Blog by Steve Laug

Sometimes you have to look past the state of a pipe to really see what could be present underneath all of the layers of dirt and grime. You have to have the right perspective as well. You need to be able to see these pipes as well loved rather than abused; as a favourite pipe rather than a neglected one. This the context in which the next pipe that crossed my worktable is to be viewed. Here is the back-story. Not too long ago I received an email from a friend of mine named Jim, whose pipes I have worked on in the past. He had an interesting story to tell me and a request. I thought rather than tell the story for him I would let him tell it himself. Here is his email in full:

Hey Steve,

I have been hunting about 1200 acres of Farm and Woodland Property owned by an area farmer and old friend of mine named Stephen Lehner. Steve knows I am a pipe aficionado, and approached me the other day with a pipe that had belonged to his father. I was able to get a little history of how this pipe came to be in this abysmal condition. Steve’s father was rather hard on his pipes. As the original owner of this pipe, Steve said his dad, in the latter years of his life, was not given to cleaning his pipes. His cleaning routine, if you could call it that, consisted of digging any ash and unburnt tobacco from the bowl with a pocket knife, then grasping the pipe by the stem, toward the mouthpiece/lip area, and banging it violently against any nearby hard object – trees, brick walls, car mirrors. It was hard enough that Steve’s son, Shawn, remarked that the old man actually damaged the mirrors on his trucks! Mr. Lehner’s pipes were so abused, that he routinely broke stems, necessitating that he acquire new stems – some of which were not well fitted.

In any case, Steve handed me this pipe, stating that it is one of a very few connections he has to his late father, and asked if I could do a cursory cleaning so he could display it as a keepsake (He is not a pipe smoker). I thought the pipe was interesting, if in bad condition. I cannot clearly make out any markings. On one side, there is a partially legible stamping, “…vage” with some cursive writing below it which I cannot make out. On the other side, I can read the number “75.” I think it is a bulldog style. The tenon will not enter all the way into the mortise, and I am not sure if that is because there is so much crud inside or because it is not the correct bit. The bowl is heavily caked and cracked. It also looks as though there was some ad hoc rustication on the bowl, as well. The bowl shows a distinct area of impact where it was banged during cleaning as well.

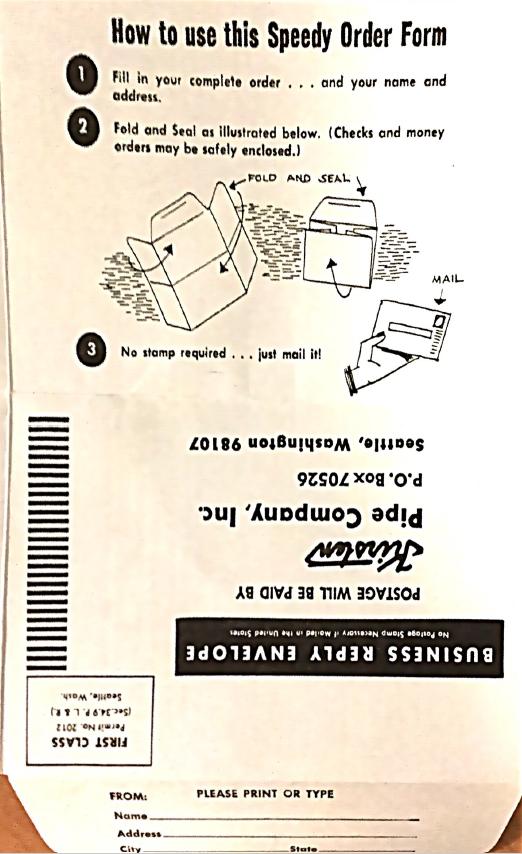

I attached some pix so you could behold this wonder: Once I saw the pictures I was quite taken back by the sheer beastly look of this old pipe. It had quite literally been beaten to death. The bowl was cracked on the outside of the bowl that started at the front of the bowl and extended to almost the back side. There was a second crack below that on the front of the bowl extending from the bottom of the first crack and extending toward the other side of the bowl. The bowl was so badly caked that I could not even get my pinky finger in the bowl. I tried to blow through the end of the shank and I was unable to get any air through the bowl. The finish was dirty and sticky to touch. The worm trail rustication ran over the bowl surface but was filled in with dirt and grit. From the photos it appeared that the shank inside was incredibly dirty. I think that it is fair to say this pipe was a stranger to pipe cleaners. The stem that was in the shank was not a fit. It was of smaller diameter than the shank. The slot in the stem was almost clogged.

Once I saw the pictures I was quite taken back by the sheer beastly look of this old pipe. It had quite literally been beaten to death. The bowl was cracked on the outside of the bowl that started at the front of the bowl and extended to almost the back side. There was a second crack below that on the front of the bowl extending from the bottom of the first crack and extending toward the other side of the bowl. The bowl was so badly caked that I could not even get my pinky finger in the bowl. I tried to blow through the end of the shank and I was unable to get any air through the bowl. The finish was dirty and sticky to touch. The worm trail rustication ran over the bowl surface but was filled in with dirt and grit. From the photos it appeared that the shank inside was incredibly dirty. I think that it is fair to say this pipe was a stranger to pipe cleaners. The stem that was in the shank was not a fit. It was of smaller diameter than the shank. The slot in the stem was almost clogged.

After reading his email and looking over the photos I wrote back to my friend. I was pretty certain from the look of the rustication and the shape number he gave me that the pipe was a GBD. The three letters that he could read on the left side of the shank were age. That led me to look in the GBD list I have and concluded that the pipe was a GBD Sauvage. I looked up some information on a chart I have of GBD lines and knew that the pipe was originally sold with a light brown stain, smooth bowl with deep carved lines to hide flaws. It was similar to a Savinelli Sherwood, but much deeper carved lines. The GBD shape number 75 was a Rhodesian with a1/4 Bent Saddle stem. While this old pipe was a mess it was awfully hard to tell if it ever was a Rhodesian. I sent him this information in my reply.

He wrote back and said he wondered if I would be willing to tackle the restoration on this one. If so he would send it to me. I wrote back and said I would do the work. I guess I will find out if my guesses on the brand of this pipe were correct. I would know more once it arrived.

The pipe arrived and it was indeed a mess. On top of the beat up old pipe, the reek of Middleton’s Cherry pipe tobacco filled the room when I opened the box. My daughters immediately commented on how strong the smell was. I examined the pipe with a lens to see if I could identify the pipe. It was stamped on the left side of the shank with the GBD logo in an oval over Sauvage over Collector in script. On the right side of the shank it is stamped Made in England over 75 which is the shape number. The next photos show what the pipe looked like when I received it.

I took a close up photo of the rim to show the absolute dreadful condition this pipe was in when it arrived. The bowl had a thick cake that still reeked of the aroma of burnt Middleton’s Cherry pipe tobacco. The rim had been hammered to what looked like the point of no return – though I would not know for sure until I had removed the cake and the buildup on the rim top. The stem was a replacement one and it was obviously a poor fitting one. The diameter of the stem and the shank were not a match and the tenon could not be pushed into the shank because of the grit and tar built up inside. The button had been flattened by biting and there were tooth dents on it and also on the top and bottom sides. I would definitely need to make a new stem for the pipe.

I took a close up photo of the rim to show the absolute dreadful condition this pipe was in when it arrived. The bowl had a thick cake that still reeked of the aroma of burnt Middleton’s Cherry pipe tobacco. The rim had been hammered to what looked like the point of no return – though I would not know for sure until I had removed the cake and the buildup on the rim top. The stem was a replacement one and it was obviously a poor fitting one. The diameter of the stem and the shank were not a match and the tenon could not be pushed into the shank because of the grit and tar built up inside. The button had been flattened by biting and there were tooth dents on it and also on the top and bottom sides. I would definitely need to make a new stem for the pipe.

I decided to start by reaming the bowl back to bare wood. I wanted to see if the cracks on the outside continued into the bowl. I fully expected the bowl to fall apart once the carbon was removed and ceased to hold everything together. I started reaming with the smallest cutting blade on the PipNet pipe reamer and worked up to the largest cutting head. I finished reaming the bowl with a Savinelli Fitsall Pipe Knife.

I decided to start by reaming the bowl back to bare wood. I wanted to see if the cracks on the outside continued into the bowl. I fully expected the bowl to fall apart once the carbon was removed and ceased to hold everything together. I started reaming with the smallest cutting blade on the PipNet pipe reamer and worked up to the largest cutting head. I finished reaming the bowl with a Savinelli Fitsall Pipe Knife. I rolled a piece of 80 grit sandpaper on my index finger and sanded the inside of the bowl. I wanted to be able to clearly see if the cracks on the outside continued into the bowl. The second photo below shows the inside of the bowl. The crack on the left side of the bowl did not seem to show through inside. The one on the front of the bowl still needed some more work to be certain but it also looked like it did not show through. Notice the buildup on the rim it probably protected the top of the bowl to a large degree.

I rolled a piece of 80 grit sandpaper on my index finger and sanded the inside of the bowl. I wanted to be able to clearly see if the cracks on the outside continued into the bowl. The second photo below shows the inside of the bowl. The crack on the left side of the bowl did not seem to show through inside. The one on the front of the bowl still needed some more work to be certain but it also looked like it did not show through. Notice the buildup on the rim it probably protected the top of the bowl to a large degree. I scraped the rim with a pen knife to peel off the cake that overflowed on the top. I carefully held the blade against the surface of the rim and scraped it slowly until all of the buildup was gone. Underneath all of the buildup the rim was in rough shape. It had been beaten pretty hard and the damage was quite extensive. The rim top showed signs of being knocked about hard against that truck mirror mentioned above. If this pipe could have talked I would love to hear the stories it could tell.

I scraped the rim with a pen knife to peel off the cake that overflowed on the top. I carefully held the blade against the surface of the rim and scraped it slowly until all of the buildup was gone. Underneath all of the buildup the rim was in rough shape. It had been beaten pretty hard and the damage was quite extensive. The rim top showed signs of being knocked about hard against that truck mirror mentioned above. If this pipe could have talked I would love to hear the stories it could tell. I topped the bowl on the topping board using 220 grit sandpaper. I decided that I would sand it until the top of the rim was smooth and the damage on the outer edge of the rim was minimized.

I topped the bowl on the topping board using 220 grit sandpaper. I decided that I would sand it until the top of the rim was smooth and the damage on the outer edge of the rim was minimized. With the rim topped and smooth I wiped the bowl down with acetone on cotton pads to remove the grime and clean up the surface so I could assess the next steps in dealing with the external cracks on the left side and bowl front.

With the rim topped and smooth I wiped the bowl down with acetone on cotton pads to remove the grime and clean up the surface so I could assess the next steps in dealing with the external cracks on the left side and bowl front.

I used a microdrill bit on my Dremel to drill pin holes at each end of the cracks in the bowl. The length of the bit ensures that I will not be able to drill too far and go into the bowl itself. There were five distinct ends to the series of cracks in the briar.

I used a microdrill bit on my Dremel to drill pin holes at each end of the cracks in the bowl. The length of the bit ensures that I will not be able to drill too far and go into the bowl itself. There were five distinct ends to the series of cracks in the briar. I used a dental pick to clean out the cracks with surprisingly had closed tighter once the cake was removed from the bowl releasing the pressure. Once they were clean I pressed briar dust into the crack surfaces and the drill holes in the bowl. I dripped clear super glue on the cracks and into the plugs in the drill holes. I gave the repair several more coats of briar dust and super glue until the surface was filled. The pictures tell the story.

I used a dental pick to clean out the cracks with surprisingly had closed tighter once the cake was removed from the bowl releasing the pressure. Once they were clean I pressed briar dust into the crack surfaces and the drill holes in the bowl. I dripped clear super glue on the cracks and into the plugs in the drill holes. I gave the repair several more coats of briar dust and super glue until the surface was filled. The pictures tell the story.

I sanded the dried repair and the rest of the bowl with 220 grit sandpaper to remove the excess briar dust and glue.

I sanded the dried repair and the rest of the bowl with 220 grit sandpaper to remove the excess briar dust and glue.

I wiped the bowl down with alcohol on a cotton pad. I used a Black Sharpie pen to colour in the worm trail rustication around the bowl sides. I had done some research and found that the rustication on the Sauvage line had been darker than the stain on the bowl.

I wiped the bowl down with alcohol on a cotton pad. I used a Black Sharpie pen to colour in the worm trail rustication around the bowl sides. I had done some research and found that the rustication on the Sauvage line had been darker than the stain on the bowl. I used the drill bit from the KleenReem Pipe reamer to drill out the buildup in the airway from the mortise to the bowl. It was thick and hard so the drill bit took several passes through the airway to clean it out. I used a dental spatula to scrape out the thick, hard tars that lined the walls of the mortise. I scrubbed out the mortise and airway with alcohol, cotton swabs and pipe cleaners until the internals were clean.

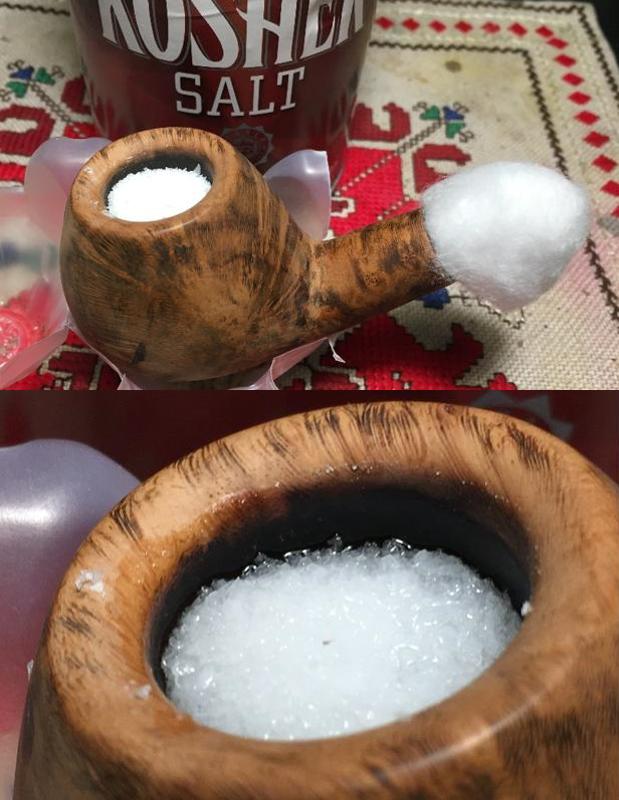

I used the drill bit from the KleenReem Pipe reamer to drill out the buildup in the airway from the mortise to the bowl. It was thick and hard so the drill bit took several passes through the airway to clean it out. I used a dental spatula to scrape out the thick, hard tars that lined the walls of the mortise. I scrubbed out the mortise and airway with alcohol, cotton swabs and pipe cleaners until the internals were clean. I stuffed the bowl with cotton balls until they were just below the edge of the rim. I put a pipe cleaner in the airway to wick the alcohol into the shank. I used an ear syringe to fill the bowl and shank with alcohol. I set the bowl upright in an ice cube tray and let it sit over night to draw the oils out of the briar. In the morning I took a photo of the darkened cotton balls. I used a dental pick to pull them out of the bowl. I cleaned out the shank and the bowl with cotton swabs to remove all the excess alcohol. I let the bowl dry.

I stuffed the bowl with cotton balls until they were just below the edge of the rim. I put a pipe cleaner in the airway to wick the alcohol into the shank. I used an ear syringe to fill the bowl and shank with alcohol. I set the bowl upright in an ice cube tray and let it sit over night to draw the oils out of the briar. In the morning I took a photo of the darkened cotton balls. I used a dental pick to pull them out of the bowl. I cleaned out the shank and the bowl with cotton swabs to remove all the excess alcohol. I let the bowl dry. I stained the bowl with a dark brown aniline stain thinned 50/50 with alcohol to make it more transparent. I flamed the stain and restained it. I repeated the process of staining and flaming the surface until the briar had even coverage.

I stained the bowl with a dark brown aniline stain thinned 50/50 with alcohol to make it more transparent. I flamed the stain and restained it. I repeated the process of staining and flaming the surface until the briar had even coverage.

I buffed the bowl with Blue Diamond on the buffing wheel and then took the following photos to send to Jim to show him the state of the bowl at this point in the process. There were still scratches in the finish that would need to be polished out but the bowl was showing promise and beauty was emerging from the beast.

I buffed the bowl with Blue Diamond on the buffing wheel and then took the following photos to send to Jim to show him the state of the bowl at this point in the process. There were still scratches in the finish that would need to be polished out but the bowl was showing promise and beauty was emerging from the beast.

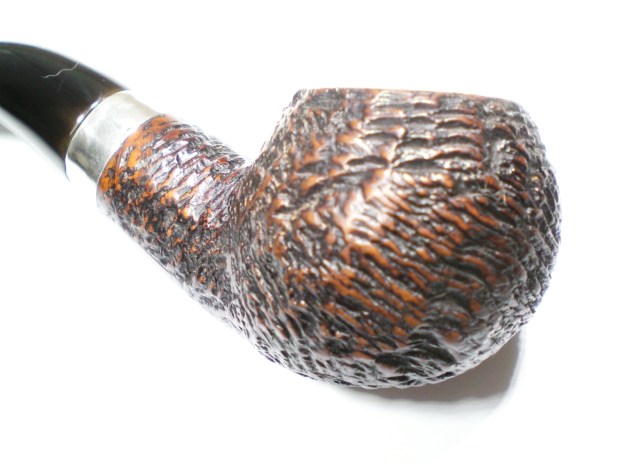

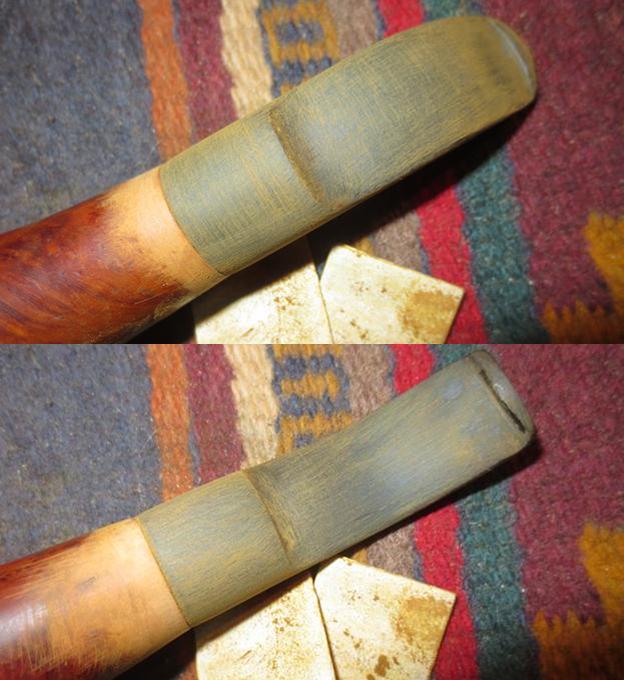

I left the pipe on my work table while I traveled to Idaho for my mom’s 90th birthday. I stay with my brother Jeff when I am there and as usual he had a batch of pipes for me. There were some amazing pipes there but what caught my eye this time was the stem I needed for this Sauvage. It was slightly bigger in diameter than the shank but it would not take much to fit it to the pipe. When I got home I lightly sanded the tenon with a Dremel and sanding drum until it fit snugly into the mortise. I took the photo below to show the new stem and the one that was with the pipe when it arrived. I took photos of the stem to show the difference in diameters of the shank and the stem. You can also see the deep tooth marks in the top and bottom sides of the stem near the button.

I left the pipe on my work table while I traveled to Idaho for my mom’s 90th birthday. I stay with my brother Jeff when I am there and as usual he had a batch of pipes for me. There were some amazing pipes there but what caught my eye this time was the stem I needed for this Sauvage. It was slightly bigger in diameter than the shank but it would not take much to fit it to the pipe. When I got home I lightly sanded the tenon with a Dremel and sanding drum until it fit snugly into the mortise. I took the photo below to show the new stem and the one that was with the pipe when it arrived. I took photos of the stem to show the difference in diameters of the shank and the stem. You can also see the deep tooth marks in the top and bottom sides of the stem near the button. I sanded the diameter with a sanding drum on the Dremel. I do this with the stem inserted in the mortise so that I can remove as much of the excess vulcanite as possible without damaging the briar on the shank. I nicked the edged of the briar but fortunately the nick was not deep. I also lightly sanded the top and underside of the stem with the Dremel and minimized the tooth marks.

I sanded the diameter with a sanding drum on the Dremel. I do this with the stem inserted in the mortise so that I can remove as much of the excess vulcanite as possible without damaging the briar on the shank. I nicked the edged of the briar but fortunately the nick was not deep. I also lightly sanded the top and underside of the stem with the Dremel and minimized the tooth marks.

I sanded the areas on the stem where the tooth marks had damaged the vulcanite with 180 grit sandpaper and smoothed out the surface damage. What remained were the deeper tooth marks. I wiped down the surface of the stem with alcohol on a cotton pad to remove the debris and dust from the tooth marks. I filled the remaining tooth marks with black super glue and set the stem aside to dry.

I sanded the areas on the stem where the tooth marks had damaged the vulcanite with 180 grit sandpaper and smoothed out the surface damage. What remained were the deeper tooth marks. I wiped down the surface of the stem with alcohol on a cotton pad to remove the debris and dust from the tooth marks. I filled the remaining tooth marks with black super glue and set the stem aside to dry. When the repairs had cured I sanded them with 180 grit sandpaper to blend them into the surface of the stem. I sanded the saddle portion of the stem to remove the marks left behind by the sanding drum.

When the repairs had cured I sanded them with 180 grit sandpaper to blend them into the surface of the stem. I sanded the saddle portion of the stem to remove the marks left behind by the sanding drum. I put the stem in the shank and sanded the stem and shank with 220 grit sandpaper to make the transition really smooth. I could have done this differently but there was enough damage to the shank that the sanding would smooth out the briar as well.

I put the stem in the shank and sanded the stem and shank with 220 grit sandpaper to make the transition really smooth. I could have done this differently but there was enough damage to the shank that the sanding would smooth out the briar as well.

I wet sanded the stem and shank with 1500-2400 grit micromesh sanding pads to smooth out the scratches on the briar and the vulcanite. I was able to remove most of the scratches. The rest would come out with more elbow grease. I cleaned out the inside of the stem with pipe cleaners and alcohol until they came out clean. I used a sharp knife to bevel the airway into the stem. I have found that doing this directs the airflow from the bowl to the button.

I wet sanded the stem and shank with 1500-2400 grit micromesh sanding pads to smooth out the scratches on the briar and the vulcanite. I was able to remove most of the scratches. The rest would come out with more elbow grease. I cleaned out the inside of the stem with pipe cleaners and alcohol until they came out clean. I used a sharp knife to bevel the airway into the stem. I have found that doing this directs the airflow from the bowl to the button.

I put the stem in the shank and took the following photos. There is still a lot of polishing to do but the pipe is beginning to look pretty decent.

I put the stem in the shank and took the following photos. There is still a lot of polishing to do but the pipe is beginning to look pretty decent.

I continued sanding with the 3200-12000 grit micromesh sanding pads to polish the stem. After each set of three pads I rubbed it down with Obsidian Oil and sanded some more. After the last pad I gave it a final coat of the oil and let it sit to dry.

I continued sanding with the 3200-12000 grit micromesh sanding pads to polish the stem. After each set of three pads I rubbed it down with Obsidian Oil and sanded some more. After the last pad I gave it a final coat of the oil and let it sit to dry. I buffed the bowl and stem with Blue Diamond on the buffing wheel and then gave both the bowl and the stem multiple coats of carnauba wax. I buffed it with a clean buffing wheel to raise the shine and hand buffed it with a microffibre cloth to deepen it. The finished pipe is shown in the photos below. I am repairing and refitting the original stem to send back with the pipe as well. Once it finished I will buff the two stems and finish removing any scratches that can still be seen in the pipe and then send it back for the surprise that Jim has in mind for it. Thanks for looking.

I buffed the bowl and stem with Blue Diamond on the buffing wheel and then gave both the bowl and the stem multiple coats of carnauba wax. I buffed it with a clean buffing wheel to raise the shine and hand buffed it with a microffibre cloth to deepen it. The finished pipe is shown in the photos below. I am repairing and refitting the original stem to send back with the pipe as well. Once it finished I will buff the two stems and finish removing any scratches that can still be seen in the pipe and then send it back for the surprise that Jim has in mind for it. Thanks for looking.