Charles a good description the process of destinking a bowl with charcoal. I have done this but have not written it up at this point. I am reblogging it on rebornpipes to pass it on to the readers of the blog that might read this here. Thanks for doing the work.

The aroma of a pipe is one of those olfactory experiences that can thrill the senses and trigger a flood of memories and emotions – chats with Grampa on the front porch, the texture of the bench seat in an aluminum fishing boat, the scent of a campfire or the warm hazy aftermath of Christmas morning. I’ve had fellow pedestrians deliberately alter the course of their afternoon stroll in order to get a whiff of my pipe and even stop me to share their pipe recollections. Sometimes I think that if I could bottle the scent of burning pipe tobacco, I could make a fortune.

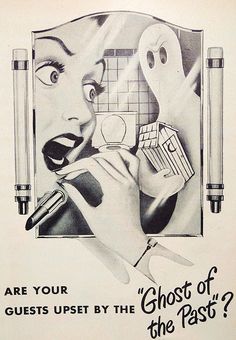

Yes, the reaction to a quality tobacco burning in a good, clean briar is almost universally positive. But everything changes when that same pipe is neglected, transformed from a stalwart briar companion to a stinking wooden husk packed full of soured, congealed tars and fouled…

View original post 1,379 more words