Blog by Kenneth Lieblich

For those of us who hunt for lost pipes, there are always peculiar tales of acquisition – but this one might be my most peculiar location of acquisition. A couple of weeks ago, my wife was out shopping with one of my daughters and they decided to go into an old-time ice cream parlour. While there, my wife spotted a jar for sale on the counter that read ‘Jar with parts + pipes’. That seemed quite odd for an ice cream joint, so she texted me the photo below and asked if I wanted it. It was very inexpensive, so I said, ‘Sure’. What an unusual spot for a jar of pipe parts!

Well, there were some interesting bits and bobs in the jar – including a couple of items that particularly caught my eye. This lithe and comely pipe is one of them – and it will enter my pipe collection. As the title says, it is a 1914 BBB pencil-shank billiard with a sterling silver band and vulcanite, tapered, orific stem. How do I know it is from 1914? Well, let us take a closer look at that sterling silver band.

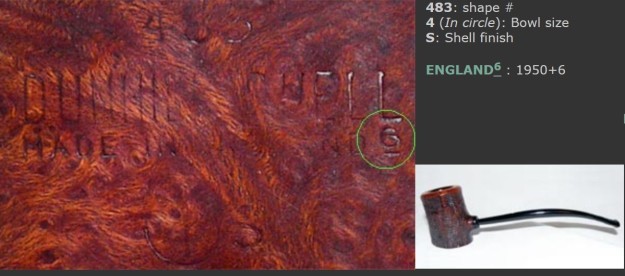

Well, there were some interesting bits and bobs in the jar – including a couple of items that particularly caught my eye. This lithe and comely pipe is one of them – and it will enter my pipe collection. As the title says, it is a 1914 BBB pencil-shank billiard with a sterling silver band and vulcanite, tapered, orific stem. How do I know it is from 1914? Well, let us take a closer look at that sterling silver band. Amidst the heavy tarnish, we can see three distinct marks. From left to right, they are an anchor, a lion passant, and a letter ‘P’. What do these marks mean? The anchor is the city mark and indicates the English city of Birmingham. The lion passant is the silver standard mark and indicates sterling – that is to say, 92.5% pure silver. The letter ‘P’ is the date letter and, as shown in the chart below, indicates the year 1914.

Amidst the heavy tarnish, we can see three distinct marks. From left to right, they are an anchor, a lion passant, and a letter ‘P’. What do these marks mean? The anchor is the city mark and indicates the English city of Birmingham. The lion passant is the silver standard mark and indicates sterling – that is to say, 92.5% pure silver. The letter ‘P’ is the date letter and, as shown in the chart below, indicates the year 1914. That information was definitive in establishing a time period for the pipe. The other marks are perhaps slightly less helpful. The left side of the shank, the left side of the stem, and the silver band each have the recognizable logo of BBB inside a diamond shape. There are no other markings – although the absence of a model name etc. tells its own story. Read on.

That information was definitive in establishing a time period for the pipe. The other marks are perhaps slightly less helpful. The left side of the shank, the left side of the stem, and the silver band each have the recognizable logo of BBB inside a diamond shape. There are no other markings – although the absence of a model name etc. tells its own story. Read on.

Let’s learn a bit about BBB. The article on Pipedia is bizarre insofar as the vast majority of the text is an egregious translation (from the French) of a good history of BBB on the Fumeurs de Pipe website. I speak French and the Babelfish translation that Pipedia uses is not helpful to anyone. I intend to make my own translation of that history one day. In the meantime, here is the non-translated text at the start of that article:

Let’s learn a bit about BBB. The article on Pipedia is bizarre insofar as the vast majority of the text is an egregious translation (from the French) of a good history of BBB on the Fumeurs de Pipe website. I speak French and the Babelfish translation that Pipedia uses is not helpful to anyone. I intend to make my own translation of that history one day. In the meantime, here is the non-translated text at the start of that article:

The initials once stood for Blumfeld’s Best Briars after Louis Blumfeld, who took over the management of the Adolph Frankau Company in 1856. After his death, the BBB gradually became known as Britain’s Best Briars. Soon to be the oldest English trademark in current use and the first pipe ever to have a registered trade mark. “Britain’s Best Briars”, often called BBB, is one of the oldest brands still in production and has always been the most popular foreign brand in Denmark. Earlier pipes included a metal rondel with a diamond shape including BBB imbedded in the stem top, and later post-Cadogan went to a stamped on logo, similar to the GBD pipes.

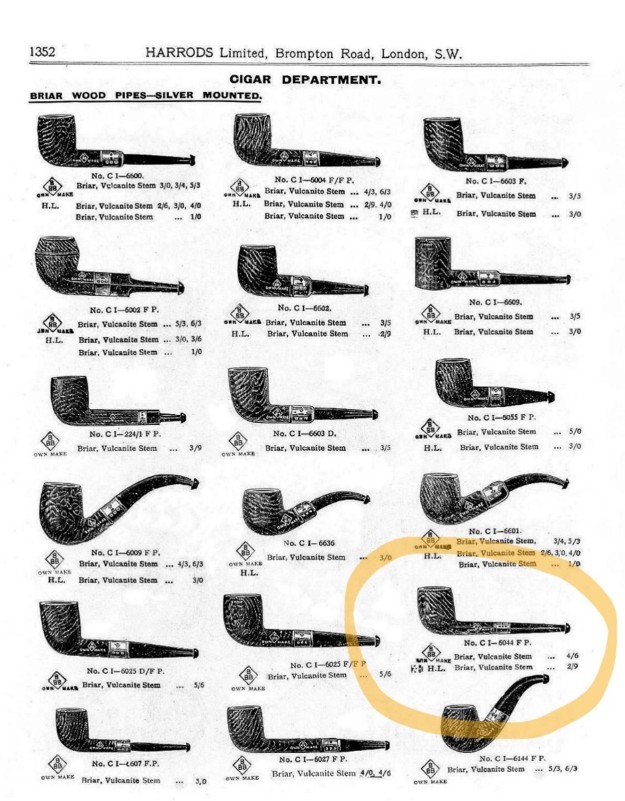

One detail that is of note from this time period of BBB pipes is that they only had two grades/models of pipe. One was ‘BBB Own Make’ (which later became BBB Best Make) and the other being simply ‘BBB’. This pipe is clearly in the latter category. Below is a page from a 1910 Harrods catalogue, showing some BBB pipes for sale. I have circled the one that most closely resembles the pipe I have and showed a close-up of it.

Let us move on to the restoration. This pipe is 110 years old and I suppose it has fared well in that time. Certainly, I have seen much newer pipes in much worse condition. As I mentioned earlier, this stem is tapered, made of vulcanite, and concludes with an orific button. For more information on the orific button, please take the time to read Steve’s interesting article on the subject. As you can see, the stem is coated with calcification and oxidation. It has a few tooth marks, but nothing too serious. Sadly, however, the stem’s tenon has broken off inside the stummel’s mortise. More about the tenon in a bit.

Let us move on to the restoration. This pipe is 110 years old and I suppose it has fared well in that time. Certainly, I have seen much newer pipes in much worse condition. As I mentioned earlier, this stem is tapered, made of vulcanite, and concludes with an orific button. For more information on the orific button, please take the time to read Steve’s interesting article on the subject. As you can see, the stem is coated with calcification and oxidation. It has a few tooth marks, but nothing too serious. Sadly, however, the stem’s tenon has broken off inside the stummel’s mortise. More about the tenon in a bit.

The stummel is in rougher shape. The wood shows wear and tear, including the odd nick and a significant gouge at the rim edge. The bowl is pretty thoroughly coated with cake and lava has erupted on to the rim. There is also some evidence of burned wood under that lava. I will have to excavate to learn more. Fortunately, this stummel does not look over-smoked (which was a real possibility), despite it clearly being a favourite of the previous owner.

The stummel is in rougher shape. The wood shows wear and tear, including the odd nick and a significant gouge at the rim edge. The bowl is pretty thoroughly coated with cake and lava has erupted on to the rim. There is also some evidence of burned wood under that lava. I will have to excavate to learn more. Fortunately, this stummel does not look over-smoked (which was a real possibility), despite it clearly being a favourite of the previous owner.

The sterling silver band (as you have already seen) is in fairly good physical condition, although it clearly has been heavily tarnished.

The sterling silver band (as you have already seen) is in fairly good physical condition, although it clearly has been heavily tarnished. I began my restoration of this pipe by cleaning the stem. I wiped it down with some oil soap on some cotton rounds in order to remove some calcification. I then cleaned the insides with pipe cleaners and 99% isopropyl alcohol. Although it was a bit dirty, it was much cleaner than I had expected after all these years.

I began my restoration of this pipe by cleaning the stem. I wiped it down with some oil soap on some cotton rounds in order to remove some calcification. I then cleaned the insides with pipe cleaners and 99% isopropyl alcohol. Although it was a bit dirty, it was much cleaner than I had expected after all these years. In order to address the oxidation, I dropped the stem in an oxidation removing fluid and left it to sit overnight. This mixture tends to draw the stem’s oxidation to the surface, where it can be more easily removed. When the stem was done soaking, I scrubbed the stem with some surface cleanser squirted on cotton rounds. This worked very well at removing the unsightly oxidation.

In order to address the oxidation, I dropped the stem in an oxidation removing fluid and left it to sit overnight. This mixture tends to draw the stem’s oxidation to the surface, where it can be more easily removed. When the stem was done soaking, I scrubbed the stem with some surface cleanser squirted on cotton rounds. This worked very well at removing the unsightly oxidation. I took a closer look at the diamond-shaped logo – it had been heavily worn over the past century or so. I hemmed and hawed about adding gold paint back to the logo on the stem. In the end I did it and figured that I can always remove later if I so desire.

I took a closer look at the diamond-shaped logo – it had been heavily worn over the past century or so. I hemmed and hawed about adding gold paint back to the logo on the stem. In the end I did it and figured that I can always remove later if I so desire. In my desire to keep original components wherever possible, I perfunctorily decided to not replace the tenon at this time. I knew that I could superglue it back in place – but I also knew that that would not hold in the long term, due to its poor shear strength. This would only be a cosmetic solution. Ultimately, however, I will replace the tenon at a later date. For now, I just want to see this thing restored!

In my desire to keep original components wherever possible, I perfunctorily decided to not replace the tenon at this time. I knew that I could superglue it back in place – but I also knew that that would not hold in the long term, due to its poor shear strength. This would only be a cosmetic solution. Ultimately, however, I will replace the tenon at a later date. For now, I just want to see this thing restored!

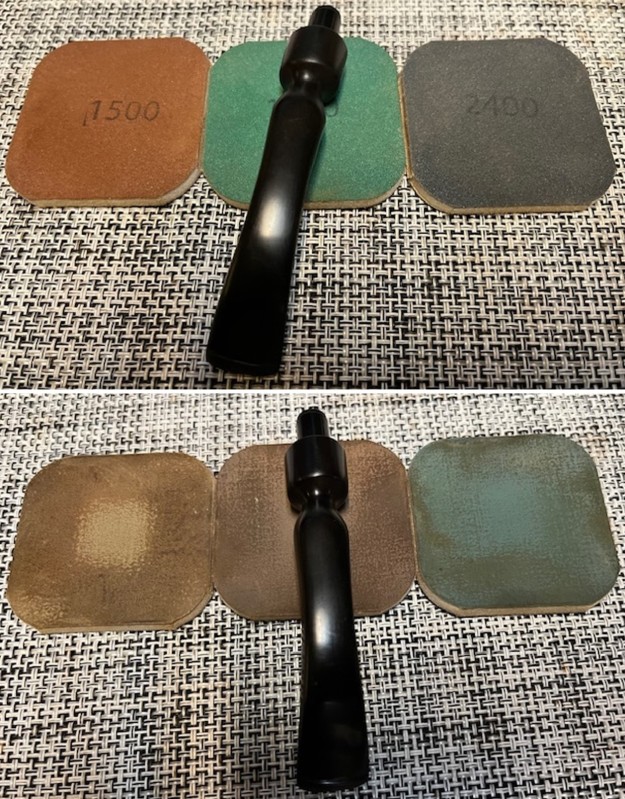

In order to smooth and shine the beautiful black surface of the stem, I used my nine Micromesh pads to sand everything down gradually and delicately. For the last five of these pads, I also use some oil, both as a lubricant and as a method of inhibiting the return of oxidation. It is a lovely stem and it complements the stummel perfectly.

On to the stummel – and my first task was reaming the cake out of the bowl. This was surprisingly challenging work, as the cake had become very hard over the years. There was a lot of debris and the narrowness of the bowl made it all the more tricky. I was also conscious of not wanting to crack the briar as I was doing this. In the end, a lot of carbonized material came out and the bowl remained perfectly intact.

On to the stummel – and my first task was reaming the cake out of the bowl. This was surprisingly challenging work, as the cake had become very hard over the years. There was a lot of debris and the narrowness of the bowl made it all the more tricky. I was also conscious of not wanting to crack the briar as I was doing this. In the end, a lot of carbonized material came out and the bowl remained perfectly intact.

Next, I wanted to address the thick layer of lava on the rim. I put some oil soap in a shallow, plastic lid and soaked the rim in it for about a dozen minutes. This softened things up and I attacked it with a toothbrush. This allowed me to clean the rim very well, also using a piece of machine metal as a gentle scraping device. There was still damage, but it was much improved.

Next, I wanted to address the thick layer of lava on the rim. I put some oil soap in a shallow, plastic lid and soaked the rim in it for about a dozen minutes. This softened things up and I attacked it with a toothbrush. This allowed me to clean the rim very well, also using a piece of machine metal as a gentle scraping device. There was still damage, but it was much improved.

As with the stem, I cleaned the insides of the stummel with pipe cleaners and 99% isopropyl alcohol. It was among the dirtiest pipes I have ever dealt with. Wow. The filth seemed as though it would never end. Obviously, it did at some point and I put the pipe down for a while – I was sick of seeing it!

As with the stem, I cleaned the insides of the stummel with pipe cleaners and 99% isopropyl alcohol. It was among the dirtiest pipes I have ever dealt with. Wow. The filth seemed as though it would never end. Obviously, it did at some point and I put the pipe down for a while – I was sick of seeing it! Of course, I came back to it and used some cleaner and tube brushes to scrub the insides clean. My efforts had not been in vain however, as the pipe looked so much better when I was done.

Of course, I came back to it and used some cleaner and tube brushes to scrub the insides clean. My efforts had not been in vain however, as the pipe looked so much better when I was done.

I removed some of the burn marks on the rim with an aqueous solution of oxalic acid. I took some cotton swabs and rubbed and rubbed. The burns did improve but never fully disappeared. I took solace from the fact that the burns were superficial and did not affect the structural integrity of the wood. Alas, I neglected to take photographs of this step.

I removed some of the burn marks on the rim with an aqueous solution of oxalic acid. I took some cotton swabs and rubbed and rubbed. The burns did improve but never fully disappeared. I took solace from the fact that the burns were superficial and did not affect the structural integrity of the wood. Alas, I neglected to take photographs of this step.

I also opted to leave the large wounds in the briar without filling them. They are part of this pipe’s long life and I am happy for them to remain as they are. The sanding will soften the edges of these wounds and that is sufficient. With that in mind, I set about sanding the stummel with my Micromesh pads. With each pad, the wood got smoother and the pipe got prettier. One product that always makes things better is the restoration balm that I use on the wood. It provides protection and revivification to the wood grain. I applied the stuff lightly but thoroughly, and then let it sit for 15 or 20 minutes. I then buffed it with a microfibre cloth and set it aside. What a beauty!

After the Micromesh pads, but before the restoration balm, I cleaned up the sterling silver band. I worked very hard and very gingerly to remove the tarnish without damaging the antique silver. I reglued it in place, back on the shank, and finally buffed with my jewellery cloth.

After the Micromesh pads, but before the restoration balm, I cleaned up the sterling silver band. I worked very hard and very gingerly to remove the tarnish without damaging the antique silver. I reglued it in place, back on the shank, and finally buffed with my jewellery cloth.

Last step: off to my bench polisher! Here, I gave both the stem and stummel a thorough going over with the White Diamond compound and followed that up with a coat (only one this time) of carnauba wax. The pipe is absolutely beautiful and is truly reminiscent of an earlier time. All finished! This is a wonderfully crafted pipe and has a very jaunty feel to it. It took some work, but I am proud of it. It retains some wounds from battle, but, as Steve would say, they are part of this pipe’s story. This is one pipe that I am keeping for myself and adding to the ‘Lieblich Collection’. I am sure that I will be enjoying this one for many years to come. The approximate dimensions of the pipe are as follows: length 6 in. (153 mm); height 1½ in. (37 mm); bowl diameter 1 in. (27 mm); chamber diameter ⅔ in. (17 mm). The weight of the pipe is ⅝ oz. (18 g). I hope you enjoyed reading the story of this pipe as much I as I did restoring it. If you are interested in more of my work, please follow me here on Steve’s website or email me directly at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.

All finished! This is a wonderfully crafted pipe and has a very jaunty feel to it. It took some work, but I am proud of it. It retains some wounds from battle, but, as Steve would say, they are part of this pipe’s story. This is one pipe that I am keeping for myself and adding to the ‘Lieblich Collection’. I am sure that I will be enjoying this one for many years to come. The approximate dimensions of the pipe are as follows: length 6 in. (153 mm); height 1½ in. (37 mm); bowl diameter 1 in. (27 mm); chamber diameter ⅔ in. (17 mm). The weight of the pipe is ⅝ oz. (18 g). I hope you enjoyed reading the story of this pipe as much I as I did restoring it. If you are interested in more of my work, please follow me here on Steve’s website or email me directly at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.