Blog by Steve Laug

The next pipe on the work table is one that a fellow sent me from England (I have since found out that he is in Scotland not England). He had written to me earlier this week about an old pipe that he had that needed some work. Here is his first email.

Hello. I have an old pipe I would like restored. Its not something I feel I could do myself. I was wondering if you provide a restoration service, and if so how I would go about sending you the pipe to work on. – Leo

I replied to him as follows:

Hello Leo, I do restoration but I am located on the west coast of Canada. Send photos of the pipe so I can have a look and we will go from there. Thanks. – Steve

He did not waste anytime and sent me an email with the first three pictures below. It is an interesting looking long, oval shank, sandblast Dublin with a vulcanite saddle stem.

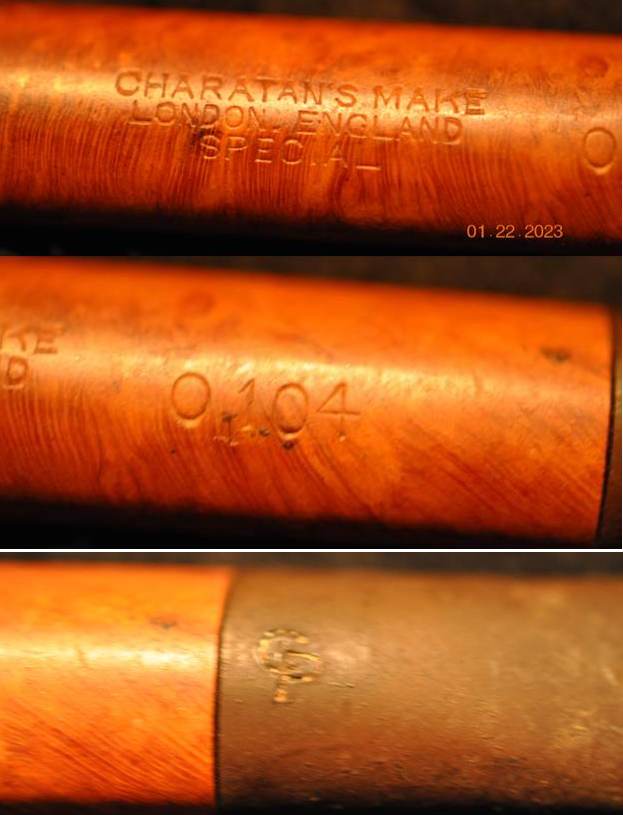

After viewing the photos and emailing back and forth with Leo about the pipe I asked him to mail it to me so I could work on it. It is an interesting sandblast, long oval shank Dublin. The bowl had a thick cake inside and a lot of lava overflow on the rim top. The finish is quite dirty with a lot of grime in the sandblast valleys. It was worn on the left side of the bowl and dark finish was light there. The photo of the underside of the shank shows scratches and marks on the surface that had all but eliminated the stamping. There is a shape number at the stem/shank junction that reads 015. Below that it is stamped Made in France. The stem is dirty with oxidation, calcification and deep scratches and marks on both sides. There are tooth marks ahead of the button on both sides that are quite deep. There is a brass square on the top of the saddle that has an L in it. There are no other identifying marks on the pipe. It will be fun identifying it and the brass L square will tell me a lot. It is a uniquely shaped pipe that I really like the looks of and I think that once it is cleaned up it will be a real beauty.

After viewing the photos and emailing back and forth with Leo about the pipe I asked him to mail it to me so I could work on it. It is an interesting sandblast, long oval shank Dublin. The bowl had a thick cake inside and a lot of lava overflow on the rim top. The finish is quite dirty with a lot of grime in the sandblast valleys. It was worn on the left side of the bowl and dark finish was light there. The photo of the underside of the shank shows scratches and marks on the surface that had all but eliminated the stamping. There is a shape number at the stem/shank junction that reads 015. Below that it is stamped Made in France. The stem is dirty with oxidation, calcification and deep scratches and marks on both sides. There are tooth marks ahead of the button on both sides that are quite deep. There is a brass square on the top of the saddle that has an L in it. There are no other identifying marks on the pipe. It will be fun identifying it and the brass L square will tell me a lot. It is a uniquely shaped pipe that I really like the looks of and I think that once it is cleaned up it will be a real beauty.

The pipe arrived this week while I was travelling. I took photos of the pipe once I brought it to the work table. I always include the pre-clean up photos to confirm what I saw in the photos that were sent to me. In this case the condition matched what I saw in the photos. The pipe was a real mess and would take some work to clean up and restore.

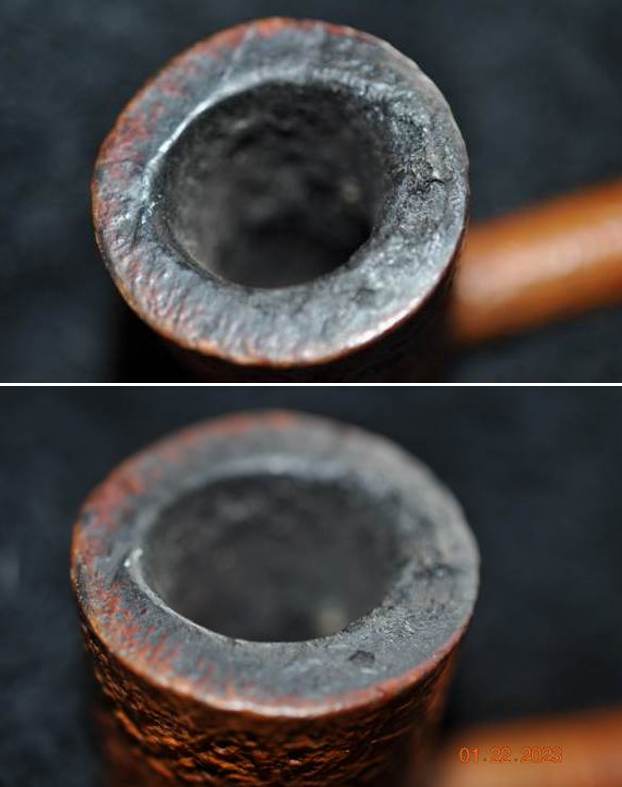

I took photos of the bowl and rim top as well as the stem. The rim top shows the thick lava coat on the top and the inner edge of the bowl. It is heavier on the back side than the front. You can also the lava fill on the rim top almost completely hiding the rustication. You can see the oxidation around the stem sides, the scratches on the surface and the deep tooth marks and chatter on both sides ahead of the button.

I took photos of the bowl and rim top as well as the stem. The rim top shows the thick lava coat on the top and the inner edge of the bowl. It is heavier on the back side than the front. You can also the lava fill on the rim top almost completely hiding the rustication. You can see the oxidation around the stem sides, the scratches on the surface and the deep tooth marks and chatter on both sides ahead of the button. I took a photo of the stamping on the underside of the shank. It reads as noted above. The hash marks and scratching on the smooth surface have obliterated the stamping and it is unreadable. The shape number 015 and the Made in France stamping is still readable at the shank/stem junction. The pipe is quite nice with the stem removed. You can see the flow of the design and the look of the parts.

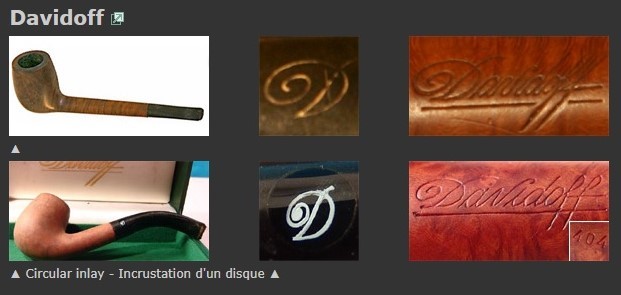

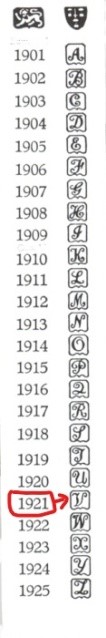

I took a photo of the stamping on the underside of the shank. It reads as noted above. The hash marks and scratching on the smooth surface have obliterated the stamping and it is unreadable. The shape number 015 and the Made in France stamping is still readable at the shank/stem junction. The pipe is quite nice with the stem removed. You can see the flow of the design and the look of the parts. Before I started my cleanup work on the pipe I decide to do a bit of digging on the brass square L logo on the stem. I scrolled through all of the pipe brands that started with an”L” on Pipephil until I came across the listing for Loewe pipes (http://www.pipephil.eu/logos/en/logo-l5.html). The third pipe down in the screen capture below has the same logo on the stem as the one I am working on. Now I knew that the pipe was a Loewe and that it was a French Made one at that. I have included the screen capture of the section below.

Before I started my cleanup work on the pipe I decide to do a bit of digging on the brass square L logo on the stem. I scrolled through all of the pipe brands that started with an”L” on Pipephil until I came across the listing for Loewe pipes (http://www.pipephil.eu/logos/en/logo-l5.html). The third pipe down in the screen capture below has the same logo on the stem as the one I am working on. Now I knew that the pipe was a Loewe and that it was a French Made one at that. I have included the screen capture of the section below. I then turned to the article on Loewe pipes on Pipedia for more information and to see if I could find anything on the French made Loewe pipes (https://pipedia.org/wiki/Loewe_%26_Co.). There was a passing note in the article in the fourth paragraph that I have marked in red. It states that French Loewes appeared in the early 1980s and are a sign that the pipes were made in more than one location before the Cadogan Era.

I then turned to the article on Loewe pipes on Pipedia for more information and to see if I could find anything on the French made Loewe pipes (https://pipedia.org/wiki/Loewe_%26_Co.). There was a passing note in the article in the fourth paragraph that I have marked in red. It states that French Loewes appeared in the early 1980s and are a sign that the pipes were made in more than one location before the Cadogan Era.

Loewe is one of the haunting old names of British pipe-making, characteristic of an almost vanished “upper middle class” of the trade, which also incorporated makes such as BBB, Orlik, Comoy’s and GBD. Along with these brands, Loewe has long dwindled into pseudo-existence, becoming little more than a logo occasionally used by the Cadogan factory in Southend-on-Sea. But owners of older Loewes treasure them as superb, featherweight smokers, excellently crafted and with grain characteristics superior to those of many contemporary Dunhills.

The Frenchman Emil Loewe founded the company, both shop and workshop, in 1856 at the Haymarket 62, London. He is said to have been the first to make briar pipes in England. Richard Hacker maintains that theatre people from the West End were among the shop’s heyday aficionados. Loewe’s spigots are especially well regarded by lovers of elegance today – they were originally introduced for practical reasons, to facilitate the production of replacement stems for customers abroad.

The firm and its facilities were later taken over by Civic, well before becoming a fully integrated part of the Cadogan group sometime in the final quarter of the twentieth century. As with other brands belonging to this group, it is not easy to pinpoint a date marking the end of Loewe’s independence and singularity. This is partly due to Cadogan’s own development from a cooperative to a monolithic entity.

In 1979, a German paperback said that the Loewe brand had been discontinued two years previously, but that the pipes themselves were due to reappear as high-end GBDs. Interestingly, the year of publication coincided with the year in which the Loewe trademark became Cadogan’s, who by this time already owned GBD. From today’s point of view, the author appears to have been working on confused, but partly true information. If there were ever really plans to fully amalgamate the two lines, they were dropped. Also, a two-year break at this time seems impossible, since we have hallmark evidence of Loewes made in 1978 and 1979. However, there are firm indications that Loewe shapes were later marketed as Comoy’s (another Cadogan brand). There may also have been a phase of dissolution regarding location. The reported appearance of French Loewes in the early 1980s is a sign that Loewes were being produced in more than one place at some stage before the Cadogan-era proper.

From what I can gather, Cadogan’s various brands continued to be made in separate facilities throughout the1970s. It was the purchase of Orlik in 1980 that enabled the Cadogan group to consolidate all manufacturing in that company’s new factory in Southend-on-Sea. Whether or not this transferral was a gradual process and when it affected Loewe is unclear. We hear that, as a company, Loewe was not formally wound up by Cadogan (the successor to Civic) until the late 1980s. Of course, today’s ‘Loewes’ are definitely made in Southend – though, according to Cadogan, the trademark is no longer used very much.

Now I knew for certain that I was working on a French made Loewe & Company pipe and that it was made in the early 1980s. Now it was time to work on the pipe.

I started my work on this pipe by reaming the bowl. I started with a PipNet reamer to clean out the cake in the bowl. I cleaned up the remnants of the cake with a Savinelli Fitsall Pipe Knife. I finished by sanding the walls of the bowl with 220 grit sandpaper wrapped around a piece of dowel to smooth out the interior of the bowl.

I cleaned out the internals of the bowl, shank and the airway in the stem. I started the clean up by scraping the shank with a pen knife to remove the tars that lined the shank. I cleaned out the mortise and airways with alcohol, cotton swabs and pipe cleaners until they were clean.

I cleaned out the internals of the bowl, shank and the airway in the stem. I started the clean up by scraping the shank with a pen knife to remove the tars that lined the shank. I cleaned out the mortise and airways with alcohol, cotton swabs and pipe cleaners until they were clean.

I scrubbed the exterior of the bowl with undiluted Murphy’s Oil Soap and a tooth brush. I worked on the bowl and rim top as well as the inner and outer edges of the bowl. The exterior of the bowl and shank cleaned up really well. I rinsed it with warm water to remove the soap and the grime from the briar. I dried it off with a cotton towel. I took photos of the bowl at this point in the process. The rim top still showed a lot of build up filling in the blast valleys. I would need to used other tools to clean that up.

I scrubbed the exterior of the bowl with undiluted Murphy’s Oil Soap and a tooth brush. I worked on the bowl and rim top as well as the inner and outer edges of the bowl. The exterior of the bowl and shank cleaned up really well. I rinsed it with warm water to remove the soap and the grime from the briar. I dried it off with a cotton towel. I took photos of the bowl at this point in the process. The rim top still showed a lot of build up filling in the blast valleys. I would need to used other tools to clean that up.

I used a dental pick to scrape out the lava deep in the sand blast. It took some detailed picked to remove it. I followed up on that with a brass bristle wire brush to further clean up the surface of the rim top. I worked over the bevelled inner edge with a folded piece of 220 grit sandpaper to smooth out the damage on the inner edge. It certainly looks much better at this point.

I used a dental pick to scrape out the lava deep in the sand blast. It took some detailed picked to remove it. I followed up on that with a brass bristle wire brush to further clean up the surface of the rim top. I worked over the bevelled inner edge with a folded piece of 220 grit sandpaper to smooth out the damage on the inner edge. It certainly looks much better at this point.  I used a walnut and a black stain pen to touch up the worn spots on the bowl side and the rim top sanded areas. It looked much better at this point.

I used a walnut and a black stain pen to touch up the worn spots on the bowl side and the rim top sanded areas. It looked much better at this point. I sanded out the scratches in the flat bottom of the shank. They were several and they were quite deep. I used a folded piece of 220 grit sandpaper to smooth the majority of them out. When finished the pipe looked better.

I sanded out the scratches in the flat bottom of the shank. They were several and they were quite deep. I used a folded piece of 220 grit sandpaper to smooth the majority of them out. When finished the pipe looked better. I rubbed down the bowl and shank with Before & After Restoration Balm. It is a paste/balm that is rubbed into the surface of the briar. The product works to deep clean the finish, enliven and protect the briar. I worked it into the briar with my finger tips. I let it sit for 10 minutes then wiped it off with a soft cloth then buffed it with a cotton cloth. The briar really began to have a deep shine and the grain shines through. The photos I took of the bowl at this point mark the progress in the restoration. It is a gorgeous pipe.

I rubbed down the bowl and shank with Before & After Restoration Balm. It is a paste/balm that is rubbed into the surface of the briar. The product works to deep clean the finish, enliven and protect the briar. I worked it into the briar with my finger tips. I let it sit for 10 minutes then wiped it off with a soft cloth then buffed it with a cotton cloth. The briar really began to have a deep shine and the grain shines through. The photos I took of the bowl at this point mark the progress in the restoration. It is a gorgeous pipe.

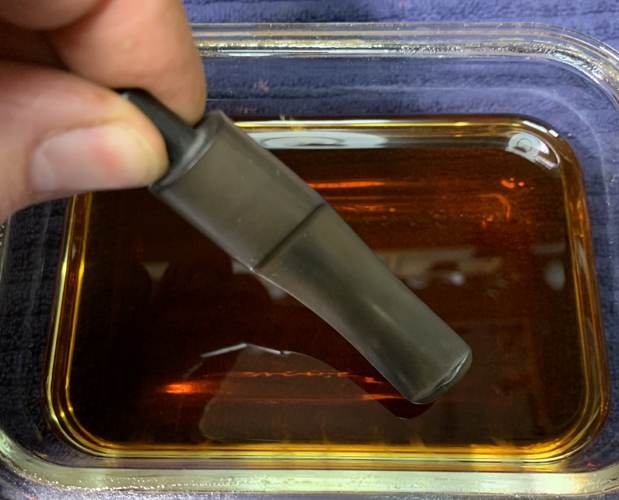

I set the bowl aside and turned to the stem. It was in rough condition with the gummy tape on the end fitting into the shank and deep tooth marks. I painted the surface of the stem with the flame of a Bic lighter to try and lift them. I lifted them but they were still distinctly present. I filled in the marks with Black CA glue and set it aside to cure. Once cured I flattened the repair with a file and then followed that up with a piece of 220 grit sandpaper and started the polishing with 600 grit wet dry sandpaper. It looked much better.

I set the bowl aside and turned to the stem. It was in rough condition with the gummy tape on the end fitting into the shank and deep tooth marks. I painted the surface of the stem with the flame of a Bic lighter to try and lift them. I lifted them but they were still distinctly present. I filled in the marks with Black CA glue and set it aside to cure. Once cured I flattened the repair with a file and then followed that up with a piece of 220 grit sandpaper and started the polishing with 600 grit wet dry sandpaper. It looked much better.

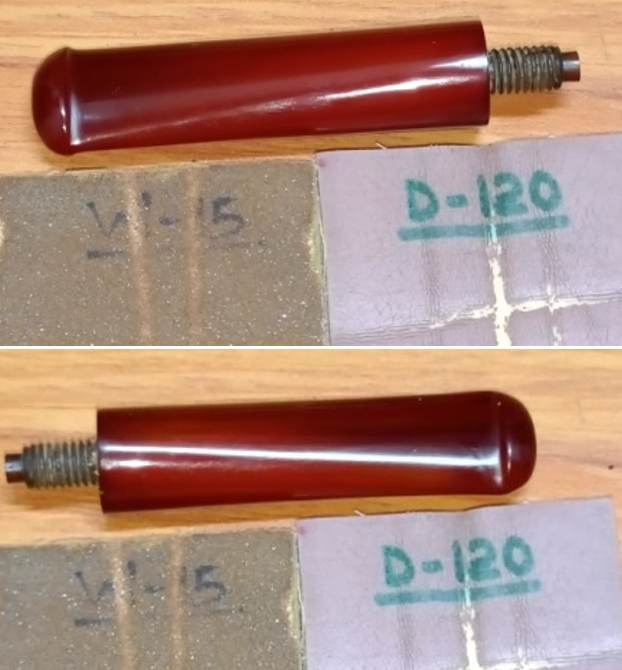

I polished the stem with micromesh sanding pads – 1500-12000 grit sanding pads and water to wet sand the stem. I wiped it down after each sanding pad with Obsidian Oil on a cotton rag after each sanding pads. I know that many say Obsidian Oil does nothing for acrylic stems, but I find it does two things – first it gives some protection to the stem from buildup and second it give the sanding pads bite in the polishing process.

I polished the stem with micromesh sanding pads – 1500-12000 grit sanding pads and water to wet sand the stem. I wiped it down after each sanding pad with Obsidian Oil on a cotton rag after each sanding pads. I know that many say Obsidian Oil does nothing for acrylic stems, but I find it does two things – first it gives some protection to the stem from buildup and second it give the sanding pads bite in the polishing process.

Fine and Extra Fine stem polish as it seems to really remove the fine scratches in the vulcanite. I rub the Fine Polish on the stem and wipe it off with a paper towel and then repeat the process with the Extra Fine polish. I finish the polishing of the stem down with a final coat of Obsidian Oil and set the stem aside to let the oil absorb. This process gives the stem a shine and also a bit of protection.

Fine and Extra Fine stem polish as it seems to really remove the fine scratches in the vulcanite. I rub the Fine Polish on the stem and wipe it off with a paper towel and then repeat the process with the Extra Fine polish. I finish the polishing of the stem down with a final coat of Obsidian Oil and set the stem aside to let the oil absorb. This process gives the stem a shine and also a bit of protection.  The final steps in my process involve using the buffer. I buffed the bowl and stem with Blue Diamond to polish out the light scratches in the briar and the vulcanite. I gave the bowl and the stem multiple coats of carnauba wax. I have found that I can get a deeper shine if I follow up the wax buff with a buff with a clean buffing pad. It works to raise the shine and then I hand buff with a microfiber cloth to deepen the shine. It is always fun for me to see what the polished bowl looks like with the polished stem. It turned out to be a nice pipe. The sandblast finish around the bowl sides and shank looks great. The oval vulcanite saddle stem works well with the pipe. The Loewe & Co. French Made 015 Oval Shank Dublin feels great in my hand. It is a well-balanced pipe. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 1.59 ounces/44 grams. It is a beautiful pipe that I will soon be going back to Leo who sent it to me for restoration. I am sure he will enjoy it and it will give many more years of service to him.

The final steps in my process involve using the buffer. I buffed the bowl and stem with Blue Diamond to polish out the light scratches in the briar and the vulcanite. I gave the bowl and the stem multiple coats of carnauba wax. I have found that I can get a deeper shine if I follow up the wax buff with a buff with a clean buffing pad. It works to raise the shine and then I hand buff with a microfiber cloth to deepen the shine. It is always fun for me to see what the polished bowl looks like with the polished stem. It turned out to be a nice pipe. The sandblast finish around the bowl sides and shank looks great. The oval vulcanite saddle stem works well with the pipe. The Loewe & Co. French Made 015 Oval Shank Dublin feels great in my hand. It is a well-balanced pipe. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 1.59 ounces/44 grams. It is a beautiful pipe that I will soon be going back to Leo who sent it to me for restoration. I am sure he will enjoy it and it will give many more years of service to him.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.