Blog by Steve Laug

The next pipe on the work table is a pipe I traded for in a recent Boxpass here in Canada. A Boxpass is made up of samples as well as tins of tobacco that are sent around to various pipe folk to sample, take out and put back tins of tobacco or pipes. It is a great way to try tobaccos you have not had as well as to trade pipes that you want to pass on to others and take out one that you want to try out. This particular pipe came to the box from Eric who say it is a great smoking pipe that his pipe mentor picked up from John Calich himself. This one is a bent Freehand shaped pipe. It has some nice mixed grain around the bowl and shank with a vulcanite stem. It was stamped on the left side of the shank and reads Calich [over] Second followed by the number 7. The rim top is smooth and the shank end is also smooth with a patch of plateau on the right surface of the shank end. The finish was clean but was a flaw on the top back edge of the bowl on the right. There was a light cake in the bowl and some darkening and lava around the inner edge. The fancy turned vulcanite stem lightly oxidized and there was some deep tooth marks and chatter ahead of the button on both sides.

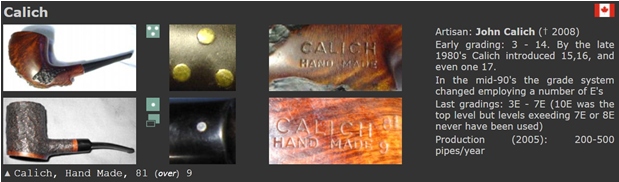

Before I started working on it I did a bit of reading about the brand to remind myself of what I knew of the maker. I turned to Pipephil’s site first (http://www.pipephil.eu/logos/en/logo-c1.html). I did a screen capture of the information on the site. I did a screen capture of the pertinent information and have included it below.  I quote the side bar: Artisan: John Calich († 2008) Early grading: 3 – 14. By the late 1980’s Calich introduced 15,16, and even one 17. In the mid-90’s the grade system changed employing a number of E’s. Last gradings: 3E – 7E (10E was the top level but levels exeeding 7E or 8E never have been used) Production (2005): 200-500 pipes/year

I quote the side bar: Artisan: John Calich († 2008) Early grading: 3 – 14. By the late 1980’s Calich introduced 15,16, and even one 17. In the mid-90’s the grade system changed employing a number of E’s. Last gradings: 3E – 7E (10E was the top level but levels exeeding 7E or 8E never have been used) Production (2005): 200-500 pipes/year

I then turned to Pipedia and read the article on the Calich brand to remind myself of the maker (https://pipedia.org/wiki/Calich). I have included it in full below.

John Calich was one of Canada’s finest carvers. He died in July 2008.

John was a full time pipe maker for the last 40 years. Calich pipes were mostly traditional shapes. His signature style is rustication and smooth on the same pipe along with his unique skill to stain a pipe in contrasting colors. He used only top quality Grecian and Calabrian briar. The mouthpieces are hand finished Vulcanite “A”. Each pipe was entirely made by hand. John Calich was featured in the summer 2005 issue of Pipes & Tobacco.

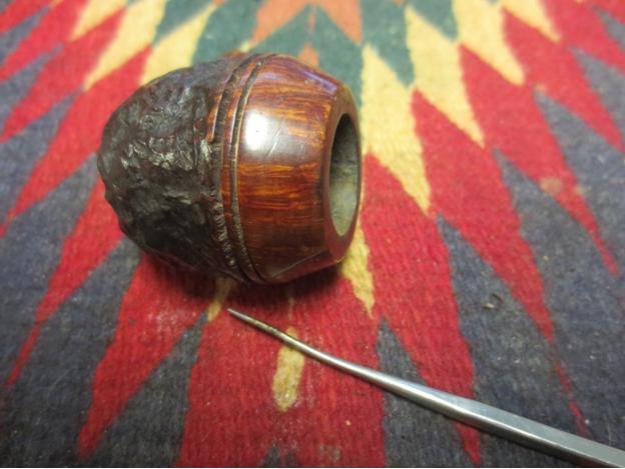

I have always appreciated John’s pipes and have quite a few in my collection. This is the first Second that I have seen and it comes with the story attached from Eric. Now it was time to clean up this pipe and get it restored. I cleaned the pipe with the methodology that Jeff and I have developed. The pipe was in decent condition when I took it out of my box so the cleanup would be straight forward. I took some photos of the pipe before I started my work on it. You can see that it is classic shaped bent billiard with a mix of grain around the bowl. The finish was surprisingly clean and quite pretty.

I took some close up photos of the rim top and the stem surface. I wanted to show the condition of the cake in the bowl and look of the rim top. I also took close up photos of the stem to show the deep tooth marks, light oxidation and general condition of the stem surface. There were deep tooth marks on the top and under side of the stem near the button.

I took some close up photos of the rim top and the stem surface. I wanted to show the condition of the cake in the bowl and look of the rim top. I also took close up photos of the stem to show the deep tooth marks, light oxidation and general condition of the stem surface. There were deep tooth marks on the top and under side of the stem near the button.  I took a photo of the stamping on the side of the shank. It is readable as noted above.

I took a photo of the stamping on the side of the shank. It is readable as noted above.  I removed the stem for the shank and took a photo of the bowl and stem to give a picture of what it looked like.

I removed the stem for the shank and took a photo of the bowl and stem to give a picture of what it looked like.  I reamed the bowl to deal with a light buildup of cake around the bottom third of the bowl. The rest of the bowl was quite clean. I chose to use a Savinelli Fitsall Pipe Knife. I sanded the inside of the bowl with 220 grit sandpaper wrapped around a piece of dowel. Once I finished the bowl was smooth and clean.

I reamed the bowl to deal with a light buildup of cake around the bottom third of the bowl. The rest of the bowl was quite clean. I chose to use a Savinelli Fitsall Pipe Knife. I sanded the inside of the bowl with 220 grit sandpaper wrapped around a piece of dowel. Once I finished the bowl was smooth and clean.  I scrubbed out the internals of the shank and the airway in the stem with alcohol, pipe cleaners and cotton swabs until the pipe was clean.

I scrubbed out the internals of the shank and the airway in the stem with alcohol, pipe cleaners and cotton swabs until the pipe was clean.  The flaw on the right rear top edge needed to be dealt with. This is probably what made the pipe a second. It was not deep but it was bothersome to my touch as I held the bowl. I filled in the flaw with clear super glue. Once the repair cured is sanded it with 220 grit sandpaper to blend it into the surrounding surface.

The flaw on the right rear top edge needed to be dealt with. This is probably what made the pipe a second. It was not deep but it was bothersome to my touch as I held the bowl. I filled in the flaw with clear super glue. Once the repair cured is sanded it with 220 grit sandpaper to blend it into the surrounding surface.

There was some darkening and nicks on the inner edge of the rim and the rim top. I used a folded to piece of 220 grit sandpaper to give it a slight bevel and smooth out the damage.

There was some darkening and nicks on the inner edge of the rim and the rim top. I used a folded to piece of 220 grit sandpaper to give it a slight bevel and smooth out the damage.  I scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime on the briar. The finish looks very good with good looking grain around the bowl and shank. Once it is polished it will come to life.

I scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime on the briar. The finish looks very good with good looking grain around the bowl and shank. Once it is polished it will come to life.

I polished the briar with micromesh sanding pads – wet sanding it with 1500-12000 grit sanding pads. I wiped the bowl off after each pad with a damp cloth.

I polished the briar with micromesh sanding pads – wet sanding it with 1500-12000 grit sanding pads. I wiped the bowl off after each pad with a damp cloth.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth and shoe brush to raise the shine.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth and shoe brush to raise the shine.

I set the bowl aside and turned my attention to the stem. I filled in the tooth dents next to the button on both sides of the stem with Black Super Glue and set the stem aside to let the glue cure.

I set the bowl aside and turned my attention to the stem. I filled in the tooth dents next to the button on both sides of the stem with Black Super Glue and set the stem aside to let the glue cure.  I sanded the stem surface with 220 grit sandpaper to blend in the repairs and remove the light oxidation and to blend the repairs into the surface of the stem. I started the polishing with 400 grit wet dry sandpaper.

I sanded the stem surface with 220 grit sandpaper to blend in the repairs and remove the light oxidation and to blend the repairs into the surface of the stem. I started the polishing with 400 grit wet dry sandpaper.  I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad.

I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad.

This restored Calich Second 7 turned out to be a nice looking pipe. The rich medium brown stain on the pipe worked really well with the polished vulcanite fancy stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and stem multiple coats of carnauba wax on the buffing wheel keeping a light touch on the buffing wheel for the bowl. I followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Calich Bent Freehand is shaped to sit comfortably in the hand. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. Now that it is cleaned up it is time to load it up and enjoy a bowl. Thanks for reading this blog and my reflections on the pipe while I worked on it.

This restored Calich Second 7 turned out to be a nice looking pipe. The rich medium brown stain on the pipe worked really well with the polished vulcanite fancy stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and stem multiple coats of carnauba wax on the buffing wheel keeping a light touch on the buffing wheel for the bowl. I followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Calich Bent Freehand is shaped to sit comfortably in the hand. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. Now that it is cleaned up it is time to load it up and enjoy a bowl. Thanks for reading this blog and my reflections on the pipe while I worked on it.