by Kenneth Lieblich

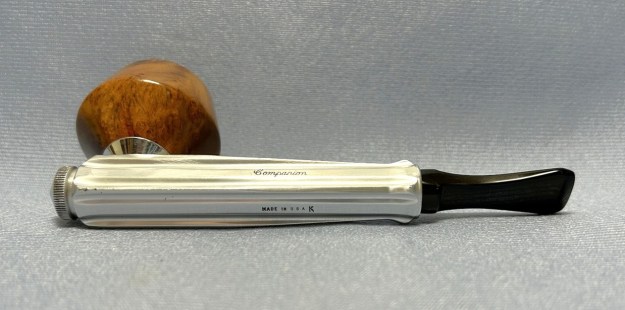

The latest restoration story belongs to a handsome Kirsten Companion ‘K’. Once again, this pipe is going to a young man from a local family who wanted some pipes restored. I’ve always been interested in Kirsten pipes – I’m not sure I always like them, but I always study them. The young fellow who acquired this pipe wanted something unusual and unlike the rest of his family – and he certainly got that! I quite like Steve’s description of Kirsten pipes:

Kirsten pipes have always been a bit of an enigma to me. The combination of briar and aluminum is unique. It is a pipe that is not really fish or fowl in terms of briar or metal. It is a pipe with an aluminum radiator with a bowl attached to it. The vulcanite stem is attached to an aluminum metal pin that extends the length of the radiator. On the end is a valve that controls the flow of air to bowl and is adjustable.

This pipe has some markings. Interestingly, the name Kirsten is not one of them, but this is unquestionably a Kirsten pipe. On the left side of the aluminum body is the word, Companion. On the underside of the body are the words, Made in U.S.A. – next to that is the shape letter, K.

This pipe has some markings. Interestingly, the name Kirsten is not one of them, but this is unquestionably a Kirsten pipe. On the left side of the aluminum body is the word, Companion. On the underside of the body are the words, Made in U.S.A. – next to that is the shape letter, K. Kirsten pipes have a long and interesting history. Naturally, Pipedia has a long article on this, but, in fact, that information comes from the fascinating Smoking Metal website. I encourage you to read the various articles they have on Kirstens.

Kirsten pipes have a long and interesting history. Naturally, Pipedia has a long article on this, but, in fact, that information comes from the fascinating Smoking Metal website. I encourage you to read the various articles they have on Kirstens. Let’s examine the pipe a bit. The aluminum is in decent shape – no major dents or scratches. There are merely micro-scratches, but no big deal. Similarly, the stem was in really nice shape. Only very minor tooth wear. Little oxidation and calcification. However, the briar bowl did have some issues. It had some cake in the bowl and was fairly dirty. The main problem was a significant burn on the rim. I’d have to take a closer look at that.

Let’s examine the pipe a bit. The aluminum is in decent shape – no major dents or scratches. There are merely micro-scratches, but no big deal. Similarly, the stem was in really nice shape. Only very minor tooth wear. Little oxidation and calcification. However, the briar bowl did have some issues. It had some cake in the bowl and was fairly dirty. The main problem was a significant burn on the rim. I’d have to take a closer look at that. My first step was to take the entire pipe apart. Here is a good photo of the various components of this Kirsten – plus the screwdriver I used to take the pipe apart.

My first step was to take the entire pipe apart. Here is a good photo of the various components of this Kirsten – plus the screwdriver I used to take the pipe apart. I decided to work on the briar bowl first on this occasion. The first step for the bowl is to ream it out – that is to say, remove all the cake inside. This accomplishes a couple of things. First (and most obviously), it cleans the bowl and provides a refurbished chamber for future smoking. Second, when the old cake is removed, I can inspect the interior walls of the bowl and determine if there is damage or not. I used a reamer, a pipe knife, and a piece of sandpaper taped to a wooden dowel. Collectively, these ensure that all the debris is removed.

I decided to work on the briar bowl first on this occasion. The first step for the bowl is to ream it out – that is to say, remove all the cake inside. This accomplishes a couple of things. First (and most obviously), it cleans the bowl and provides a refurbished chamber for future smoking. Second, when the old cake is removed, I can inspect the interior walls of the bowl and determine if there is damage or not. I used a reamer, a pipe knife, and a piece of sandpaper taped to a wooden dowel. Collectively, these ensure that all the debris is removed. The damage to the rim is significant. In order to lessen the burns and nicks on the rim, I ‘topped’ the pipe – that is to say, I gently and evenly sanded the rim on a piece of 220-grit sandpaper. This effectively minimizes the damage, without altering the look of the pipe.

The damage to the rim is significant. In order to lessen the burns and nicks on the rim, I ‘topped’ the pipe – that is to say, I gently and evenly sanded the rim on a piece of 220-grit sandpaper. This effectively minimizes the damage, without altering the look of the pipe. Some of the burn remained on the rim, so I took some crystalized oxalic acid and dissolved it in warm water. I took some cotton swaps, dipped in the solution, and rubbed the burned spot vigorously. Some of the burn was removed, but, unfortunately, some will always remain as part of this pipe’s history.

Some of the burn remained on the rim, so I took some crystalized oxalic acid and dissolved it in warm water. I took some cotton swaps, dipped in the solution, and rubbed the burned spot vigorously. Some of the burn was removed, but, unfortunately, some will always remain as part of this pipe’s history. To tidy up the briar, I also wiped down the outside with some oil soap on cotton rounds (and a toothbrush). This does a good job of cleaning any latent dirt on the surface of the briar. The last step of the cleaning process is to scour the inside of the stummel with some soap and tube brushes. This is the culmination of a lot of hard work in getting the bowl clean.

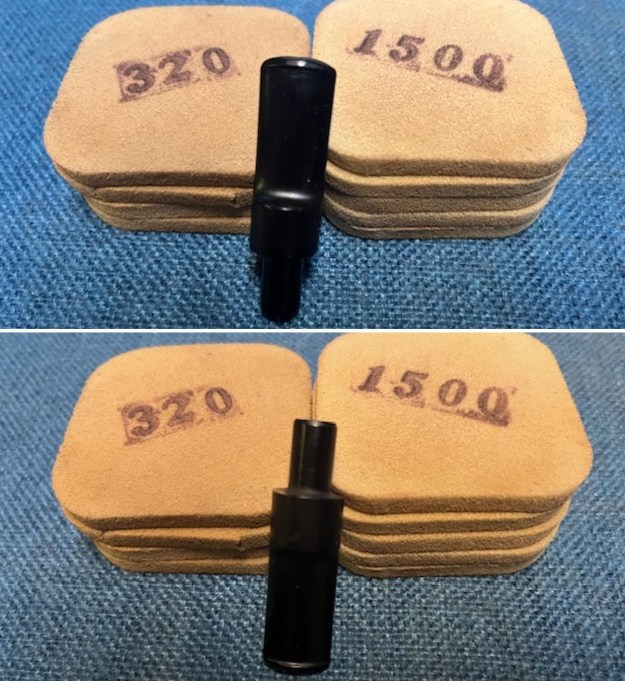

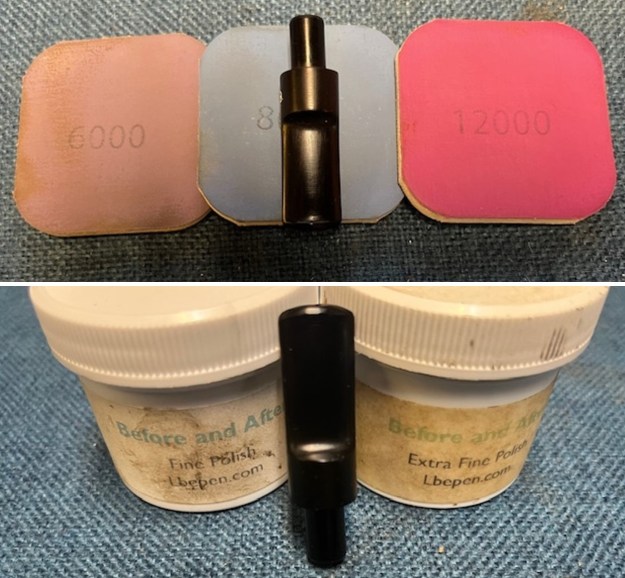

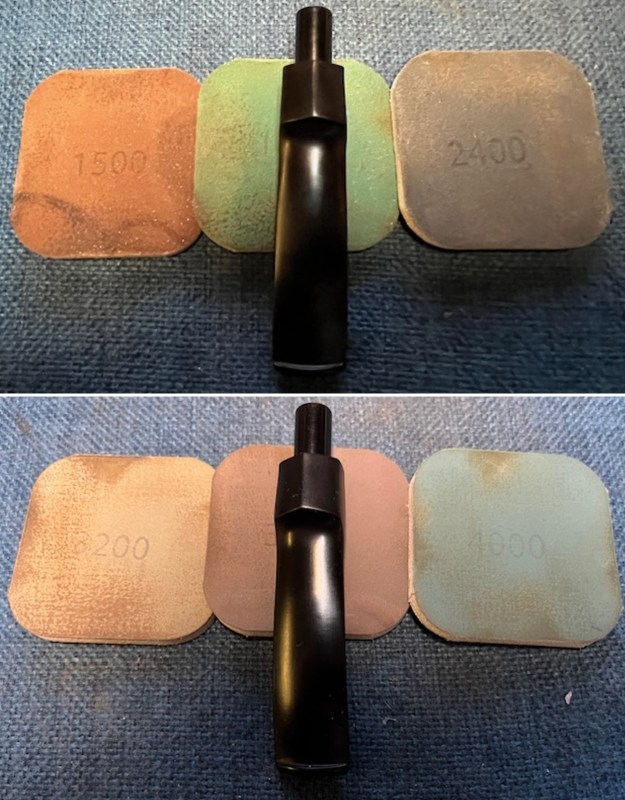

To tidy up the briar, I also wiped down the outside with some oil soap on cotton rounds (and a toothbrush). This does a good job of cleaning any latent dirt on the surface of the briar. The last step of the cleaning process is to scour the inside of the stummel with some soap and tube brushes. This is the culmination of a lot of hard work in getting the bowl clean. I took a solid wooden sphere, wrapped a piece of 220-grit sandpaper around it, and sanded the inner edge of the rim. This achieves two things: first, it removes some of the burn marks; and second (and more importantly), the circular shape and motion of the sphere gradually returns the edge to a perfect circle. I then used all nine micromesh pads (1,500 through 12,000 grit) on the outside of the stummel to finish it off. This sanding minimizes flaws in the briar and provides a beautiful smoothness to the wood. I rubbed some Before & After Restoration Balm into the briar and let it sit for 20 minutes or so. The balm moisturizes the wood and gives a beautiful depth to the briar. I then buffed it with a microfibre cloth.

I took a solid wooden sphere, wrapped a piece of 220-grit sandpaper around it, and sanded the inner edge of the rim. This achieves two things: first, it removes some of the burn marks; and second (and more importantly), the circular shape and motion of the sphere gradually returns the edge to a perfect circle. I then used all nine micromesh pads (1,500 through 12,000 grit) on the outside of the stummel to finish it off. This sanding minimizes flaws in the briar and provides a beautiful smoothness to the wood. I rubbed some Before & After Restoration Balm into the briar and let it sit for 20 minutes or so. The balm moisturizes the wood and gives a beautiful depth to the briar. I then buffed it with a microfibre cloth.

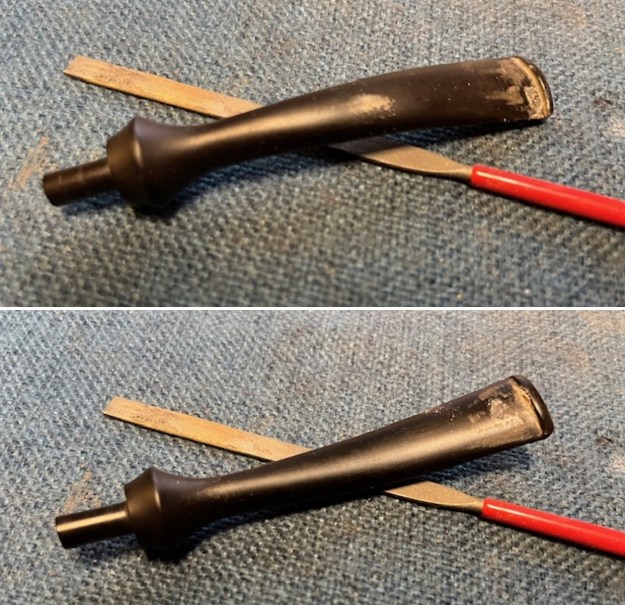

On to the stem. I cleaned the inside with both pipe cleaners and cotton swabs dipped in 99% lemon-infused isopropyl alcohol. I scrubbed thoroughly to make sure the interior was clean.

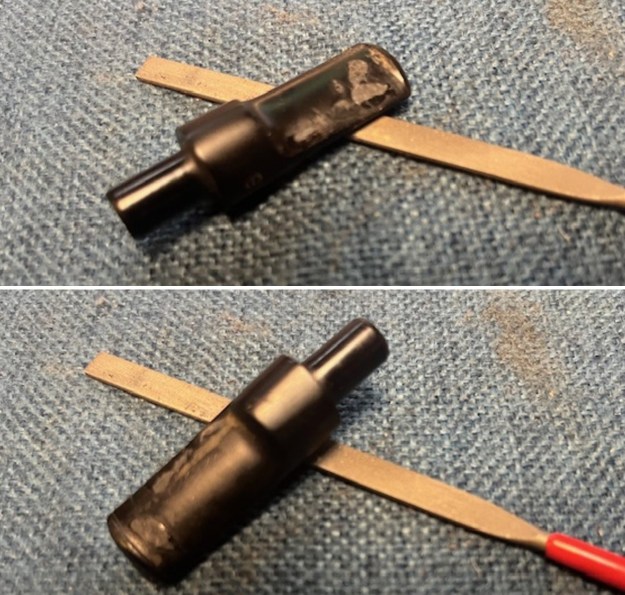

On to the stem. I cleaned the inside with both pipe cleaners and cotton swabs dipped in 99% lemon-infused isopropyl alcohol. I scrubbed thoroughly to make sure the interior was clean. The goal of the next step is the removal (or minimization) of oxidation. Going to my sink, I used cream cleanser, cotton rounds, and a toothbrush, and scoured the stem to remove as much surface oxidation as possible. As the photos show, the result is a hideous brownish mess – but better off the stem than on it.

The goal of the next step is the removal (or minimization) of oxidation. Going to my sink, I used cream cleanser, cotton rounds, and a toothbrush, and scoured the stem to remove as much surface oxidation as possible. As the photos show, the result is a hideous brownish mess – but better off the stem than on it. Once the stem was reasonably clean, I soaked it overnight in some de-oxidation fluid. This solution works to draw oxidation in the stem to the surface. This is a major aid and an important step in ensuring a clean stem. The following day, I drew the stem out from its bath and scrubbed the lingering fluid with a toothbrush.

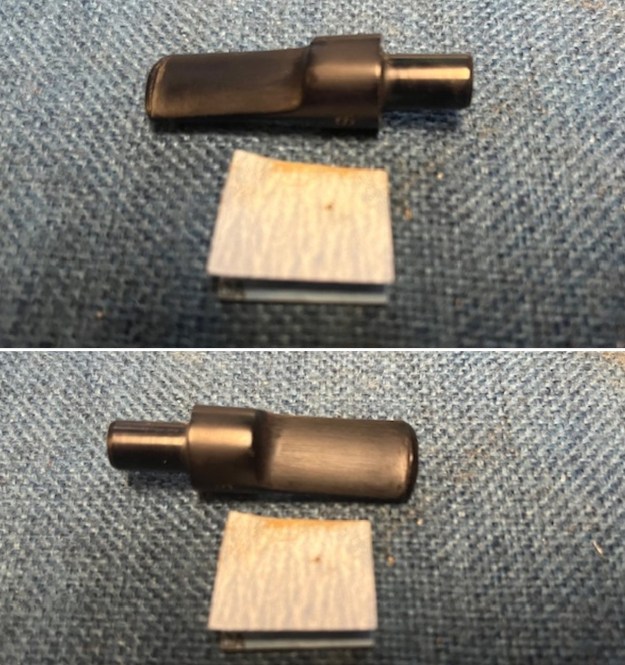

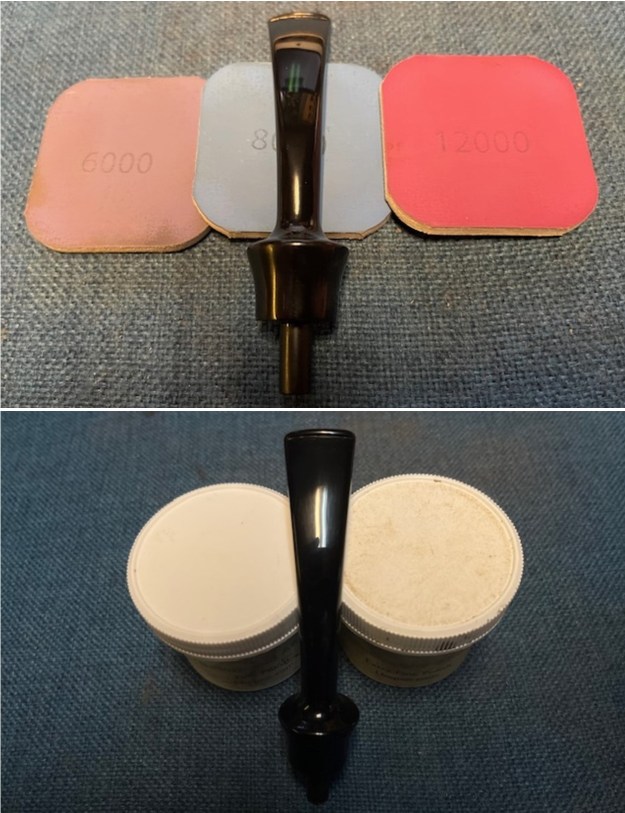

Once the stem was reasonably clean, I soaked it overnight in some de-oxidation fluid. This solution works to draw oxidation in the stem to the surface. This is a major aid and an important step in ensuring a clean stem. The following day, I drew the stem out from its bath and scrubbed the lingering fluid with a toothbrush. I used all nine of the micromesh sanding pads (1,500 through 12,000 grit) to sand out flaws, even out the vulcanite, and provide gentle polishing of the finished surface. I also applied pipe-stem oil while using the last five micromesh pads. There was a wonderful, deep black shine to the stem when I was done.

I used all nine of the micromesh sanding pads (1,500 through 12,000 grit) to sand out flaws, even out the vulcanite, and provide gentle polishing of the finished surface. I also applied pipe-stem oil while using the last five micromesh pads. There was a wonderful, deep black shine to the stem when I was done. Next was the aluminum body of this old Kirsten. In order to loosen up some of the old filth, I soaked all the metal pieces in a vinegar solution. This was only mildly successful and I would need to do more.

Next was the aluminum body of this old Kirsten. In order to loosen up some of the old filth, I soaked all the metal pieces in a vinegar solution. This was only mildly successful and I would need to do more. Just like other pipes, I cleaned the insides thoroughly with cotton swabs dipped in 99% lemon-infused isopropyl alcohol. This wasn’t enough – I also cleaned the inside of the aluminum with my cream cleanser and some tube brushes. That worked well! I then used my grey micromesh pads and polished the metal to a beautiful shine. Boy, it looked terrific after that.

Just like other pipes, I cleaned the insides thoroughly with cotton swabs dipped in 99% lemon-infused isopropyl alcohol. This wasn’t enough – I also cleaned the inside of the aluminum with my cream cleanser and some tube brushes. That worked well! I then used my grey micromesh pads and polished the metal to a beautiful shine. Boy, it looked terrific after that. For the final step, I took the bowl to my bench buffer and carefully polished it – first with a white diamond compound, then with three coats of carnauba wax. This procedure makes the pipe look its best – the stummel sings and the stem glows.

For the final step, I took the bowl to my bench buffer and carefully polished it – first with a white diamond compound, then with three coats of carnauba wax. This procedure makes the pipe look its best – the stummel sings and the stem glows. All done! This Kirsten Companion K looks fantastic again and is ready to be enjoyed by its new owner. It was great fun to work on. The approximate dimensions of the pipe are as follows: length 5⅓ in. (136 mm); height 1⅞ in. (48 mm); bowl diameter 1½ in. (39 mm); chamber diameter ⅞ in. (22 mm). The weight of the pipe is 1⅝ oz. (49 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I enjoyed restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.

All done! This Kirsten Companion K looks fantastic again and is ready to be enjoyed by its new owner. It was great fun to work on. The approximate dimensions of the pipe are as follows: length 5⅓ in. (136 mm); height 1⅞ in. (48 mm); bowl diameter 1½ in. (39 mm); chamber diameter ⅞ in. (22 mm). The weight of the pipe is 1⅝ oz. (49 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I enjoyed restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.