Blog by Steve Laug

On our recent Victoria Day Weekend (5/18/24) my family met Jeff and his wife in Bellingham for breakfast, a visit and a bit of pipe hunting. We visited three of my favourite antique malls and worked out way through the aisles of wares for sale. Jeff and I tend to divide and conquer, each walking through the aisles looking for pipes. The rest of the family moves through looking for their own treasures. The second shop we visited is a treasure trove of items from the past and one that I could spend a lot of time working through. As we went through the aisles of treasures I found a case with carved animal pipes and a Ropp Cherrywood, really none of them captured my interest this time around. I looked them over and set them aside. Then I saw an interesting pipe standing in the back of the case. It was called The Pedestal Pipe and was made in Israel – presumably by the Shalom Pipe Manufacturing company. We left the shop with this addition to the hunting bag (https://rebornpipes.com/tag/bellingham-pipe-hunt/). I decided to take a break from the pipes in my queue of pipes to work on and deal with the Pedestal Pipe shown above next. It was an interesting shape stands on its own – like a pipe on a pedestal. It had some nice grain under the grime and varnish coat on the bowl and shank. The pipe is stamped on the left side of the shank and reads The Pedestal [arched over] Pipe. On the right side it is stamped and reads Mediterranean [over] Briar Israel. Here is what I saw. The bowl had a thick cake in it a thick lava coat on the rim top and edges. The finish was spotty with varnish or some shiny coat that was peeling around the bowl. The stem was fancy and there was a round saddle portion that sat against the shank end. The blade of the stem was flattened and had panel sides. It was dirty and had tooth marks and chatter on both sides ahead of the button. I took some photos of the pipe before I started working on it.

I decided to take a break from the pipes in my queue of pipes to work on and deal with the Pedestal Pipe shown above next. It was an interesting shape stands on its own – like a pipe on a pedestal. It had some nice grain under the grime and varnish coat on the bowl and shank. The pipe is stamped on the left side of the shank and reads The Pedestal [arched over] Pipe. On the right side it is stamped and reads Mediterranean [over] Briar Israel. Here is what I saw. The bowl had a thick cake in it a thick lava coat on the rim top and edges. The finish was spotty with varnish or some shiny coat that was peeling around the bowl. The stem was fancy and there was a round saddle portion that sat against the shank end. The blade of the stem was flattened and had panel sides. It was dirty and had tooth marks and chatter on both sides ahead of the button. I took some photos of the pipe before I started working on it.

I took photos of the rim top and stem to show the general condition of the pipe. The bowl is heavily caked and the rim top and edges have a heavy coat of lava overflowing on to them. There is some burn or reaming damage on the inner edge of the bowl. The stem is oxidized, calcified and has tooth marks and chatter on both sides ahead of the button.

I took photos of the rim top and stem to show the general condition of the pipe. The bowl is heavily caked and the rim top and edges have a heavy coat of lava overflowing on to them. There is some burn or reaming damage on the inner edge of the bowl. The stem is oxidized, calcified and has tooth marks and chatter on both sides ahead of the button. I took photos of the stamping on the sides of the shank. You can see it is readable and in person looks much better with a light and lens. I removed the stem from the shank and took a photo of the parts to show the look of the pipe.

I took photos of the stamping on the sides of the shank. You can see it is readable and in person looks much better with a light and lens. I removed the stem from the shank and took a photo of the parts to show the look of the pipe.

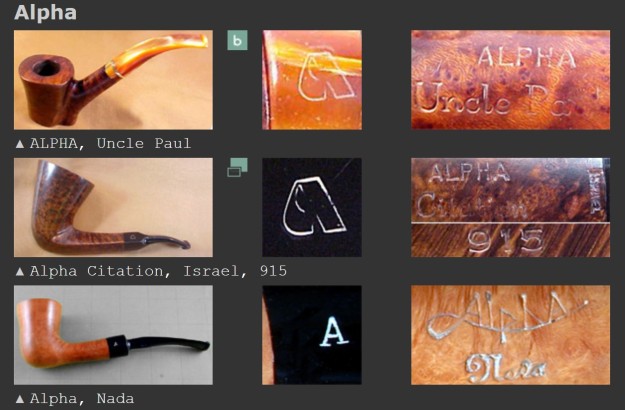

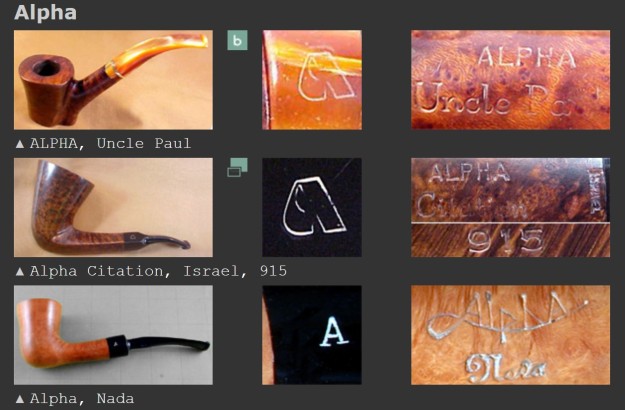

I decided to do some digging on the net about the brand. I turned first to Pipephil’s site to see what I could find. I could not find any link to the Pedestal line from Israel but I turned to the section on the site for Alpha pipe (also made by Shalom Pipe Factory). Here is the link to the Alpha section (http://www.pipephil.eu/logos/en/logo-a4.html). I did a screen capture of the section on the pipes. The third pipe in the photo below has an identical stem to the Pedestal Pipe that I am working on. This ties the brand to Alpha at some level and even more to Shalom Pipe Factory.

I decided to do some digging on the net about the brand. I turned first to Pipephil’s site to see what I could find. I could not find any link to the Pedestal line from Israel but I turned to the section on the site for Alpha pipe (also made by Shalom Pipe Factory). Here is the link to the Alpha section (http://www.pipephil.eu/logos/en/logo-a4.html). I did a screen capture of the section on the pipes. The third pipe in the photo below has an identical stem to the Pedestal Pipe that I am working on. This ties the brand to Alpha at some level and even more to Shalom Pipe Factory. With that information I turned to Pipedia and looked up the information on the Shalom Pipe Factory (https://pipedia.org/wiki/Shalom_Pipe_Factory). I quote the information from the site below. I have highlighted the Pedestal link in the article.

With that information I turned to Pipedia and looked up the information on the Shalom Pipe Factory (https://pipedia.org/wiki/Shalom_Pipe_Factory). I quote the information from the site below. I have highlighted the Pedestal link in the article.

Not much is known about Israel’s sole pipe factory though it’s reported to have operated quite successfully on international markets.

Beside the brand “Shalom” the mainstay brand was Alpha – especially well known in the USA. Alpha was popular for a range of fresh and unusual shapes. Series (afaik): Caprice (s), Citation (s), Classic (b), Pedestal (s), Regent, Region (b), Rex (s). (1)

(1) (b) = blasted, (s) = smooth…

Alpha also produced at least one of its Citation forms for Carey’s “Magic Inch” series.

Mentioned in context with Shalom Pipe Factory was a Danish pipemaker named ‘Muki Liebermann’, who later lived and worked in the USA. Muki is known for his unique briar bending technique and his original shapes that gave inspiration to many of the most praised Danish pipemakers.

Shalom was taken over by Robert L. Marx of New York City, later Sparta, NC, then of Mastercraft. Mastercraft continued the Alpha pipes introducing new lines.

I did a Google search for the The Pedestal Pipe and came up with a few links that I followed up on. The best of them was a link to a thread on Pipesmagazine forum to a discussion on a pipe very much like this one (https://pipesmagazine.com/forums/threads/unique-original-sitter-pipe-designs.25944/). I quote the starting post in the thread below:

I liked this pipes unique design as a sitter and the briar doesn’t look too shabby. I’m guessing this came from the Shalom Pipe Factory and made by Muki Liebermann since he was known for his unique briar bending technique and original shapes.

The only stamping found is ‘THE PEDESTAL PIPE’ and ‘Mediterranean Briar Israel’. I’ve searched the internet and cannot find any information on this pipe other than what I have mentioned. Been smoking it for the past week and it’s an excellent smoker.

Feel free to post images of your sitters!! Love to see them.

Now I was ready to start the work on the pipe. I wiped the bowl down with acetone to remove the spotty shiny coat on the pipe. It took a few wipe downs to remove it but once finished it definitely was better. Interestingly there was some red dye under the shiny coat that came off as well.

I moved on to work on the internals of the pipe. I reamed the bowl with a PipNet pipe reamer to take the cake back to bare briar. I took the cake back to bare briar and cleaned up the remnants of the cake with a Savinelli Fitsall Pipe Knife. I sanded the bowl walls with sandpaper wrapped around a piece of briar to smooth them out. The inside walls were clean and there was no sign of burning or checking on them.

I moved on to work on the internals of the pipe. I reamed the bowl with a PipNet pipe reamer to take the cake back to bare briar. I took the cake back to bare briar and cleaned up the remnants of the cake with a Savinelli Fitsall Pipe Knife. I sanded the bowl walls with sandpaper wrapped around a piece of briar to smooth them out. The inside walls were clean and there was no sign of burning or checking on them.

I scrubbed the inside of the shank and the airway in it and the stem with pipe cleaners, cotton swabs and isopropyl alcohol. Once it was clean it smelled much better was ready for the next steps in the process.

I scrubbed the inside of the shank and the airway in it and the stem with pipe cleaners, cotton swabs and isopropyl alcohol. Once it was clean it smelled much better was ready for the next steps in the process. I scrubbed the externals of the bowl and shank with undiluted Murphy’s Oil Soap and a tooth brush to remove the grime in the finish. I rinsed the bowl off with warm water. I scrubbed the internals with shank brushes and soap to remove the grime inside. I was able to remove a lot of the lava on the rim top as well. The bowl was beginning to look much better at this point.

I scrubbed the externals of the bowl and shank with undiluted Murphy’s Oil Soap and a tooth brush to remove the grime in the finish. I rinsed the bowl off with warm water. I scrubbed the internals with shank brushes and soap to remove the grime inside. I was able to remove a lot of the lava on the rim top as well. The bowl was beginning to look much better at this point.

I sanded the bowl with sanding pads – sanding with 320-3500 grit pads and wiped down with a damp cloth after each sanding pad. The bowl began to take on a real shine. It was going to be a beautiful pipe.

I sanded the bowl with sanding pads – sanding with 320-3500 grit pads and wiped down with a damp cloth after each sanding pad. The bowl began to take on a real shine. It was going to be a beautiful pipe.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping the bowl down after each sanding pad. The grain really began to shine through. It is a beautiful pipe.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping the bowl down after each sanding pad. The grain really began to shine through. It is a beautiful pipe.

The polishing of the rim top and inner edge brought the rim top colour to match the rest of the bowl. I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

The polishing of the rim top and inner edge brought the rim top colour to match the rest of the bowl. I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I set the bowl aside and turned to address the stem issues. I “painted” the surface of the stem with the flame of a Bic lighter. I was able to lift the marks on the stem top leaving light marks but the ones on the bottom side were much deeper and the flame lifted them slightly but they still remained. I filled in the marks that remained with clear CA glue.

I set the bowl aside and turned to address the stem issues. I “painted” the surface of the stem with the flame of a Bic lighter. I was able to lift the marks on the stem top leaving light marks but the ones on the bottom side were much deeper and the flame lifted them slightly but they still remained. I filled in the marks that remained with clear CA glue.

Once the repair cured I flattened the repair with small files. It looked much better. I cleaned up the repairs with a folded piece of 220 grit sandpaper. I was able to flatten them and blend them in very well with the surface of the vulcanite.

Once the repair cured I flattened the repair with small files. It looked much better. I cleaned up the repairs with a folded piece of 220 grit sandpaper. I was able to flatten them and blend them in very well with the surface of the vulcanite.

Before continuing with the sanding process, I heated the stem with my lighter to soften the vulcanite and bent it to match the flow of the bowl. It looked much better with the proper bend.

Before continuing with the sanding process, I heated the stem with my lighter to soften the vulcanite and bent it to match the flow of the bowl. It looked much better with the proper bend. I sanded out the scratches and marks in the stem surface with 320-3500 grit sanding pads. I wiped the stem down with a damp cloth after each sanding pad. It looked much better and really started to take on a shine.

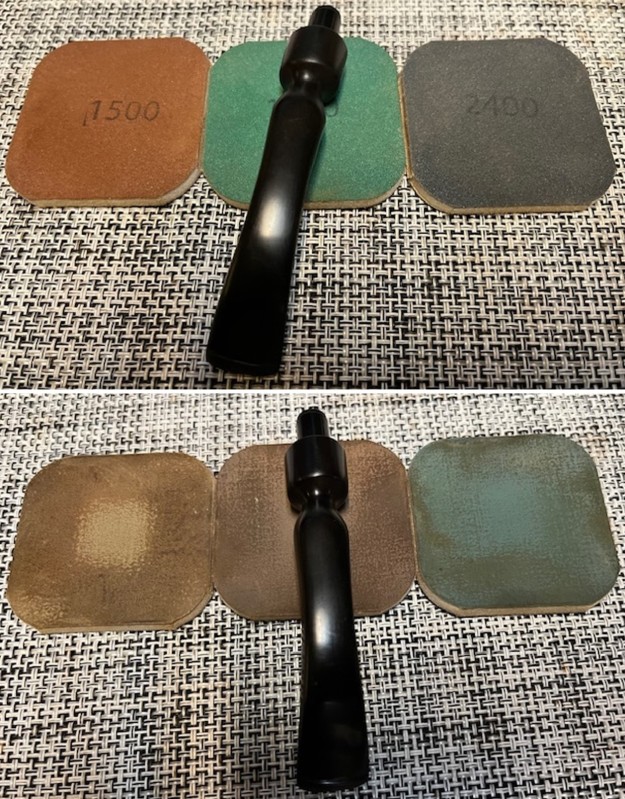

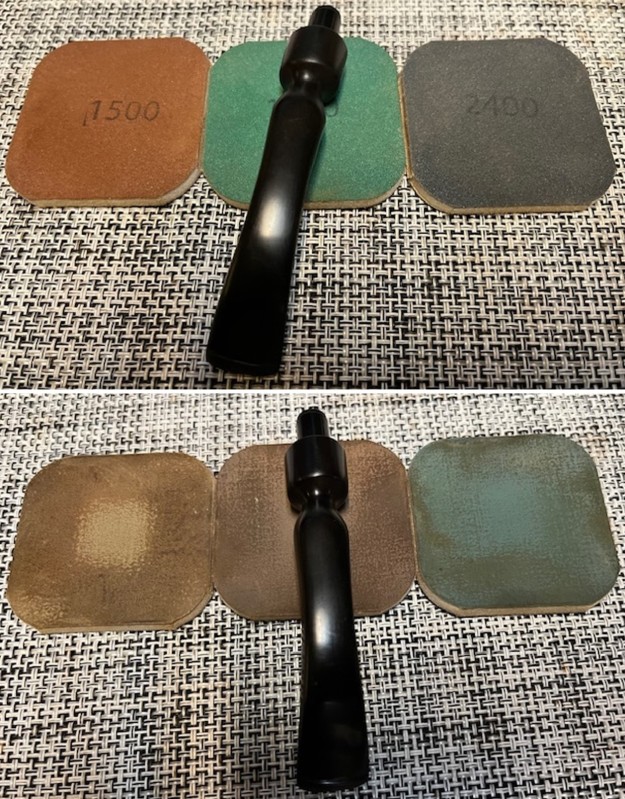

I sanded out the scratches and marks in the stem surface with 320-3500 grit sanding pads. I wiped the stem down with a damp cloth after each sanding pad. It looked much better and really started to take on a shine. I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine.

I am excited to put the final touches on this interesting Israeli Made pipe by Muki Liebermann of the Shalom Pipe Factory. It is a beautiful and uniquely shaped pipe called The Pedestal Pipe. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with beautiful grain on the bowl sides, top and bottom. The polished black vulcanite, newly fitted stem combined with the bowl to make a stunning pipe. This smooth The Pedestal Pipe is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 56 grams/1.98 ounces. I will be adding it to the Pipes By Various Makers Section of the rebornpipes store. If you are interested in adding it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.

I am excited to put the final touches on this interesting Israeli Made pipe by Muki Liebermann of the Shalom Pipe Factory. It is a beautiful and uniquely shaped pipe called The Pedestal Pipe. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with beautiful grain on the bowl sides, top and bottom. The polished black vulcanite, newly fitted stem combined with the bowl to make a stunning pipe. This smooth The Pedestal Pipe is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 56 grams/1.98 ounces. I will be adding it to the Pipes By Various Makers Section of the rebornpipes store. If you are interested in adding it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.