by Steve Laug

Back in January I received an email from Robert with a group 12 pipes that needed to be restored in various ways from cleanup to restemming. I chose to work on the second Duncan Hill Aerosphere pipe that he sent next. It is a nice-looking rusticated apple – one of my favourite shapes. The bowl and shank were in good condition but the finish was very dirty. The bowl had been reamed at some time so there was no cake in it. The rim top was clean but had some darkening around the top and the inner edge. The pipe was stamped on the underside of the bowl and shank and read Aerosphere [over] Duncan Hill. This one came with the original stem in place on the shank. It had the triple rings on the stem and a white acrylic (Delrin) tenon. It was oxidized and calcified on the button end. There were light tooth marks on the top and underside of the stem near the button. It had the classic Aerosphere system stem with the carburetor on the left side of the half saddle stem. I took some photos of the pipe to show its condition before I started my work on it.

I took some closer photos of the bowl and rim top to show its condition before I started my work on the pipe. You can see the clean bowl and the darkening on the rim top. The stem photos also show the general condition of the stem as noted above.

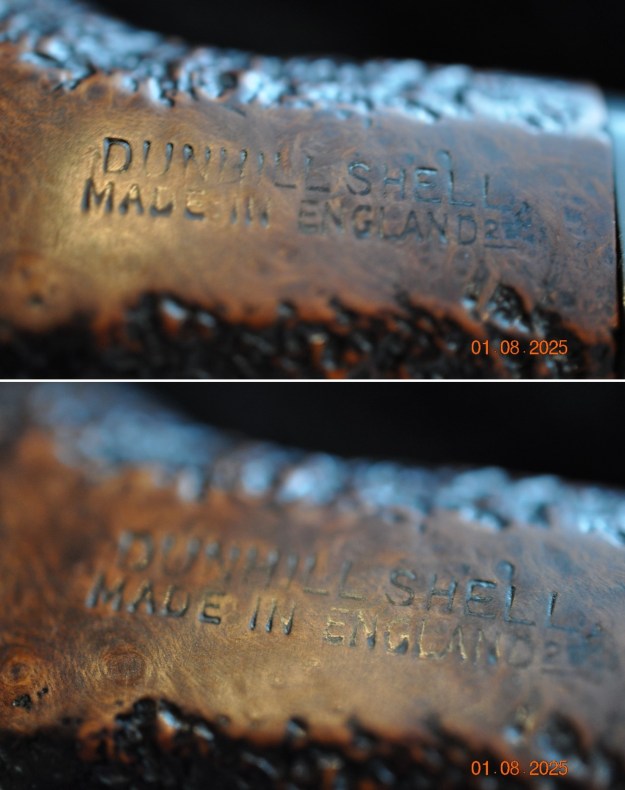

I took some closer photos of the bowl and rim top to show its condition before I started my work on the pipe. You can see the clean bowl and the darkening on the rim top. The stem photos also show the general condition of the stem as noted above.  I took a photo of the stamping on the underside of the bowl and shank. It was stamped on a smooth panel and was faint but readable. It reads as noted above. I removed the stem and took a photo of the parts of the pipe to show the look of the pipe.

I took a photo of the stamping on the underside of the bowl and shank. It was stamped on a smooth panel and was faint but readable. It reads as noted above. I removed the stem and took a photo of the parts of the pipe to show the look of the pipe. Before I started work this one I reread what I had posted on the Duncan Hill Restem job I did. I have included what I found below. I Googled Duncan Hill Aerosphere and the first bit I found was from a Google group for ASP. There I found the following quote. I have the reference link placed at the end of the quote if you want to follow up on the information:

Before I started work this one I reread what I had posted on the Duncan Hill Restem job I did. I have included what I found below. I Googled Duncan Hill Aerosphere and the first bit I found was from a Google group for ASP. There I found the following quote. I have the reference link placed at the end of the quote if you want to follow up on the information:

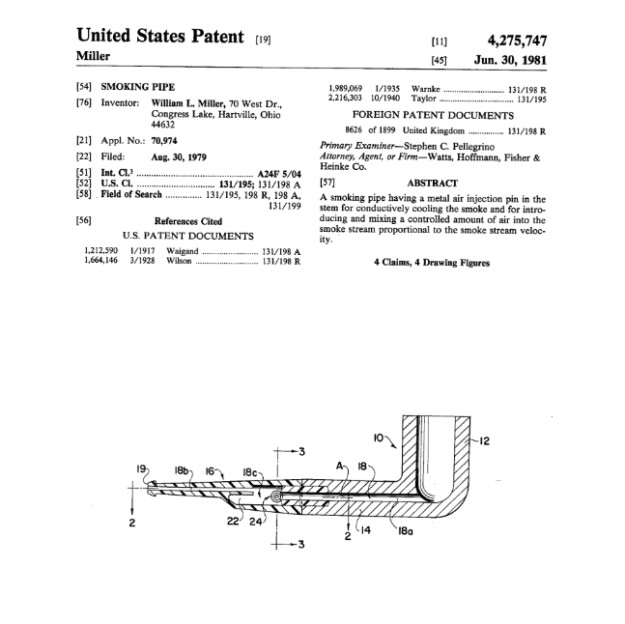

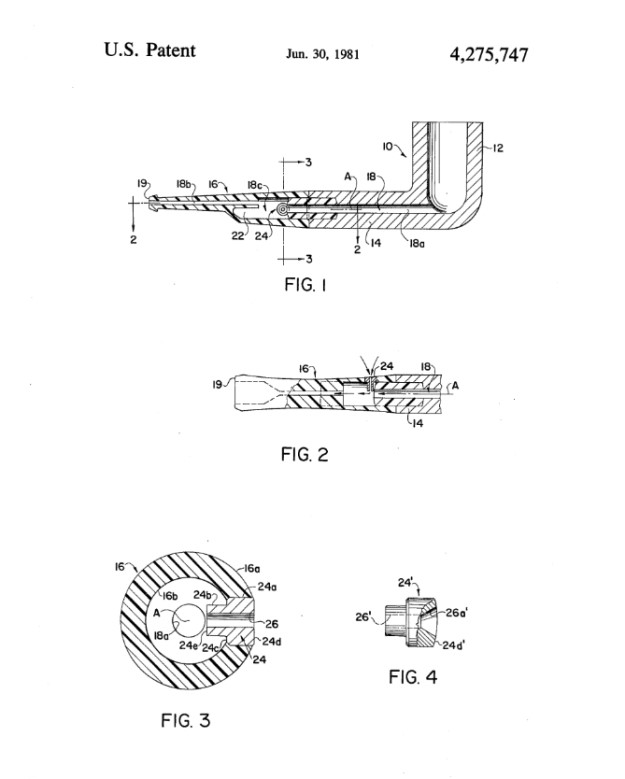

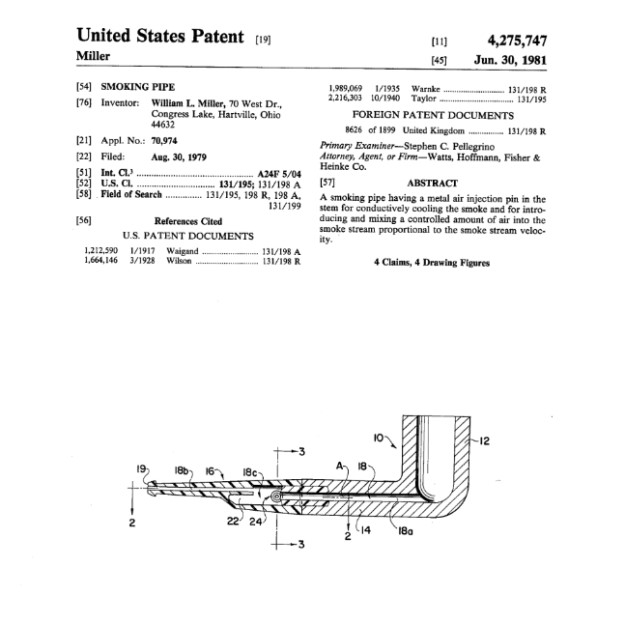

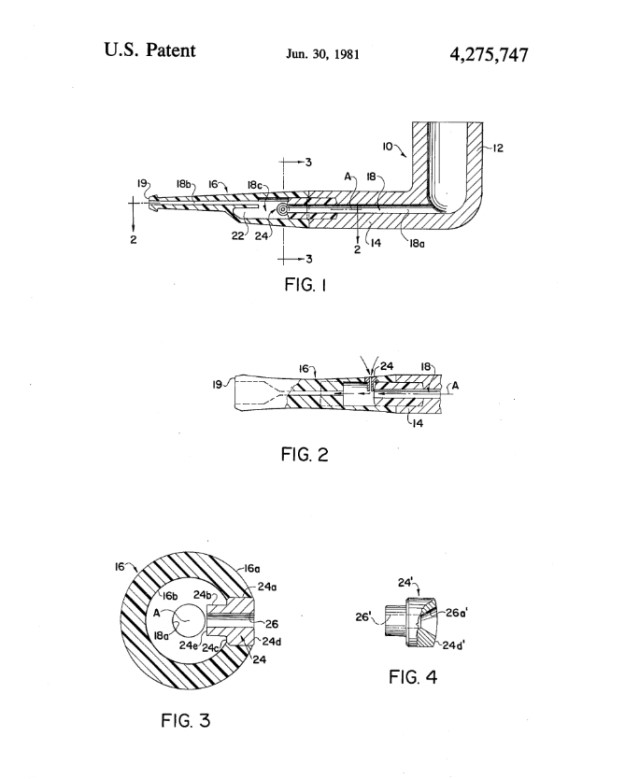

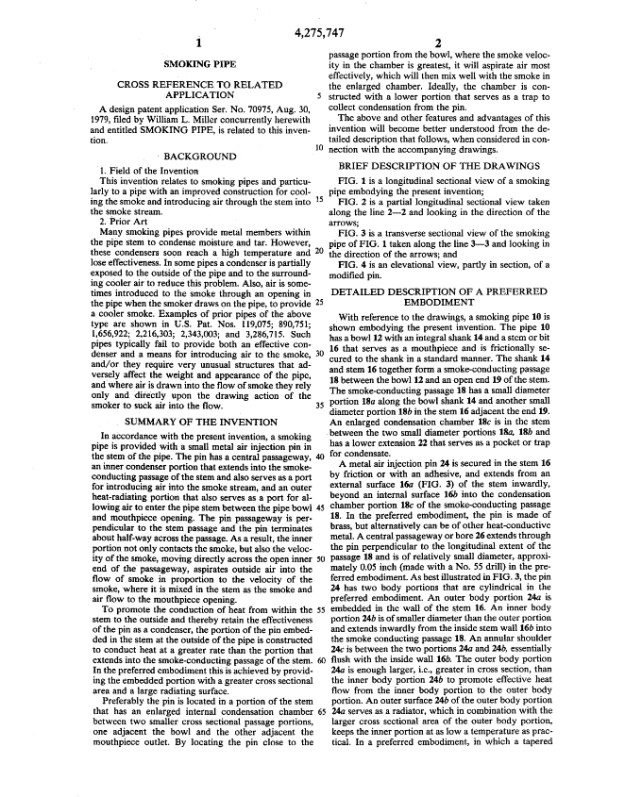

“The Duncan Hill Aerosphere smoking system (U.S. patent #4,275,747) utilizes the same principle of physics as the manometer. The Aerosphere, visible as the brass pin on the side of the mouthpiece, brings a scientifically measured amount of air into the stem with each puff. The control of the amount of air and the velocity of the air produces two effects that result in superior smoking pipe performance.” https://groups.google.com/forum/#!topic/alt.smokers.pipes/GUxdN5Dus4Q

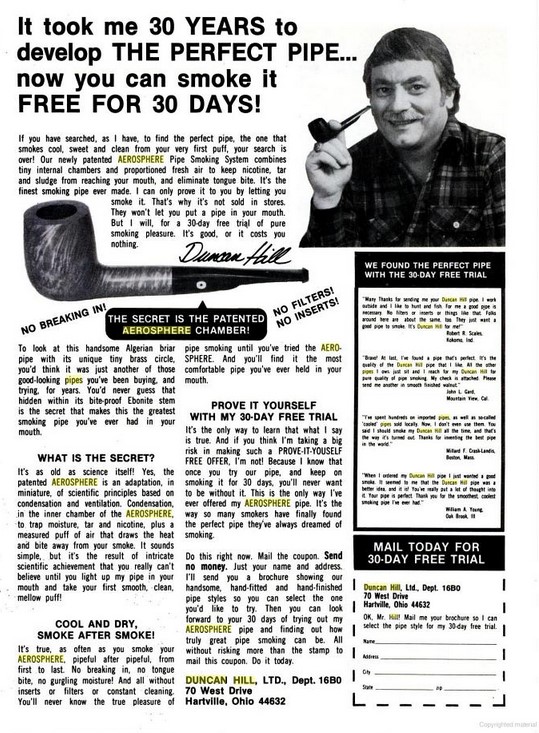

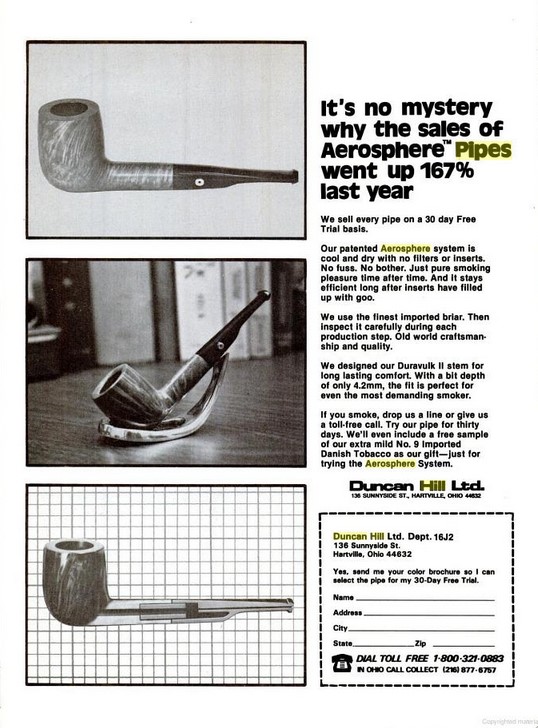

I also found a link to an advertisement for the brand featuring the designer in Popular Mechanics Magazine, February 1980, pg. 31 on Google books. Here is the link:

https://books.google.ca/books?id=m9UDAAAAMBAJ&pg=PA31&lpg=PA31&dq=Duncan+Hill+Aerosphere+Pipes&source=bl&ots=tR4egGI0ig&sig=XeACE0-Vh19-1JNcA0kAgS87kRI&hl=en&sa=X&ei=p1QbVbPTEpLvoATEpoLoCQ&ved=0CBwQ6AEwADgU#v=onepage&q=Duncan%20Hill%20Aerosphere%20Pipes&f=false Next is an advertisement from Popular Mechanics Magazine, September 1982, pg. 216 on google books. Here is the link. https://books.google.ca/books?id=f9kDAAAAMBAJ&pg=PA216&lpg=PA216&dq=Duncan+Hill+Aerosphere+Pipes&source=bl&ots=fsZtVqD0z9&sig=Kl3wI-76NJqpFxAg8SPndnnWyqM&hl=en&sa=X&ei=owEcVdGGKdj9oQSD_4L4Bw&ved=0CCgQ6AEwAjgo#v=onepage&q=Duncan%20Hill%20Aerosphere%20Pipes&f=false

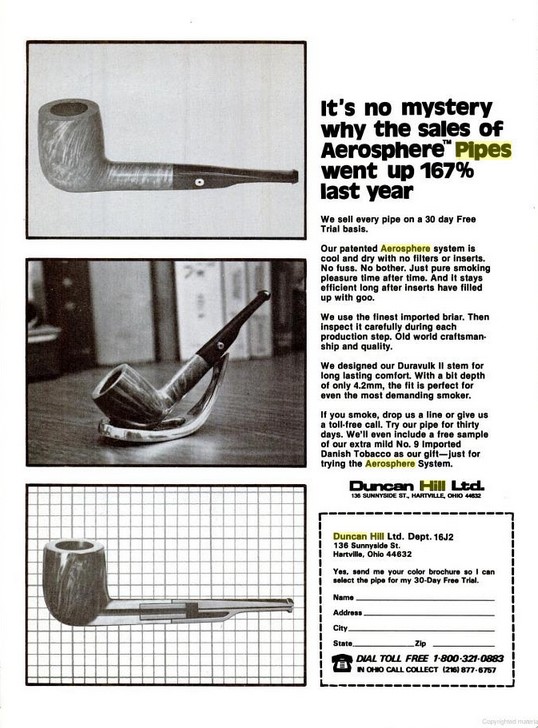

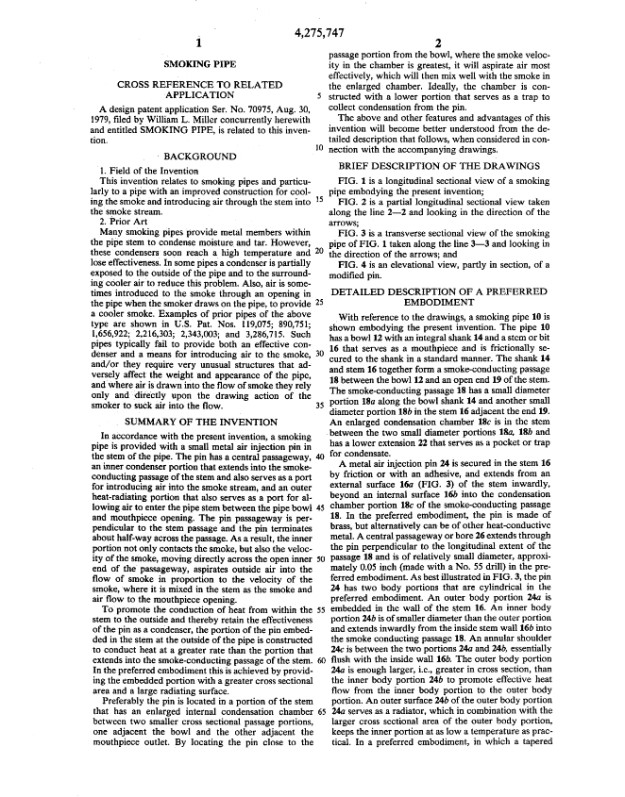

Next is an advertisement from Popular Mechanics Magazine, September 1982, pg. 216 on google books. Here is the link. https://books.google.ca/books?id=f9kDAAAAMBAJ&pg=PA216&lpg=PA216&dq=Duncan+Hill+Aerosphere+Pipes&source=bl&ots=fsZtVqD0z9&sig=Kl3wI-76NJqpFxAg8SPndnnWyqM&hl=en&sa=X&ei=owEcVdGGKdj9oQSD_4L4Bw&ved=0CCgQ6AEwAjgo#v=onepage&q=Duncan%20Hill%20Aerosphere%20Pipes&f=false Finally using the patent number in the ASP quote I was able to find the patent documents for the pipe on the US Patent Office site. I have included the documents from the US Patent Office here. There are four pages – 2 of drawings and two of description.

Finally using the patent number in the ASP quote I was able to find the patent documents for the pipe on the US Patent Office site. I have included the documents from the US Patent Office here. There are four pages – 2 of drawings and two of description.

I love finding this old information and reading about the persistent search for the dryer cooler smoking pipe that has led to many creative solutions. It lends some colour to the work of my refurbishing to be able to read about the design ideas and the inventors themselves as I work on the pipes. Armed with new information it was time to work on the pipe.

I love finding this old information and reading about the persistent search for the dryer cooler smoking pipe that has led to many creative solutions. It lends some colour to the work of my refurbishing to be able to read about the design ideas and the inventors themselves as I work on the pipes. Armed with new information it was time to work on the pipe.

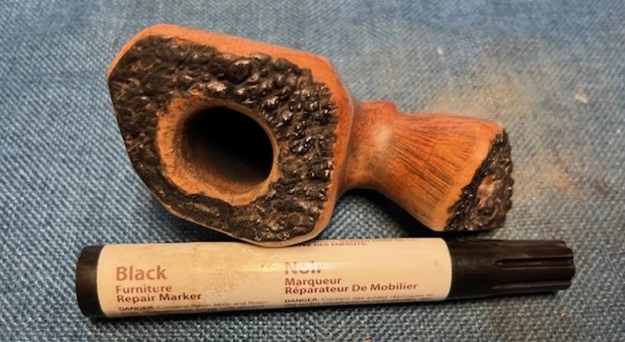

I decided to start on the bowl itself. I worked over the rim darkening with a folded piece of 220 grit sandpaper. The smooth rim top was crowned so it was an easy process to clean it up at the same time as the edge. I scrubbed the exterior of the with undiluted Murphy’s Oil Soap and a tooth brush. I worked on the rustication and the smooth rim top. I rinsed it off with warm running water and dried it off with a cotton towel. It is definitely looking better.

I scrubbed the exterior of the with undiluted Murphy’s Oil Soap and a tooth brush. I worked on the rustication and the smooth rim top. I rinsed it off with warm running water and dried it off with a cotton towel. It is definitely looking better.

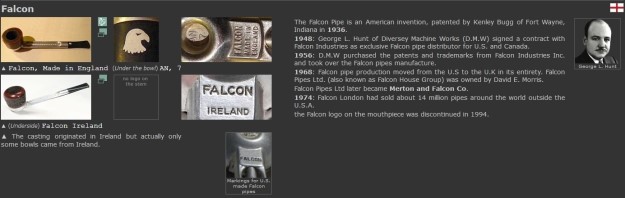

I worked on the rim top and edges with 320-3500 grit sanding pads to further remove the darkening on the briar. It is improving with each pad. I wiped the top down with a damp cloth to remove the sanding debris.

I worked on the rim top and edges with 320-3500 grit sanding pads to further remove the darkening on the briar. It is improving with each pad. I wiped the top down with a damp cloth to remove the sanding debris.

I polished it with 1500-12000 grit sanding pads and wiped it down with a damp cloth after each pad. The rim top looked very good.

I polished it with 1500-12000 grit sanding pads and wiped it down with a damp cloth after each pad. The rim top looked very good.

I cleaned out the shank, mortise and the airway in both the shank and the stem with alcohol, cotton swabs and pipe cleaners. The shank was very dirty. The airflow is great.

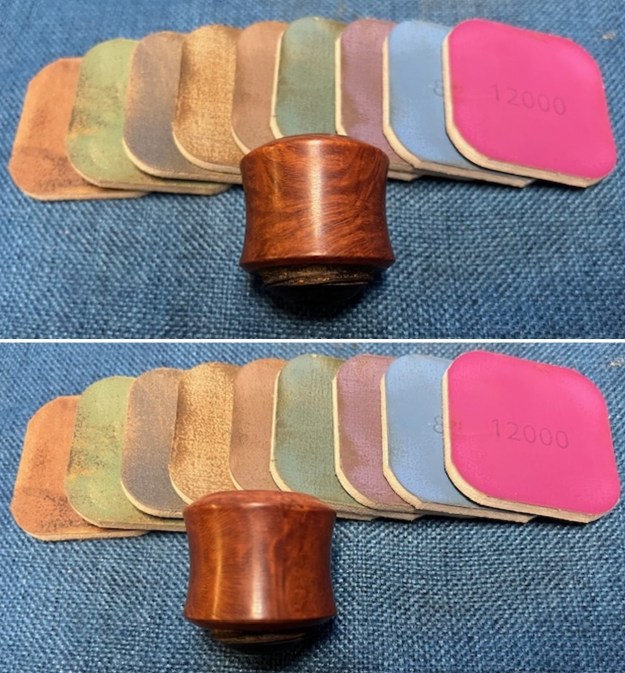

I cleaned out the shank, mortise and the airway in both the shank and the stem with alcohol, cotton swabs and pipe cleaners. The shank was very dirty. The airflow is great. I rubbed the bowl down with Before & After Restoration Balm. It is a paste/balm that works to deep clean the finish, enliven and protect the briar. I worked it into the briar with my finger tips to make sure that it covered every square inch of the pipe. I set it aside for 10 minutes to let it do its work. I buffed it with a cotton cloth. The briar really began to have a deep shine. The photos I took of the bowl at this point mark the progress in the restoration.

I rubbed the bowl down with Before & After Restoration Balm. It is a paste/balm that works to deep clean the finish, enliven and protect the briar. I worked it into the briar with my finger tips to make sure that it covered every square inch of the pipe. I set it aside for 10 minutes to let it do its work. I buffed it with a cotton cloth. The briar really began to have a deep shine. The photos I took of the bowl at this point mark the progress in the restoration.

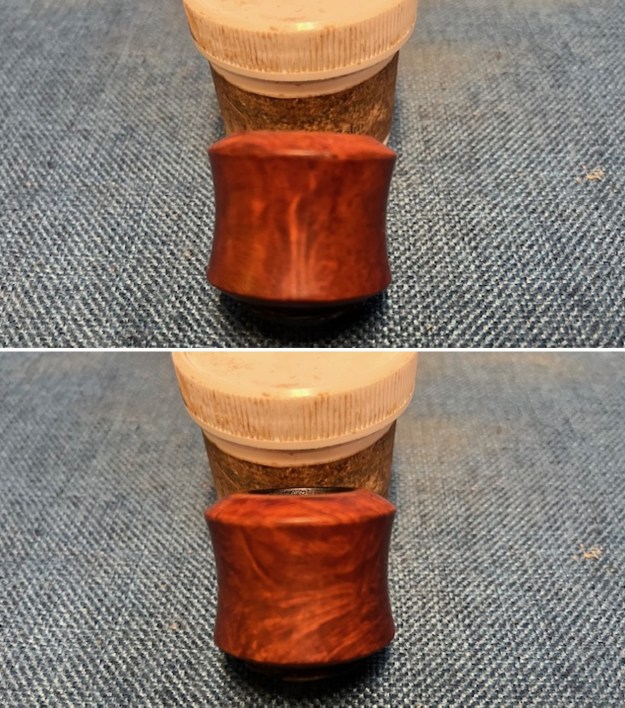

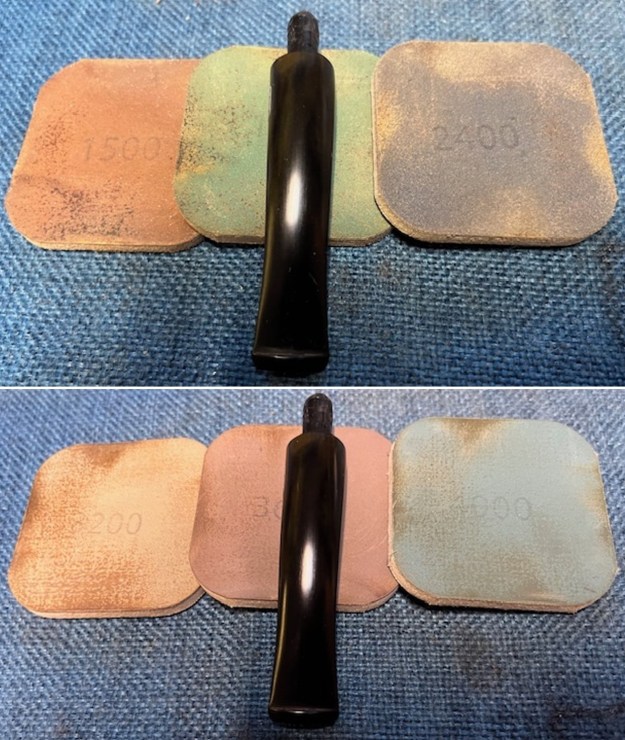

I set the bowl aside and turned my attention to the stem. I scrubbed the stem surface with Soft Scrub to remove the oxidation and the calcification. It looked much better. The tenon was a clear/white Delrin that was stained with tars and oils.

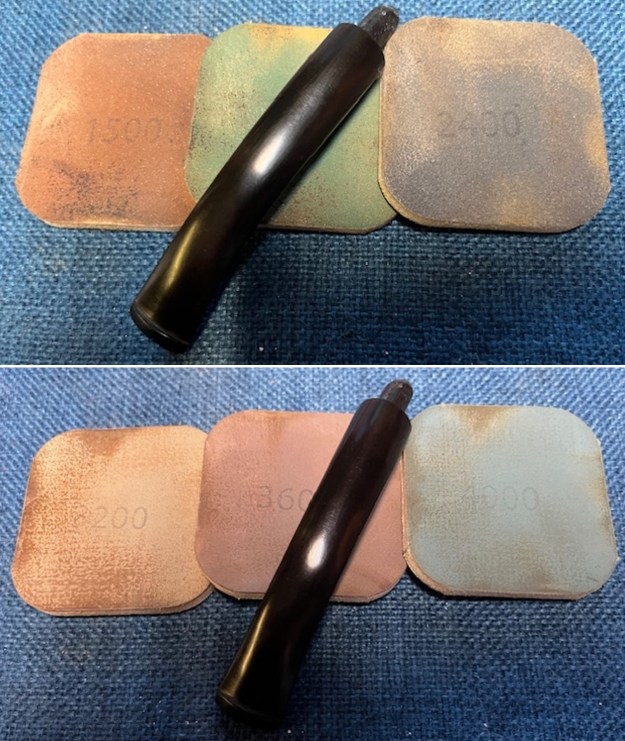

I set the bowl aside and turned my attention to the stem. I scrubbed the stem surface with Soft Scrub to remove the oxidation and the calcification. It looked much better. The tenon was a clear/white Delrin that was stained with tars and oils. I sanded the stem with 320-3500 grit sanding pads. I wiped the stem down after each pad with an Obsidian Oil impregnated cloth to remove the sanding debris. It began to take on a shine.

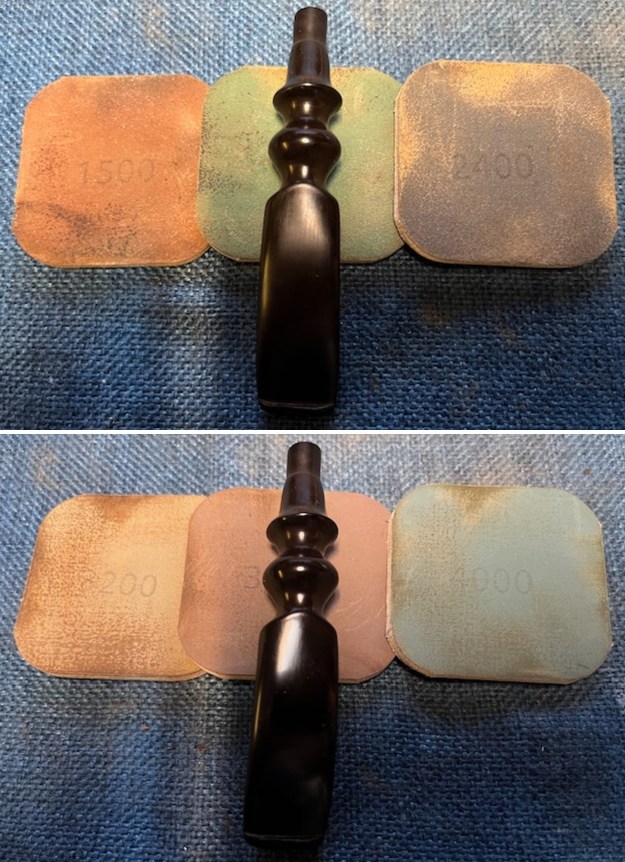

I sanded the stem with 320-3500 grit sanding pads. I wiped the stem down after each pad with an Obsidian Oil impregnated cloth to remove the sanding debris. It began to take on a shine. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped it down with some Obsidian Oil after each sanding pad. I polished it further with Before & After Stem polish – both Fine and Extra Fine and then wiped it down another time with the oil.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped it down with some Obsidian Oil after each sanding pad. I polished it further with Before & After Stem polish – both Fine and Extra Fine and then wiped it down another time with the oil.

I put the Duncan Hill Aerosphere Rusticated Apple and the stem back together. I polished the bowl and stem with Blue Diamond to polish the briar and the vulcanite. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The original brown stains gave depth to the rustication and worked amazingly well with the polished vulcanite half saddle stem. The grain around the bowl and shank and looks quite remarkable. This is truly a beautiful Duncan Hill Aerosphere. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 1.52 ounces/42 grams. This is such a unique shape that I am going to enjoy it for awhile before deciding what to do with it. Thanks for walking through the restoration with me. Cheers.

I put the Duncan Hill Aerosphere Rusticated Apple and the stem back together. I polished the bowl and stem with Blue Diamond to polish the briar and the vulcanite. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The original brown stains gave depth to the rustication and worked amazingly well with the polished vulcanite half saddle stem. The grain around the bowl and shank and looks quite remarkable. This is truly a beautiful Duncan Hill Aerosphere. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 1.52 ounces/42 grams. This is such a unique shape that I am going to enjoy it for awhile before deciding what to do with it. Thanks for walking through the restoration with me. Cheers.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.