Blog by Steve Laug

I thought it might be helpful to take you through my process of working on each pipe that we purchase. Jeff has set up a spread sheet to track where the pipe came from, the date of purchase and what we paid for it so that we know what we have invested in the pipe before we even work on it. This takes a lot of the guess work out of the process. This particular pipe was purchased on 09/18/2020 from a seller in Los Angeles, California, USA. I also want you to understand why we take the photos we do. If you have followed for a while then you will see the familiar pattern of the photos we include both in the before and midstream process of working on a pipe. It is not accidental or chance as the photos have been taken to help me make an assessment of the pipe Jeff sees before he starts his clean up work. We do this to record the condition that the pipe was in when received it and to assess what kind of work will need to be done on. When I look at these photos this is what I see.

I thought it might be helpful to take you through my process of working on each pipe that we purchase. Jeff has set up a spread sheet to track where the pipe came from, the date of purchase and what we paid for it so that we know what we have invested in the pipe before we even work on it. This takes a lot of the guess work out of the process. This particular pipe was purchased on 09/18/2020 from a seller in Los Angeles, California, USA. I also want you to understand why we take the photos we do. If you have followed for a while then you will see the familiar pattern of the photos we include both in the before and midstream process of working on a pipe. It is not accidental or chance as the photos have been taken to help me make an assessment of the pipe Jeff sees before he starts his clean up work. We do this to record the condition that the pipe was in when received it and to assess what kind of work will need to be done on. When I look at these photos this is what I see.

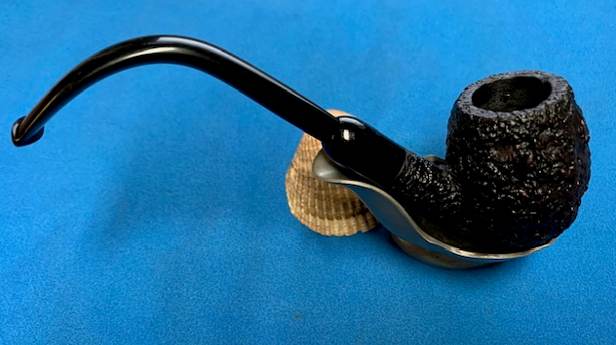

- The first thing I see is a classic Italian Made Castello Sea Rock Briar Bent Egg with a acrylic ferrule/shank extension and a military mount stem. It is well proportioned and well made with a Bent Egg shape.

- The finish is dirty and there is grime and grit ground into the rugged rustication on the sides of the bowl and shank. It is dusty and dull looking but under the grime the pipe looks good.

- The rim top has some lava and debris in the valleys of the rustication on the top and the edges. It is dirty looking but cleaning will reveal a real beauty.

- The bowl has a thick cake and debris on the walls that hides the walls and some grime on the inner edge of the bowl but once it is clean we will know what the bowl and edges really look like. The outer edges look good and there does not appear to be any obvious burn damage to the top or bowl edges.

- The acrylic military mount acrylic stem is in good condition – dirty and has light tooth chatter and marks on both sides ahead of button. There is a crinkled/Diamond insert logo on the left side of the stem.

Overall my impressions of this pipe is that it is a beauty that once cleaned up will look pretty amazing. I love the tactile rustication on the Sea Rock Briars and have found nothing that comes close to it. The photos below confirm the assessment above.  Jeff took close up photos so that I could have a clearer picture of the condition of the bowl, rim edges and top. The rim top photos confirm my assessment above. The cake in the bowl is moderate with tobacco debris stuck on the walls. The rim top has some lava, grime and debris in the rusticated surface. You can also see the condition of the outer edge and the inner edge is in great condition. This is what I look for when assessing a pipe. There is no visible burn damage at this point. The bowl is still round and other than being in a used condition it is in great shape.

Jeff took close up photos so that I could have a clearer picture of the condition of the bowl, rim edges and top. The rim top photos confirm my assessment above. The cake in the bowl is moderate with tobacco debris stuck on the walls. The rim top has some lava, grime and debris in the rusticated surface. You can also see the condition of the outer edge and the inner edge is in great condition. This is what I look for when assessing a pipe. There is no visible burn damage at this point. The bowl is still round and other than being in a used condition it is in great shape.

The photos of the acrylic stem surface from various angles confirmed my assessment of its condition. You can see the dirty/sticky substance on the stem in the first photo below. Fortunately the stem does not appear to have deep tooth marks – chatter yes, but no deep marks. The stem is quite dirty but otherwise undamaged.

The photos of the acrylic stem surface from various angles confirmed my assessment of its condition. You can see the dirty/sticky substance on the stem in the first photo below. Fortunately the stem does not appear to have deep tooth marks – chatter yes, but no deep marks. The stem is quite dirty but otherwise undamaged.

Instead of telling you what I see in the next photos of the sides of the bowl and the heel I want to hear from you. Tell me what you see? What does the finish look like to you? Are there any visible problems or issues that stand out to you? Are the cracks or scratches in the valleys of the rustication or the high spots? Are there visible flaws or fissures in the briar? How random does the deep rustication look? Is there a pattern to it? Any visible issues on the heel of the bowl? These questions should help you to see what I am looking for when I see these photos.

Instead of telling you what I see in the next photos of the sides of the bowl and the heel I want to hear from you. Tell me what you see? What does the finish look like to you? Are there any visible problems or issues that stand out to you? Are the cracks or scratches in the valleys of the rustication or the high spots? Are there visible flaws or fissures in the briar? How random does the deep rustication look? Is there a pattern to it? Any visible issues on the heel of the bowl? These questions should help you to see what I am looking for when I see these photos.

He took photos of the stamping on the underside of the shank. On the heel of the bowl is stamped the shape number 93. That is followed by the Made in Cantu [over] Italy stamp (two lines) Next that it is stamped Castello [over] Sea Rock Briar. The acrylic ferrule is stamped on the underside and reads HAND MADE [over] Castello [over] the number 3. What stands out for you in the photos of the stamping on the pipe? What do you look for in the stamping? I know it is dirty but what do you see underneath the grime on the surface of the briar and the acrylic?

He took photos of the stamping on the underside of the shank. On the heel of the bowl is stamped the shape number 93. That is followed by the Made in Cantu [over] Italy stamp (two lines) Next that it is stamped Castello [over] Sea Rock Briar. The acrylic ferrule is stamped on the underside and reads HAND MADE [over] Castello [over] the number 3. What stands out for you in the photos of the stamping on the pipe? What do you look for in the stamping? I know it is dirty but what do you see underneath the grime on the surface of the briar and the acrylic?

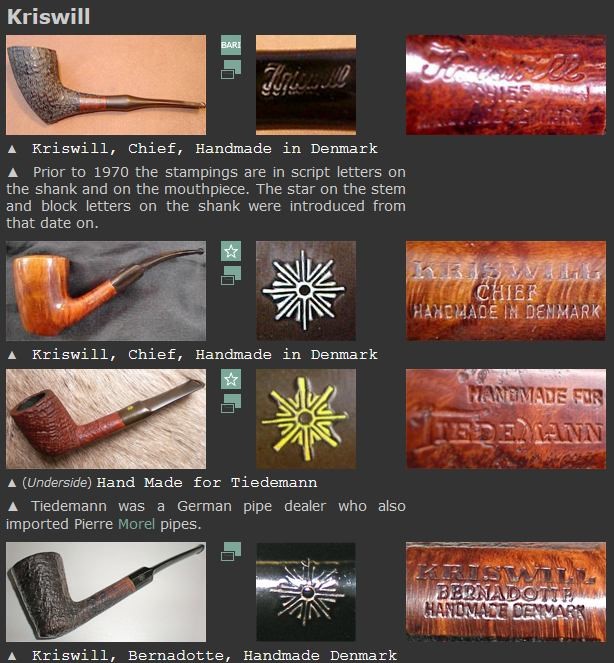

As a part of the restoration of the pipe that I work on I love to research the background information on the stamping of this pipe to get an idea of the time period it was carved and a sense of when it left Italy for the export to the US. I turned to Pipephil’s site for a quick overview of the brand (http://pipephil.eu/logos/en/logo-castello.html). I have included a screen capture of the brand below as well as the sidebar notes below the photo.

As a part of the restoration of the pipe that I work on I love to research the background information on the stamping of this pipe to get an idea of the time period it was carved and a sense of when it left Italy for the export to the US. I turned to Pipephil’s site for a quick overview of the brand (http://pipephil.eu/logos/en/logo-castello.html). I have included a screen capture of the brand below as well as the sidebar notes below the photo. Rhinestone logo was originally on pipes for the US market. It is occasionally used now.

Rhinestone logo was originally on pipes for the US market. It is occasionally used now.

I knew now that the pipe was made for export to the US Market as noted above by the rhinestone or faux diamond logo on the stem side.

I quote further the introductory information at the top of the Pipephil page regarding the brand as I find it quite helpful to set a context.

Castello PIPA CASTELLO di Carlo Scotti & C. was founded in 1947 by Carlo Scotti (†1988). Franco Coppo (AKA “Kino”) who married Carlo Scotti’s daughter Savina, manages (2012) the corporate since 1985.

The site also gave a good summary of the grading and sizes of the pipes. I quote that in full so you can see where the Sea Rock Briar fits in the scheme of things Castello.

Sizes (ascending):

1K to 4K, G (Giant) and GG (Extra large)

Rusticated grading: SEA ROCK, OLD SEA ROCK, NATURAL VIRGIN,

Sandblasted grading: ANTIQUARI, OLD ANTIQUARI

Smooth grading (ascending): TRADEMARK, CASTELLO, COLLECTION

Other stampings: Great Line (Non-standard or freestyle) Fiammata (Straight grain)

Production (2012): ~4000 pipes / year

I turned then to Pipedia for more information on the brand (https://pipedia.org/wiki/Castello). The majority of the information was what was already quoted above in abbreviated form. However there was a link to an article by Bob Hamlin that gave some interesting bits of information that I found helpful (http://www.pipes.org/BURST/FORMATTED/196.016.html). I quote in part from that article.

SEA ROCK [Carved Black or dark brown]: This is the lowest grade of the Castello line and is the most common in the USA. Sea Rocks are produced by taking a smooth bowl that has not been “final finished” and surface carving the finish with tools. This “carved” finish is then evened out using a steel wire brush, stained and then waxed. The Natural Vergin carved finish is left unstained and unwaxed as a rule, although we have seen waxed and partially waxed “Vergins”.

All carved Castello pipes are graded by the number of K’s that are stamped on each piece and are K-graded by SIZE. 1K is the smallest and fairly rare, 2K is small to medium, with 3K or 4K being the most common and ranges from medium to medium large. Large pieces are stamped “G” for giant and extra large pieces are stamped “GG” for double giant. In addition to the number of K’s on a carved Sea Rock piece the shape number is almost always added. As a rule a Sea Rock Castello is stained Black, although recently there have been quite a few coming in stained deep brown and still stamped “Sea Rock”. American Logo’d Sea Rocks are all priced the same to the consumer, although most are 2 or 3 K’ed models. G/GG models are charged at a higher price on American pieces and are basically the same as their European counterparts.

The Castello Sea Rock briar I was working on did not have any K designation in terms of the size of the pipe. It definitely was made for the American Market with the Rhinestone in the stem. It had the dark finish. The shape number still needed to be determined.

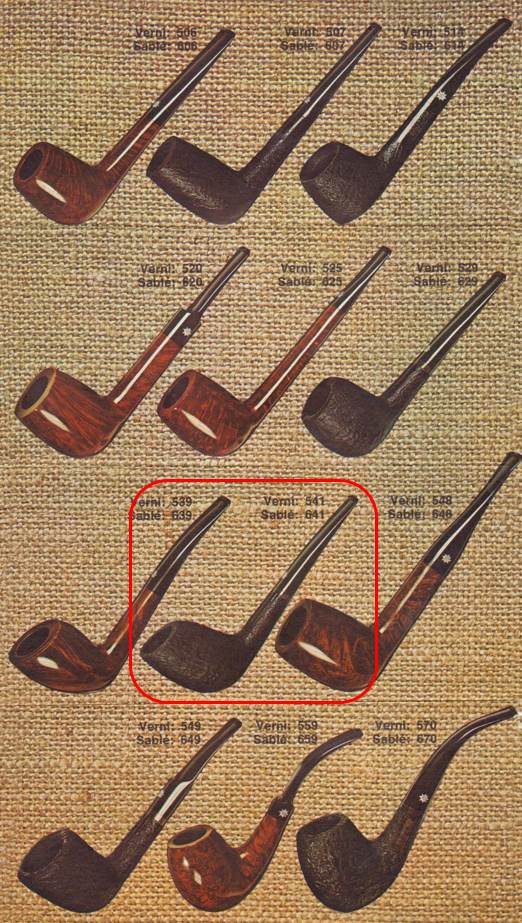

Pipedia also gave a link to Mike’s Briar Blues site for help in dating and determining shapes (http://www.briarblues.com/castello.htm). I quote a section on the shape numbers.

Shape numbers. Shape numbers are all 2 digits. A 2 in front indicates a “fancy” interpretation, a 3 in front means that the carving is somehow unique. I don’t know when the change was made, but currently, a π symbol is used instead of the 3xx. I’ve only seen this on Sea Rocks, but that doesn’t mean anything…

Now I had more information to work with. The Castello Sea Rock in my hands that probably came out in the late 1960s onward. The number 93 makes it a bent egg.

I am sure many of you will shake your head and ask maybe even out loud, “Why is he including this again?” However, please remember that the point of these blogs is not to wow your with the work or make you shake your heads but I want you to know the details of the work we do so you can do your own. Back in 2020 Jeff wrote a blog about his cleaning process. I am including a link to that now so you can see what I mean about his process. Do not skip it! Give it a read (https://rebornpipes.com/2020/01/20/got-a-filthy-estate-pipe-that-you-need-to-clean/). Here is the introduction to that blog and it is very true even to this day.

Several have asked about Jeff’s cleaning regimen as I generally summarize it in the blogs that I post rather than give a detailed procedure. I have had the question asked enough that I asked Jeff to put together this blog so that you can get a clear picture of the process he uses. Like everything else in our hobby, people have different methods they swear by. Some may question the method and that is fine. But it works very well for us and has for many years. Some of his steps may surprise you but I know that when I get the pipes from him for my part of the restoration they are impeccably clean and sanitized. I have come to appreciate the thoroughness of the process he has developed because I really like working on clean pipe!

For the benefit of some of you who may be unfamiliar with some of the products he uses I have included photos of three of the items that Jeff mentions in his list. This will make it easier for recognition. These three are definitely North American Products so you will need to find suitable replacements or order these directly on Amazon. The makeup pads are fairly universal as we were able to pick some up in India when we were with Paresh and his family.

In the blog itself he breaks his process down into two parts – cleaning the stem and cleaning the bowl. Each one has a large number of steps that he methodically does every time. I know because I have watched him do the work and I have seen the pipes after his work on them. He followed this process step by step and when the pipe got to me it was spotlessly clean and ready for my work. The inside of the stem, shank and bowl were clean and to me that is an amazing gift as it means that my work on this end is with a clean pipe! I cannot tell you how much difference that makes for my work.

When the pipe arrives here in Vancouver I have a clean pipe and I go over it keeping in mind my assessment shared in the opening paragraph above. Now that I have it in hand I am looking for confirmation of what I saw in the photos as well as any significant structural changes in the bowl and finish as I go over it.

- The classic Castello Sea Rock Bent Egg looks amazing. The rustication is beautiful and the acrylic ferrule and stem work very well on the pipe. It is probably a Castello version of an Oom Paul.

- The finish is clean and the grime and grit have been removed from the finish on the bowl. The rustication and depth in the valleys has just come alive around the bowl sides.

- The lava, grime and dust on the rim top has been removed and it looks to be in good condition on the top and edges of the bowl.

- The walls of the bowl are clean and I do not see any checking or burn damage. The inner edge of the bowl looks good. The outer edges look good and there does not appear to be any obvious burn damage there.

- The acrylic military mount stem is clean and has very light tooth chatter and marks on both sides. The Rhinestone/Diamond logo on the side of the stem looks very good.

Hopefully the steps above show you both what I look for when I go over the pipe when I bring it to the work table and also what I see when I look at the pipe in my hands. They also clearly spell out a restoration plan in short form. My work is clear and addressing it will be the next steps. I took photos of the whole pipe to give you a picture of what I see when I have it on the table. This is important to me in that it also shows that there was no damage done during the clean up work or the transit of the pipe from Idaho to here in Vancouver.

I carefully went over the bowl and rim top to get a sense of what is happening there. In this case once the rim top and edges were cleaned, they looked very good. There was no damage on the edges or the top of the rim. It is clean should come back to its original beauty quite easily. I also go over the stem carefully. There were just some faint tooth marks chatter on the surface of the stem. I took photos of the rim top and stem sides to show as best as I can what I see when I look at them.

I carefully went over the bowl and rim top to get a sense of what is happening there. In this case once the rim top and edges were cleaned, they looked very good. There was no damage on the edges or the top of the rim. It is clean should come back to its original beauty quite easily. I also go over the stem carefully. There were just some faint tooth marks chatter on the surface of the stem. I took photos of the rim top and stem sides to show as best as I can what I see when I look at them.  I always check to make sure that the clean up work did not damage the stamping on the shank in any way. It is in excellent condition and is very clear and readable. I really like the way that the carvers at Castello do the Sea Rock Briar rustication. To me it stunning and very tactile. I love just looking at the beauty of the lay of the pipe and the proportion of the hand made pipes. I like to remove the stem from the shank to get a sense of what was in the mind of the pipe maker when he crafted the pipe. It is a beauty in flow and shape.

I always check to make sure that the clean up work did not damage the stamping on the shank in any way. It is in excellent condition and is very clear and readable. I really like the way that the carvers at Castello do the Sea Rock Briar rustication. To me it stunning and very tactile. I love just looking at the beauty of the lay of the pipe and the proportion of the hand made pipes. I like to remove the stem from the shank to get a sense of what was in the mind of the pipe maker when he crafted the pipe. It is a beauty in flow and shape.  When a rusticated finish is in as nice a condition as this one is immediately apply Before & After Restoration Balm to the briar. It is a paste/balm that is rubbed into the surface of the briar and the plateau. The product works to deep clean the nooks and crannies of finish, enliven and protect the briar. I worked it into the briar with my finger tips and a horse hair shoe brush. I let it sit for 10 minutes to do its work. I wiped it off with a soft cloth then buffed it with a cotton cloth. The briar really began to have a deep shine in the briar and the grain shone through. The photos I took of the bowl at this point mark the progress in the restoration. It is a gorgeous pipe.

When a rusticated finish is in as nice a condition as this one is immediately apply Before & After Restoration Balm to the briar. It is a paste/balm that is rubbed into the surface of the briar and the plateau. The product works to deep clean the nooks and crannies of finish, enliven and protect the briar. I worked it into the briar with my finger tips and a horse hair shoe brush. I let it sit for 10 minutes to do its work. I wiped it off with a soft cloth then buffed it with a cotton cloth. The briar really began to have a deep shine in the briar and the grain shone through. The photos I took of the bowl at this point mark the progress in the restoration. It is a gorgeous pipe.

I set the bowl aside and turn to work on the stem. Because the marks and chatter are so light I use micromesh sanding pads – 1500-12000 grit sanding pads and water to wet sand the stem. I wiped it down after each sanding pad with Obsidian Oil on a cotton rag after each sanding pad even though people say it does nothing for acrylic stems. But I find it does two things – first it gives some protection to the stem and second it give the sanding pads bite in the polishing process.

I set the bowl aside and turn to work on the stem. Because the marks and chatter are so light I use micromesh sanding pads – 1500-12000 grit sanding pads and water to wet sand the stem. I wiped it down after each sanding pad with Obsidian Oil on a cotton rag after each sanding pad even though people say it does nothing for acrylic stems. But I find it does two things – first it gives some protection to the stem and second it give the sanding pads bite in the polishing process.

After finishing with the micromesh pads I rub the stem down with Before & After Fine and Extra Fine stem polish as it seems to really remove the fine scratches in the acrylic. I rub the Fine Polish on the stem and wipe it off with a paper towel and then repeat the process with the extra fine polish. I finish the polishing of the stem down with a final coat of Obsidian Oil and set the stem aside to let the oil absorb. This process gives the stem a shine and also a bit of protection.

After finishing with the micromesh pads I rub the stem down with Before & After Fine and Extra Fine stem polish as it seems to really remove the fine scratches in the acrylic. I rub the Fine Polish on the stem and wipe it off with a paper towel and then repeat the process with the extra fine polish. I finish the polishing of the stem down with a final coat of Obsidian Oil and set the stem aside to let the oil absorb. This process gives the stem a shine and also a bit of protection.  The final steps in my process involve using the buffer. I don’t buff a rusticated pipe with Blue Diamond as it can build up in the deep grooves of the finish. I used it on the stem and find that it works very well to polish out the light scratches in the acrylic. I finished with the Blue Diamond and moved on to buffing the pipe – I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. Once I have a good shine in the briar and acrylic. I have found that I can get a deeper shine if I following up the wax buff with a clean buffing pad. It works to raise the shine and then I follow that up with a hand buff with a microfiber cloth to deepen the shine. It is always fun for me to see what the polished bowl looks like with the polished acrylic stem. It really is a beautiful pipe. The rusticated finish around the bowl sides and shank has some amazing depth and contrast with the rich black and dark brown stains. Castello Sea Rock Briar 93 Bent Egg with a military bit feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.32 ounces/41 grams. It is a beautiful pipe and a Castello shape I have been looking for to add to my own collection. I plan on loading it up and enjoying a bowl in it.

The final steps in my process involve using the buffer. I don’t buff a rusticated pipe with Blue Diamond as it can build up in the deep grooves of the finish. I used it on the stem and find that it works very well to polish out the light scratches in the acrylic. I finished with the Blue Diamond and moved on to buffing the pipe – I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. Once I have a good shine in the briar and acrylic. I have found that I can get a deeper shine if I following up the wax buff with a clean buffing pad. It works to raise the shine and then I follow that up with a hand buff with a microfiber cloth to deepen the shine. It is always fun for me to see what the polished bowl looks like with the polished acrylic stem. It really is a beautiful pipe. The rusticated finish around the bowl sides and shank has some amazing depth and contrast with the rich black and dark brown stains. Castello Sea Rock Briar 93 Bent Egg with a military bit feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.32 ounces/41 grams. It is a beautiful pipe and a Castello shape I have been looking for to add to my own collection. I plan on loading it up and enjoying a bowl in it.

Hopefully the style of writing of this blog is helpful to you in some way. In it I wanted to show both what I am looking for and how I move forward in addressing what I see when work on a pipe. Let me know if it is helpful to you. It is probably the most straightforward detailed description of my work process that I have done. As always I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.