Blog by Steve Laug

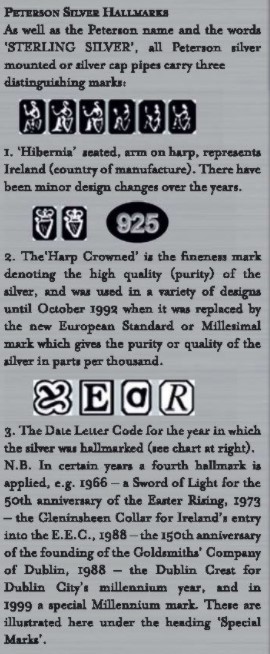

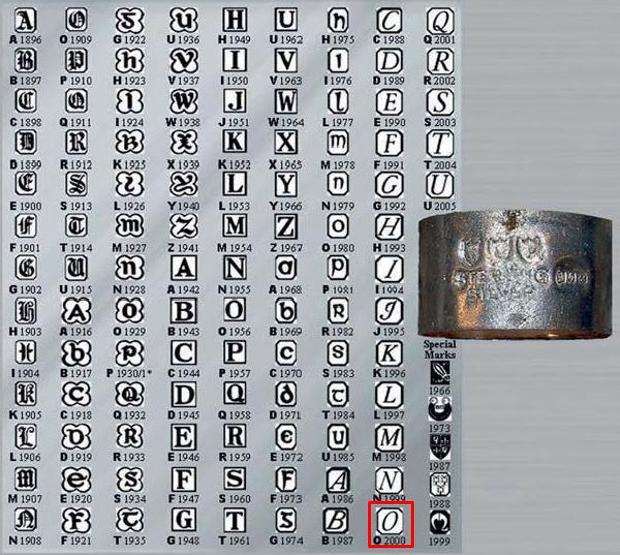

The next pipe I have chosen is smooth finished Peterson’s Billiard pipe. This one is a Dublin 3 Billiard that has a rich coloured finish with amazing grain around the bowl sides and shank. It also came to us from the estate of Anglican minister that was a great friend of mine here in Canada. This Billiard had a badly oxidized nickel ferrule on the shank end. The contrast of the brown stains makes the grain really pop. It was stamped on the left side of the shank and read Peterson’s in an arch [over] Dublin 3 in an arch. It was stamped on the right side and reads Made in Ireland (2 lines). The tarnished ferrule is stamped with K&P [over] 3 shields as follows: in the first was a shamrock, in the second was a lion and in the third was a tower. Underneath those marks it read Peterson’s [over] Dublin. It was in filthy when he brought it to the table. The finish was dirty with grime ground into the briar sides and rim. There was a cake in the bowl and light spattering of lava on the rim top and the inner edge of the bowl. There was some damage to the inner edge of the rim. The stem was oxidized, calcified and had tooth marks and chatter on the top and underside on and near the button. Jeff took photos of the pipe before his cleanup work. They tell the story and give a glimpse of the promise that we see in this pipe.

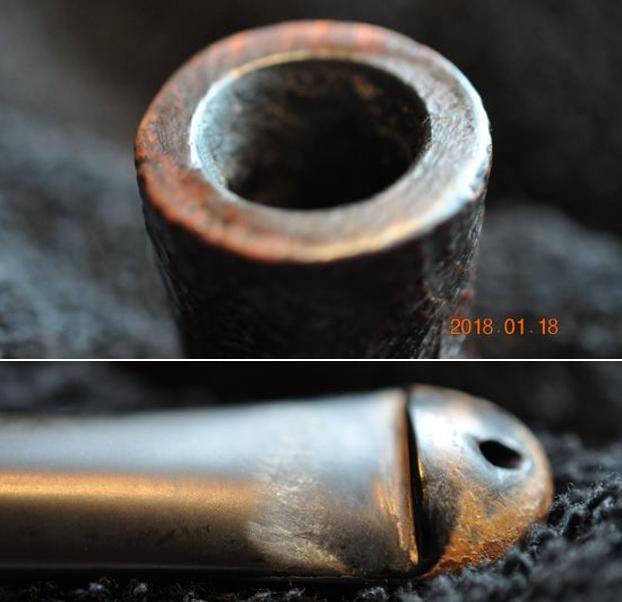

Jeff took photos of the rim top and stem to show the general condition of the pipe. The bowl is heavily caked and the rim top and edges have some light lava overflow. There is some damage to the rim edge on the back of the bowl. The stem is oxidized, calcified and has tooth marks on the top and underside near the button.

Jeff took photos of the rim top and stem to show the general condition of the pipe. The bowl is heavily caked and the rim top and edges have some light lava overflow. There is some damage to the rim edge on the back of the bowl. The stem is oxidized, calcified and has tooth marks on the top and underside near the button.

Jeff took some photos of the bowl sides and heel to show the amazing grain that was around this bowl. It is a nice looking pipe.

Jeff took some photos of the bowl sides and heel to show the amazing grain that was around this bowl. It is a nice looking pipe.  He took photos of the sides of the shank to show the stamping. The stamping is readable in the photos below and is as noted above. He also took a photo of the band.

He took photos of the sides of the shank to show the stamping. The stamping is readable in the photos below and is as noted above. He also took a photo of the band.

I am including the link to the Pipedia’s article on Peterson pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Peterson).

I am including the link to the Pipedia’s article on Peterson pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Peterson).

I turned to “The Peterson Pipe” by Mark Irwin and Gary Malmberg to get some background on the Peterson’s Dublin 3. On page 298 it had the following information.

Dublin (1906-2003) Although DUBLIN appears under PETERSON’S on many pipe over the decades, it has served mostly as part of the brand name. The word first appeared on pipes hallmarked 1906-11, stamped PETERSON’S over PATENT over DUBLIN. The simpler PETERSON’S over DUBLIN first appeared on pipes hallmarked 1912 after the expiration of the patent. Illustrations of pipes in the ’37 catalog show a random dispersion of the stamp PETERSON’S over OF DUBLIN together with the ordinary PETERSON’S over DUBLIN on every model offered. Specimens of the former will bear either and Irish COM or LONDON MADE over ENGLAND COM and almost certainly date from 1945062. It ws first mentioned as part of a model name in the ’68 price list, as K&P DUBLIN, in ’92 for a Danish market line and in 2017 (see below).

“Dublin” (1992-2003) An orange-brown smooth line with a brass-nickel-brass sandwich band, vulcanite fishtail mouthpiece, consisting mostly of D shapes released for the Danish market. Stamped PETERSON’S in script over “DUBLIN”. A tenth anniversary pipe for the line was produced with a sterling band stamped 2001. Market demand fell shortly thereafter and several pipes stamped “DUBLIN” were released in ’03 for the Fourth of July commemoratives for the US market.

I turned to Pipephil’s site (http://www.pipephil.eu/logos/en/logo-peterson.html) and found a Pre-Republic Era pipe that has the same stamping on the left side of the shank and the ferrule/band. The difference lies in the stamping on the right side of the shank which were stamped Made in Ireland. The Peterson’s Dublin 3 stamp is the same with the forked P at the head of Peterson’s. I wrote to Mark Irwin to confirm the information I had found and to give any more helpful information on the stamping on this particular pipe. Mark replied and I quote that in full below:

I wrote to Mark Irwin to confirm the information I had found and to give any more helpful information on the stamping on this particular pipe. Mark replied and I quote that in full below:

Hi Steve,

Without the measurements of the bowl I can’t give you the shape number, but I can tell you quite a bit more. The “3” after Dublin indicates it was made between 1937 and 1959 (see p. 301, first column). The nickel-mount marks were on all nickel-mount Petes from 1896 to c. 1963. The nickel was probably hand-soldered (you can often see the solder mark before polishing). The ferrule was also turned down where it meets the mortise by hand. MADE IN IRELAND doesn’t help much, since it has been used in nearly every decade, although I am beginning to believe it indicates a pipe made for export to the US through Rogers Imports, Ltd during the days they were the distributor for K&P (1937-1966, I think was the latter date). The slight swell in the mouthpiece was there because it was a true graduated bore, unlike those made by K&P from c. 1980s forward. This means the pipe will smoke dryly and need no mid-smoke pipe cleaner—a fact I have verified time and time again in my own vintage Petes with type of mouthpiece. Should be a great smoker!

Peace,

Mark

Now it was time to work on the pipe. Jeff had done a great job cleaning up the pipe as usual. He reamed the pipe with a PipNet reamer and cut back the cake back to the bare briar. He cleaned up the walls with a Savinelli Fitsall Pipe Knife. He scrubbed the interior of the bowl and shank with pipe cleaners, cotton swabs and alcohol to remove the tars and oils. He scrubbed the exterior of the pipe with Murphy’s Oil Soap and a tooth brush to remove the grime from the finish. He worked on the rim top lava and darkening with the soap and tooth brush. He scrubbed the inside of the stem with alcohol and pipe cleaners. He scrubbed the exterior with Soft Scrub and then soaked it in Before & After Deoxidizer. He washed it off with warm water to remove the Deoxidizer. The pipe looked far better when it arrived.

I took some close up photos of the rim top and also of the stem surface. I wanted to show how well it had cleaned up. The rim top had some looked quite good and the inner edge had some darkening and damage. It should clean up really well. I also took close up photos of the stem to show the tooth marks on the surface near the button.

I took some close up photos of the rim top and also of the stem surface. I wanted to show how well it had cleaned up. The rim top had some looked quite good and the inner edge had some darkening and damage. It should clean up really well. I also took close up photos of the stem to show the tooth marks on the surface near the button.  I took photos of the stamping on the sides of the shank. You can see that it is stamped as noted above. It is clear and readable.

I took photos of the stamping on the sides of the shank. You can see that it is stamped as noted above. It is clear and readable.  I removed the stem and took a photo of the pipe to have a look at the parts and overall look.

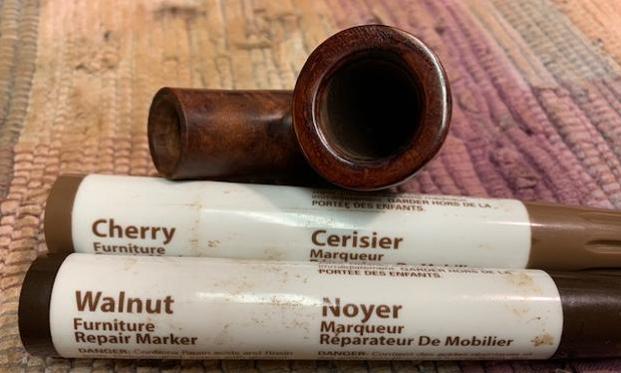

I removed the stem and took a photo of the pipe to have a look at the parts and overall look. I decided to address the damage to the edge of the bowl and the rim top first. I used a folded piece of 220 grit sandpaper to give the inner edge of the bowl a slight bevel to accommodate the burned areas and blend them into the surrounding briar. I also worked over the darkening on the rim top with the sandpaper.

I decided to address the damage to the edge of the bowl and the rim top first. I used a folded piece of 220 grit sandpaper to give the inner edge of the bowl a slight bevel to accommodate the burned areas and blend them into the surrounding briar. I also worked over the darkening on the rim top with the sandpaper.  I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each sanding pad.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each sanding pad.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I set the bowl aside and turned my attention to the stem. I “painted” the stem and button surface with the flame of a lighter to lift the tooth marks. It worked amazingly well and the majority of them lifted completely or significantly. I filled in the remaining marks with clear super glue. Once the repairs had cured I flattened them out with a small file. I sanded them with 220 grit sandpaper to blend them into the surface of the vulcanite. I started polishing the stem by wet sanding it with 400 grit wet dry sandpaper.

I set the bowl aside and turned my attention to the stem. I “painted” the stem and button surface with the flame of a lighter to lift the tooth marks. It worked amazingly well and the majority of them lifted completely or significantly. I filled in the remaining marks with clear super glue. Once the repairs had cured I flattened them out with a small file. I sanded them with 220 grit sandpaper to blend them into the surface of the vulcanite. I started polishing the stem by wet sanding it with 400 grit wet dry sandpaper.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine.

I am excited to finish this Peterson’s Dublin 3 Straight Billiard. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with beautiful flame grain all around it. Added to that the polished Sterling Silver band and the black vulcanite stem was beautiful. This smooth Classic Older Peterson’s Dublin 3 is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 29grams/1.02oz. It is a beautiful pipe and one that will be stay in my collection for the time being. It is yet another of my friend’s estate that will stay in my trust. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.

I am excited to finish this Peterson’s Dublin 3 Straight Billiard. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with beautiful flame grain all around it. Added to that the polished Sterling Silver band and the black vulcanite stem was beautiful. This smooth Classic Older Peterson’s Dublin 3 is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 29grams/1.02oz. It is a beautiful pipe and one that will be stay in my collection for the time being. It is yet another of my friend’s estate that will stay in my trust. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.