Blog by Steve Laug

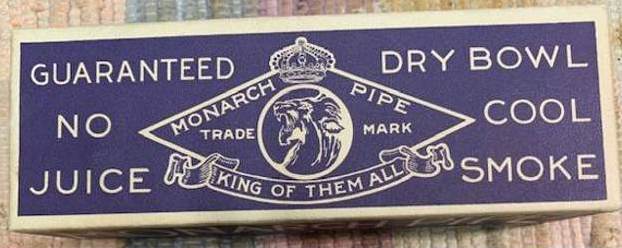

In recent purchase of pipes that Jeff and I made from a friend who picked up a bunch of pipes from a closed pipe shop were two of these Monarch Pipes. Both of them were unsmoked and new old stock. What made them interesting to me was the box advertising that was with both pipes. It read as is shown below: Guaranteed Dry Bowl – No Juice/Cool Smoke. The logo in the centre of the box read Monarch Pipe [over] Trade Mark [over] King of them All in a diamond with a banner. The side of the box read MONARCH PIPE [arched over] Pat. Pend. The end of the box read Monarch Pipe with a white box for writing a shape number or inventory number. In this case the number written was “4”. The box was in good condition with no tears or damage. It was clean and quite nice. When I opened the box I found that the pipe was wrapped in bubble wrap and sat on top of the paperwork on the pipe. It was a beautiful pipe in an apple shape.

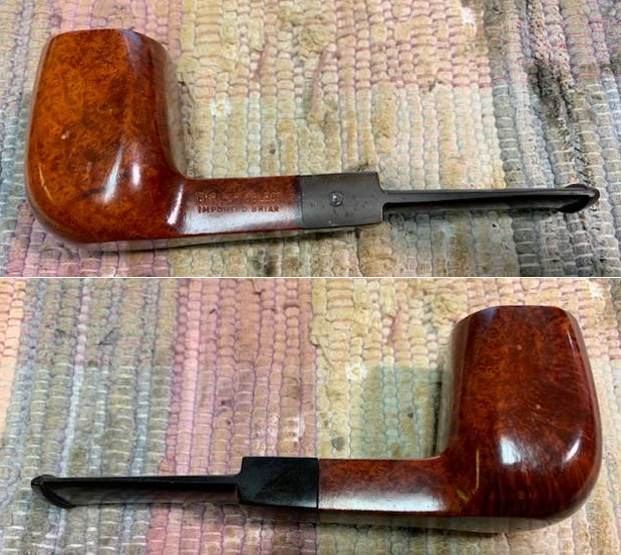

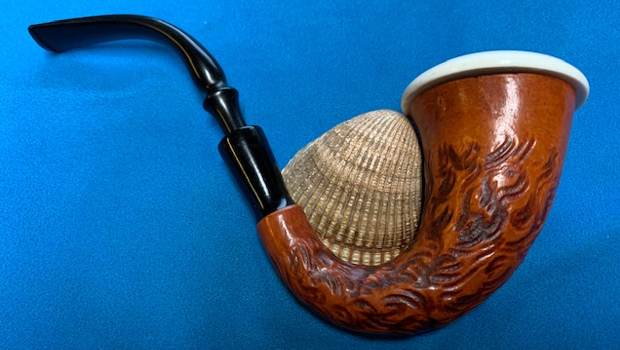

When I opened the box I found that the pipe was wrapped in bubble wrap and sat on top of the paperwork on the pipe. It was a beautiful pipe in an apple shape.  I took the pipe out of the box and took photos of it. It really is a beautiful, well made pipe that is in flawless condition. The three silver rings on vulcanite were attached to the shank as an extension which housed the hardware of the Patent pipe. The stem was vulcanite and was well made with a nice taper. There was a single small inlaid silver ring on the topside of the taper stem. The shank was stamped on the left side and read Monarch in script over Pat. 1989069 in a curled banner. On the right side of the shank it is stamped with the number 2133 which is a shape number. The bowl is well turned and conical shaped. It is smooth but still shows some tooling marks on the bowl walls mid wall half way down the bowl. The drilling was perfectly centered at the bottom of the bowl. I took some photos of the pipe before taking it apart.

I took the pipe out of the box and took photos of it. It really is a beautiful, well made pipe that is in flawless condition. The three silver rings on vulcanite were attached to the shank as an extension which housed the hardware of the Patent pipe. The stem was vulcanite and was well made with a nice taper. There was a single small inlaid silver ring on the topside of the taper stem. The shank was stamped on the left side and read Monarch in script over Pat. 1989069 in a curled banner. On the right side of the shank it is stamped with the number 2133 which is a shape number. The bowl is well turned and conical shaped. It is smooth but still shows some tooling marks on the bowl walls mid wall half way down the bowl. The drilling was perfectly centered at the bottom of the bowl. I took some photos of the pipe before taking it apart.

The stem was screwed onto the metal “plumbing” on the inside of the shank. The stem was perfectly aligned with the shank. The metal part extending from the shank is a tube that lined up with the airway in the stem.

The stem was screwed onto the metal “plumbing” on the inside of the shank. The stem was perfectly aligned with the shank. The metal part extending from the shank is a tube that lined up with the airway in the stem.

In the bottom of the box was a display card for attaching the pipe in the box and allowing it to stand on its side with the pipe held in place like a shadow box. There was also a metal tool there that was a wrench with two sized slots for removing the plumbing from the shank.

In the bottom of the box was a display card for attaching the pipe in the box and allowing it to stand on its side with the pipe held in place like a shadow box. There was also a metal tool there that was a wrench with two sized slots for removing the plumbing from the shank. I fitted the wrench to the plumbing on the shank. The fit was perfect and I was able to slide it over the end. I loosened it with the wrench and removed it from the part. I unscrewed it the rest of the way from the shank. I took the piece apart – slipped the shank extension off the plumbing and took photos. You can see the threads on the outside of the tube that fit well inside the threaded mortise in the shank. I also took a photo of the inside of the stem to show the threaded internals of the stem. It is a really interesting looking pipe and the contraption works as a condenser in the shank.

I fitted the wrench to the plumbing on the shank. The fit was perfect and I was able to slide it over the end. I loosened it with the wrench and removed it from the part. I unscrewed it the rest of the way from the shank. I took the piece apart – slipped the shank extension off the plumbing and took photos. You can see the threads on the outside of the tube that fit well inside the threaded mortise in the shank. I also took a photo of the inside of the stem to show the threaded internals of the stem. It is a really interesting looking pipe and the contraption works as a condenser in the shank.

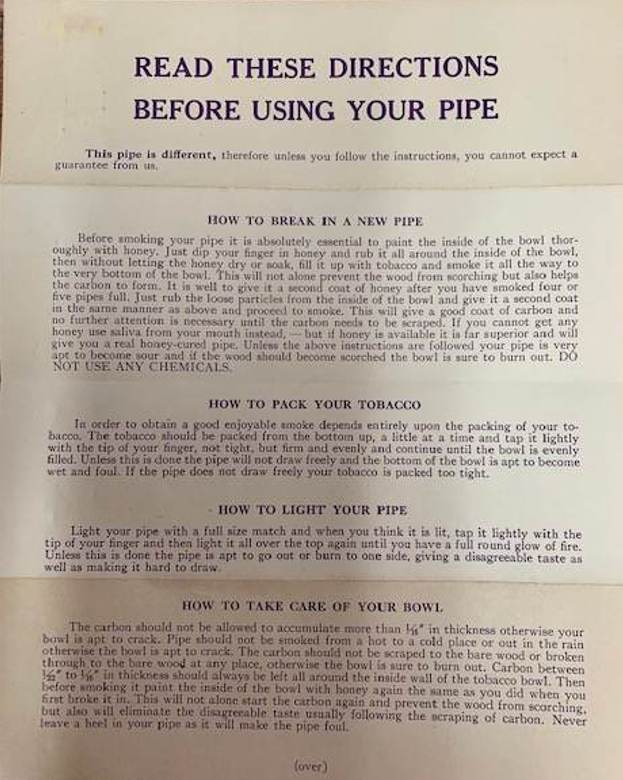

I took out the folded documentation that was in the bottom of the box. It is entitled READ THESE DIRECTIONS BEFORE USING YOUR PIPE. Underneath that it reads, “This pipe is different, therefore unless you follow the instructions, you cannot expect a guarantee from us.”

I took out the folded documentation that was in the bottom of the box. It is entitled READ THESE DIRECTIONS BEFORE USING YOUR PIPE. Underneath that it reads, “This pipe is different, therefore unless you follow the instructions, you cannot expect a guarantee from us.”

I love the straightforward disclaimer on the top of the brochure. It is quite different from any other system pipe that I have used or worked on over the years. None of those system pipes were that clear in stating – read this or we won’t honour the guarantee. Makes me like the company who made this pipe. I took photos of both sides of the brochure and included them below. Give them a read as they are quite clear.

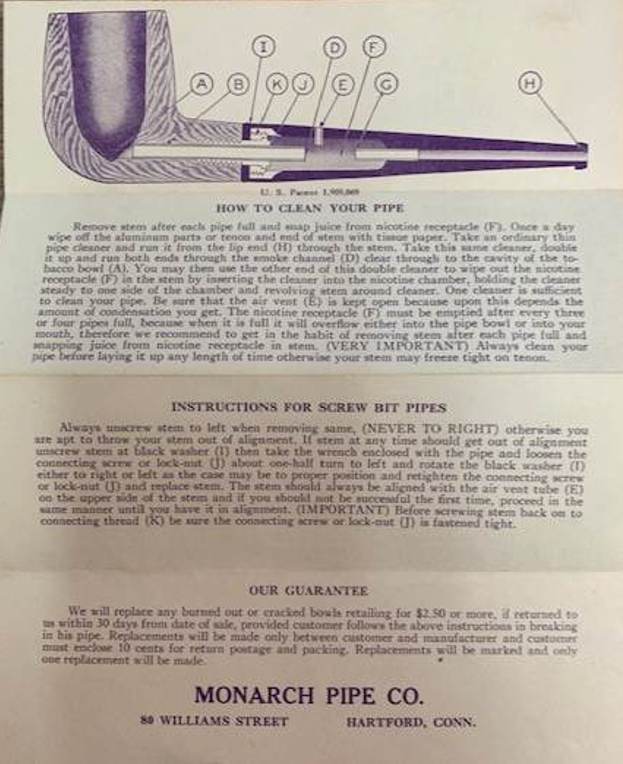

Under the section on how to clean your pipe is a great description of the apparatus in the shank. It reads as follows:

Under the section on how to clean your pipe is a great description of the apparatus in the shank. It reads as follows:

Remove stem after each pipe full and snap juice from nicotine receptacle (F). Once a day wipe off the aluminum parts or tenon and end of the stem with tissue paper. Take an ordinary thin pipe cleaner and run it from the lip end (H) through the stem. Take the same cleaner, double it up and run both ends through the smoke channel (D) clear through to the cavity of the tobacco bowl (A). You may then use the other end of this double cleaner to wipe out the nicotine receptacle (F) in the stem by inserting the cleaner into the nicotine chamber, holding the cleaner steady to one side of the chamber and revolving stem around cleaner. One cleaner is sufficient to clean your pipe. Be sure that the air vent (E) is kept open because upon this depends the amount of condensation you get. The nicotine receptacle (F) must be emptied after every three or four pipes full, because when it is full it will overflow either into the pipe bowl or into your mouth, therefore we recommend to get in the habit of removing stem after each pipe full and snapping juice from nicotine receptacle in stem. (VERY IMPORTANT). Always clean your pipe before laying it up any length of time otherwise you stem may freeze tight on the tenon.

Reading through the brochure was very helpful in identifying the parts on the pipe. The space between the end of the tube in the plumbing and the airway in the stem is a collection area for the juices. The silver inset ring on the top of the stem that I thought was a logo is actually an air vent like those on Duncan Aerosphere pipes. I find these documents fascinating to read. They gave me all the documentation for taking the plumbing apart and putting it back together again.

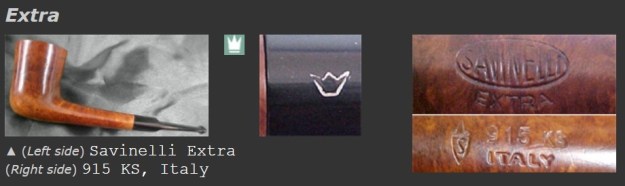

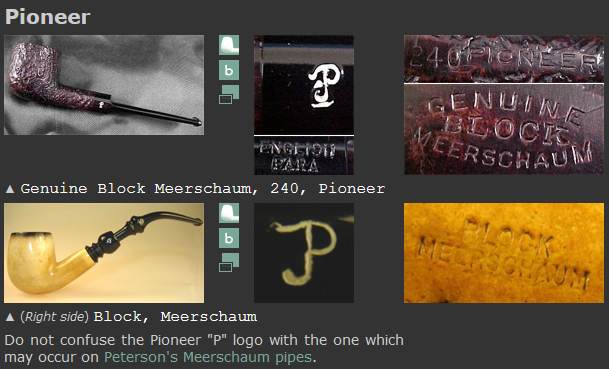

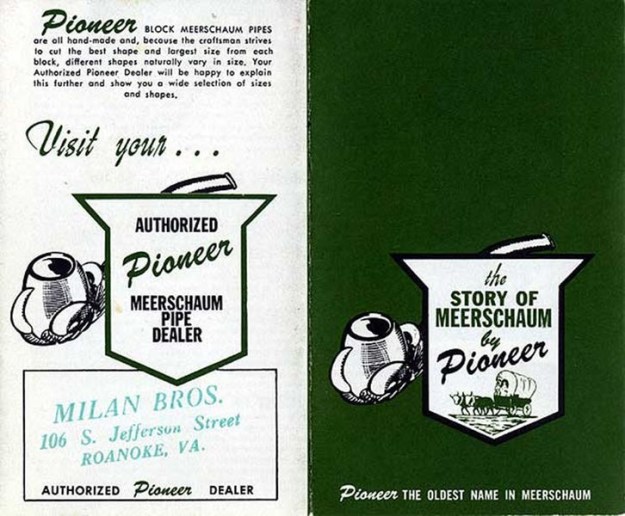

I wanted to see if I could learn anything else so I turned to Pipephil’s site to read what was there and learned some more (http://pipephil.eu/logos/en/logo-m6.html). I did a screen capture of the section on the site and have included it below. I also included the information from the side bar below the screen capture. It turns out that the company also made the Carey Magic Inch and the Duncan Aerosphere pipe both of which use similar plumbing with refinements to capture the perfect smoke. Fred Warnke established the brand in the late 1930 in Hartford (CT). The company moved in the 1950s to Tusla (OK). Other brands distributed by Monarch Pipe Co: Carey Magic Inch, Aerosphere. The Monarch label has also been used by Imperial Tobacco Co (England), by Civic (England) and by LA BRUYERE (France). The later were distributed by WDC.

Fred Warnke established the brand in the late 1930 in Hartford (CT). The company moved in the 1950s to Tusla (OK). Other brands distributed by Monarch Pipe Co: Carey Magic Inch, Aerosphere. The Monarch label has also been used by Imperial Tobacco Co (England), by Civic (England) and by LA BRUYERE (France). The later were distributed by WDC.

I turned to the section on Pipedia on the brand to read (https://pipedia.org/wiki/Monarch). I quote in full

Monarch Pipe Co. was established in Hartford Con, most likely in the late 1930 by Fred Warnke, who obtained a patent on the system pipe on January 22 1935. The company moved to Tulsa Oklahoma at some point in the 1950s, after which Monarch Pipe Co was moved to Bristow, Oklahoma. The Monarch Pipe Co. also makes E.A.Carey Magic Inch and Duncan Hill Aerosphere Pipes.

The site also included a copy of the Patent drawings that were submitted to the US Patent Office in November, 1931. I include that below. I remembered that Dal Stanton had worked on one of these pipes previously and had done more research on the brand (https://rebornpipes.com/tag/monarch-pipes/). I quote from that blog below. Thanks for the information Dal.

I remembered that Dal Stanton had worked on one of these pipes previously and had done more research on the brand (https://rebornpipes.com/tag/monarch-pipes/). I quote from that blog below. Thanks for the information Dal.

I was also intrigued by reading the full patent document submitted by Fred L. Warnke in 1931. I clipped the header from that document and placed it below. The first several paragraphs describes how the system would provide the holy grail of pipe technology – a cooler and dryer smoke!  Dal also confirmed the information on the logo being a ventilator on the top of the stem. I quote:

Dal also confirmed the information on the logo being a ventilator on the top of the stem. I quote:

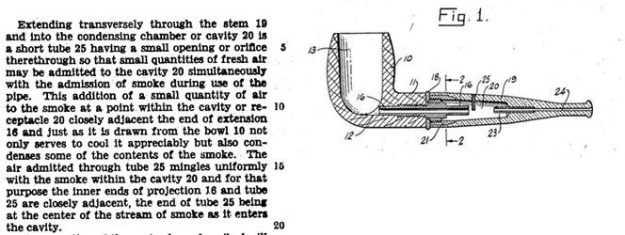

One last interesting item to note which I referenced earlier. The dot on the top of the stem is a hole or a vent air regulator which is labeled #25 in the Fig. 1 1931 patent diagram. I found this caption that I clipped from the patent document interesting as it describes the purpose of the vent and how it contributes to a ‘dryer and cooler’ smoking experience as it regulates the introduction of fresh air to the to the smoke. I really wish I could try out some of the pipes I restore to experience these inventions in practice! I have the opportunity to try out this old timer and see what it works like. I am looking forward to smoking it and seeing what it is like. There is also one for sale on the rebornpipes store – another unsmoked apple – it is listed under the American (US) Pipe Makers section. That way someone else can give it a smoke along with me. It should be an interesting opportunity and one that will be a new experience. Thanks for reading the blog.

I have the opportunity to try out this old timer and see what it works like. I am looking forward to smoking it and seeing what it is like. There is also one for sale on the rebornpipes store – another unsmoked apple – it is listed under the American (US) Pipe Makers section. That way someone else can give it a smoke along with me. It should be an interesting opportunity and one that will be a new experience. Thanks for reading the blog.