Blog by Steve Laug

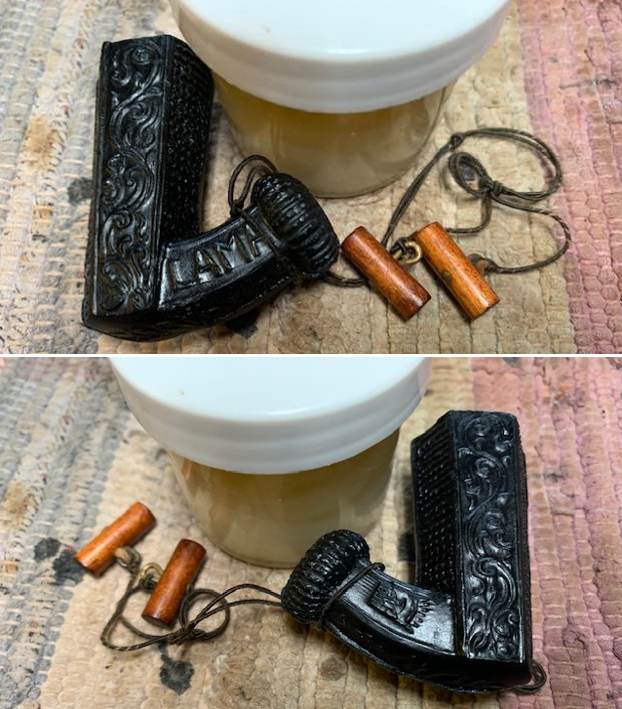

This rainy evening here in Vancouver I decided to work on was another one that was purchased on 11/14/2022 in a lot of pipes that came to us from Copenhagen, Denmark It included a group of Stanwell Bamboo pipe that are quite beautiful, combining a briar bowl, a bamboo shank and a an acrylic stem. The grain around the bowl and shank has a mix of straight and flame grain. The pipe is stamped on the left side of the bamboo and reads STANWELL. The pipe was a well used pipe when Jeff received it. There was dust and grime ground into the finish. The mixture of brown stains highlights some beautiful grain under the dirt. The bowl was heavily caked and there was an overflow of lava on the rim top. The inner edge was hard to see clearly and the lava could easily be hiding damage. The stem is acrylic and was dirty with light tooth marks and chatter on both sides ahead of the button and on the button itself. There is a brass/gold crown S logo inlaid on the left side of the saddle stem. Jeff took photos of the pipe before he started his clean up work on it.

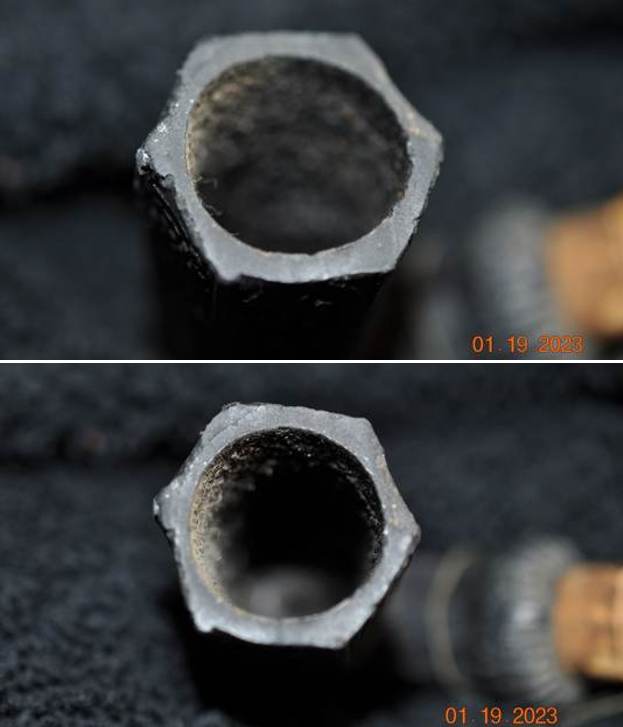

He took photos of the bowl and rim top to show what they looked like before his clean up. He also took some of the stem to show the condition of both sides.

He took photos of the bowl and rim top to show what they looked like before his clean up. He also took some of the stem to show the condition of both sides.

The photos of the sides and heel of the bowl show the uniquely stained grain around the bowl and shank. The mixture of black and brown stains adds depth finish on the pipe. Even under the grime it is a real beauty. The two knuckle bamboo has a nice patina on it and will only get better with time.

The photos of the sides and heel of the bowl show the uniquely stained grain around the bowl and shank. The mixture of black and brown stains adds depth finish on the pipe. Even under the grime it is a real beauty. The two knuckle bamboo has a nice patina on it and will only get better with time.

The stamping on the left side the bamboo is shown in the photo below. It is clear and readable as noted above. The second photo shows the gold crown S on the stem side.

The stamping on the left side the bamboo is shown in the photo below. It is clear and readable as noted above. The second photo shows the gold crown S on the stem side.  Before I started my work on the pipe I wanted to see if I could find any information that would help me date this pipe and get a sense of the line. I turned to Pipephil to get a quick review of the brand (http://pipephil.eu/logos/en/logo-stanwell.html). The Brass Crowned S inlaid logo on the stem is shown in the photo below. I have included a screen capture of the brand info there.

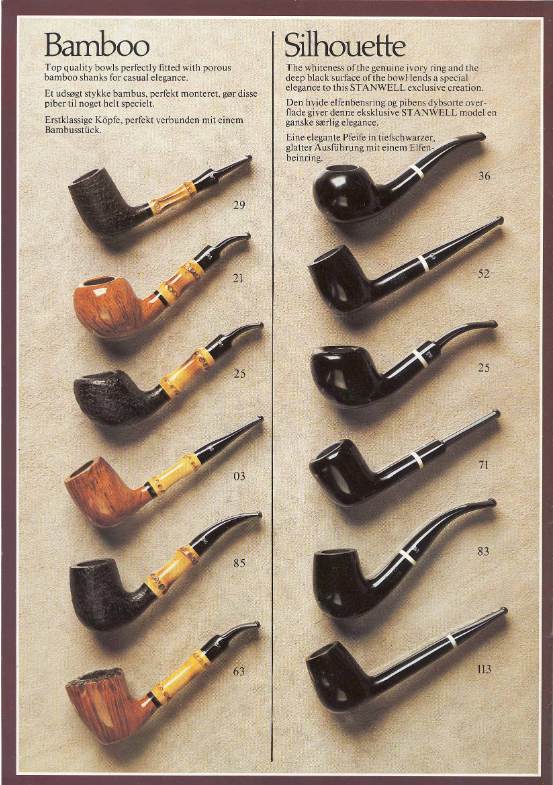

Before I started my work on the pipe I wanted to see if I could find any information that would help me date this pipe and get a sense of the line. I turned to Pipephil to get a quick review of the brand (http://pipephil.eu/logos/en/logo-stanwell.html). The Brass Crowned S inlaid logo on the stem is shown in the photo below. I have included a screen capture of the brand info there. I then turned to Pipedia (https://pipedia.org/wiki/Stanwell) for more information. The article is great and gives a lot of history on the brand. There were also links to catalogues at the bottom of the page. I am including a page from a catalogue on the site below that gives a bit of a glimpse into the brand. Here is the link (http://www.axeljeske.de/Pfeifen/Stanwell_Amager.pdf).

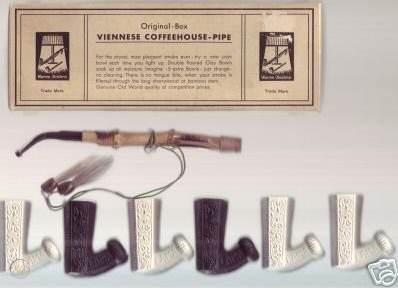

I then turned to Pipedia (https://pipedia.org/wiki/Stanwell) for more information. The article is great and gives a lot of history on the brand. There were also links to catalogues at the bottom of the page. I am including a page from a catalogue on the site below that gives a bit of a glimpse into the brand. Here is the link (http://www.axeljeske.de/Pfeifen/Stanwell_Amager.pdf).  The catalogue page gives a great description of the Bamboo line. It reads as follows: Top quality bowls perfectly fitted with porous bamboo shanks for casual elegance.

The catalogue page gives a great description of the Bamboo line. It reads as follows: Top quality bowls perfectly fitted with porous bamboo shanks for casual elegance.

Now it was time to work on the pipe.

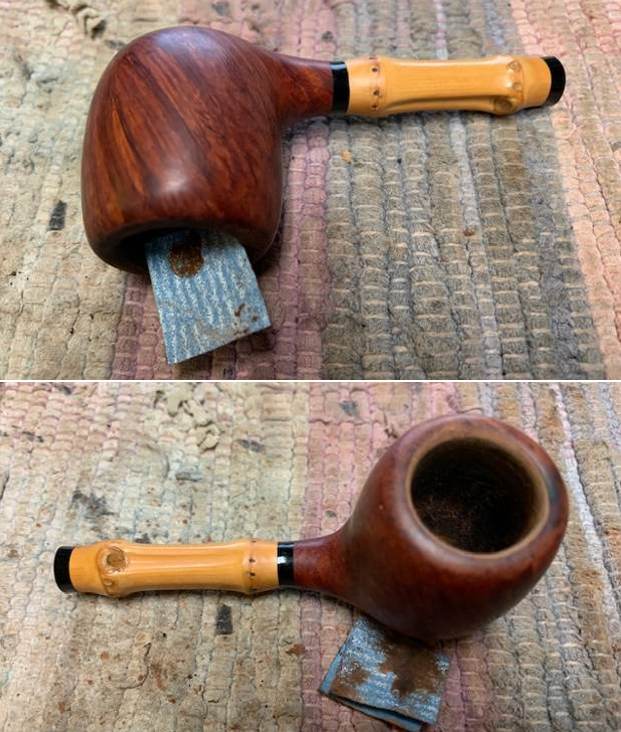

Jeff had thoroughly cleaned up the pipe. He reamed the pipe with a PipNet Pipe Reamer and cleaned up the remnants with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the stem with Soft Scrub to remove the grime and calcification. He soaked the stem in Before & After Deoxidizer and rinsed it off with warm water. The pipe looked very good when it arrived here in Vancouver.

I took close up photos of the bowl, rim and the stem. You can see the darkening and scratches on rim top and edges. The bowl is quite clean inside. The stem is in good condition with light tooth marks and some chatter as noted above.

I took close up photos of the bowl, rim and the stem. You can see the darkening and scratches on rim top and edges. The bowl is quite clean inside. The stem is in good condition with light tooth marks and some chatter as noted above. I took photo of the stamping on the left side of the shank. It is readable as noted above.

I took photo of the stamping on the left side of the shank. It is readable as noted above.  I removed the stem from the shank and took a photo to give a sense of the proportions of the pipe.

I removed the stem from the shank and took a photo to give a sense of the proportions of the pipe. I started my work on the pipe working on the damage to the inner edge and the rim top with a folded piece of 220 grit sandpaper to bring the edge back into round and it looked much better.

I started my work on the pipe working on the damage to the inner edge and the rim top with a folded piece of 220 grit sandpaper to bring the edge back into round and it looked much better. I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad to remove the grit. The bowl began to take on a rich shine. It is a beauty.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad to remove the grit. The bowl began to take on a rich shine. It is a beauty.

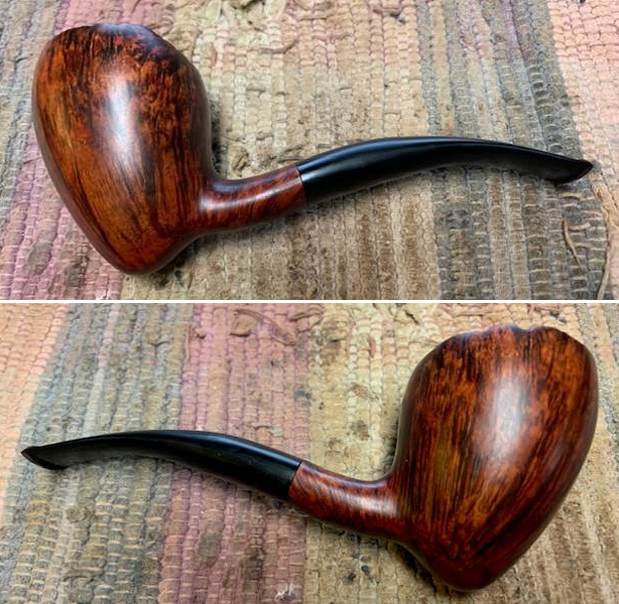

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the briar with my finger tips. I let it sit for 10 minutes and the Balm did its magic. It enlivens, cleans and preserves the briar. It certainly brought this bowl back to life. I buffed it off with a clean cloth and took the following photos.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the briar with my finger tips. I let it sit for 10 minutes and the Balm did its magic. It enlivens, cleans and preserves the briar. It certainly brought this bowl back to life. I buffed it off with a clean cloth and took the following photos.

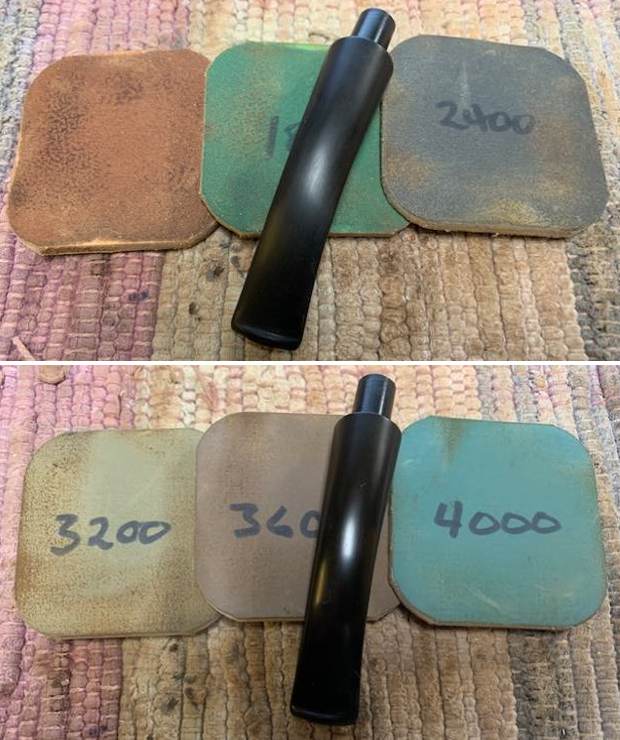

I set the bowl aside and turned my attention to the stem. I was able to polish out the light tooth marks and chatter with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I set the bowl aside and turned my attention to the stem. I was able to polish out the light tooth marks and chatter with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

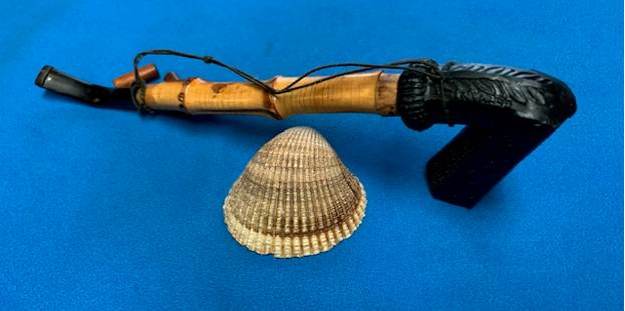

This Stanwell Bamboo Apple with an acrylic saddle stem is a great looking pipe now that it has been restored. The beautiful finish really highlights the grain and the polished finish is stunning. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Stanwell Bamboo Apple fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 1/8 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 34 grams / 1.20 ounces. I will be adding the pipe to the Danish Pipe Makers Section of the rebornpipes store. If you are interested in purchasing this pipe send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it.

This Stanwell Bamboo Apple with an acrylic saddle stem is a great looking pipe now that it has been restored. The beautiful finish really highlights the grain and the polished finish is stunning. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Stanwell Bamboo Apple fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 1/8 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 34 grams / 1.20 ounces. I will be adding the pipe to the Danish Pipe Makers Section of the rebornpipes store. If you are interested in purchasing this pipe send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it.