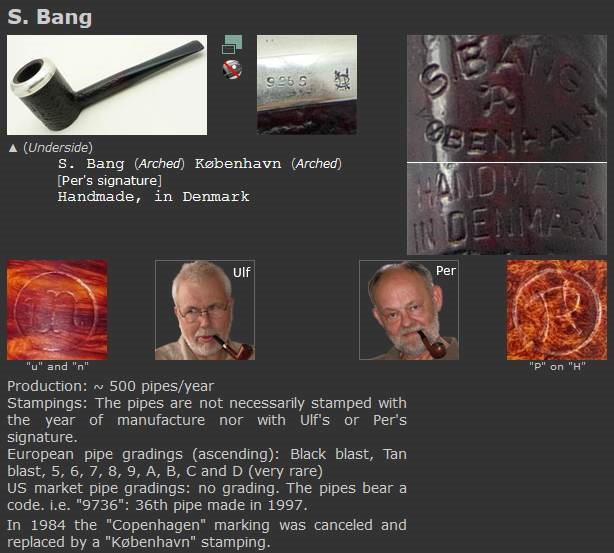

I reamed the bowl with a Savinelli Fitsall Pipe Knife to take back the cake to bare briar. I sanded the walls smooth with some 220 grit sandpaper wrapped around a piece of dowel. I have to say that I was spooked by what I found on the S. Bang Brandy I just finished. I ran my fingers over the sides of the bowl and gladly they were smooth. As mentioned above the bottom of the bowl showed a trough carved in the bottom of the bowl. It was certainly not as deep as the other two pipes but appeared to be carved by zealous use of pipe cleaners. I was able to ream out the ridge with the Pipe Knife. It looked much better. I took a photo of it as best as I could but it is hard to see. I sanded the walls with a piece of 220 grit sandpaper wrapped around a dowel. It was smooth to touch. I cleaned out the stinky, fruity smelling tobacco oils and tars in the shank and the airway in the stem. I used 99% isopropyl alcohol, cotton swabs and pipe cleaners and was able to remove the debris and some of the stench.

I cleaned out the stinky, fruity smelling tobacco oils and tars in the shank and the airway in the stem. I used 99% isopropyl alcohol, cotton swabs and pipe cleaners and was able to remove the debris and some of the stench.  I needed to “deghost” the bowl and try to exorcise the smell. I stuffed bowl with cotton bolls and used an ear syringe to fill it with alcohol. I set it aside to let the alcohol do its work and wick the oils into the cotton. While it sat for the afternoon, I did some other work. The next morning when I came back to it the cotton and alcohol had wicked out the oils and tars. The cotton was brown and the bowl smelled much better.

I needed to “deghost” the bowl and try to exorcise the smell. I stuffed bowl with cotton bolls and used an ear syringe to fill it with alcohol. I set it aside to let the alcohol do its work and wick the oils into the cotton. While it sat for the afternoon, I did some other work. The next morning when I came back to it the cotton and alcohol had wicked out the oils and tars. The cotton was brown and the bowl smelled much better.

The damages demanded some restoration and repair. I started with the rough inner edge of the rim. I used a folded piece of 220 grit sandpaper to minimize the damage on the inner edge of the rim and smooth it a bit. I was careful to not change the profile of the rim top and edges.

The damages demanded some restoration and repair. I started with the rough inner edge of the rim. I used a folded piece of 220 grit sandpaper to minimize the damage on the inner edge of the rim and smooth it a bit. I was careful to not change the profile of the rim top and edges.  I mixed up a batch of bowl coating – sour cream and activated charcoal powder to give a top coat on the bottom of the bowl and the walls to facilitate the build up of a cake in the bowl. I applied it to the bowl with a folded pipe cleaner and painted it on the sides and pressed it into the trough marks on the bottom. Once finished I set it aside to cure. I love this recipe for a bowl coating as it leaves no residual taste once the coating cures. It is black and provides perfect protection.

I mixed up a batch of bowl coating – sour cream and activated charcoal powder to give a top coat on the bottom of the bowl and the walls to facilitate the build up of a cake in the bowl. I applied it to the bowl with a folded pipe cleaner and painted it on the sides and pressed it into the trough marks on the bottom. Once finished I set it aside to cure. I love this recipe for a bowl coating as it leaves no residual taste once the coating cures. It is black and provides perfect protection.

I rubbed the exterior of the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The Balm did its magic and the grain stood out.

I rubbed the exterior of the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The Balm did its magic and the grain stood out.

I set aside the bowl and turned my attention to the stem. I touched up the J.S. Logo stamp on the topside of the taper stem with Rub’n Buff Antique Gold. I robbed it into the stamping with a tooth pick. Once it had cured I buffed it off with a cotton cloth then wiped it down with some Obsidian Oil. It looked very good.

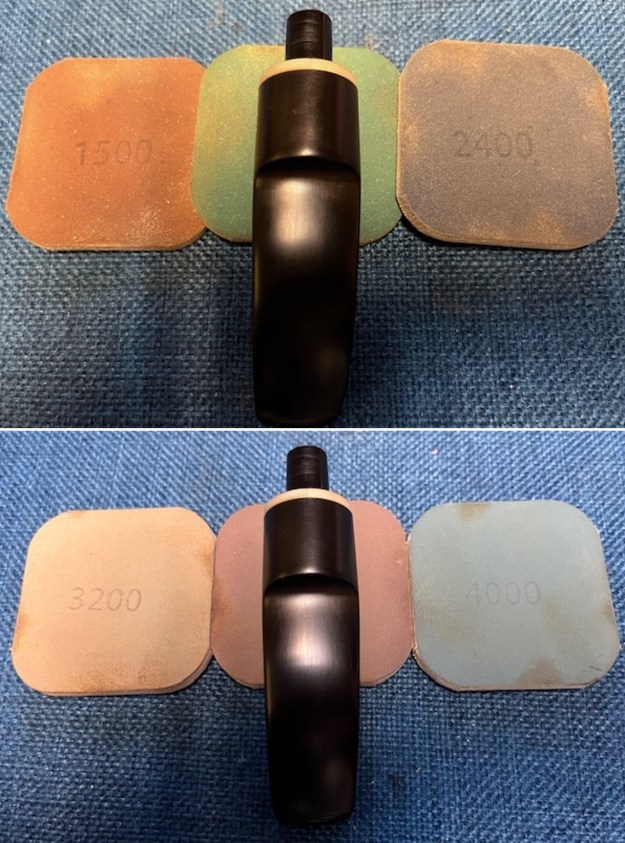

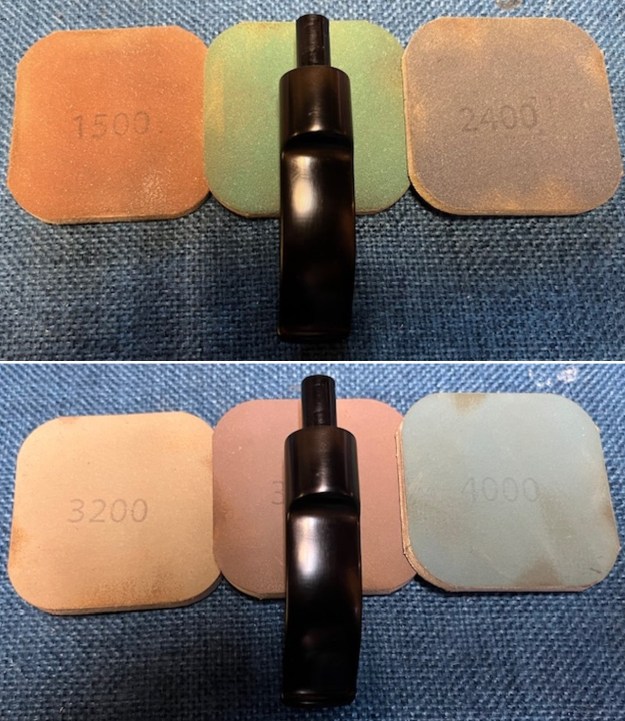

I set aside the bowl and turned my attention to the stem. I touched up the J.S. Logo stamp on the topside of the taper stem with Rub’n Buff Antique Gold. I robbed it into the stamping with a tooth pick. Once it had cured I buffed it off with a cotton cloth then wiped it down with some Obsidian Oil. It looked very good. The transitions between the ebony and the vulcanite had a slight ridge and the bite marks and chatter were not too deep. I was able to smooth out the transitions between the ebony inset and the vulcanite and the tooth chatter and remove the light oxidation with 320-3500 grit sanding pads. I wiped the stem down after each pad with an Obsidian Oil cloth. It was beginning to look very good.

The transitions between the ebony and the vulcanite had a slight ridge and the bite marks and chatter were not too deep. I was able to smooth out the transitions between the ebony inset and the vulcanite and the tooth chatter and remove the light oxidation with 320-3500 grit sanding pads. I wiped the stem down after each pad with an Obsidian Oil cloth. It was beginning to look very good. I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I put the cleaned and restored Julian Schäffer JULS Freehand Straight Brandy and its vulcanite taper stem with a Ebony Insert back together. The rich browns and blacks of the contrasting stain makes the grain come alive with the polishing and waxing. I carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Julian Schäffer JULS Freehand Straight Brandy really is a beauty and fits nicely in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 ½ inches, Height: 2 ½ inches, Outside diameter of the bowl: 1 ¼ inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 2.79 ounces/79 grams. This pipe will soon be on the Pipes From Various Makers Section of the rebornpipes store if you would like to add it to your collection. Send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it.

I put the cleaned and restored Julian Schäffer JULS Freehand Straight Brandy and its vulcanite taper stem with a Ebony Insert back together. The rich browns and blacks of the contrasting stain makes the grain come alive with the polishing and waxing. I carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Julian Schäffer JULS Freehand Straight Brandy really is a beauty and fits nicely in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 ½ inches, Height: 2 ½ inches, Outside diameter of the bowl: 1 ¼ inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 2.79 ounces/79 grams. This pipe will soon be on the Pipes From Various Makers Section of the rebornpipes store if you would like to add it to your collection. Send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it.